Roger Pellett

NRG Member-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Roger Pellett

-

I like the Zona brand razor saws. These are miniature “Backsaws” where a very thin blade is reinforced with a thicker back piece. These are usually available in sets with different blade tooth counts; the coarsest cuts wood and the finest brass tubing and structural shapes. Like the X-Acto products above, the different blades fit into a common handle. They are semi-disposable. While they last a long time they would be very hard to sharpen. Roger

-

BI have read that the masts for the large multimasted American Schooners c 1880-1918 were single piece made from very large Douglas Fir logs that were shipped to the East Coast from the Pacific NW on specially built rail cars. These could have been turned on equipment like the one shown in Joseph’s post. Roger

-

A really nice, well done model. Although it’s impossible to avoid the hype- Gordon Lightfoot et al, the Fitzgerald also represents the culmination of the Great Lakes Straight Deck bulk carrier design that began to evolve in the last quarter of the Nineteenth Century. Built in the later 1950’s; when originally built she was still powered with coal. She was lengthened and although still steam powered I believe she was converted to burn heavy oil shortly before her loss. The next generation of bulk carriers built in the 1970 ‘s and ‘80’s to take advantage of the 1000 ft long SOO locks are of a completely different design. Running small local history museums is a tough business, and many older buildings in northern cities like Ashland, Wisconsin are not air conditioned during the summer months. I hope that their initial enthusiasm lasts long enough to see the model be properly displayed. Roger

-

Not mentioned, is that the longitudinal SHAPE of the spar can be more easily layed out and cut, planed, etc. when it is a square cross section prism than a cylinder. Once the square cross section block is cut to the correct shape it is not difficult to make it round by using the 7:10 rule. Trying to turn or sand the correct longitudinal shape into a cylindrical dowel is much harder. Roger

-

During my working career, I made several business trips to Great Britain. Whenever I had some free time I tried to visit a bookstore. Before Herrods decided to limit themselves to luxury goods, their book department carried a wonderful variety much of interest to us. It was a great opportunity to “stock up,” not just for me but also for our two young children. In those days, the duty free allowance entering the USA was rather low, but “printed matter” which included books was exempt. More recently, used books bought from British booksellers and from one Canadian source also arrive without duty. If our free trade negotiators have failed to exempt legitimate exchange of intellectual materials between out countries then that is a shame. Hopefully duty will not somehow be charged on Seawatch’s E books. Roger

-

Keith, For reasons that I don’t pretend to understand, my IPad refuses to let me send a PM. I’ve tried twice today since receiving your’s. Nothing that you said was either stupid or offensive. On this forum, “everyone gets to put their oar in the water”. Maybe this results in a consensus, maybe not. It does in any case give the person posing the question a menu of ideas from which to select. The “correct” solution will vary depending on the questioner’s skills and resources. I should apologize for missing the point of your beautiful Tennessee build. Of everyone who has commented here, you are the one with serious experience in rescuing an old model! Roger

-

solid hull vs. plank on bulkhead/frame

Roger Pellett replied to rtropp's topic in Wood ship model kits

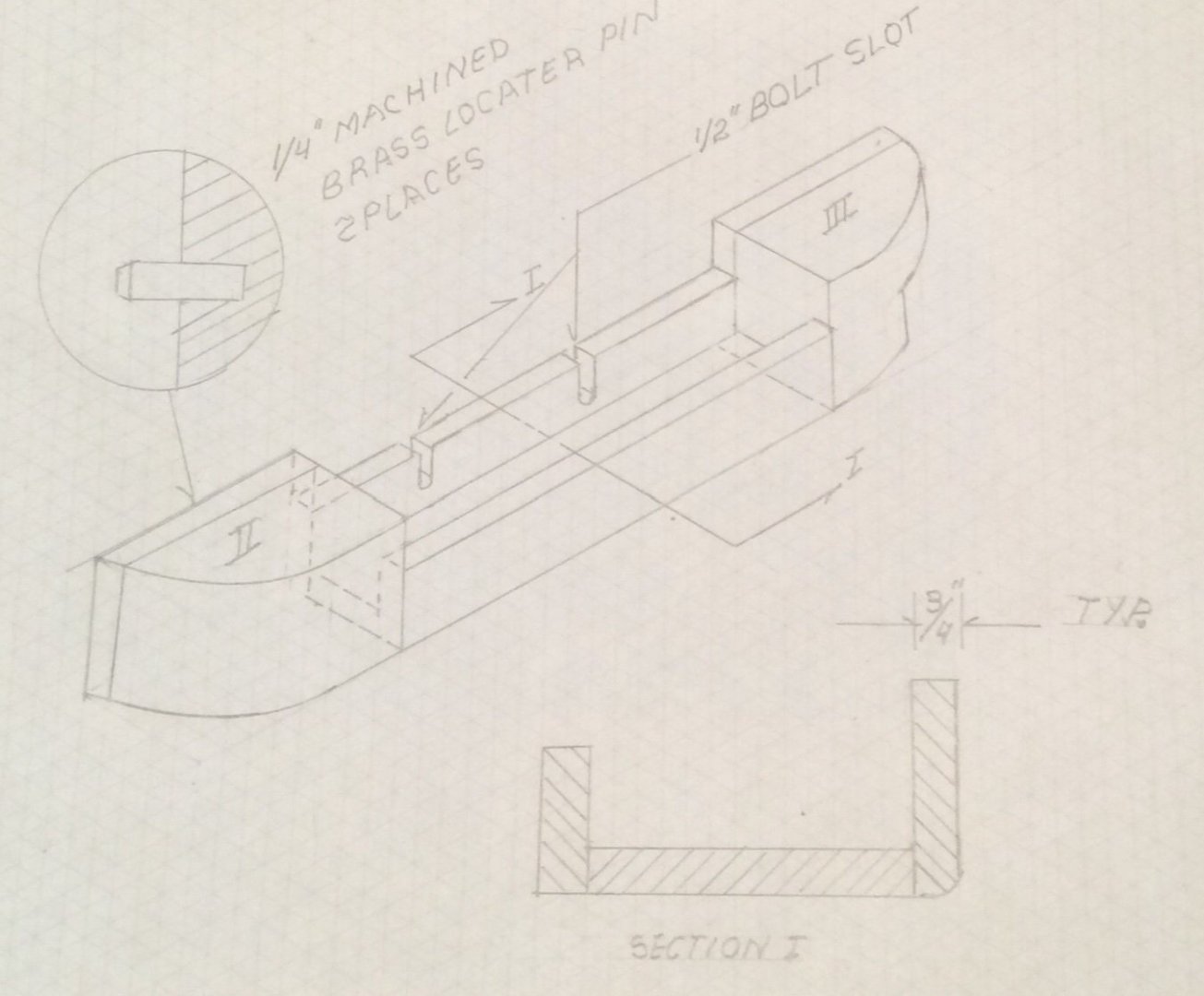

Accurately determining a centerline to use as a datum was a stumbling block when finish shaping one of the old machine carved kit model hulls so when I began carving my own hulls I carved two half models. This automatically provides a flat centerline datum for each hull half. Each hull half can then be laid on a flat surface to check with templates as carving proceeds. Laying out the hull block to include accurately spaced location pins for joining the finished halves is part of the Engineering that takes place before carving. The first photo below shows the design for a hull half for my current project. This also gives an idea of shaping that can take place with my bandsaw prior to carving. The second photo shows the carved hull halves prior to joining. -

I have a home made adaptor that fits on my shop vacuum. It consists of the cap from a paint spray can lined with a plywood disc epoxied in place. A 1/2in dia. flexible plastic tube fits snugly into a hole drilled through the plastic cap and plywood disc. The adaptor slips over the nozzle at the end of the regular shop vac hose. Vacuum holds all in place. The 1/2in tube gets into small places. I would not try cleaning the Model by blasting it with any form of compressed air. First of all, this just moves the dirt around, and at worst can dislodge parts where glue is losing it’s grip. Second, it is important to save any loose parts that may be embedded in the dirt. Gallons of ink have been spilled on the forum about the “carpet monster” that likes to inhale dropped tiny parts. Blasting with compressed air is just likely to feed the carpet monster. With my vacuum system it should be possible to fasten a piece of panty hose over the end of the 1/2in tube to catch any loose parts. Roger

-

I realize that I am repeating myself, BUT! Before touching this model, I urge you to invest in a copy of “Caring for Ship Models” by Rob Napier and published by Seawatch Books. You can find them on the list of sponsors at the end of this forum. Note- I have no connection with either the author or publisher of this book. At $70 plus shipping this slim volume might seem expensive but you are actually paying for the experience of a master modeler who specializes in Ship model restoration. Rob has tackled projects for private collectors as well as institutions including The US Naval Academy, The New York Yacht Club, and the Boston Museum of Fine Arts. On the other hand, I believe that few forum members bring to table much experience restoring a valuable model. People routinely write to the forum about “priceless” ship modes that they have inherited or found at an antique shop. 99% of these are misshapen, mass produced, decorator models with of little or no intrinsic value. In my opinion, your model fits into the 1% as it is of an unusual subject, and is nicely built. It deserves a sensitive restoration. Roger

-

The builders drawings for the SS Benjamin Noble built in 1909 show a “lamp room” in the forward quarters even though the ship was fitted with an electric generating plant. So, even at this late date, navigation lights were apparently lit by oil. The lamp room would provide a sheltered work space where lamps could be filled and lit out of the weather before being hung. The separate lamp room also kept open flame away from paint, varnish, etc. kept in the bosun stores. Great Lakes Crews included a Watchman for each watch. He would have been equivalent to a very junior Petty Officer (NCO) on a naval vessel. His duties would have included setting out navigation lights at sunset each evening, making sure that they kept burning and returning them to the lamp room in the morning. I assume that naval routine would be no different. Roger

-

Chisels: I have a set of Stanley “yellow handle” chisels that were new (to my father) in the 1950’s. They seem to hold an edge well. I also have a 1/8in and a 1/16in chisel bought new from a specialty woodworking tool distributor. The most often used tool of the group is the 3/8in chisel from the Stanley set. I find the larger blade to be easier to control than the smaller sized tools. One “tool” that does not appear on your list is an effective sharpening system for your chisels and plane. What material do you plan to use for building your model? If you will need to reduce lumberyard or other bulk lumber into special sized strips then you will need access to a table saw or bandsaw. Roger

- 72 replies

-

If I need precision when drilling and if as often is the case, I don’t feel like setting up the milling column and sensitive drilling attachment on my Sherline Lathe, it is a simple matter to chuck a pin vise fitted with the correct wire sized drill in my FULL SIZED drill press. This 50+ year old belt driven drill press is by far the most commonly used power tool in my shop. Although speeds can be changed via stepped pulleys I have not bothered to change drilling speeds for as long as I can remember. If I were shopping for a new drill press, which I don’t intend to do, it would be another FULL SIZED tool with at least 3/8 in chuck capacity, not a “hobby sized” tool. Roger

-

The benefit of using any type of power tool to turn any wire sized (<1/16in) bitt is, maybe, time. Thicknesses of material are usually quite thin and an Archimedes Drill works quite well. For fractional sized drills larger than 1/16 in. a full sized drill press is useful and often necessary. I see no reason to own a micro or “hobby sized” drill press for either scratch or kit building. Roger

-

I suspect that the deck is probably just paper with planking ruled with India ink. Assuming that the model is prewar the builder did not have access to today’s pressure sensitive adhesives. Depending on the model’s age he would have had access to nitro-celluloid glue (model airplane cement) or varnish. This has obviously failed. Any sort of aggressive cleanup will result in more failure. As things stand now, someone looking at the model will understand what the original builder intended. Roger

-

Nic, A handsome model beautifully built as usual by the two of you. A clipper brig might be appealing to customers without the display room or desire to build a Clipper Ship. If MS no longer offers, perhaps add it to your line. Roger

- 121 replies

-

- Newsboy

- Model Shipways

-

(and 2 more)

Tagged with:

-

Plastic or Wood models? Your Favorite?

Roger Pellett replied to Bill97's topic in Modeling tools and Workshop Equipment

It sounds like you feel that you have reached a plateau building plastic models and now are seeking new challenges. Why don’t you skip wooden kits and try building a model from scratch? By doing so you can select both subject and level of difficulty. In addition, when you finish you will have something unique. Roger -

IMHO, you have a very nice antique there. Barkentine models are unusual. In his History of American Sailing Ships the Dean of American Maritime History, Howard I. Chapelle devotes several pages to these vessels and points out that they were a West Coast design for Pacific Ocean offshore voyages. In addition, I have never seen a model before of a sailing tank vessel. Proceed slowly with your restoration, thoroughly documenting things as you go. Try to reuse as much of the existing model as possible and resist the temptation to improve it beyond the intent of the original builder. The deck? I suggest gentle cleaning, then leaving it alone. Roger

-

Scroll saw versus band saw

Roger Pellett replied to Juddson's topic in Modeling tools and Workshop Equipment

In general, I am of the opinion that with a few notable exceptions (Byrnes and Sherline) when it comes to power tools, “they don’t make ‘‘em like they used to.” My shop is, therefore, equipped with old, solidly built, equipment. On the other hand I would be leery about buying a used scroll saw. My old power tools all have separate motors with power transmitted to the tool by V belts. If the motor dies or if the tool is underpowered it is a simple matter to replace it with a new or more powerful one bought from a local electric supply house. V belts, likewise are stocked by hardware stores. Scroll saws, however, almost always are powered by “integral motors.” The motor is built right into the tool. If the motor on one of these dies, or if the internal transmission system fails repair probably means dealing with the manufacturer- possibly one overseas. Roger -

English fleets and small vessels in the early 1700s

Roger Pellett replied to Dan DSilva's topic in Nautical/Naval History

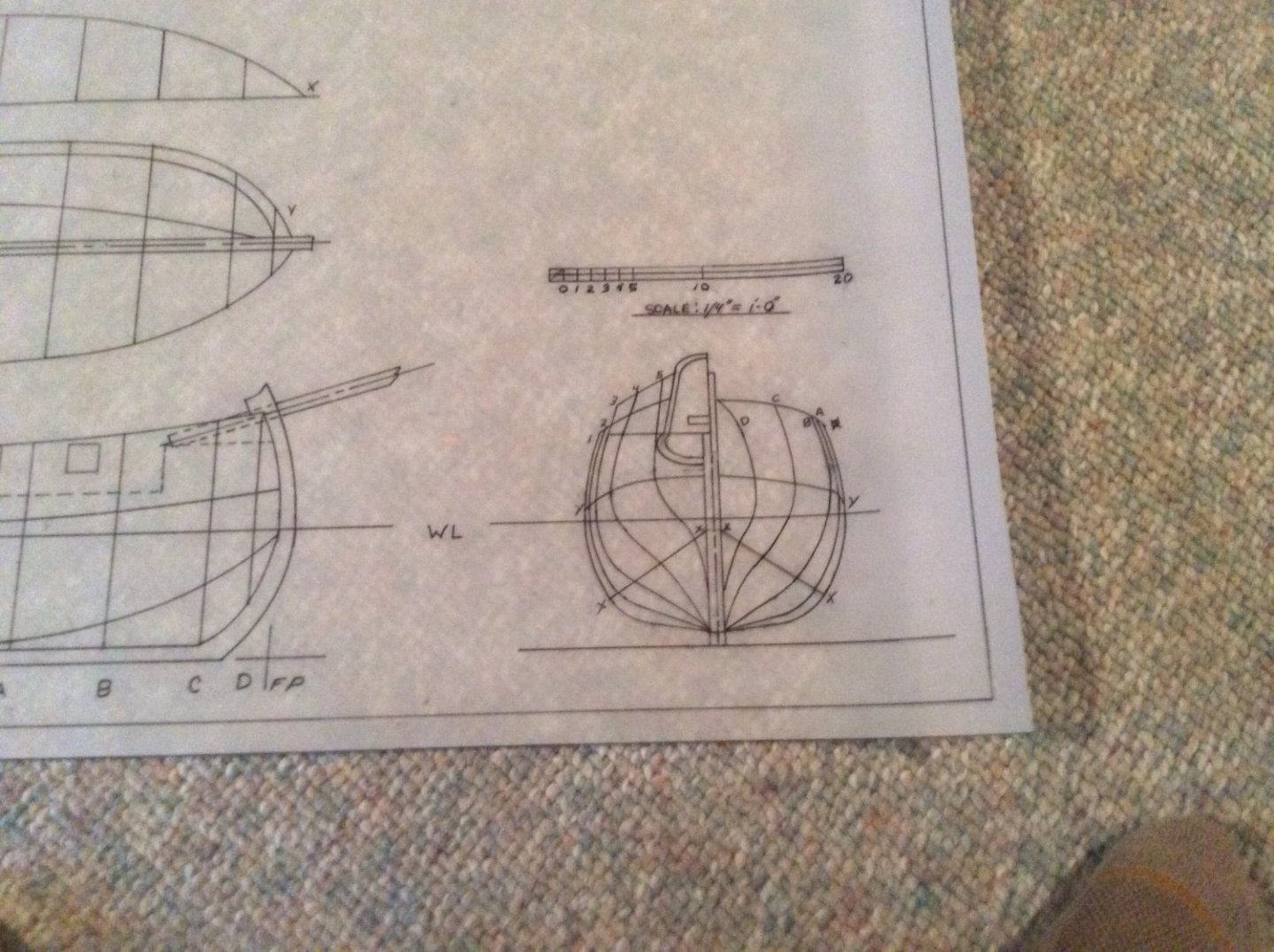

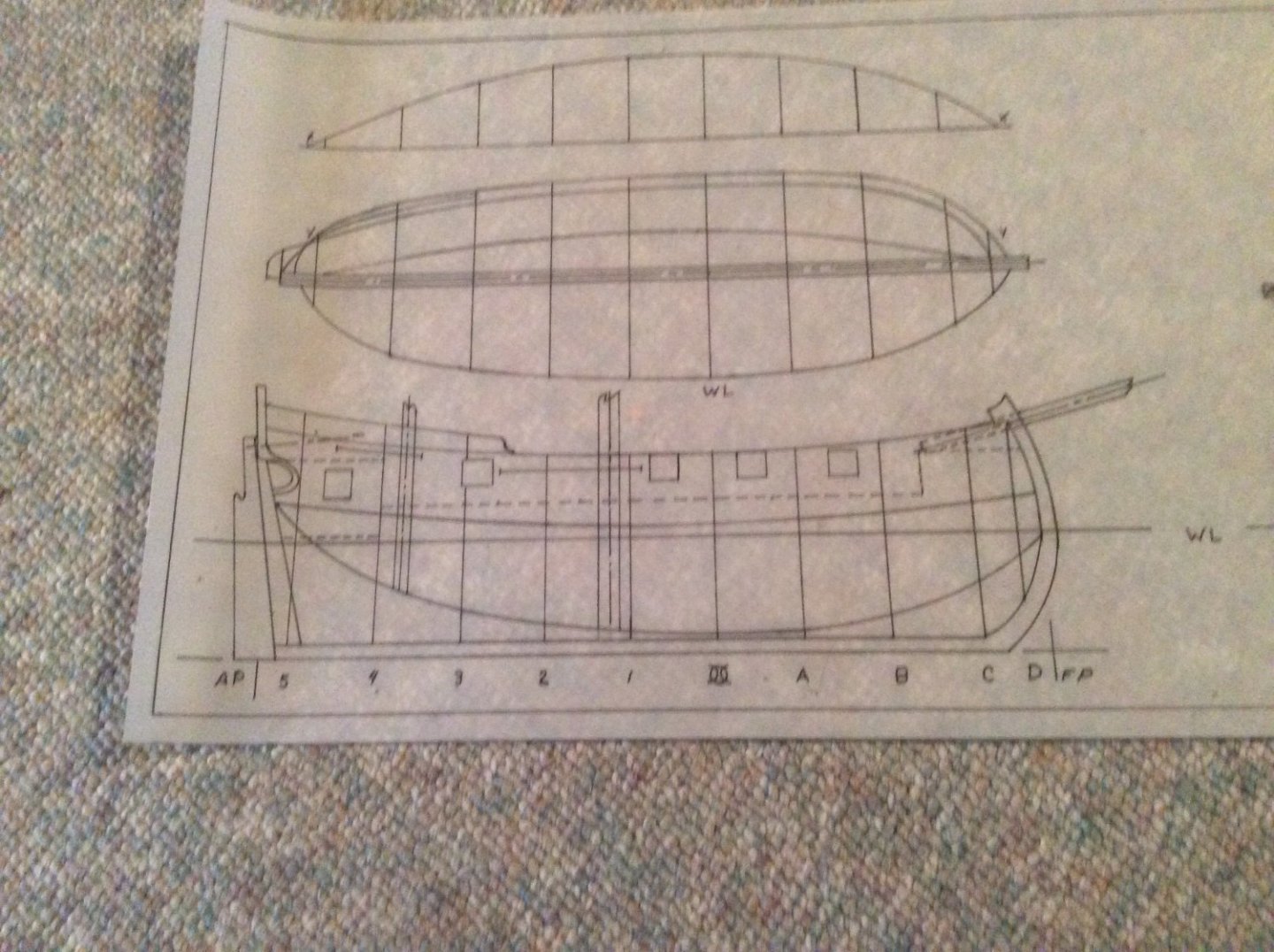

I got interested in these small vessels after reading Frank Fox’s excellent account of the Four Days Battle. These small tenders accompanying sailing battle fleets appear to be unique to Stuart Era naval battles. With fireship tactics common, among other things, they were thought to be useful for moving affected vessels out of the way. These are not the famous Royal Yachts, but the far more humble vessels shown in the Van De Velde drawings. Many were pink sterned and rigged as ketches. My interest peaked with the publication of Endsor’s excellent “The Shipwright’s Secrets.” I, therefore, wondered if I could use the information in Endsor’s book to recreate one of these small ketches. Mc Laughtan’s excellent book also includes much information including dimensions of known vessels. I am not a CAD drafter. My drawing techniques date back to a pre CAD Naval Architecture education of the 1960’s. In this case I also used 1660’s information from Ensor to make body plan moulds from wood. The ink on Mylar drawing is shown below. I never turned the drawing into a model, and probably never will as I decided instead to focus on an existing project. So, if this interests you you are free to make use of it. If you would like a better copy send me a PM. -

solid hull vs. plank on bulkhead/frame

Roger Pellett replied to rtropp's topic in Wood ship model kits

I am presently building a model of the Benjamin Noble, a steel hulled Great Lakes Freighter launched in 1909. You can find a currently active build log on the Scratch Builds 1901 and Later section of the forum. The hull for this model was carved from “solid” pine to make two half models as Bob describes. The hull block was drilled for Brass locator pins before shaping to assure accurate alignment of the finished hull. The hull was then plated to simulate the riveted hull of the actual ship and the hull halves were joined. Look it up! Roger

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.