-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Izzy Madd

-

Thanks for all the likes As you've done him before. You may be able to help out as regards the sails. Or anyone for that matter. Normall they were painted with a delightful mixture of fish oil and red ochre. While I'm all for realism I'm not into the smell of rancid fish oil for the next few years. What's the best thing to use to colour the sail? As they are a lovely shade of as we called it in the rag trade ecru. Better know to us mortals as unbleached. I know I could just paint them but I'm concerned about the paint being to thick and looking like I've painted them rather than some sort of stain. I don't really want to go and buy fabric dye as it cost a fortune and is carefully measured for colouring several yards of fabric. Would food colouring work or even red ochre and mineral oil. As that's inert. So won't go off. And I have loads of that for protecting razors. Also as I've moved Little Willy back a few decades I've realised that the planks would have been nailed on. Would I be right in assuming these would be normal 4" copper boat nails or even roves? Does any one know.? And if they used roves no wonder they used to wrap chains around the hull when filled with loose cargos like bricks and coal. As they would have been copper rove plates flying everywhere. And the cargo sat at the bottom of the river

-

Well I can defiantly possibly unofficially confirm that reading the great and mighty Dafi (no offence intended, I mean that as a compliment). Is contagious. Or is seems to be for me. Not only have I ended up kit bashing slightly, but to what I can only describe my self as being obsurd. That's me not the act of ultimate detail. While Little Willy, which he told me he prefers, not on anywhere near the same par as the almighty Dafi's Victory. At 1/64 and being my first wooden kit. It's not bad even though I say so my self. After much soul searching, and not finding one spare. I've decided to go for a slightly earlier version of the Thames river barge. That of the all wooden era. Simply as I don't want to have to paint the wood. And because I'm too far away for you to stop me

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

Izzy Madd replied to Izzy Madd's topic in Plastic model kits

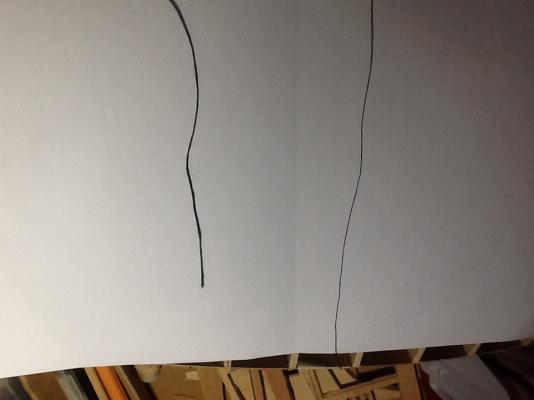

Quick update on the rope walk. While it's not fully finished. It is a working item not just needs mounting Just a shame all the fun goes on inside. And before anyone asks. Yes they are upside down. Thanks to apples latest updat/downgrade. Nearly as bad as ebays... -

Just a query about the salt boxes and brass monograms. While I'm sure I've got more than enough thanks to your kit. Do you think that once embossed that the recess could be filled with fine powdered brass and CA? Or is the recess to small? Love the workmanship and attention to details I can only wish for.

-

H.M.S. Victory, Heller, 1/100, Onward and Upwards.

Izzy Madd replied to Izzy Madd's topic in Plastic model kits

Hi, Just a quick question for anyone who'll answer please Did I read somewhere that the victory had teak decks? And if so did this also hold true for the Cutty Sark? Only I've got about twenty 50mm strips of teak veneer 2.800mm long. Which would look great colour wise even if it's to dark for reality. -

ADVICE PLEASE Decking. I know the "Will" was never fully planked. But as she is my boat it's my choice. Having said that. What is anyone's opinion about such a complete change of the kit.? The reason I want to Kit bash in this way is I simply love wood and would like to leave it as unpainted as still looks right. But shows as much of the beauty of the material. I'm also thinking of adding a new single veneer piece as the base of the hull to hide the joint and possibly veneer the keel for the same reasons. I know some pieces will look better if they are accentuated with paint such as say the masts. Who'd have no real grain to feature. And I wanted to get another ponint of view. Is it shunned as "not true to the original? Or lauded as imaginative? Or just ignored as its up me what I do.? Or what ever. Please leave some answer. As I'm assuming not many are over impressed as I've had 65 views but just one recognition/like. If I'm doing something wrong in my build log PLEASE tell me. As this is my first time sharing a build of any kind.

-

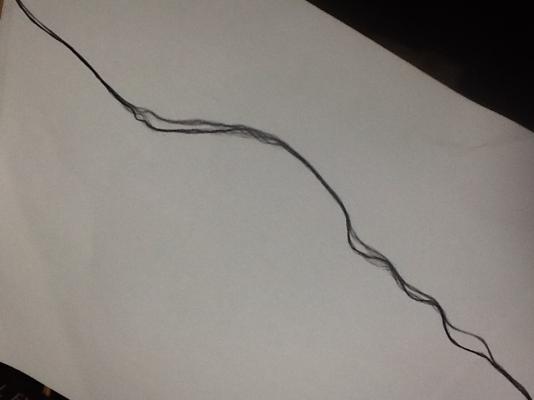

THREAD Before you keel haul me Cap'n read on. This may seem and my be needless to say. But we all use threads of differing thicknesses and colours. But I've only heard one side of the market mentioned. That of the 'cotton' thread. Now I also know we are trying to reproduce rigging etc. from way back when. BUT there are exceptions to any rule. Firstly even home made ropes are restricted by the material used as to there strength. Well if you move from a lock stitch machine to an overlock machine you will find. dare I say it, polyester thread. So what you say well poly thread is twenty times stronger at least. As it will cut through to the bone before snapping in your hands. Also, see below, it has a very marked resemblance to oakam. In that it is actually multiple threads loosely put together. So it can be thick if not stretched, see picture 1, the thread on the left is normal cotton thread, the piece in the middle is poly thread layed flat. And this shows how the separate threads can be allowed to open out. The second picture is of the poly thread doing what the cotton could not do. That is under tension. You can the thickness when stretched reduces dramatically and it decreases further when squashed. And this is the poly thread with a quick strain test showing it being pulled as far as I dare as its holding my model together at the moment. But the gauge read over 500g. Or half a kilo. And no sign of snapping. Just something that may not have caught your attention. Especially the strength. That is in the home. Cap'n A quick update on this post This shows the "fluffy" state better. And the breaking strain is 1.2 kilos. More than enough to snap most model boats mast clean off and that's for a single length.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

COFFEE STIRERS I know we don't normally use them in the home but... Namely the ones that are made of wood that's about 5mm wide and 1mm thick. While not the best quality timber they are just the right size for a nice bit of deck planking. Or any other such timber needs. And they are great for scraping unwanted glue from tight corners. But mostly as modellers consumable. Does this one count Cap'n?

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Oh and one last thing about the supply of lotto cards before they all dissapear to be used on some one models. If groves are cut into the edge they make great glue spreaders for large ares. Please don't have me flogged over this one Cap'n as its to do with a household item just another use. Please grovel grovel

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Sorry my fault I started it and you are right. As are you Nenad, I just assumed they would be the first to be looked at. So didn't mention them but there is always someone who doesn't know. But enough of tools. Wrists fully and justifiably slapped and I'll try not to do it again Cap'n. Or you'll have keel haul the lot of us. Har Jim me lad.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

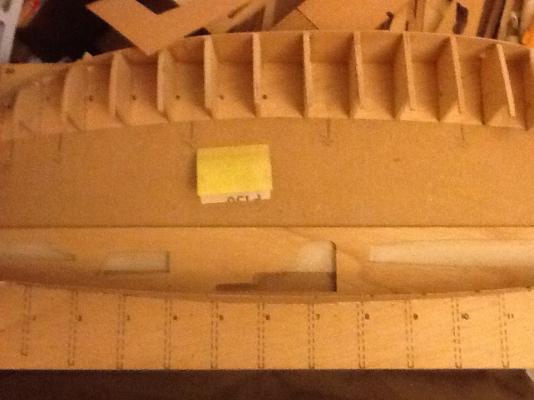

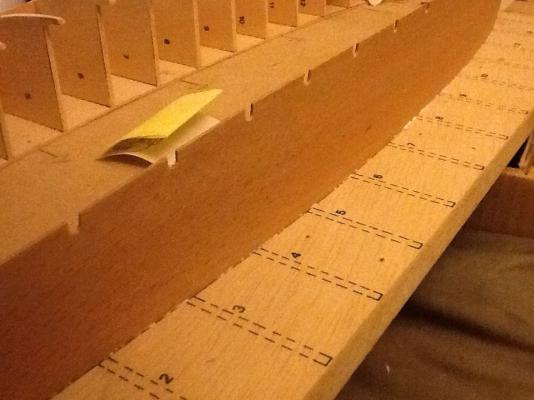

Ahoy there, Just a bit of surprisingly early update. But as things have turned out there is quite a bit I want to add today. So sorry for all the images. Hopefully they are all right way up. First of all, thanks for the like Ray. Second as as far as I can see very few logs as to the build of "Will" I'm going to assume there are very few and treat you all to the gory details. I know there was a built on here back in 2013. But none I can find now. Please feel free to correct me. Also I want to avoid using CA as much as possible on the wooden parts as I find I crystallises over time as the wood moves and the glue doesn't. So parts become loose or fall of. So it's very similar to the way a wooden boat would have been built. All will become clearer as we go along Yesterday I'd gotten as far as glueing the the ribs on one half. As this is built in two hales then the halves glued together. I'd also started to fix the base of the boat on. For now I'm going to write about halves so anyone following me double up what I've written as I'll most likely be doing both side the same.w In more detail the base is made of a single piece of three mill ply. And the boat is made in such a way that all but the last four ribs on each end are flat along the bottom. So this meant I'm able to secure the base to the middle ribs as there is a line printed on the base for alignment with th seventh rib. Which I'm then able to leave to set over night. That way I'm not trying to hold 15 ribs and the base at the same time. The first thing I did was to sand the last. Four ribs on each side to the right angle. This is very arbitrary as the ribs vary slightly so I decide to sick with a line that was smooth and visually nice. This done I need to bend the base ply three ways. Hence the glueing the middle down yesterday. Well ther are only three ways of doing this that I know. Brute force, which worked but not easy to maintain for two hours wiphile the glue sets. Heat/Steam, messy smelly and needs extra equipment. Or they way I did. That is to apply several coats of warm soapy water for about ten minutes then bend it like paper and turn on the fan to dry it our. One dry it's three parts there. Then I glued and taped the hell out of it to hold it in place The end with the least tape I allowed to dry before gluing so less pressure needed also the front is such a low angle I had to add to scraps of ply left over to pin it down because the angle is REALLY low. As you'll see next time So today I was able to cut all the pieces out and try to make some sort of headway out of sorting the planking etc. As this is an "old" kit see the lid and the bloke with the beard and pipe tells you that much. But the parts don't all add up as to the modern version of the instructions. This said I do think they were far more generous back then as I seem to have about twice as much as nowadays. :-). Great for those slight redesigns later. See what I mean Well the first thing I did was to replace the slipway that is supplied as this one had twisted and was only able to hold one half. Too slow. So I've gone for a piece of MDF 10 x 300x 500 mm ish. Then I can just spin the board around to work on the other half. This done you'll notice a few oddities. First off I should have glued the deck on befor the base. In my defence I disuse the deck piece to ensure alignment. Secondly was a spark of inspiration on my part. The makers tell you to put the ribs on making sure there all square and vertical. Very good advice but I was arranging parts when I suddenly realised the the keel boards are from a square set in the same sort of arrangement I've pinned them down to. This is where the idea struck me. If the scrap piece is the same shape as the deck needs to be AND I need to stick the ribs in the right place. Then brainwave. Glue the dec on first, ribs have to sit in the notches, and hold it there with the scrap piece already shaped. Everything is now in place perfectly and I can just shove, technical term that, the ribs in the right places bang bang bang, another technical term. One thing I did learn from the build from 2013, sorry terrible with names, drill the holes in the ribs for any fittings before planking the sides. As there is only 10mm night so it can only be done from the outside. So until next time heave ho. And pass me the rum as its weekend and PARTY TIME

-

Ahoy, me hearties. I'm just starting this log a little after the event but too far. Any suggestions or criticism welcome. I'm spreading my self a little thin as I'm also doing a 1/130 & 1/350 Cutty Sark at the same time as this so progress my be patchy. But they will all be finished. Eventually. When I first bid on this "vintage" model on eBay. It was simply for a chance to try building a wooden boat. As I've always stuck to plastic kits in the past. But as an ex cabinetmaker I though it was about time to take the plunge. When I got the winning bid I began to do a little research. Only to discover that this small working boat which was bought by OCL way back when. Was the very same boat I spent a day sailing up and down the Thames way back when OCL had just bought her/him. Back even befor there were a comforts just long benches and wooden tables. But that day has sat in my mind all these years, 40 ish that is. And to find I've been a victim serendipity thrills my inner child with great pleasure. Like I said having been a wooden top for too many years I'm hoping to leave her with as much wood showing as possible. Which considering she's built of steel is fine by me. As she will still be the same memory for me but why try to hide the wood. Let the beauty of nature shine is my hope and feeling. But time will tell. Sadly there are no instructions for this model. I don't know if there ever were. As the new laser cut version varies in several details. But I've got the plans, the knowledge of wood, and a stubborn streak a mile wide. So I'll end this part of my journey with a picture or two of her as she was yesterday, on arrival. And how we stand this afternoon So I'm going to set sail for now and add to the captains log soon.

-

The beading needles are very similar but have that longer reach for when finger are too big to get close enough. Bu I have these as well. Also as they are so dirt cheap I canalised one and fixed it to a piece of dowel for the same thighs spaces.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

BEADING NEEDLE Not sure if these have found there way into anyone's tool kit yet. But they come in long lengths 150mm average. Cost £3 ish for ten. And come in diameters/gauge of 0.2mm, may be less. Also they have a large eye 3-5mm that collapses. To pass through those pesky pulleys and dead eyes not to mention through that bit of the hull you forgot to thread when you could get to it. They are also quite flexible so easy to reach behind that winch that's in the way:-)

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

That's in the "news breakthrough" at the bottom of the posting :-)

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

SPRUE This is one that may well be known if so I apologise. But in the past when I've needed a glue that will fill larger gaps or just won't run off. If you collect the dust from filling/sanding/sawing bits of sprue and add a few drops of, I use pure acetone, USER BEWARE. But mix the dust withe the solvent of choice and you end up with a thick sticky glue come filler. A similar effect can be done with CA and the baking soda trick. Only using sprue dust in place of the baking soda. But baking soda can also be used if it's going to be painted. Best if you can grind it to an even finer powder. Also if you have a large gap an are trying these methods CA glue sets instantly upon contact with brass or copper. So if you add fillings of these to your gap filling powder the CA will set solid in seconds. Aluminium can be used but I find it's a bit slower. IMO

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

LOTTO/CREDIT/LOYALTY CARDS The lotto plastic cards for writing your numbers on that is reused each time. Same size as a credit card(UK I don't know about other countries). But these are made from styrene if the edges are white. In a pinch if you are out of sheet plastic very handy. Just sand/scrape the paint off, there may be other ways I will update after test. Best part they are free. The lotto one are anyway.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Then added the Dafi's victory sign , it comes with a template so you cannot go wrong on the spacing of the letters. Try saying that to a graphic designer you can always go wrong with the placing of characters. Even down to the pixel level. :-) Love the work but a bit more detail than I'm planning. Just as side note did you consider soaking fabric in PVA and water then rolling and folding for the hammocks? Only seeing what you've done and not having two sets its something I may need to consider.

-

FLOWERS OF SULPHUR/LIVER OF SULPHUR not the same thing flowers a weaker form. WARNING HIGHLY TOXIC IF USED INDOORS also stinks. It's the stink, hydrogen sulphide, that is dangerous smell of rotten eggs. Great for blackening brass copper or gold and silver. It's the main ingredient of most blackening liquids but cheaper. Loads of instructions either pm or google it. Also can use over boiled eggs but takes longer. Same smell same result These can also be used to produce actual thick layer of verdigris within a week but using the fumes not dipping. Simplist way is to place the model or parts in a plastic bag. Ensuring none of the desired bits are covered or touching the bag. And then plac a jar lid with the solution in, inside. And seal the bag and leave to get on with it. Clear bags are best then you can see when it's done. If possible a gentle source of heat help.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

FOAMALITE Not exactly a household product but anybody looking for a low weight medium for building this is PVC based but low density cuts like balsa but reasonably water proof. And stronger than balsa I've just bout 100square foot for £20 delivered. Very good for any part that needs strength but not hard to cut. Softer cutting than ply but harder and glue with pic pipe glued. Just doesn't like long exposure to solvents or heat. Foamalite is the brand name so there may be other names used mainly by sign makers. It's solid sand to a beautiful finish and can be welded so becomes as one no seam to crack or flex. I don't know what else to say if you want any more info pm me Oh yes main dimensions are 5mm thick. Best deal on 4' x 1' can also be got in 3mm but not from the same suppliers but can be got in sheets 4' x 4' from same suppliers normal sizes start at A4 can be bought at A5 for £0.99 as a sample.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Just follow them as they are always dropping them around here. Just make sure your far enough away that they don't think your stalking them. I'd hate for them to "go postal":-)

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Ah but not as eco friendly as stopping your postal worker dropping rubber bands. Not only is it cheap it's saves the planet :-) And it's it suitable for both left and right handed tweezers?

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

I understand what you are saying and agree totally like I saw I was a cabinetmaker for several decades so wood and scale are things I know well it was just an observation of the layout of the rigging. Both real and model. It seems that just about every stress point is countered by either gravity or lines. While I'm not going to throw the tips out of the window. It will be interesting to see the differences. And an interesting discussion point. As apart from a heavy pre Nelson three masted model done in my teens which vanished with several moves and marriages. And was never finished. I've not got beyond the decks myself other than the baby.. So time as always will be the great teacher of life.

- 79 replies

-

- cutty sark

- airfix

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.