-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Izzy Madd

-

As this has gone totally of track the best way to end this direction and perhaps get bac to the original question is to quote the Guinness book of records "A rope measuring 251 m (823 ft) long, with a diameter of 2.2 m (7 ft 2 in), was made from rice straw and was used for tug of war by citizens of Uiryeonggun, South Korea during the Righteous Army Festival on 22 April 2005. Weighing 54,500 kg (120,150 lb), it is the largest rope made from natural materials." And as for measuring diameters I was able to judge a circle to within 10mm from 100mm up to and beyond 1400mm with out a measure. It's called experience. Measure it how you like I don't care the question was why only three strands, how many yarns, and why not six strands. So either get back to the subject or start your own.

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

Izzy Madd replied to Izzy Madd's topic in Plastic model kits

I'd love to get an untranslated version as the images are brilliant but as it is I have enough trouble reading English never mind German.... -

You've not seen the state of the parts. The two sides of the hull were different heights where they met. And different keel alignments and the lengths were out by nearly 5mm. Thankfully I went to art uni so I may just end up calling it Cutty Sark after Dali and leave it on the radiator:-) Thanks for the comment. Hopefully it will look something like even if it's after the fire that resemblance is...

- 79 replies

-

- cutty sark

- airfix

-

(and 1 more)

Tagged with:

-

Hi, You may well be right about circumference rather than diameter the exact measurements were not stated. But I've seen rope personally well over 18" in diameter at Liverpool dock museum. And yes it was a rope not cable although it did have six not three strands. As for the conversion 2πr or 2x3.14xradius is the accurate measure but yes a third of the circumference is usually close enough especially with things like natural rope which will swell and shrink.

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

Izzy Madd replied to Izzy Madd's topic in Plastic model kits

Thanks Dafi Some great info in the ones I've already got. "The 100-Gun Ship Victory (Anatomy of the Ship Series) " got "HMS Victory: her construction, career and restauration" from McGowan not ordered yet "The Anatomy of Nelson's Ships" from Longridge ordered waiting for it to arrive all 2.5kg of it. Just a little light reading... "Rigging Period Ship Models: A Step-by-Step Guide to the Intricacies of the Square-Rig I think I've got "Owners´Workshop Manual" from Goodwin got Nice to have: "The Construction and Fitting of the English Man of War: 1650-1850" from Goodwin not ordered yet "Arming and Fitting of English Ships of War, 1600-1815" from Lavery not ordered yet "HMS Victory" from Hackney (German Version) Waiting for -

How many yarns would be used to make each strand of a rope? Is there a limit or is it just dependant on what size rope you want? Only I've seen years ago. People making rope in a traditional ropewalk. Walking back and forth dozens of times but there are still only three strands. Obviously there has to be an equal number per strand. But if you can make ropes upto 9" thick then why are they mostly three stranded when the twisters are capable of doing at least six strands. And when would you make a rope out of more than three? Or is it just that its smoother and perhaps stronger because of the reduction in angle of lay?

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

Well I've taken the plunge and put my work on display here. Not something I've done before as I said the Internet wasn't even an idea for the armed forces.so let me know what you think and I'll try and get some better images up.

-

From what you've said it seems that both practices where equally used so it's likely that some "posh" artist or writer saw one sailor barefoot and it just seemed more romantic. As even soft canvas shoes would offer protection against rusty iron work and again the sailors or sail maker could soon knock up a hemp sole, a splash of tar and you've got a pair of decent forward..,

-

I was looking at images of the Mary Rose so some 300 years before but newish finds. One thought that strikes me as a knot worker as well. There would have been a lot of old sail cloth nocking around and the sail maker could make a fair living making quick simple shoes for all on board. And plenty of takers and materials. If he kept his prices right the sailors could afford them as well. Just a thought.

-

Hi, When I wrote my profile. I said I was going to be building the HMS Victory with the Cutty Sark mixed in to help me retain some of my insanity. Well after getting the Heller Victory. And realising just how detailed she is. I realise I need a lot of research before wading in. So I've started the Cutty Sark just to blow away a few cobwebs. And relearn what I've forgotten and learn all that's new. Since the invention of the Internet... Now as I say I'm just having fun. But any suggestions or alternative methods whatever will be most welcome. And before any one says anything yes I've started off with the wrong colour paint. Ah well... So here she is. Sorry the pics are so naff but I'm still waiting to get my camera back from my daughter. Not quite from day one but due to handicaps near enough please be gentle. It's my first time. :-) But be honest Not much I can say as a commentary but here she is. I just hope the real Cutty Sark is in better condition even after the fire. This is one awful kit So watch this space. Either it will grow nicely or end up in Davey Jones Locker.

- 79 replies

-

- cutty sark

- airfix

-

(and 1 more)

Tagged with:

-

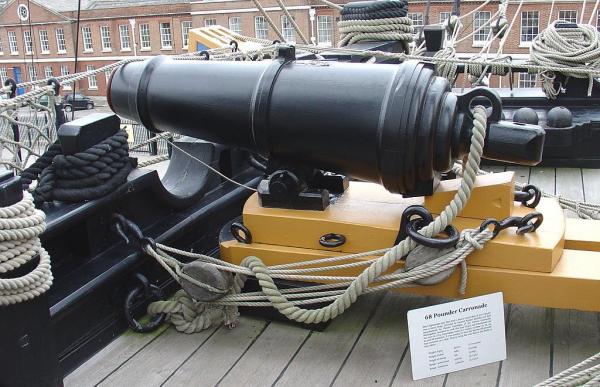

I'm no physicist but I do know that an iron bar of even two inches 60 mm. Would bend like toffee when faced withe the weight of the barrel flying back at at least ten tons of force. Look at cars and they are only one maybe two tons. I once snapped an axel going at ten miles an hour because the verge I hit was solid ice. Very little impact. Yet snapped a 100mm bar designed for the job. Wrought iron is renowned for being flexible that it's main benefit over cast. But you say you've only seen wedges in 19th century replicas. I assume you mean 1900-2000(20th century) otherwise they would the same era as Victory. But how many times have old timers said. "I used to use something like that when I was a lad" While it may not be documented until much later it may well be like the story of eating carrots during WWII. To prevent the enemy suspecting we had a secret weapon, radar, the rumours went around that carrots were good for your eyesight. The same with the guns. It could and probably was common practice to use a wedge just not put down in the instructions. the same as devinci did with his plans. There was always a fault to prevent others just copying it. There is no way a small screw or even a large one. Not bending under the strain. I've seen modern bolts 150mm snapped like twigs when the force was in the wrong direction. Even a foot bridge collapsed under the weight of people because the builder moved two bolts. The designers of the guns probably never even saw one up close.and just thought that looks better without the wedge.

-

Hi, Not wishing to hijack you other thread. I'll cont here but I realise that there is a metal plate for the screw to slide on but with several tons of recoil that would be like putting a biscuit under a wobbly table leg. The bar would still bend if not embedding in the wrought iron plate... At least digging into the wood at one side or the other. And if not in the plans surely a Wiley old sea dog would have realised this drawback and used something in his own redesigned version.. Being unable at the moment to actually read the entire thread due to my condition. But having spotted several words on the issue I feel that the gun be mounted I such a way that the pivot was able to slide but not able to rise. Either a removable spike through the pivot making it simpler to transport around deck if needed. Or a fixed system of some kind. Or else the same force that drives the back down would flip the barrel over. Unless you can find a loop hole in all three of newtons laws of motion.

-

Slight variation of question, But in all the illustrations and written work mentioning the sailors feet. They are alway depicted as barefoot. But when they bought up the Mary Rose. A ship some 300 years older they found numerous leather shoes. Now I realise the more senior crew may have had shoe nd the marines I assume had boots. But there seem to be far too many shoes to be just for the senior seamen. So is this idea of sailor running around barefoot a myth? As the number of injuries sustained without even the most basic shoe would be far greater. If not just from the huge amount of splinters flying around in battle. Or is it that they only wore them for shore leave? I doubt there's a definitive answer but a worthwhile though perhaps. Especially going up and around the ropes. It would play havoc with the men's ability to walk and the risk of even a minor injury. Was risking amputation a best. If not a slow and painful death from infection.

-

Thanks for the pointer as it was only a few days ago I found that section. And it does help in explaining the butt systems just not specific ships. So don't dissape too far down that hole. Just sort of regroup for another salvos (-)

-

I've already scoured through the very helpful articles. I'm looking for information relating as much as poss to the Victory herself. Izzy

-

[quote name="dafi" post="298857" ... while in the front ... ... the radius is surprisingly limited. Cheers, Daniel Sorry to be going somewhat off subject. But looking at your excellent trials. I'm still troubled by the use of the screw for height adjustment. In one of your earlier pictures I think. You show both the wedge and the screw. Which I can understand. The screw gives the adjustment but the wedge takes the force. But without the wedge how you have it rigged. Which I'm not doubting for a moment. But basic physics shows that the rope is going to want to end up straight. To do that the back end is going to be dragged down onto the screw as well as back which would give you a one shot deal as the screw would just embed itself in the carrige. So my wondering is while the use of screw or wedge for aiming was upto the individual captains. Was it a case of at the actual firing that the wedge was always put inas that would then take the full force of the recoil. Leaving the screw safe? Would not the screw be easier to turn with an eye loop at the top for turning? Just speculation and not intended as any sort of knock or slur. But just a query of greater knowledge against pure guesswork.

-

Hi, Im what I describe as a Re-Newbie, as it's been so long since my last kit model. I'm about to start on the Heller 1/100 HMS Victory. While this is plastic I'd like to add a set of wood decks. Simply because. Working with wood is no problem as I've been making scratch models of furniture for years. Usually 1/1 scale :-). I was a cabinetmaker until illness. But enough of that. I'm struggling to find any idea of how the planks were laid out, what size they should be, width and length, how far the treenails should be placed. Anything really. I'm not after über accurate just looks good. Can anyone help, with anything even just a link or decent image. Thanks Izzy

-

Hi, Nori is a glue used by samurai sword sheath makers. It's used because it set solid like epoxy but dissolves in water as its starch based. I've used it when making watch glass replacement and needed to be able to file from any angle. I usually used Perspex for the glass so I would imagine of similar hardness but I never had anything move until soaked to remove it. And it's very readily available as its made from over boiled rice.. And if you always filed towards the edge as apposed to away then the CA should hold it if your substrate is rough enough. And loctite thread lock would grip brilliantly and a bottle would last years. And even more so if it's none ferrous metal as there is a chemical reaction between the glue and metal. That a lot of engineers haven't realised as they always seem to use the thread locks etc which are CA based on metal so don't experience the difference especially in curing times. Slight side issue I've had loctite thread lock and other liquids by them that in them selves won't set even after several days, add a few grains of none ferrous metal and instantly a disc 5mm x 40mm sets solid.

-

And as far as I'm concerned that's good enough reason to go with right hand lay for none cabled. As its not as if I'm rebuilding the original I just wanted and have got confirmation as to which was right est. in that it may have been determined by which side of the ship they were on but all the same will be fine as its simpler to make and looks uniform and the cabled ones will add a source of conversation as to why they are the other way. And I can say "go and fight it out with Tallshiptragic in Perth". Always a good start to the day when I can blame someone on the other side of the world :-). I've been asking this question of a number of people, on this and other forums. But yours was the clearest and most helpful. As I'm happy to go with right hand, I'll check that later, lay. And as for anyone else they are welcome to make and re rig my model if they want to. Just let me finish it first. :-)

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

Far more than a grasp. And now I can stop trying to sort out which should be S and which Z and concentrate on learning the names and making the ropewalk. As I didn't know if I'd be swapping everything around to do have one way and the rest the other. But as its only multiple rope into a cable, sorry it's just keeping it in terms I understand, that is S twist. Then I can go ahead and make the ropewalk as I wanted as the change over will be all in one go so being a little more complicated isn't an issue. I may even make one for each way. Just like making anything really so it give me a good excuse :-) thanks agan

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

Thanks. It's a great help. I did wonder if it was a case of the photo being whatever was at hand. And also assumed as you say ropes were only s twist when reworked to form a cable, excuse my inaccurate naming, I'm trying to understand before fixing actual titles to things. As its the look I wish to capture as much as anything and being a landlubber and dyslexic names don't change the job things do. Thanks again for the authorative answer. While I'll have to look up some of the correct names the main question is answered. And I have a detailed description to refer to. Sorry to be so thick, thanks for being so helpful Izzy

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

Thanks for that. Is there a certain diameter or just the need for re twisted to make a cable? Not the best worded question I know. But the best I can manage at this time of night. Also I'm a little confused by this picture As there are ropes of All sizes but going in both directions? With no perticular reason. Please if you can set me right

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

-

Hi, I'm confused by the talk of Z or S twist. I understand the differences, direction. What I don't understand is why? Especially after looking at some pictures of the Victory which I'm about to start. As there are clearly several ropes of each kind same size and same sorts of use. So when would which be used? Or was it a question of which way they ran the machine that day? Or would it normally be one for ropes under a certain diameter and the other for cables? Any help would be gladly received. Izzy

- 29 replies

-

- Rope making

- z twist

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.