-

Posts

2,932 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rafine

-

Having built those same masts ( not nearly as well), I know just how good yours are. Beautiful. Bob

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Grant, your interest in my little project stirred my interest in your rather large project. A simply wonderful build . I'm sorry that I missed out on your full log. Bob

-

Thanks, Russ and Grant. Your interest is always appreciated. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

Many thanks, guys for all the kind words. Funny thing, Russ about the detail at this large scale, If you leave something out it really sticks out. In looking at the pictures I posted, I realized that I had forgotten to put the bolts in the boiler door hinges. Now they're in. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

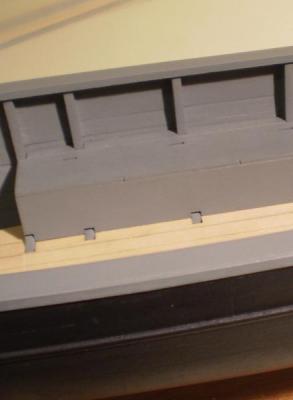

Work on the boiler is now complete, although it won't be mounted on the ship for a while yet until other work is done. The kit provides laser cut framing for the boiler and steam dome along with separate boiler ends and steam dome top. The parts all fit perfectly. The framing was then planked to reproduce the jacketing. The dome planking required extensive shaping by sanding on sandpaper wrapped around the boiler. I used boxwood for the boiler jacket and left it unpainted. It was finished with Wipe-on Poly. Bands were made from black painted paper for both the boiler and steam dome. Mounts for the boiler were made from stripwood. The smoke hood and funnel were made for one end. The hood used laser cut framing that was assembled and then filed and sanded to shape. The funnel is a piece of dowel with the top drilled out. The funnel bands are also paper. After assembly of the various parts, the detail items were made up and installed. Photoetched brass was used for the boiler door hardware.The steam pressure gauge was made from a slice of brass tubing, a disk of styrene, a paper face from the kit and a drop of Micro Kristal Klear for the glass. The various piping items were made using the kit supplied cast metal els and valves and aluminum tubing, as well as additional photoetched and wood parts and a piece of clear plastic rod for the sight glass. The piping work was painted using Polyscale flat aluminum ,with some red and black details. The boiler is one of those things that is just fun to make. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

Great looking work, Rusty. I'm very happy to see you back up. Bob

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Thanks, Robert, Chuck, Joe and Ryland. I just hope that everyone decides to get back on board to make the site even bigger and better. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

I'm glad to see you back up and running, John. I look forward, as always to your future work on her. Bob

-

Great to see your photos back. Now, its time for some more of your great work. Bob

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

-

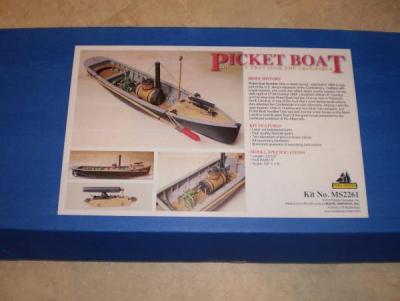

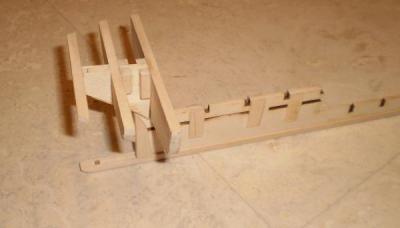

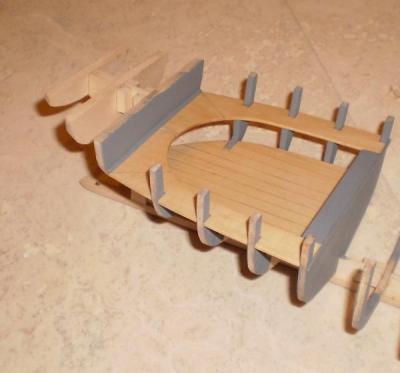

Like everyone else, I am devastated by the loss of all of the prior log material on the site. Although it won't be possible for me to reproduce the logs of my previous builds, I will, at some point, try to post pictures from those builds. For now, I will update my current build. I wll try soon to repost the pictures that I previously posted on this log. My most recent completed work was to make and add the propeller, rudder and tiller. The propeller is the kit casting, mounted to a shaft and painted brass. The rudder was shaped and tapered and mounted to a two part shaft made of tube and painted black to match the hull. The tiller was shaped, stained golden oak, finished with Wipe-on Poly and mounted on the rudder shaft with a pin. I'm now working on the boiler which is a complex, but fun project. Bob

- 103 replies

-

- picket boat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.