-

Posts

2,434 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dafi

-

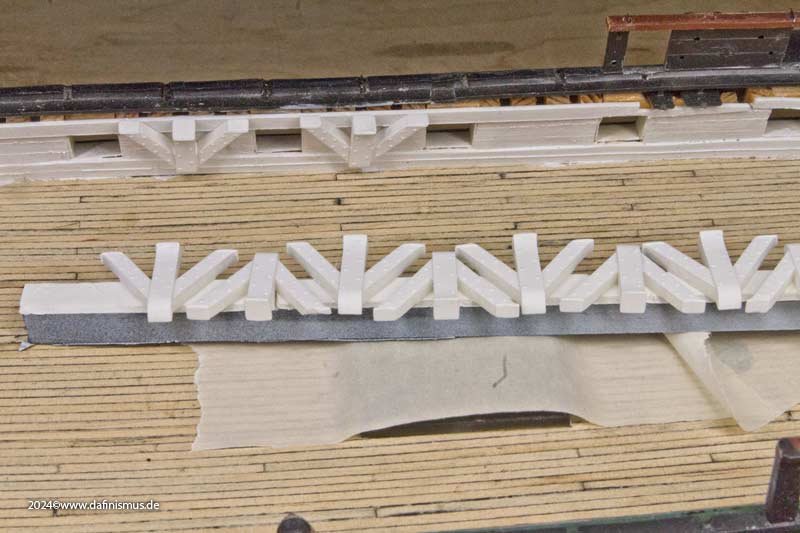

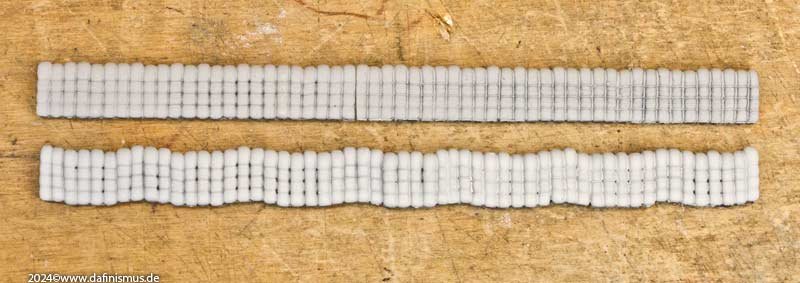

And then it was time to paint those hammocks http://www.shipmodels.info/mws_forum/images/smilies/icon_smile.gif Now with the build on hammock net holders I was able to adjust the rhythm of the cranes to the wave of the hammocks. Now gravity could take it´s toll properly, resulting in some more convincing sagging in the print data. After printing I still fine-tuned the new print by hand, so that the hammocks would fit nicely into the holders without any unlogical gaps to the mainrail. The first step in painting was to apply a white spray primer and then brush on a tinted white to create a uniform base colour. As described above, a lot of effort went into giving the mats a natural disorder so that they would not look like sterile printed parts. Therefore the painting must, of course, support this step. In the next step, each mat was given its own individual colouring. The paint was mixed fresh on the wet palette and the colour nuances were distributed evenly. In times before the advent of Tide, when there was not enough fresh water to wash with soap, and with plenty of tar and other sources of dirt, I assume that the colour was more of a greyish natural tone, with each roll having a different colour, just like the ropes too. In the final step, I used a few washes of ink to highlight the structure again and restore depth and life to the rolls. It looks more massive in the close-up than it does to the naked eye. In addition, there will be the hammock netting in front of them, which also contribute to the colour shades becoming less nuanced. Hope you enjoy 🙂 XXXDAn

- 64 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

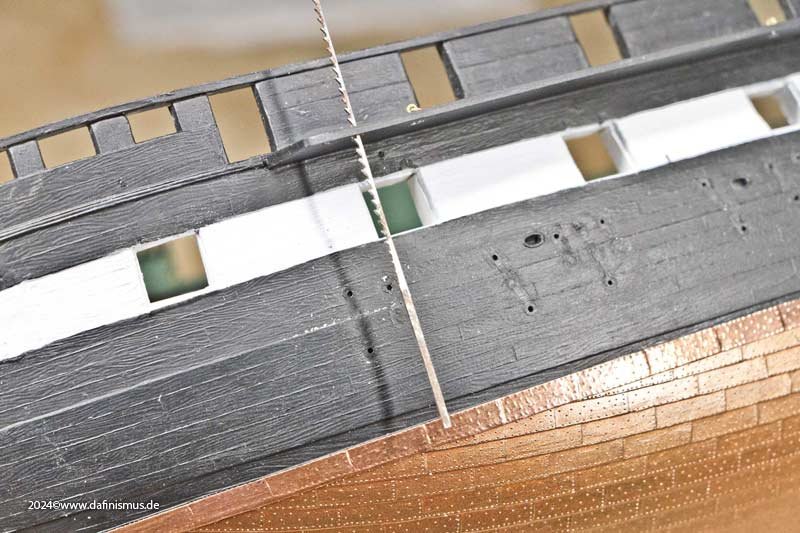

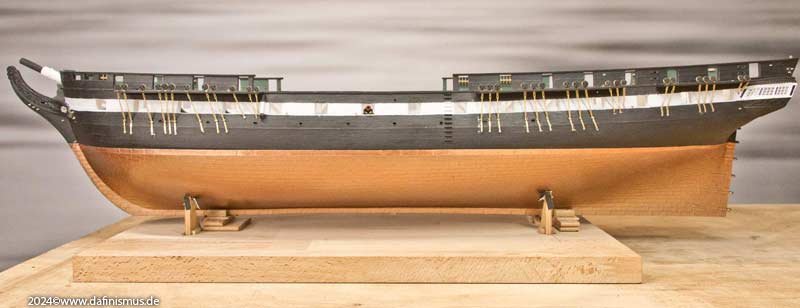

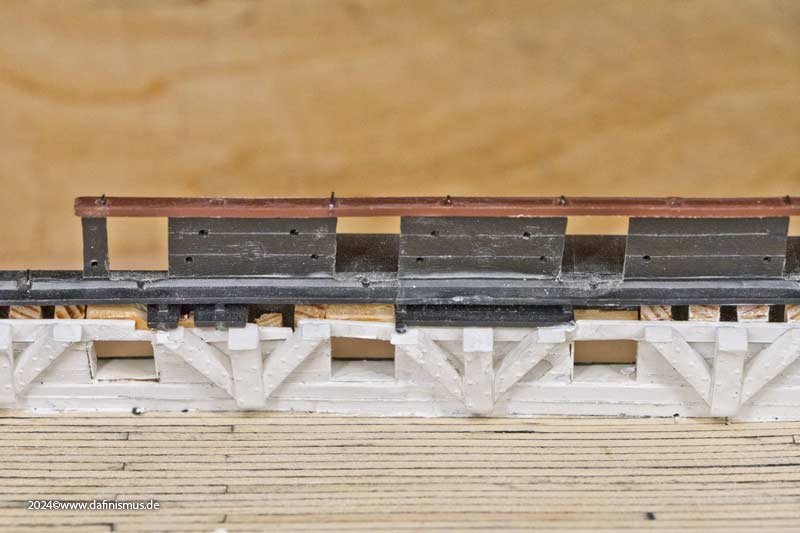

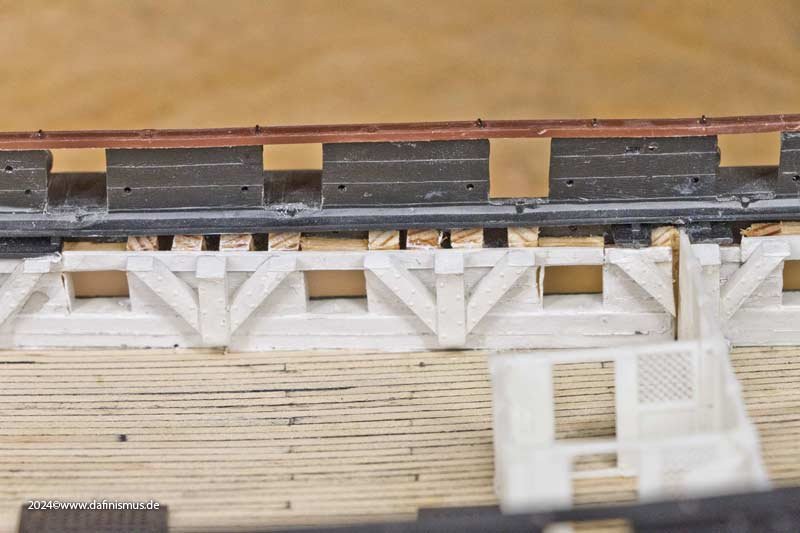

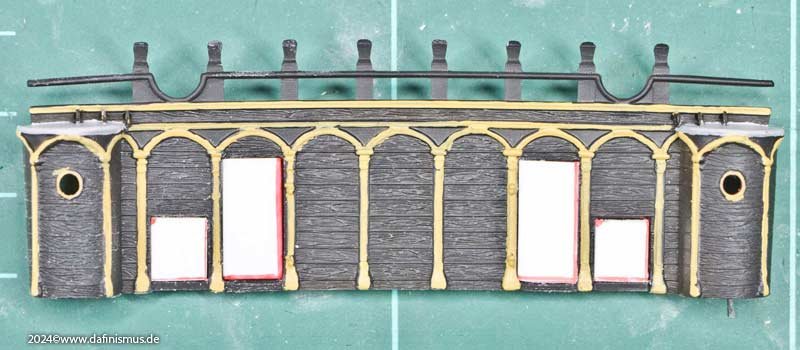

At some point, I noticed on the model that the channel boards have no supports. The contemporary models of the constitution and the drawings also omit them, but could this have been one of the details that are not shown as they are too unimportant? Just as a point of discussion I retrofitted them. Next, I put in some dummy hammock nets. Just to see how they look. The real ones will come once the weather deck is installed. They're just too delicate. But it was worth it, because the side view has changed again. XXXDAn

- 64 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

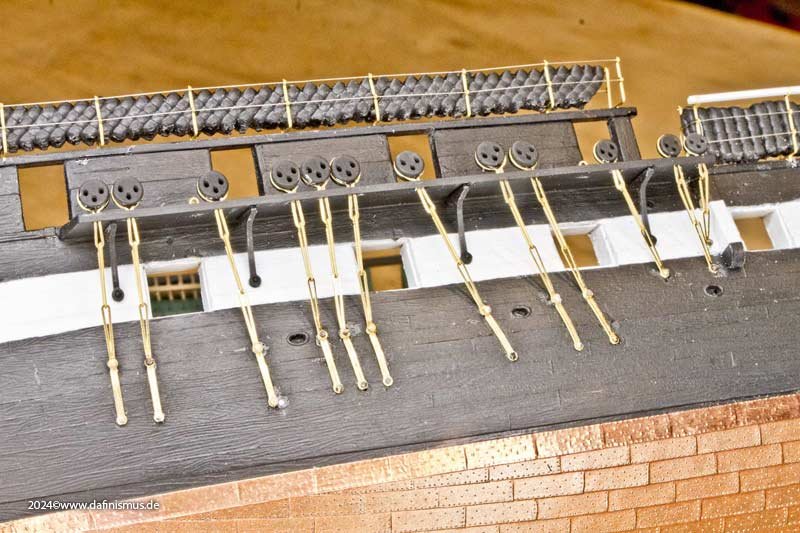

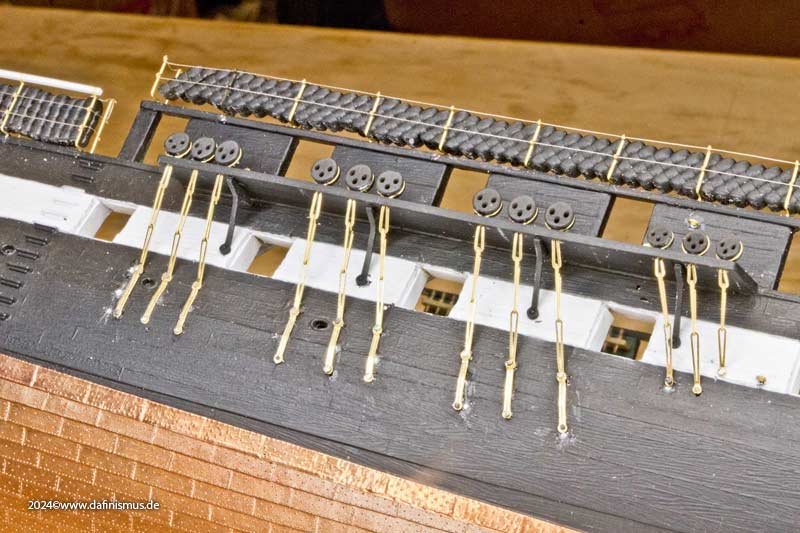

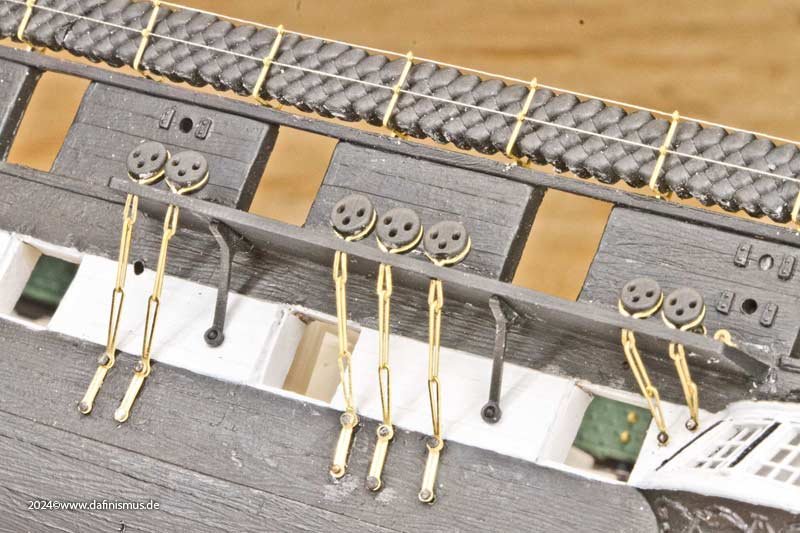

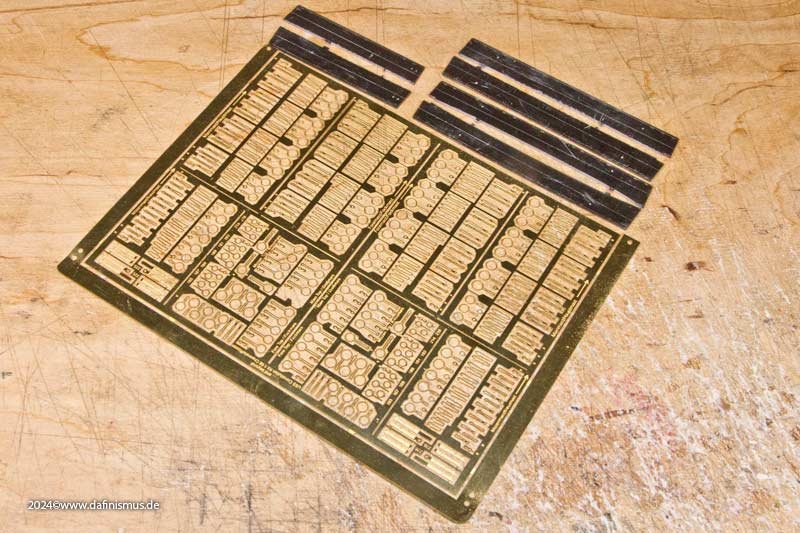

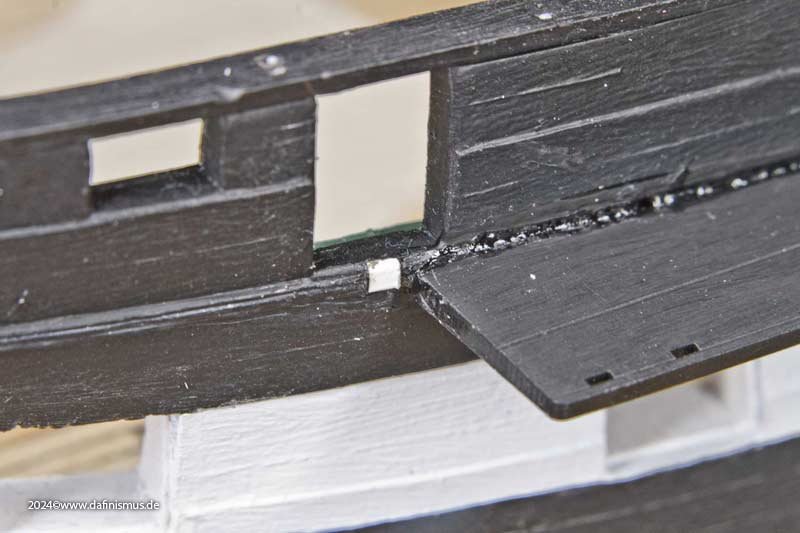

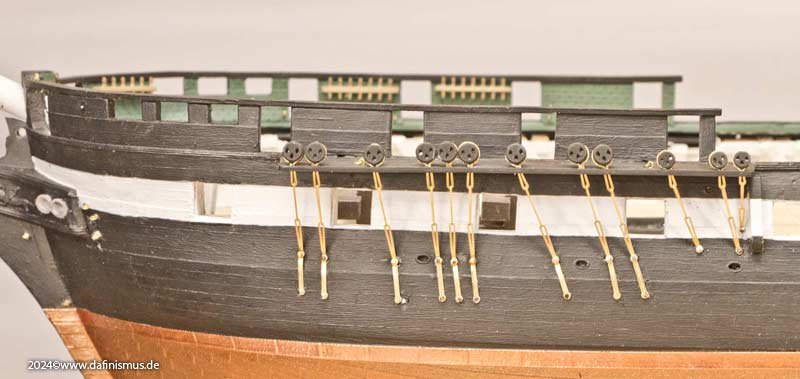

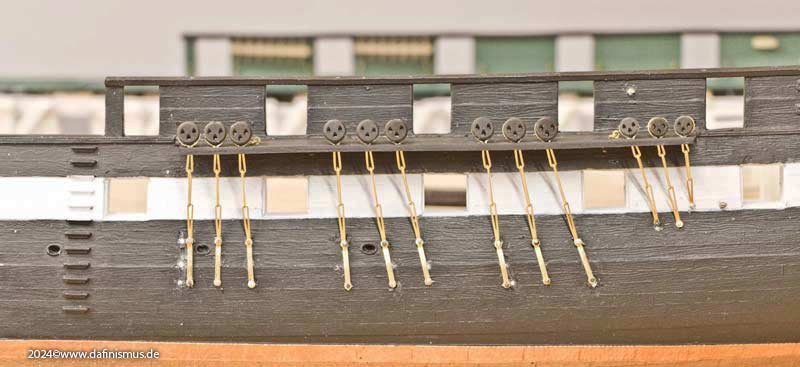

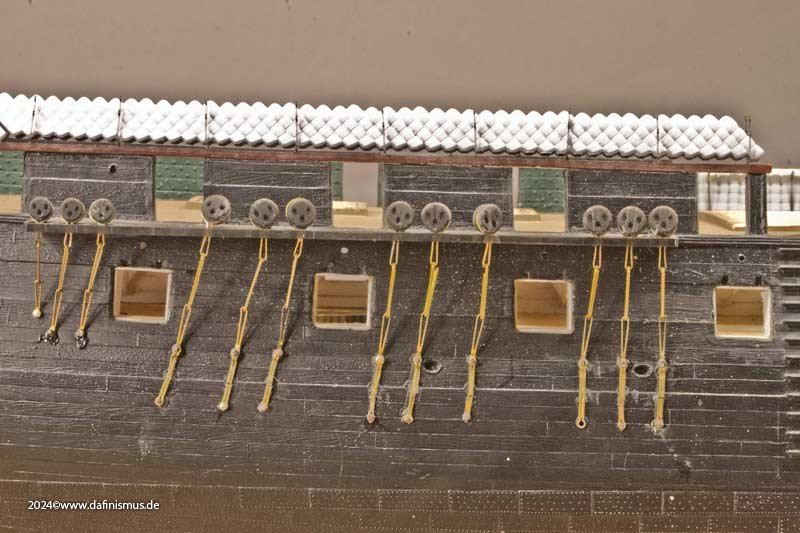

And now came the part I was most looking forward to: things immediately got exciting again, the old test channels had to come down! And just like centuries ago, the fire separated the iron parts from the rest and cleaned them of adhesive residue. Me, lazy sod that I am, wanted to save the needle head bolts, which always takes a while to get done. And there they were, ready and waiting, the new channel boards and irons 🙂 It took a lot of effort to clean up the glue residues on the slots for the channel boards, as the model had already had about five previous versions glued on, including the original kit´s channels :-O. Once everything was clean and fitted, the new boards were put in place and a horizontal stop helped with the alignment ... ... and, although only minimally visible, the print-induced steps on the edge were sanded down... ... and the inner edges and connections were cleaned up ... ... and paint cleared from the holes for the irons with a fretsaw blade. And then it was time to start cutting out the etched iron parts, bending the eyes, fitting the dead eyes, adjusting the length of the links and bolting them to the side wall. Just like in the big original. The result was quite impressive; the new parts fit perfectly. In some places, I deliberately left the white stubs in place to show that the original holes in the kit were sometimes not ideally placed. It turned out quite satisfying, here's a close-up, just because we can http://www.shipmodels.info/mws_forum/images/smilies/icon_wink.gif And next up are the hammock net holders. XXXDAn

- 64 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

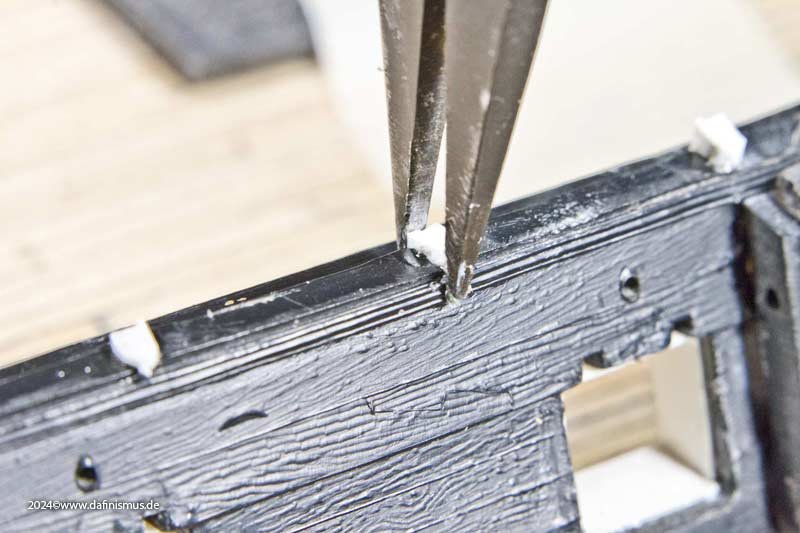

But first, it was time to tidy up. The kit had suffered greatly, having been assembled quickly under time pressure, pushed from one place to another, and generally not treated like a beloved model child. I'm sorry about that. Really. Reall-really … First, the old copper test had to be removed. The stuff sticks like hell. Unfortunately, it had been primed underneath – something I don't normally do – and even a lot of isopropanol couldn't prevent the paint from coming off in places. But I was able to smooth it out inconspicuously. But that's part of the demolition process, which fits in with dafi's whole artistic concept 😉 Then the self-printed hammock crane holder dummies flew through the workroom in a high arc and the lower links of the preventer chains that had been injection moulded onto the hull were scraped off with a scalpel and excess holes were closed with plugs. For the huge gaps in the gangway in the kit forseen for the kit´s holders, there were matching polystyrene plugs, which were softened with plenty of styrene glue and then pressed into the gap with pliers. The bitts on the side of the ship for the main tack were also sanded down, sawn with a fretsaw, fitted with a roller and shortened so that it would fit under the new channel boards. The interior also needed a lot of work. Spray and glue the knees. Where there are bulkheads, I cut off the arms for simplicity's sake. Then, as usual, I used some diluted ink to emphasise the corners and screw heads. And then it looked much more homely. XXXDAn

- 64 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

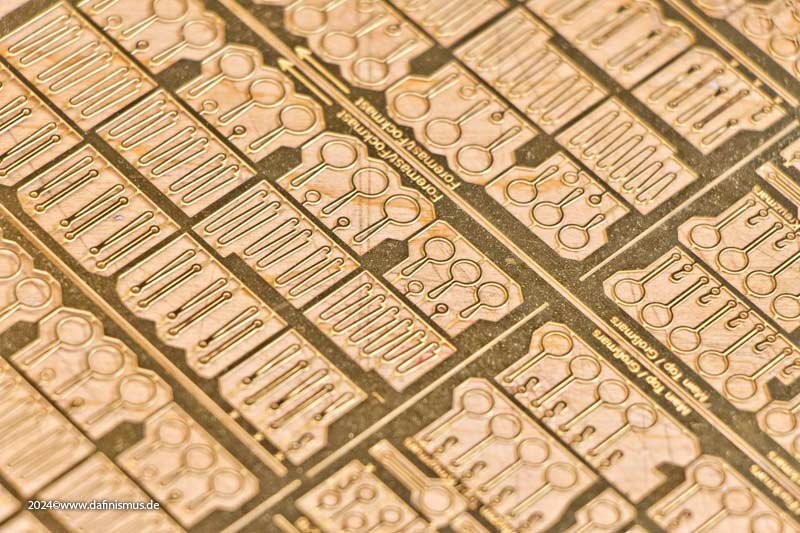

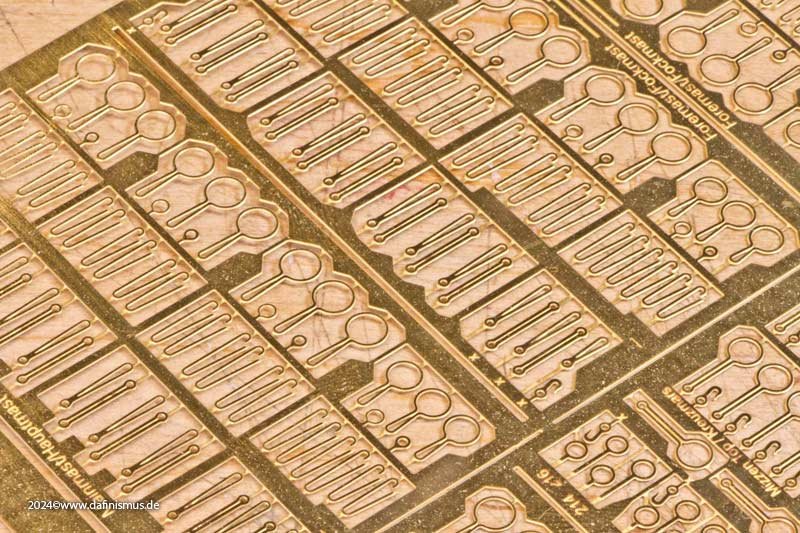

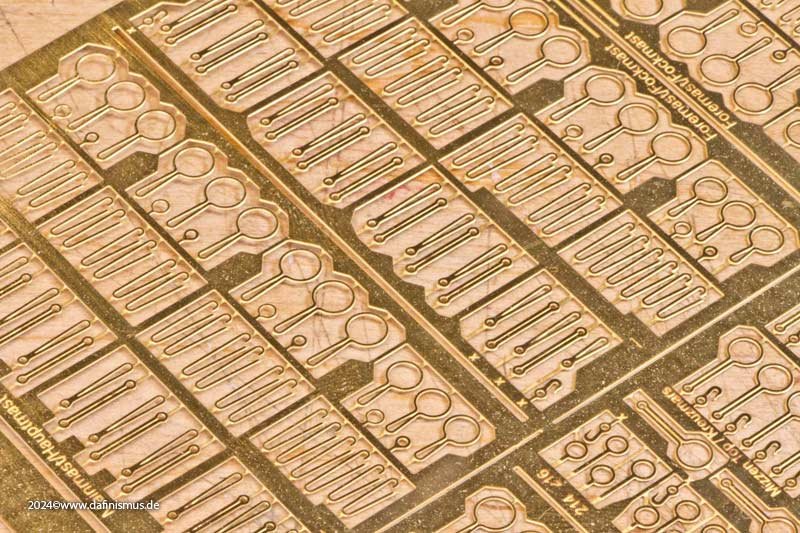

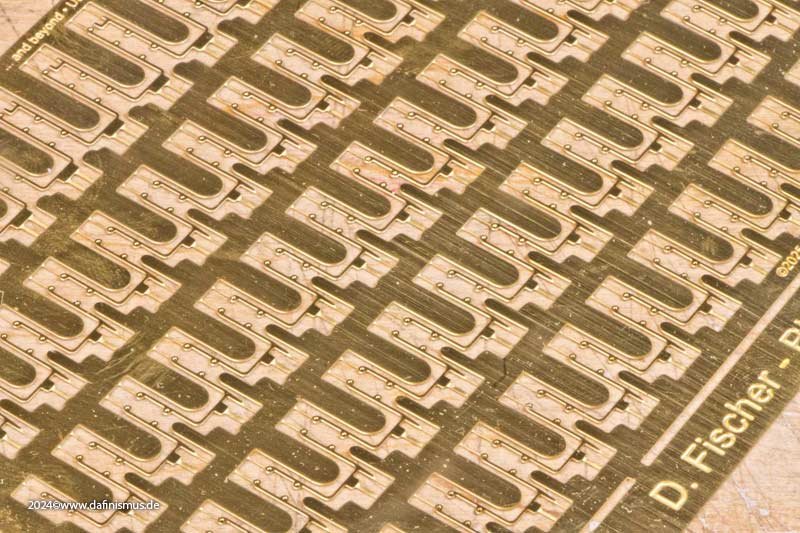

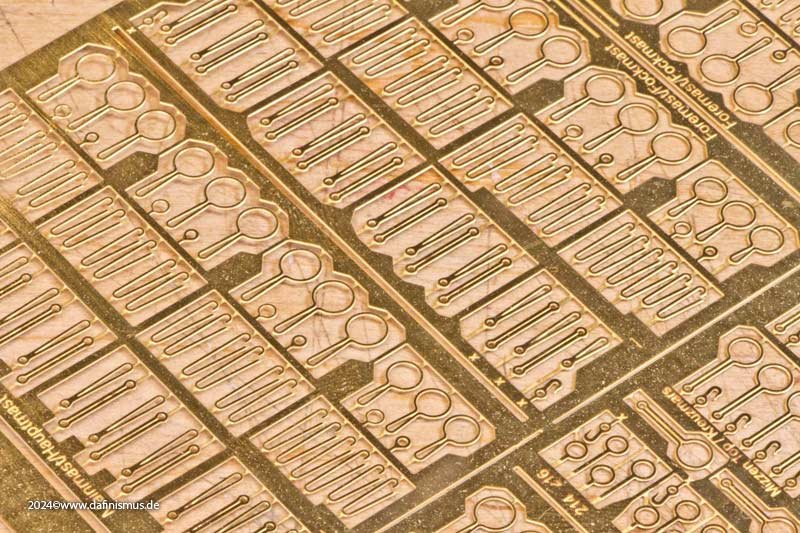

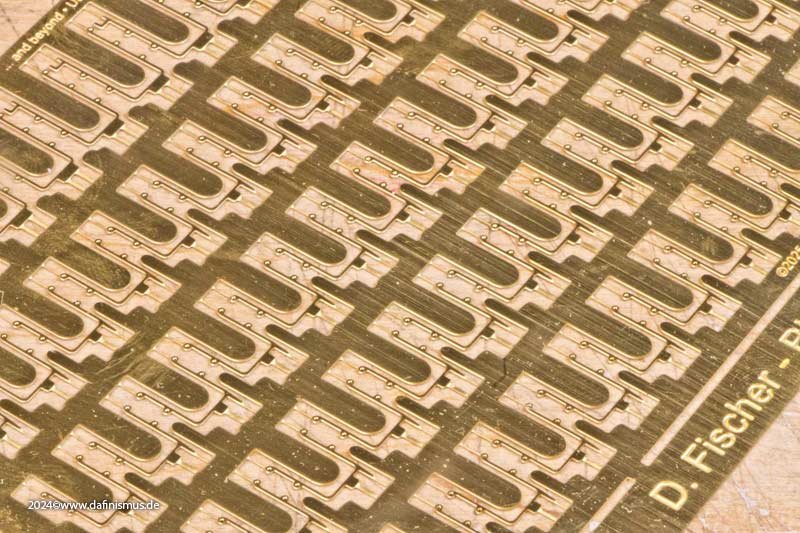

Before I get to the current events, here is a brief summary of what else has been happening here. At the beginning of last year, I started working on the hammock holders and channels. This is how Revell envisions it. You can't even fit hammocks in there... ... ... so I hijacked some of the holders from my Vic. Still too small. So I drew new etched parts for the holders, and the nice thing is that you can try them out right away in print – and notice during assembly that print is too weak for such parts. But I was able to clarify that the parts really are the right size. And this is what it looks like when installed. I had rolled lots of virtual hammocks to match, so I could estimate the result. Here you can see that the mats have been given a good dose of unshipshapeness. This serves to prevent a sterile-looking impression. I had already used the wave effect, where gravity pulls between the holders on the mats, on my hand-rolled mats on the other models, and it made the result look much more realistic. But as perverse as it sounds, it is much easier to make hand-rolled mats look nice and uniform than to give virtually created mats a certain amount of unevenness http://www.shipmodels.info/mws_forum/images/smilies/icon_wink.gif But judge for yourself. The net is still missing here, as the printed supports are too fragile for it. The curve at the bow has also been covered with hammocks ... ... and the aft deck as well. Here is a sequence from back to front. I cannibalised the channel irons from my Victory. Except for the lower preventer link, all the required lengths were in stock, but there was a lot of waste. But I was able to check the lengths using this test setup. The channel boards were also adapted anew. Fore mast channels Main mast channels Mizzen mast channels For being just a mere test, it was already an improvement. Enjoy http://www.shipmodels.info/mws_forum/images/smilies/icon_smile.gif And then with a years distance of not having time, drawing the real parts and producing, the Christ Child (as it is this one that brings the X-Mess gifts in our area) was in a very good mood before Christmas and delivered the first samples of the channels and hammock holders for my Constitution *jumping for joy* And finally, I had a little time to tinker with it So, popcorn and beer at the ready, X-Files in the DVD player, and off to work with joy! XXXDAn

- 64 replies

-

- Revell

- Constitution

-

(and 1 more)

Tagged with:

-

And now something completely different: The Christ Child was in a very good mood before Christmas and delivered the first samples of the armour and finch nets for my Constitution *jumping for joy* And finally, I had a little time to tinker with it 🙂 So, popcorn and beer at the ready, X-Files in the DVD player, and off to work with joy! See you on a ship yard on other side of the Atlantic. XXXDAn

-

And to finalise this study here's a comparison between out of the box and something crafted with a little dedication 😉 First, the upper decks. And the upper battery deck. Okay – the comparison isn't entirely fair, but it looks good what you can conjure up with it 😉 XXXDAn

-

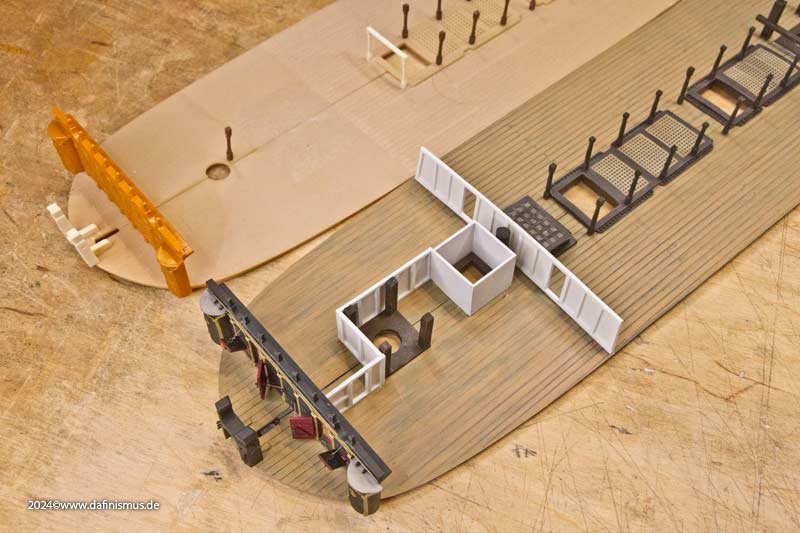

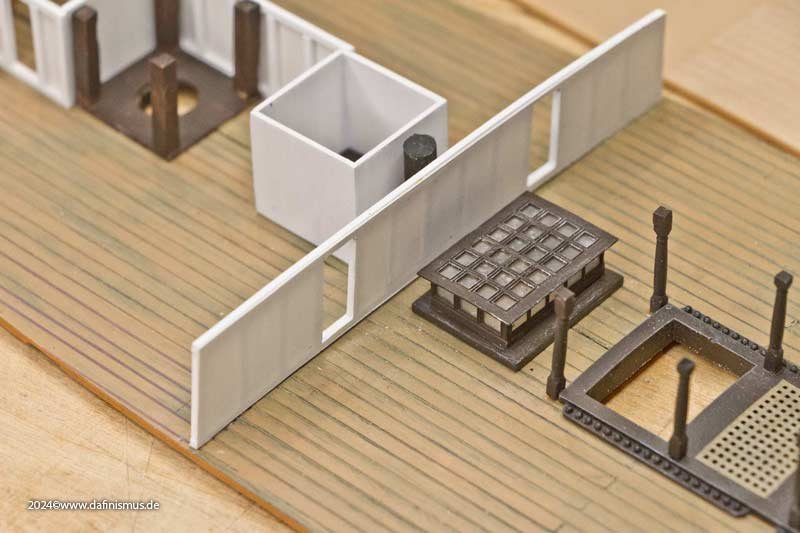

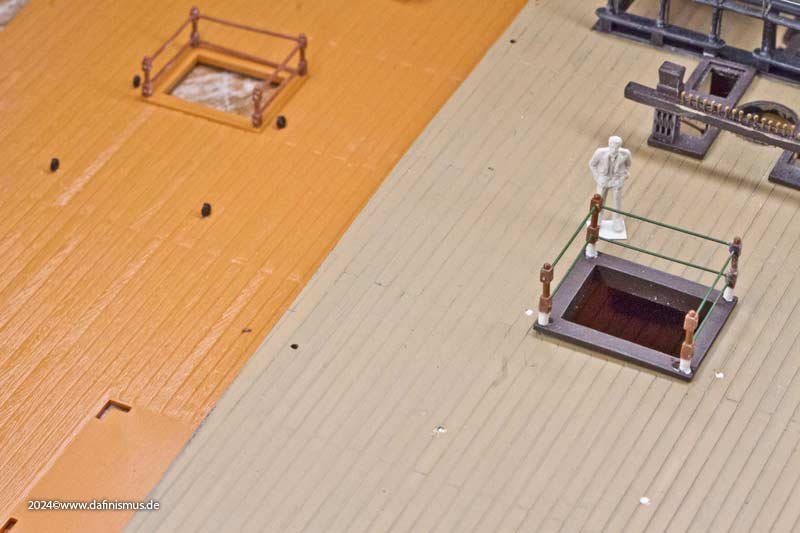

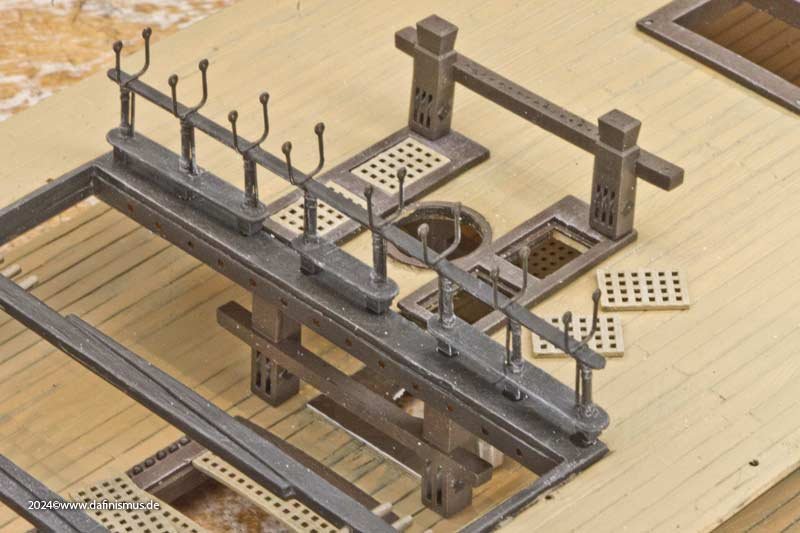

And once again, we're well into the new year, Christmas and New Year are over, and there's still no time for contemplativeness. Nevertheless, I managed to secure a little time for myself and at least finish Victory´s deck comparison. First, I jazzed up the beakhead bulkhead a bit. Since all contemporary models from around 1800 show this in black, I also decided to forego the usual blue colour. To fit in the doors, I used the old trick of applying a thin coloured strip to the side, which provides a good visual check when sanding in the tenth of a millimetre range. Then came the first additions in the freerunning section. In addition to the four supports for the foremast bitts and the stovepipe, the steam truck was added, which diverted the steam from the Brodie stove over the gratings on the forecastle. This required another open-heart surgical procedure, as another breakthrough was needed. The trunk consisted of a solidly constructed box sitting above a coaming. It was a bit tricky to position it so that the box was only under two parts of the triple grating on the forecastle and the partition wall was covered exactly. And that wasn't all, yet another hole had to be made: the kitchen skylight. So that the cooks have at least some daylight when preparing meals. To do this, the deck was perforated and opened with heavy clearing tools. Then a little scalpelling and sanding and the next hole was in. The skylight itself was a bit tricky. The part from my etch kit is two window grids too long, respectively too wide. So I cheekily cut out two grids and, after sanding the cuts down well, simply glued the remains back together with superglue. And, believe it or not, it worked 🙂 And this is what it looks like in place, and you can also see what it's for. These two openings were missing from the museum ship for a long time, and I don't even know if they have been reinstalled there in the meantime ... But you can already see the other addition: the area under the forecastle was also used as a sick bay, for which light temporary bulkheads were used, in this case painted canvas on wooden frames. If necessary, these could be quickly knocked down in the original. The lower parts of the mainmast bitts were already presented earlier. But I had to rework the positioning so that they were directly below the extensions on the quarter deck. Another popular activity was sealing the old holes on the deck, as the etched parts have a smaller diameter than the standard 1 mm holes in the kit. So 1 mm plastic rods are glued in... ... levelled, centred with a scriber and re-drilled with 0.5 mm. The supplied railing around the rear companionway also proved to be suboptimal. According to contemporary models, the principle is correct, wooden posts with iron bars, but the proportions are wrong: much too low and the bars much too thick. So a quick reworking to thinner wire bars ... ... and raising the posts, with the figure serving as a guide for the height. This completed the preparations and we were ready to take photos. Happy tinkering in the New Year from your dafi! PS: And thank you for all the nice feedback during the last year! Very appeciated.

-

Matt it is! 🙂 XXXDAn

-

Not to forget, these instructions were done more than 45 years ago and base on the 1920 reconstruction. Thus said one understand the color "cadmium yellow" being indicated in the instructions. And yes, I have pictures of the ship in cadmium yellow as it once was 🙂 Yellow ochre, sunflower yellow or yellow ochre blended with red and white (latest result, but sure not last), also feel free a bit for your own taste. The correct shade of color will surely never be revealed as even "newer" ships like Bismark there are raging discussions about this topic ... XXXDAn

-

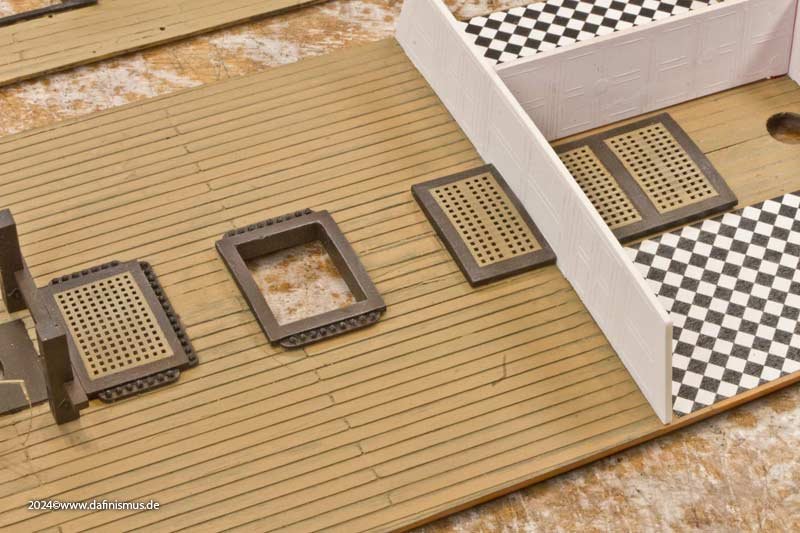

And this was the result of what I was able to complete during the public crafting session at the trade fair. The gratings also have the correct different thicknesses for the longitudinal and transverse battens on the underside. The admiral's quarters area was given a chequerboard floor. Here you can also clearly see the rollers of the bitts in the deck below. And the forecastle looks much more structured and tidier too. Well, that's it for now 🙂 XXXDAn

-

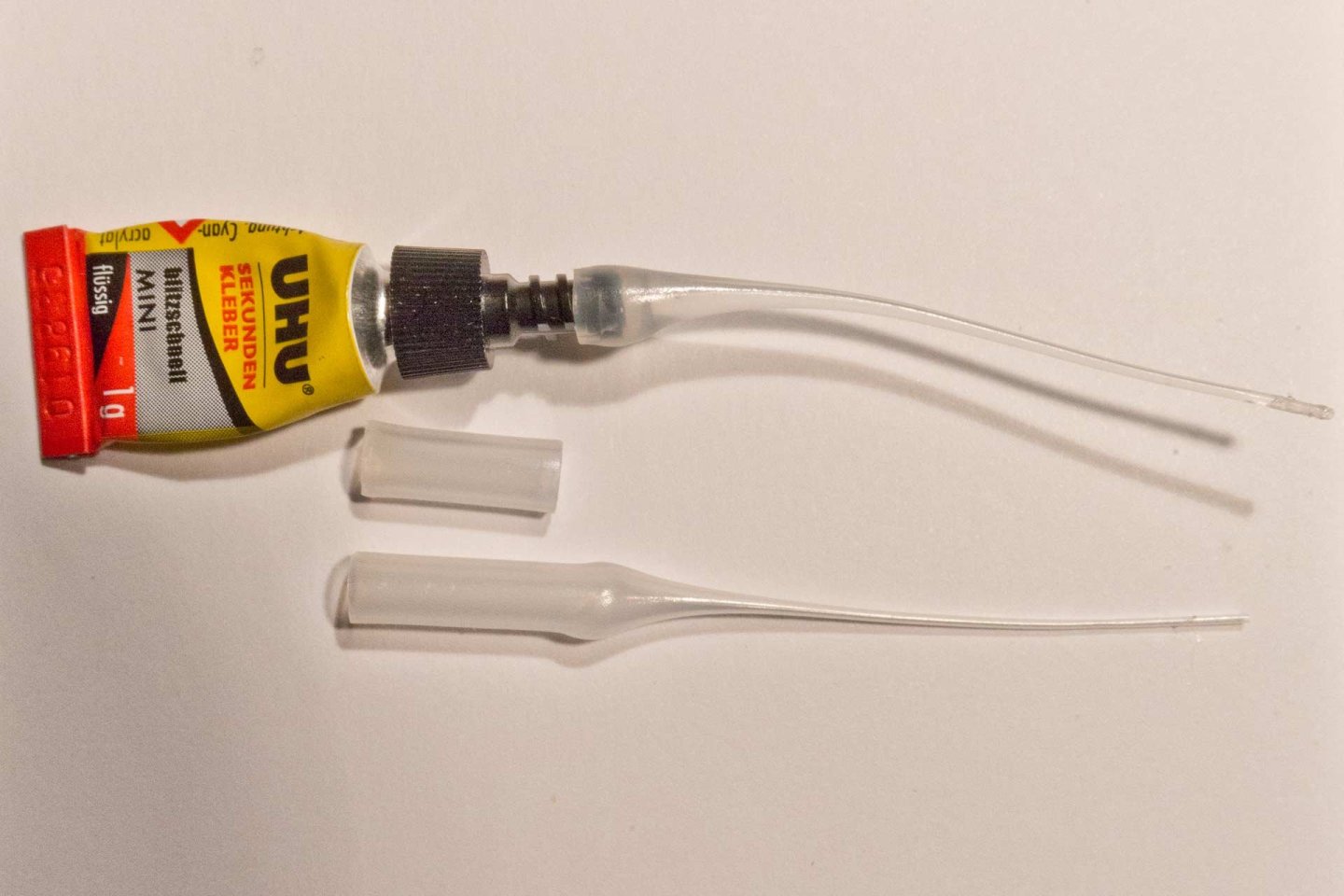

And for really tiny applications these applicators are unbeatable. They do not need to be closed and stay open for a long time. If closed, just cut off a quarter of a millimeter and its fresh again. Only safety hint: Start pressing gently until the air bubble rises. If it does not rise the tube immediately it is closed and needs to be cut. And if you cut after having applied too much pressure it will release quite a bit of glue until the over pressure is released. Otherwise this cheap things reduced the amount of wasted glue immensely! XXXDAn

-

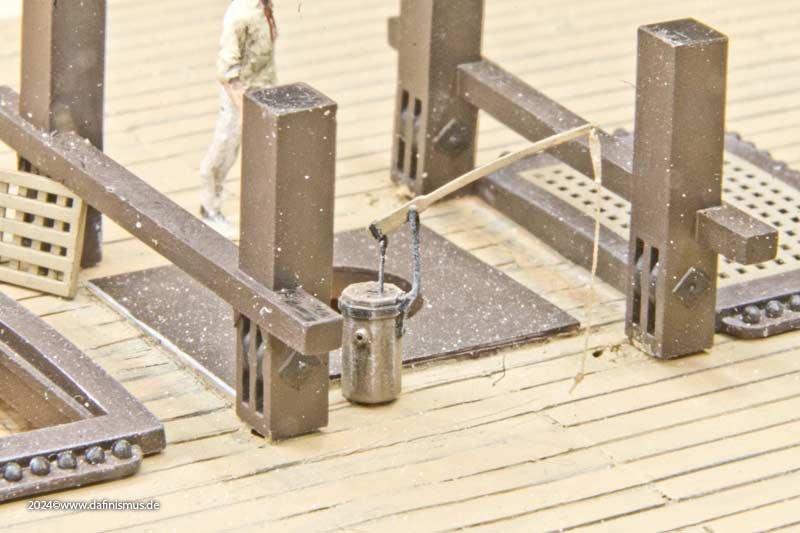

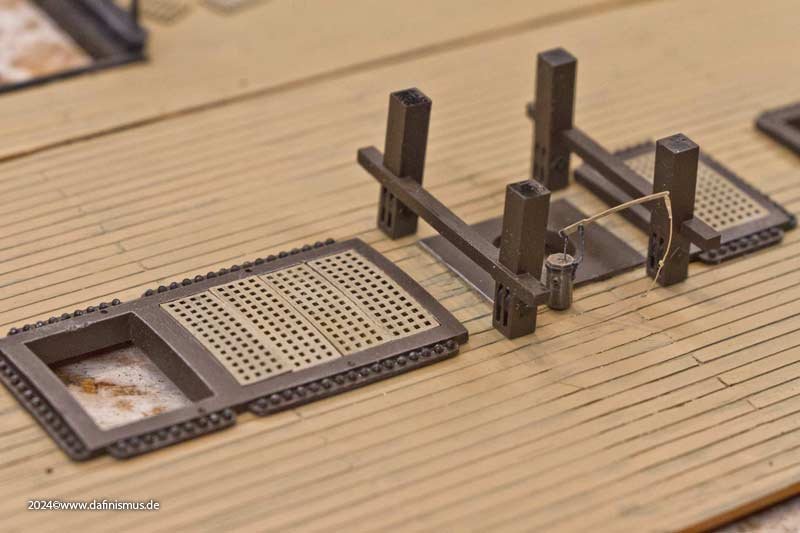

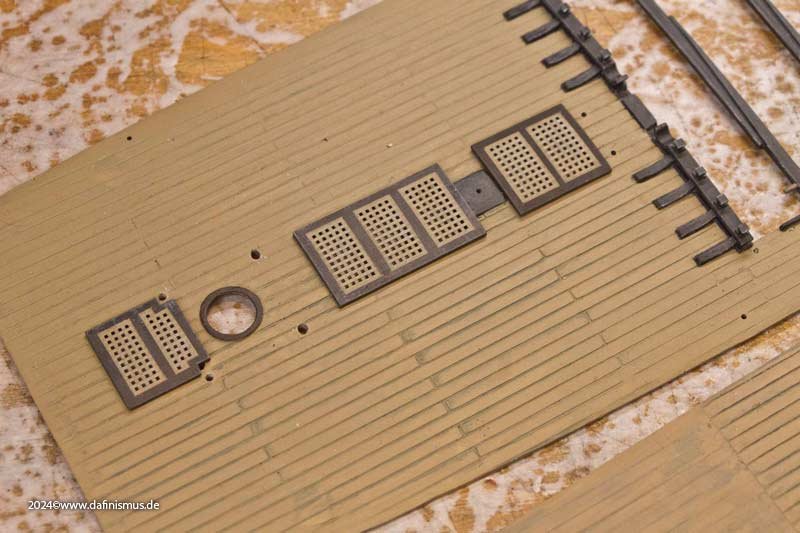

Oups, and I forgot to tell you that before the planned mess, we first had to test fit the new parts. Non-existent openings in the admiral's quarters were marked... ... cut out ... ... and adjusted to the bulkheads. The coamings and gratings were also adapted to their openings, or vice versa. And at some point, the upper battery deck was completely covered with coamings. The same procedure was followed for the forecastle and aft deck. The coamings are not as high here, as there were open decks underneath. In the area of the main mast, the gratings can be taken out, as there are some ropes leading to the bits in the deck below. This makes it easier to belay them. I also installed those bits and, as a little treat, a new hand pump was also installed there. Then the coamings were given their colour. The gratings were then masked off and painted light brown, then inked very thinly with black ink and brushed with white. And then there was the slave labour: gluing in the cannonballs... ... and securing them on the underside with thin-flow superglue. Finally, I doped the railing with the net holders... ... and add some thickness to the gangway with white Evergreen on the underside ... ... and this part of the task is finished.

-

🙂 🙂 🙂 XXXDAn

-

Next, I had to come to terms with the not *quite* correct planking pattern. A few beers later, I was fine ... Then I realised that the plank gaps were much too wide and would be far too prominent for my liking when filled with paint or wash. So I came up with the following plan: I sprayed the deck black ... ... and then scraped off with a blade so that the black paint remained in the depths like preshading. As always with my best plans, it ended up being a big mess. Then I tried out different shades of brown, both solvent-based, acrylic and water-based, in various opacities. It resulted in a pretty patchwork. The forecastle in particular was quite colourful ... ... which is why grey tones were used on the gangway. But what can I say, I really didn't have such a grimy deck in mind. So I sprayed it again and stripped it off again. In the meantime, I had remembered the other moulded parts, especially the gratings, which I had tuned to wood. That was the specification it had to match. And even though there are usually no major colour differences in the wood on original decks, except for traces of moisture, preshading with black prevents it from looking too much like a painted steel deck. You just have to throw your imagination a few little treats now and then to keep it happy. It was just a matter of finding the right balance. So I applied three glazed coats of paint until the black was only very faintly visible. Interestingly, the plastic of the upper deck was a light beige, while the lower deck was reddish brown. This was easily remedied by applying a grey glaze under the brown glazes. This technique also brings the area under the forecastle, which has no plank engraving, to life so well that engraving was not necessary and simple pencil strokes can substitude the engraving. I think that, given the limited visibility of this area, this is a good effort-appearance ratio. So, quickly in with the printed parts... ...and take some beauty shots.

-

Before heading to the trade show, things were naturally crazy for me – splinters were flying once again. One of the things I wanted to show was a comparison between the original kit parts and what you can actually make out of them. To do this, the decks had to be prepared. First, the old gratings had to be removed. Then the good parts of the deck were protected with gaffer tape and the old coamings were sanded down with a coarse file ... ... and the remains were removed with a blade ... ... or helped along with a fine file. For the finishing touches, I sawed a batten to the right width and covered it with sandpaper, which allowed me to achieve a nice even surface. Since the new coamings are also supposed to cover the thickness of the decks, I had to cut larger the openings of the companionways a little. A red pencil line serves as a mark. This was trickier on the upper deck, as the deck is not divided in half. But here too, I first had to cut out the grating ... ... cut out the coamings with the flat blade and finish them in the same way as the lower deck. For the wide openings at the rear with the thicker coamings, I made a 45° relief cut with the scalpel, which meant there was less material to remove horizontally. This made it much easier to work with the blade. And then again, enlarging the section by the width of a pencil. For this exhibit, I deliberately chose not to use a purchased wooden deck or one built one like on the other model, but to experiment with what could be achieved with paint. Now it was getting exciting ...

-

Captain Dafi, personal logbook, addendum: Recently, it was time once again for public tinkering at the game fair in Stuttgart / Southern Germany. I had brought quite a bit of material with me again. A little reminder of Èvian 🙂 And my Soleil in full sun—simply ROYAL! One of my topics was the comparison between the parts that come from the kit and what you can make from them. Here is a comparison of the two upper decks. And as usual, there was plenty of delicacies to enjoy: pumpkin-sweet-potato-carrot-potato-ginger-soup special recipe dafi — yum! Enjoy, Daniel

-

I was in model-building deprivation, with no time to do anything and not even to document what I had already built. The version of the Launch with sails has to be stored in the back for now, as martens have damaged it by chewing on the sails ... That's why I continued with the version equipped with a davit for anchoring and fishing. Here some pictures last stage. First, there was the question of where to put the cable that had been hauled up. Instinctively, I had stowed it in the bow during the first test. But in order to attach a pulley to the capstan that can only be attached forwards to the stem and the cable accordingly had to go to the rear. So I decided to store it in the middle of the boat, which is also better balanced, and you can see that this is a good solution. But first, a little bit of small stuff, which also makes a difference http://www.shipmodels.info/mws_forum/images/smilies/icon_wink.gif The pulleys are pre-assembled; this one should hang loosely, so I shaped it with wallpaper glue. The grapnel anchor and ladles have also arrived. To tie in the anchor rope, I clamped a pair of tweezers in my vice. And then I built a nice bunch with the rest of the rope. And here it is the small menagerie. And now it got pleasantly exciting, but see for yourself... While two lads secure the pulley, the capstan bar is being changed on the other side. The lieutenant keeps a watchful eye on the whole process, while one man checks to see if anything is happening at the back end at the cable. In the middle, one man holds the cable taut and clears it neatly. That setup certainly wouldn't have worked with the rope at the front in the bow, as crowded as it already is there. Cheers, Daniel

-

I always would like to warn to take the museum ship/reconstruction in Portsmouth as a reference. Actually that was the hardest learning for me to ignore this wonderful exhibit on my trip down Victory roads 🙂 Not moaning or beefing around at all those people that were and still are keeping her alive untill today, but for ressources and other reasons it is far off being a reference. It is a wonderful inspiration, it really is, but not more. Showing the treenails or the covers for the nails in the model? Simply a question what one wants to achieve with the build. Do you want to show the construction principles - then show the nails. If you like a realistic view omit them. Simply a personal choice. All the best, Daniel

-

Wales

dafi replied to -Dallen's topic in Building, Framing, Planking and plating a ships hull and deck

But it is very tricky to take everything past ≈1860 as a referenece (if not for that very special time) as the ships were heavily reworked with view on the costs and the fact that those ships mostly went into harbour duty. There is not "one" place for the wales as it followed the "fashion" of the times and the needs of the ship. As the internal structures were always improved, so were the outer parts too. If I recall well, the wales on Victory changed place during the great repair in 1803. And in ≈ 1860 they were completely replaced by a smooth and cheap planking as only harbour duties were done. And even today (or at least before the last restauration) Victory´s wales were just a fake by being much thinner than the looks suggested and being invisibly augmented by steel bolts to give some distance to the frame ... XXXDAn -

Thank you for all the thumps up, as always very appreciated! And I am always delighted by the fine structures that are now possible in printing. Once again, parts whose diameter is half as wide as my papillary ridges, these are some of the finest parts of my products 🙂 XXXDAn

-

As I have wrecked the sails, there is a forced break at this point to ‘reweave’ them. Since my day-to-day business leaves little time for this, it is taking longer than expected. Therefore, I am continuing with a rowed version as an interim action to build. According to the armament list, the Victory had a 24-pounder carronade for the big launch, for landing operations and similar tasks. It is time to continue with this little vignette. To this end, I have acquired a 24-pounder from my Constitution model, removed the first thwart, reinforced the second one, and already have a passable support. I have also added the swivel guns from the fighting tops of the my Constitution. First, I checked the length of the breech rope. The green underlay is good for rigging the small blocks, as you can push two needles into it as holding points. The blocks themselves were slotted into the vice as already described. And then it was finished http://www.shipmodels.info/mws_forum/images/smilies/icon_smile.gif The tools for the carronade are already included, shortened in comparison to the other guns. The cannonballs are stowed deep in the boat in the rack. All that's missing are the small salt boxes for the powder cartridges and a toolbox. Enjoy, Daniel

-

Mara thread - what colors do you use for fabricating ropes

dafi replied to Sterling59's topic in Masting, rigging and sails

I still wonder if this block is a Stay Tackle Pendant / Fore hatch Tackle Pendant. Also it appears as it has an iron thimble around the stay. Often a sign that it should slide up and down. But there is a small seizing just beside that seems to block it - also what about the snaking in between the main and preventer stay. By the worming this block is attached at the main stay. XXXDAn -

Mara thread - what colors do you use for fabricating ropes

dafi replied to Sterling59's topic in Masting, rigging and sails

Just to support Chuck´s and Greg´s observation: When I started to hit the french forums, I was surprised them not doing the "usual" diffentiation in color inbeteen the standing and running rigging. Even more they were surprised that we or better I did. Eversince I orientate myself more on the style I saw on Hermione: different colors due to different level of tarring and also different bleaching by sun and salt. To the question if parts are wormed but not served I would like to show you the pictures of Invincible´s stays, nice to see the different worming, serving and the differences of stay and preventer stay 🙂 The mainstay wormed the whole length, served around the masthead up to the mouse, the preventer no worming along the length but wormed and served around the masthead. All pictures taken from the Facebook site of Invincible wreck. Enjoy! XXXDAn

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.