-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Thanks so much Paul, Jean-Paul and the “likes”. Bob

- 78 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

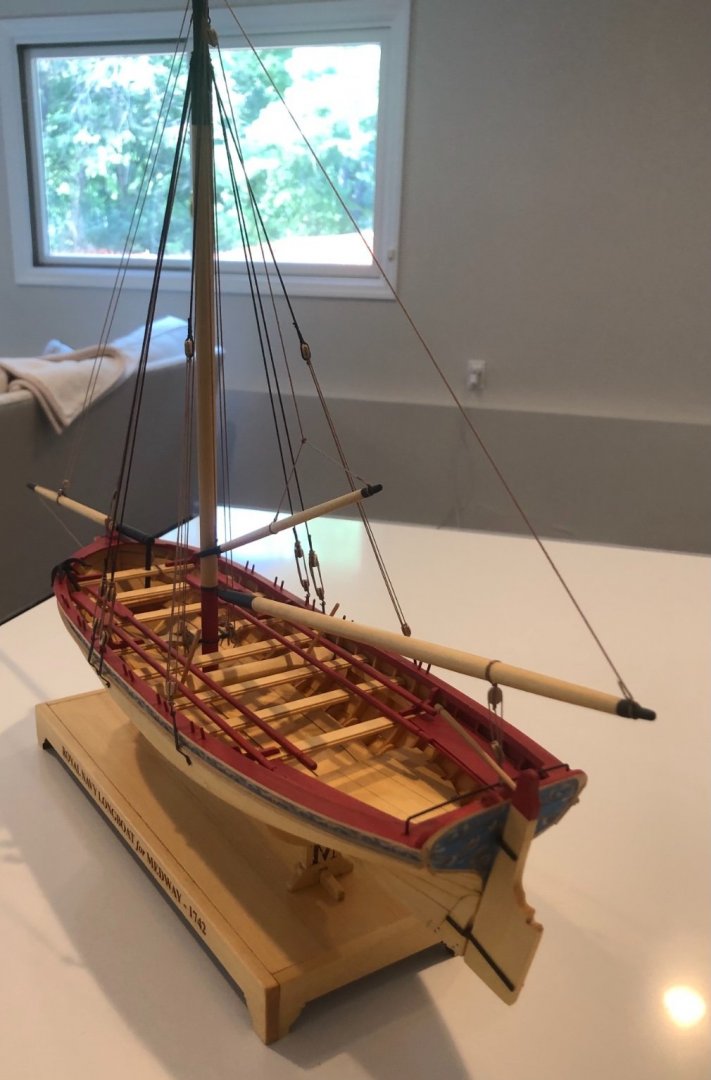

Finally, I’ve gotten to finish. This was my New Jersey summer project, but because of COVID we haven’t been here In two years. The last of the rigging has been done, lines have been tightened and coils added. The grapnel is in place. Whew!! Bob

- 78 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

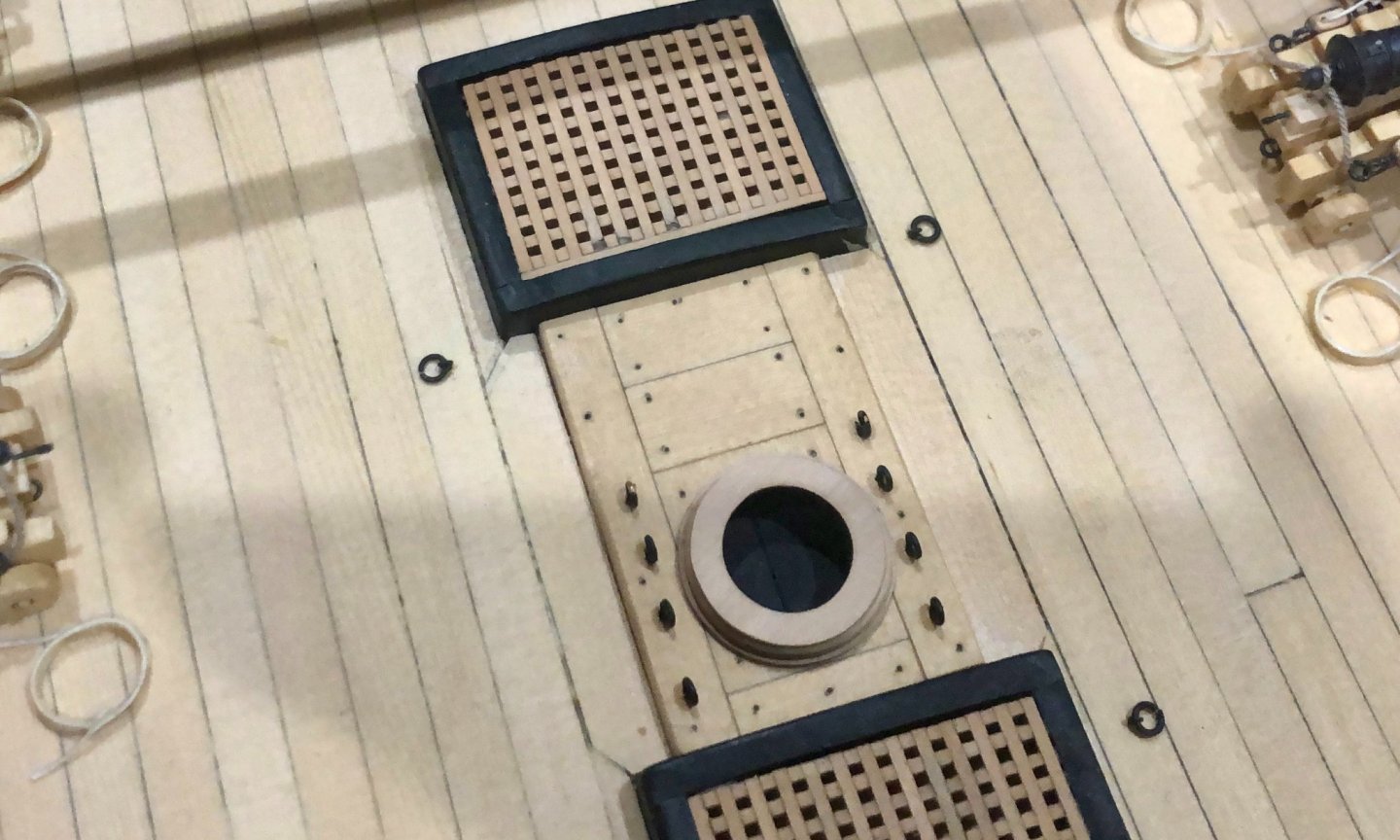

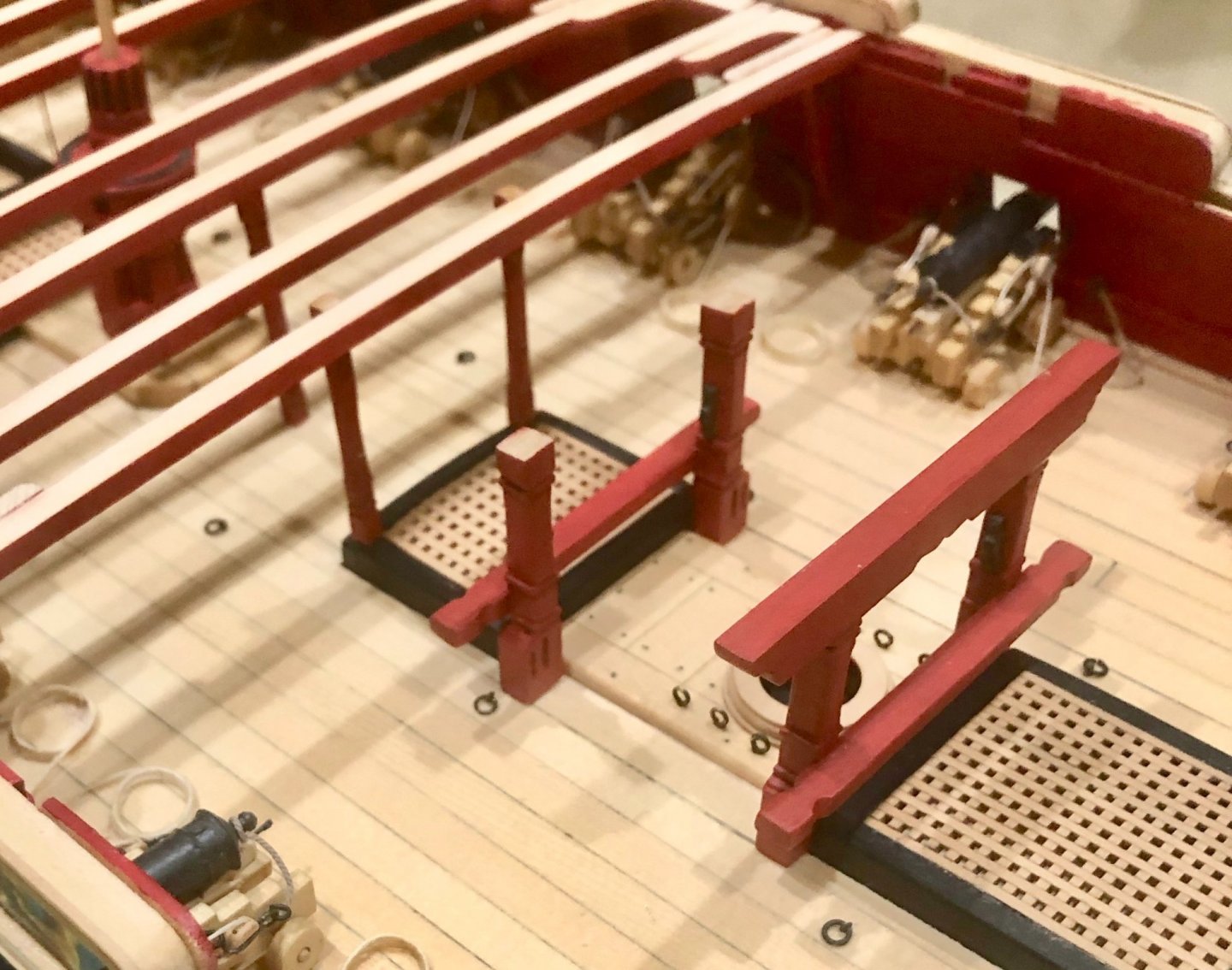

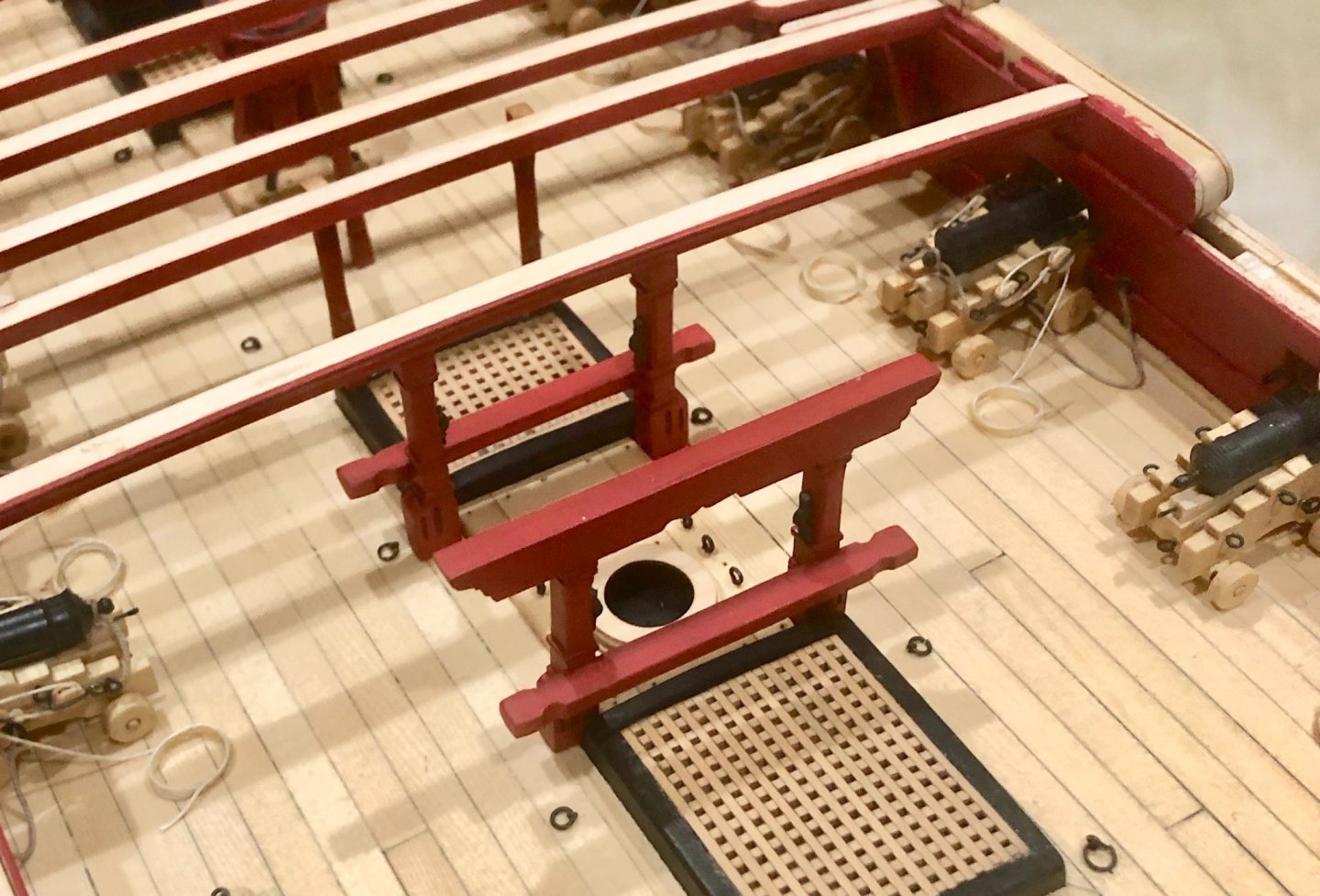

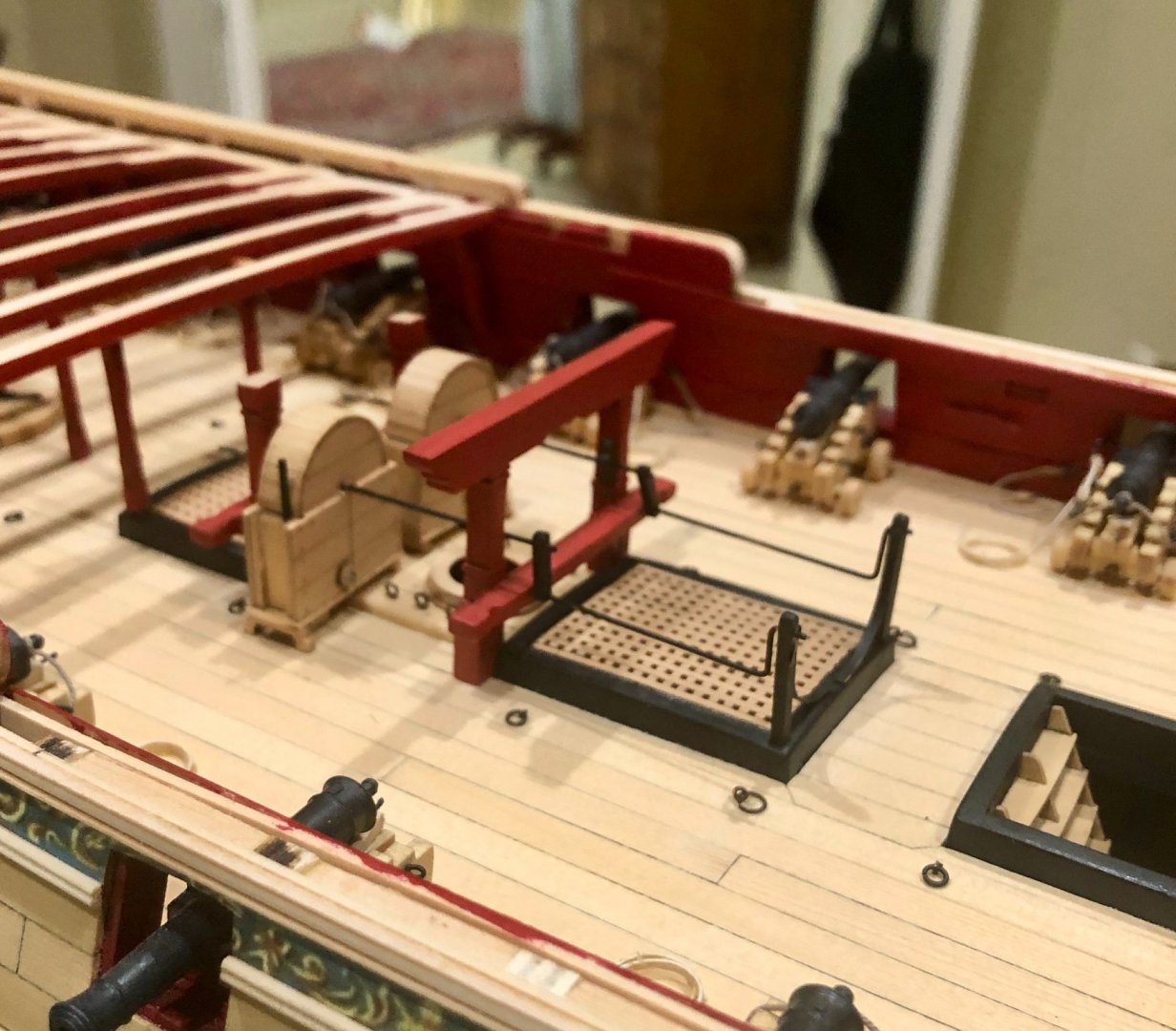

I've now made up and added the main mastcoat, jeer bitts and gallows, the two columns for the aft part of the chain pump crank handles and the stanchions for the forward part of the crank handles. The deck beams forward of the beam above the columns have not been permanently installed yet. I then made up the chain pump cisterns. The great laser cut parts for all of these items made the process relatively easy and fun. Getting everything lined up properly was less easy and less fun. Making up and installing the cranks was even less so. At this point, I have done only the center and forward portions, and I'm seriously considering redoing them. I will have just over a month to think about this, since we're leaving for New Jersey tomorrow and won't be back until early September. Bob

-

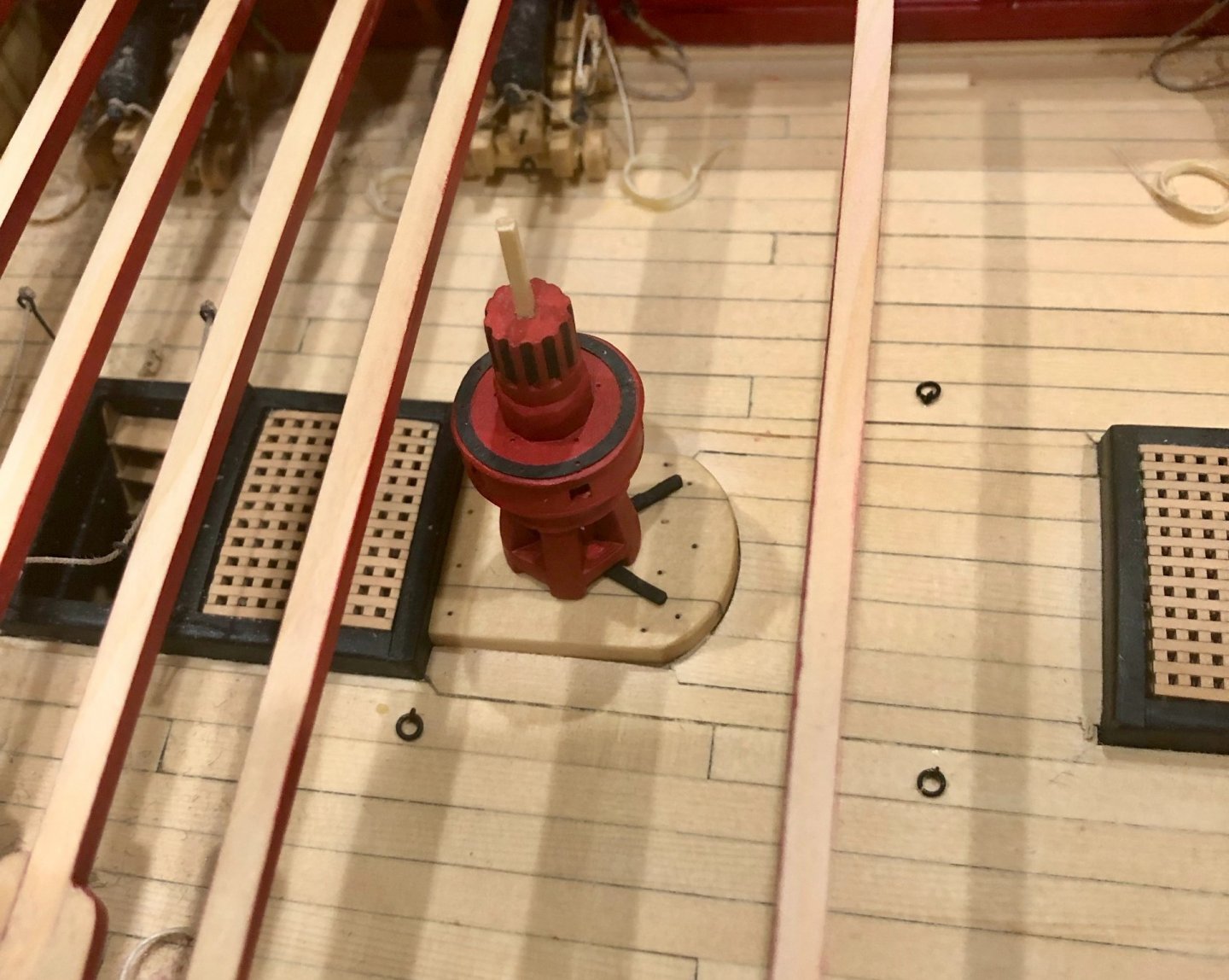

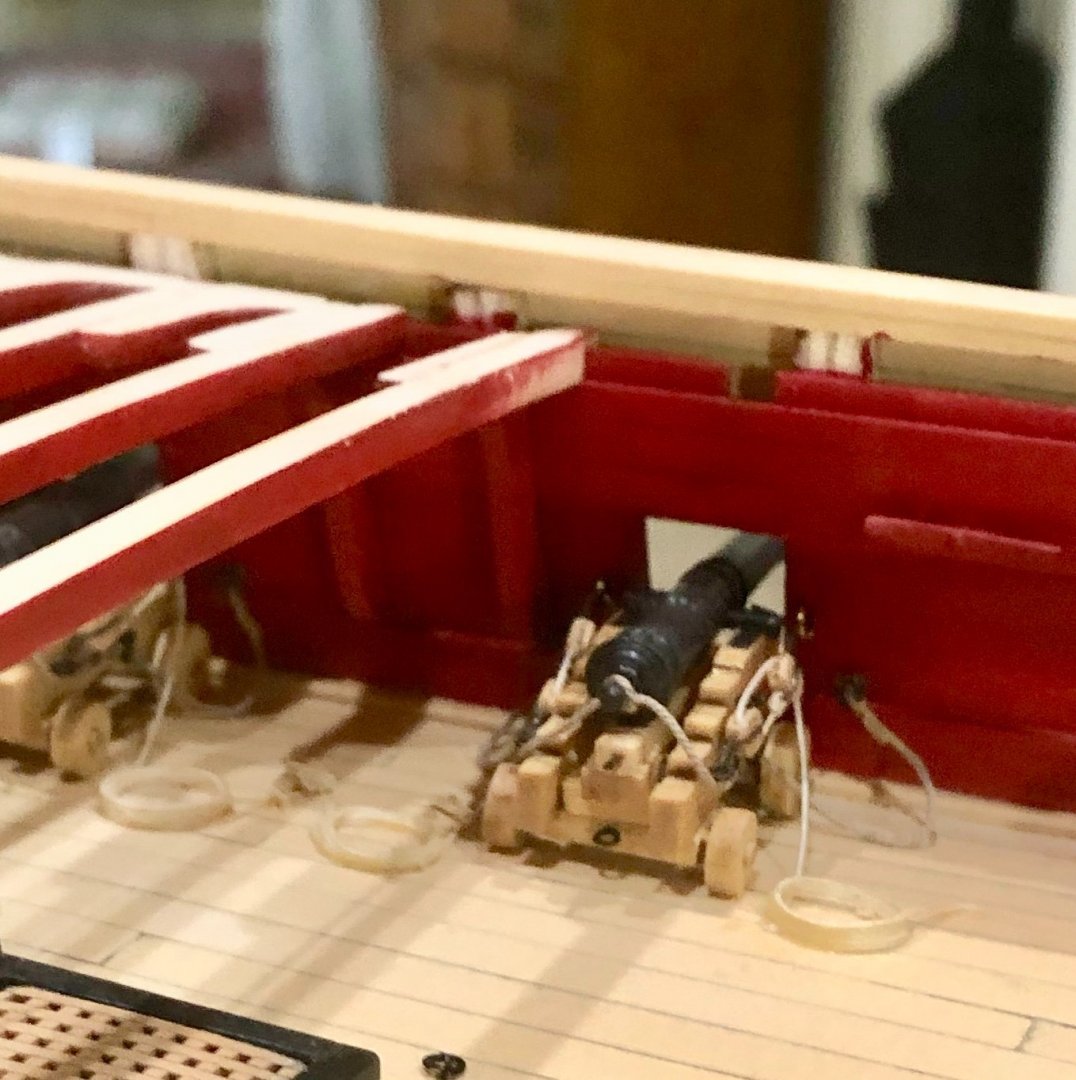

A small update. I have continued to move forward with beams, lodging knees and hanging knees. I also added the second column, glued in the capstan and added the pawls. With the addition of a hanging knee, I was able to mount and rig the remaining two guns under the quarterdeck. Now it's time to tackle the chain pumps. Bob

-

Continuing to move forward. I first dealt with the companionway. I chose to do metal stanchions with a rope rail, rather than the wooden posts and railing used by Chuck. I just liked the lighter look better. The stanchions are #24 wire with eyes bent at the top.The rope is .018". I then did the first column, shaping the laser cut part with files and painting it red. The remaining work was adding additional beams with their lodging and hanging knees. The laser cut lodging knees had to be adjusted slightly to fit, and the laser cut hanging knees were shaped to fit using files and sanding sticks. The sides of the beams, the edge of the lodging knees and the whole of the hanging knees were painted red. Bob

-

The guns look great Reg. I know just how much work that took. Bob

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

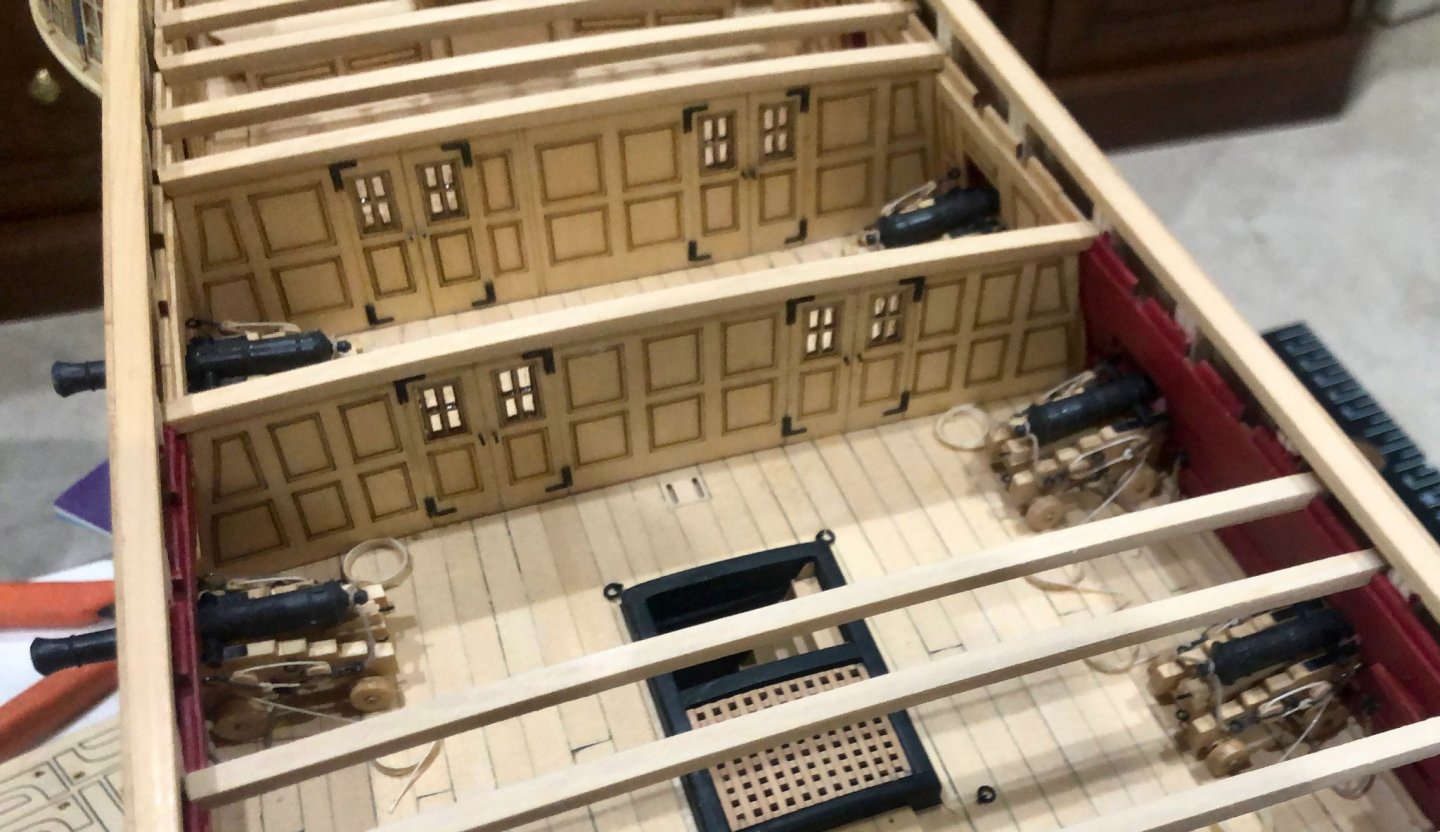

Moving forward, I made up and added the mizzen mast coat. I then made up and added the forward bulkhead and then the panel between the two bulkheads, adding the small pieces atop the panel to fit around the beams. After that work was completed, I permanently mounted the three beams between the bulkheads and then fitted and added the lodging knees between those beams. All of the exposed wood was given a coat of Wipe-on Poly. While adding the beams and knees, I continually checked with a planking strip to ensure that everything remained fair and level. Bob

-

I'm afraid that indefinitely still means indefinitely. I'm happily involved with Winchelsea and will continue with that until completion. Although I agree that builder effort can overcome bad kits, I have already built this Lexington once before and feel little compulsion to prove that I can do it again. Bob

-

A wonderful job Grant. A great looking Longboat. Bob

- 109 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

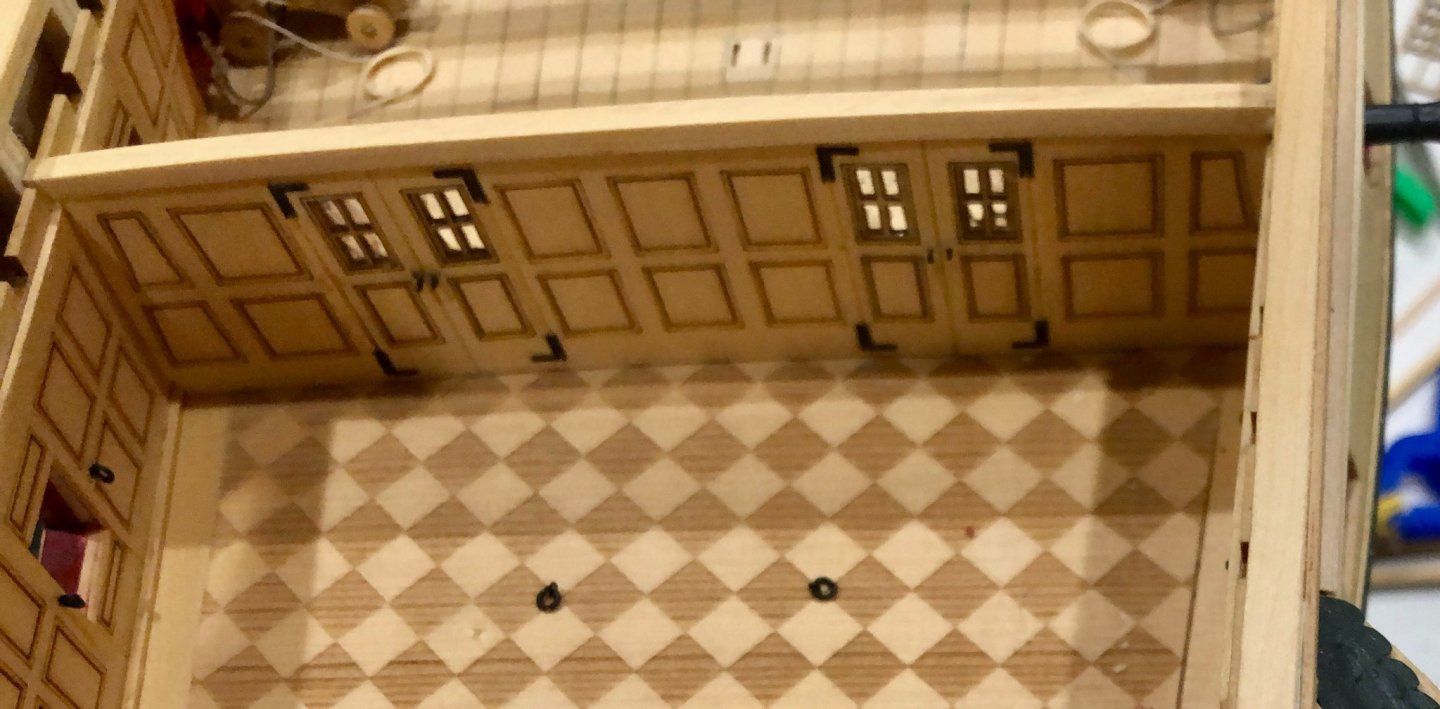

I received my Chapter 7 parts package and eagerly began work on it. I guess that I'm going to be the pioneer or guinea pig for this part, so here goes. I chose to paint the inboard transom first. The next task was to fit the quarter deck beams. These are laser cut, but must be cut to size. Although straightforward, care is required. I also found that the beams didn't quite fit into the deck clamp notches, so some sanding adjustment was necessary. When fitting the beams, I used a planking strip to continually check that everything is aligned properly. The last beam against the transom is a bit tricky, but worked out all right. The last item was to add the the laser cut straps to the last beam. These tested my aging dexterity. The beams are still only dry fitted to allow removal for doing the upcoming work. Bob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.