Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

3,377 -

Joined

-

Last visited

Reputation Activity

-

Cathead reacted to FriedClams in New England Stonington Dragger by FriedClams - FINISHED - 1:48 - POB

Cathead reacted to FriedClams in New England Stonington Dragger by FriedClams - FINISHED - 1:48 - POB

Thank you Jean-Paul, Keith B, Ekis, Wefalck, Keith A, John and Michael for your wonderful comments and generous appraisal of my work. I truly appreciate it. And thanks to all for hitting the like button and to those following along quietly.

Ratlines and Other Stuff

The stays and shrouds on the real fishing boats were made-up of wire rope – 1/2” and 3/4” stainless cable mostly. So I wanted to reproduce this in scale using 7 strand stainless fishing leader, but the wire thwarted my every attempt. To be honest, it chewed me up and spit me out like a piece of gristle. I had satisfactory results putting the shrouds together, but I just couldn't tension the cables properly on the boat. I've used beading wire in the past on larger scale models (1:24) for boiler stack guy wires and the like, but never on a mast at 1:48. Many years ago I heard about a modeler who used a below deck spring mechanism that somehow connected to selected cables and kept the rigging taut even with changes in humidity. Clever solution, urban legend or straight-up nonsense? I don't know, but I'm always amazed how creative people can be.

In the end, I used miniature rope soaked in gray paint and a little PVA to keep it from frizzing.

These boats typically had a single ratline on the port side, so I began by drawing up a construction template.

Basswood rungs that scale to 1” x 2” are stuck to the template with double-sided tape. A razor saw is used in cutting notches to receive the “cable”.

A second set of wood rungs are cut in the same way. These are glued to the first set making a two-piece rung with the cables sandwiched between them. Holes for carriage bolts are drilled and the injection-molded bolts are glued in with the rounded heads face outward.

The nut/washers go on the backside.

The turnbuckles are made from .035” stainless tubing sleeved over brass wire. The scale length of the buckles are about 1'9”.

The chainplates with connected chain are made from two different sizes of chain and narrow strips of aluminum can sidewall. The larger chain shown in the image below is 21 LPI and used only for the rings that connect chain to plate. Once the individual links are separated, they are squeezed into a “D” shape and the straight section of the ring is split open. A length of 27 LPI chain is worked onto the ring and the aluminum strip is slipped through, folded in half and epoxied together. The split in the ring is hidden under the aluminum fold. It's more difficult to explain than to actually do.

Injection-molded bolt/washers are added along with some paint and pigment.

Chain and plates are attached to the lower end of the ratline assembly. A lower rung has been added and it clamps across the turnbuckles. I have seen instances where this lowest rung is nothing more that a piece of rebar worked through links in the chain or eyes on the turnbuckles.

The stays and shrouds are made up. The center bolt/washer on the chainplate shown below is missing. The bolts have an 1/8” long shank and I've decided to pin the center of each chainplate to the hull. This will add a little extra shear strength beyond the glue alone.

The port ratline and center stay chainplates are attached to the hull and pinned.

And then the starboard side.

All the “cables” were then tied off to eye bolts on the mast. This took considerable time and involved some shameful mumbling. The center stay cables run through eye bolts on the ends of the spreader.

Thanks so much for swinging through. Stay safe.

Gary

-

Cathead reacted to Jonathan_219 in Revenge 1577 by Jonathan_219 - FINISHED - Amati Models - 1/64

Cathead reacted to Jonathan_219 in Revenge 1577 by Jonathan_219 - FINISHED - Amati Models - 1/64

Gun Deck Finishing and Rudder:

I finished installing the rudder and it was just like the instructions stated, no issues. I have found out since that if the Whipstaff goes all the way to one side or the other that the tiller arm can come out from it but it's easy to put back in by just going all the way to one side again. I may try to see if there's a way to put a stop in place to prevent that from happening once that deck is covered up as it could be a real pain to put back in if I couldn't grab the Whipstaff securely. I did have to cut a piece out of scrap to bring the end of the keel to the same level as the back of the stern deck so the rudderpost could sit flush against the back but I'm pretty sure that was just a relic of me not being precise enough earlier on. Just glued it on and sanded it back to fit flush with the planking. In the pictures the pins I used to attach the hinges to the rudder are still brass and I think I'll probably end up touching those up with black paint but I thought I look at it for a while before deciding.

The cannons and deck coverings for the gun deck were straightforward with one exception. When doing test fits of the cannons in the default build the cannon pointed so high up that it often was touching the top of the gunport and I didn't like that so I cut short pieces of some old lime wood that was 4x1.5mm and placed that in the carriage where the butt of the gun rests to push the back up 1.5mm and the front down a bit. That gave, to my eyes at least, a much more pleasing angle for the cannons to poke out of the gunports. I scotch taped a cannon to each carriage and then was able to eyeball the position as I glued each carriage in place. I just placed most of the cannons to get a look at things and to take a picture before removing the cannons and starting on the next deck.

-

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Thanks Patrick!

All the brass parts were treated with Brass Black Metal Finish. This includes all the parts in the photo etched sheet except for the letters, the belaying pins and the eye bolts. I used Robin's method to do this where I reused the same solution multiple times.

I can now finally work on the rest of the hull details 😀

-

Cathead reacted to Binho in Viking Longship by Binho - Dusek - Scale 1:72 - Model based on the 11th Century Skuldelev 2 wreck

Cathead reacted to Binho in Viking Longship by Binho - Dusek - Scale 1:72 - Model based on the 11th Century Skuldelev 2 wreck

Found a useful resource from the Danish National Museum. The actual scientific article is only in Danish, but there is a good article on Science Nordic about it in English, including a color palette with a description of each pigment and the presumed relative cost.

https://sciencenordic.com/denmark-history-society--culture/how-to-decorate-like-a-viking/1455997

They hypothesize green would have been from malachite (copper ore) and would have been imported, so would probably be expensive. As you said Steven, reds blacks, yellows, and whites would be the most common. I think I’ll try red and black with maybe a white accent or decorative motif, like the Skuldelev 5 had.

-

Cathead reacted to Balclutha75 in Oseberg Viking Ship by killickthere - FINISHED - Billing Boats - 1:16 - SMALL

Cathead reacted to Balclutha75 in Oseberg Viking Ship by killickthere - FINISHED - Billing Boats - 1:16 - SMALL

Ditto that! I've wondered about the iron anchor that came with my Amati kit. Didn't feel right, yours looks great.

Are these the kind of lace pins you used?

https://www.amazon.com/dp/B000PSFC46/

Thanks.

-

Cathead reacted to killickthere in Oseberg Viking Ship by killickthere - FINISHED - Billing Boats - 1:16 - SMALL

Cathead reacted to killickthere in Oseberg Viking Ship by killickthere - FINISHED - Billing Boats - 1:16 - SMALL

Thank you all for the kind words. The anchor was a really fun little aside from building the ship. Going out and finding a suitable rock then messing around with the fit, (for the better part of the day!). Squaring the holes for the wedges etc.

Louie thank you for the pictures yes they do need pommels.

Bulclutha75, they are something like that except I purchased mine on eBay. I tried to go back to my purchasing history for them but that only goes back to 2018. I don't remember if they were nickel plated or not. I do remember though that I soaked them in an electronic etching solution for various times. The longer they soaked the more rusty they became. If you want the name I still have the solution.

-

Cathead got a reaction from tarbrush in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead got a reaction from tarbrush in Chaperon by joep4567 - 1:48 - Sternwheeler

When building paddlewheels from scratch, I've found it surprisingly difficult to get them all perfectly the same, and even tiny variations will ripple throughout the wheel once you try to line up all the spokes with straight buckets (the horizontal planks that tie the spokes together). It can help to define your first wheel as the pattern, then build each subsequent one directly on top, using clamps or pins to guarantee that they match.

It also helps to clearly mark one spoke as the starting point for when you try to line them up later. Again, even tiny variations in the pattern will cause problems later, so knowing which is spoke A on each ring is really helpful, as is which way it should be oriented (mark the starboard or port side of each ring). Otherwise you can end up rotating them around like tumblers in a lock, trying to find the right combination.

-

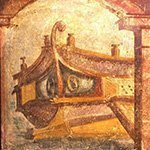

Cathead got a reaction from mtaylor in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead got a reaction from mtaylor in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cool project, seems like a great chance to follow along and learn some more history.

-

Cathead got a reaction from joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

Cathead got a reaction from joep4567 in Chaperon by joep4567 - 1:48 - Sternwheeler

When building paddlewheels from scratch, I've found it surprisingly difficult to get them all perfectly the same, and even tiny variations will ripple throughout the wheel once you try to line up all the spokes with straight buckets (the horizontal planks that tie the spokes together). It can help to define your first wheel as the pattern, then build each subsequent one directly on top, using clamps or pins to guarantee that they match.

It also helps to clearly mark one spoke as the starting point for when you try to line them up later. Again, even tiny variations in the pattern will cause problems later, so knowing which is spoke A on each ring is really helpful, as is which way it should be oriented (mark the starboard or port side of each ring). Otherwise you can end up rotating them around like tumblers in a lock, trying to find the right combination.

-

Cathead got a reaction from CiscoH in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from CiscoH in Viking longship by Cathead - Dusek - 1:35 - FINISHED

I did indeed soak the keel, then laid the two pieces out on my garage floor (a known smooth, flat surface) and weighted them down with a set of bricks. 24 hours later, the pieces were much straighter.

I then stained them using a Model Shipways walnut stain that I bought for this project, then attached the two halves using clamps and an extra reinforcing strip of scrap wood. I laid the whole keel onto a 4' straightedge/level for this, which allowed me to clamp them into place perfectly straight while the glue dried (joint is under the two black clamps in the image below):

I then set about figuring out how to construct a proper build frame using scrap wood available in my shop (which is mostly rough-milled Eastern Red Cedar from lumber I harvested). Here's what I came up with, following the examples shown above:

This is very sturdy and holds the fragile stem and stern solidly in place. The whole thing was screwed together, as I hate using glue on things that won't be permanent as then I can't burn or naturally dispose of the wood scraps. Now I can take it all apart again when I'm done. The thin strips holding the central part of the keel in place are partially cedar and partially some random leftover wood from my scrapbox, no idea what it is. If you look closely, you can see that I did use curved portions of the original laser-cut sheet to support the stem and stern; I just cut off the long extensions under the central part of the keel so I wouldn't have to worry about the whole thing being straight. This worked great.

Here's a detail of the jig I built for attaching frames, again based on examples from other build logs (especially jack.aubrey's):

I used a Byrnes table saw to ensure that everything was completely square. The series of horizontal lines drawn on the surface allow the frames to be lined up at various heights. The "feet" allow this to be clamped in place on the build board anywhere I want, following lines drawn onto the board using a square. I think it'll work well, and can adapt it if I find a flaw.

It's all rough, but seems like it'll do the trick. Time to stain the frames and then start assembling things.

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

bigpetr, Thanks for that thought.

The Amati instructions say "Before applying upper strakes it is advisable to make small cuts (along dotted line) ... These cuts will help the wood to bend and to lean into the lower stake for an easy glueing".

However your post got me thinking. I just received a pointed divider from Model Expo. I guess I can use that to transfer the distance between strakes from the plans to the model, and make tick marks on the frames, just like a real model builder!

- Nelson

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Thanks for the encouragement Steven.

I have not looked at many scratch build logs since they can be intimidating to a newbie! But I'll take you advice and dive in.

Here's my question, which may be answered in a log, but I'll post here anyway.

The planks need to be both bent and twisted. Amati says to soak the planks in 50/50 solution of white glue and water, and also to score the center of the plank with a blade. I'm not too thrilled about doing that, as I'm pretty sure I'll mess it up.

What if I tried to bend the planks using heat and water? I've seen Chuck's planking video and he makes using the travel iron look easy (ha-ha). I could get one of those irons, or invest in a basic plank bender. Seems like that would be more interesting and educational than the water/glue/score process. I could practice on strips from the plank sheets.

Thoughts appreciated. But I will look through more logs.

And I am having fun!

Thanks,

Nelson

-

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

Cathead reacted to Balclutha75 in Viking Drakkar by Balclutha75 - Amati - 1:50 - First Ever Wooden Model

For research I purchased these two books. Both are enjoyable and give a layperson background to Viking ship history and construction.

There is plenty of stuff to find online and I have a bunch of links saved if anyone is interested, some of which came from MSW. Last night we started watching a 3-part YouTube series “Evolution of the Viking Longship”. That link is the first episode, it’s pretty good.

At this point I tried to fit the mast and learned that the slot in the keel was too narrow to accept the dowel, so I filed that out. I realize this is not an exciting photo to you guys, but I was pleased I discovered this before the deck or planks were glued. Learning the importance of dry fitting.

Next up: the intimidation of planking the hull. I will definitely have a question or two.

- Nelson

-

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

Cathead reacted to WalrusGuy in US Brig Syren by WalrusGuy - FINISHED - Model Shipways - Scale 1:64 - Second wooden ship build

The metal stern carvings have been painted and stuck on the hull. So have the Syren letters. I found the letters tricky to glue to place since they are so small. For these parts I used wood glue to stick them since I could play around with the locations before it set. I also had the ship secured upright to make it easier to stick the items.

Here is the paint I used:

Here are some pics of the stern with the carvings and letters:

I painted the figurehead the same color as the carvings.

Another note, I need to taper the stem knee a bit more since the figurehead does not go in smoothly. The paint on the knee probably made it thicker.

-

Cathead reacted to Louie da fly in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead reacted to Louie da fly in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Nice jig. Looks like you're doing well with solving problems as they arise.

-

Cathead reacted to Louie da fly in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to Louie da fly in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Happy to be of help, Christos.

The Byzantine galea YK4 found at Yenikapi (the old harbour of Theodosius) had the rowing benches anywhere between 0.874 and 1.048 metres apart - with an average spacing of 0.96 metres. I found in my own dromon (also with 25 rowing positions, though on two levels rather than one) that allowing for about a meter between benches the bow and stern both needed to be longer than originally estimated. If I were to build it again I would make it 4 metres longer.

I think your judgment regarding the bow shape, colours, ornamentation etc could well be better than that of the people who built the Argo reconstruction.

-

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

@Louie da fly thank you very much Steven.No I was aware of the reconstruction of Argo, but I wasnt aware of the youtube video. I just saw it.. . thank you.

What I have just seen, seems to be very near to what I had in mind out of my study. Though Argo is far shorter than I think a penteconter could have been .... I believe am more on the right side.

Argo (replica), is said to be 28 meters, but if you allow a meter plus (according to the trireme Olympias expirement) for each oar's man, then you got more than the 28 meters without the ικρία, thats the forecastle and quarter deck. Lionel Casson's calculations are favourable to my view that a penteconter reached 40 m. That as a maximum, because above that, other issues appear (frame dynamic behaviour problems), making (for example) the existence of an exiconter εξηκόντορος (60 oars) impossible. Ofcourse there are scholars who believe that there were smaller penteconters even 28 to 30 meters. (S.Mark - Homeric Seafahring)

I also have some minor objections concerning the beaklike bow, the colours the ornamentation etc

Thank you Steven for adding usefull information to my work.

Christos

-

Cathead reacted to Louie da fly in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to Louie da fly in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

I love the research you're putting ginto this, Christos.

I take it you've seen the footage on Youtube of the Argo reconstruction?

and

It's hard to count the oars, but I think she's a pentekonter.

-

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

Cathead reacted to MESSIS in Odysseus homeric ship (penteconter) by MESSIS - FINISHED - kit-bashed from Dusek bireme

A sketch showing the frame and its upper and lower ζυγά, the seats σέλμα, and lastly the planking, the wale and the decks.

-

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from FriedClams in Viking longship by Cathead - Dusek - 1:35 - FINISHED

I did indeed soak the keel, then laid the two pieces out on my garage floor (a known smooth, flat surface) and weighted them down with a set of bricks. 24 hours later, the pieces were much straighter.

I then stained them using a Model Shipways walnut stain that I bought for this project, then attached the two halves using clamps and an extra reinforcing strip of scrap wood. I laid the whole keel onto a 4' straightedge/level for this, which allowed me to clamp them into place perfectly straight while the glue dried (joint is under the two black clamps in the image below):

I then set about figuring out how to construct a proper build frame using scrap wood available in my shop (which is mostly rough-milled Eastern Red Cedar from lumber I harvested). Here's what I came up with, following the examples shown above:

This is very sturdy and holds the fragile stem and stern solidly in place. The whole thing was screwed together, as I hate using glue on things that won't be permanent as then I can't burn or naturally dispose of the wood scraps. Now I can take it all apart again when I'm done. The thin strips holding the central part of the keel in place are partially cedar and partially some random leftover wood from my scrapbox, no idea what it is. If you look closely, you can see that I did use curved portions of the original laser-cut sheet to support the stem and stern; I just cut off the long extensions under the central part of the keel so I wouldn't have to worry about the whole thing being straight. This worked great.

Here's a detail of the jig I built for attaching frames, again based on examples from other build logs (especially jack.aubrey's):

I used a Byrnes table saw to ensure that everything was completely square. The series of horizontal lines drawn on the surface allow the frames to be lined up at various heights. The "feet" allow this to be clamped in place on the build board anywhere I want, following lines drawn onto the board using a square. I think it'll work well, and can adapt it if I find a flaw.

It's all rough, but seems like it'll do the trick. Time to stain the frames and then start assembling things.

-

Cathead reacted to mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead reacted to mbp521 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Eric,

Great job on the build frame. Looks like you may be able to save it and use for other builds. Glad to hear the “wet and weight” method worked to straighten the keel.

-Brian

-

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from Binho in Viking longship by Cathead - Dusek - 1:35 - FINISHED

I did indeed soak the keel, then laid the two pieces out on my garage floor (a known smooth, flat surface) and weighted them down with a set of bricks. 24 hours later, the pieces were much straighter.

I then stained them using a Model Shipways walnut stain that I bought for this project, then attached the two halves using clamps and an extra reinforcing strip of scrap wood. I laid the whole keel onto a 4' straightedge/level for this, which allowed me to clamp them into place perfectly straight while the glue dried (joint is under the two black clamps in the image below):

I then set about figuring out how to construct a proper build frame using scrap wood available in my shop (which is mostly rough-milled Eastern Red Cedar from lumber I harvested). Here's what I came up with, following the examples shown above:

This is very sturdy and holds the fragile stem and stern solidly in place. The whole thing was screwed together, as I hate using glue on things that won't be permanent as then I can't burn or naturally dispose of the wood scraps. Now I can take it all apart again when I'm done. The thin strips holding the central part of the keel in place are partially cedar and partially some random leftover wood from my scrapbox, no idea what it is. If you look closely, you can see that I did use curved portions of the original laser-cut sheet to support the stem and stern; I just cut off the long extensions under the central part of the keel so I wouldn't have to worry about the whole thing being straight. This worked great.

Here's a detail of the jig I built for attaching frames, again based on examples from other build logs (especially jack.aubrey's):

I used a Byrnes table saw to ensure that everything was completely square. The series of horizontal lines drawn on the surface allow the frames to be lined up at various heights. The "feet" allow this to be clamped in place on the build board anywhere I want, following lines drawn onto the board using a square. I think it'll work well, and can adapt it if I find a flaw.

It's all rough, but seems like it'll do the trick. Time to stain the frames and then start assembling things.

-

Cathead got a reaction from mtaylor in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead got a reaction from mtaylor in Viking longship by Cathead - Dusek - 1:35 - FINISHED

I did indeed soak the keel, then laid the two pieces out on my garage floor (a known smooth, flat surface) and weighted them down with a set of bricks. 24 hours later, the pieces were much straighter.

I then stained them using a Model Shipways walnut stain that I bought for this project, then attached the two halves using clamps and an extra reinforcing strip of scrap wood. I laid the whole keel onto a 4' straightedge/level for this, which allowed me to clamp them into place perfectly straight while the glue dried (joint is under the two black clamps in the image below):

I then set about figuring out how to construct a proper build frame using scrap wood available in my shop (which is mostly rough-milled Eastern Red Cedar from lumber I harvested). Here's what I came up with, following the examples shown above:

This is very sturdy and holds the fragile stem and stern solidly in place. The whole thing was screwed together, as I hate using glue on things that won't be permanent as then I can't burn or naturally dispose of the wood scraps. Now I can take it all apart again when I'm done. The thin strips holding the central part of the keel in place are partially cedar and partially some random leftover wood from my scrapbox, no idea what it is. If you look closely, you can see that I did use curved portions of the original laser-cut sheet to support the stem and stern; I just cut off the long extensions under the central part of the keel so I wouldn't have to worry about the whole thing being straight. This worked great.

Here's a detail of the jig I built for attaching frames, again based on examples from other build logs (especially jack.aubrey's):

I used a Byrnes table saw to ensure that everything was completely square. The series of horizontal lines drawn on the surface allow the frames to be lined up at various heights. The "feet" allow this to be clamped in place on the build board anywhere I want, following lines drawn onto the board using a square. I think it'll work well, and can adapt it if I find a flaw.

It's all rough, but seems like it'll do the trick. Time to stain the frames and then start assembling things.

-

Cathead reacted to Balclutha75 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead reacted to Balclutha75 in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Nice job on the “Jack Aubrey Frame Jig”. I discovered that after I haphazardly glued my Viking frames. Yours will hopefully turn out great.

-

Cathead reacted to Jim Lad in Viking longship by Cathead - Dusek - 1:35 - FINISHED

Cathead reacted to Jim Lad in Viking longship by Cathead - Dusek - 1:35 - FINISHED

A bit late finding your log, Eric. This will make a stunning model and you've already overcome the first hurdle.

John