Roger Pellett

NRG Member-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Roger Pellett

-

Two methods for painting on sails.

Roger Pellett replied to modeller_masa's topic in Masting, rigging and sails

The stencil and sprayed paint method will work if used in conjunction with a simple homemade vacuum box hooked up to a shop vacuum. Roger -

Brian, The bell is an interesting question. These bells on Western River Boats resembled what farmers called “dinner bells.” Mounted on a post they were rung to call those working in the fields to dinner or to summon neighbors in an emergency. They were rung by pulling on a rope to tilt the bell. Naval bells were different. They were hung from a fixed bracket and struck by pulling on a rope tied to the clapper. This allowed the precise time keeping during the four hour watch cycle. Ding ding- ding ding, etc. I had assumed that a principal use of the farm type bell in the Western River passenger steamboats was to announce arrivals and departures. Rung in an uncontrolled manner they were the steamboat equivalent to “all aboard.” So what were these bells used for on the gunboats? By tilting the bell it would seem difficult to accurately toll the half hours of the watch cycle. Maybe a rope from the clapper to the Pilot house? A fog signal? Roger

-

Good morning from the banks of the Ohio River

Roger Pellett replied to Mike James's topic in New member Introductions

Hi Mike, Welcome to MSW! Although we now live near the shore of Lake Superior, I am familiar with the Banks of the Ohio River. We lived in Marietta, Ohio for 20 years, and my son now lives in Evansville, Indiana- both river towns with a history of shipbuilding; Some ocean going vessels were actually built in Marietta as well as US Navy gunboats both in the late 1700’s and early 1800’s. LST’s were built in Evansville during WW II. Evansville is also the home of LST-325, one of the very few still surviving. A beautiful and interesting part of the country. Roger -

Question about Sails on the Yacht "Westward"

Roger Pellett replied to Ferrus Manus's topic in Masting, rigging and sails

I have heard that the sail between the two mast is called the Fisherman’s Staysail. Gybing the spinnaker. On small boats the spinnaker can be gybed by end for ending the pole. On a 40ft boat that I crewed on we gybed the spinnaker by dipping the pole which was short enough to clear the forestay. The pole dipping approach means that when the sail crosses the bow of the boat it is flying from the sheet and guy but not attached to the pole. This would be risky for a huge sail like this. Furthermore, the pole on a big boat is a heavy spar that is too long to clear the foredeck rigging. I agree with mnl that the sail would have been gybed with double sheets and guys and two poles- port and starboard. The inboard end of each pole was probably attached to some sort of track on the mast. When a gybe was anticipated the inboard end would have been run up on its track and the outboard end with the lazy guy fed through the new pole’s end fitting would have been lifted with the topping lift. As the stern of the boat swung through the wind, the active guy would have been released and what had been the lazy guy hauled in. Same thing with the sheets. My guess is with all of that canvas set, the skipper of this boat has no intention of gybing. Roger -

NICE!! Forget African Queen. It’s just a Hollywood adaptation of the boat in C.S. Forester’s excellent novel anyway. You have a nice working live steam model of a c1900 steam launch. Wealthy people back then used these as yacht tenders and to go to the nearby beach or island for a picnic. The power plant itself appears to be quite sophisticated and worthy of further examination. I am wondering if it could be steam electric hybrid with the steam engine turning a generator feeding an electric propulsion motor under the wooden semi-circular shield. My guess is that the builder was someone with knowledge and expertise in steam engineering who built the steam plant and then the hull to try it out in. I envy you for your “dumpster find.” Roger

-

Making a Silk-fabric(?) Sail

Roger Pellett replied to modeller_masa's topic in Masting, rigging and sails

Many years ago there was a shop note in the Journal about painting flags using Japanese Rice Paper. I bought some and had good luck making the flags for my last model. This is a very light weight almost translucent acid free tissue paper. The Hanji material got me wondering if the Rice Paper might not be a good material for sails. -

I looked up Madawaska in Canney’s Old Steam Navy. He gives a launch date of July 1865 but no commissioning date. In the text he mentions a September 1866 sea trial. Her sisters required 2-3 years from launch until commissioning. I see no reason to doubt the authenticity of your nameplate. I believe that the tank was probably made especially for the ship at the New York Navy Yard. Roger

-

Keith, After launching, she would be brought to the fitting out pier to be finished. This would have included installation of major machinery to heavy to be hoisted aboard while she was on the building ways. The fitting out pier would have been equipped to do this. Launching can also apply abnormal longitudinal bending stresses to the hull so her Naval Architects would have wanted to keep launch weight to a minimum. Finishing her could well have extended into 1866; particularly with her complex machinery installation. Roger

-

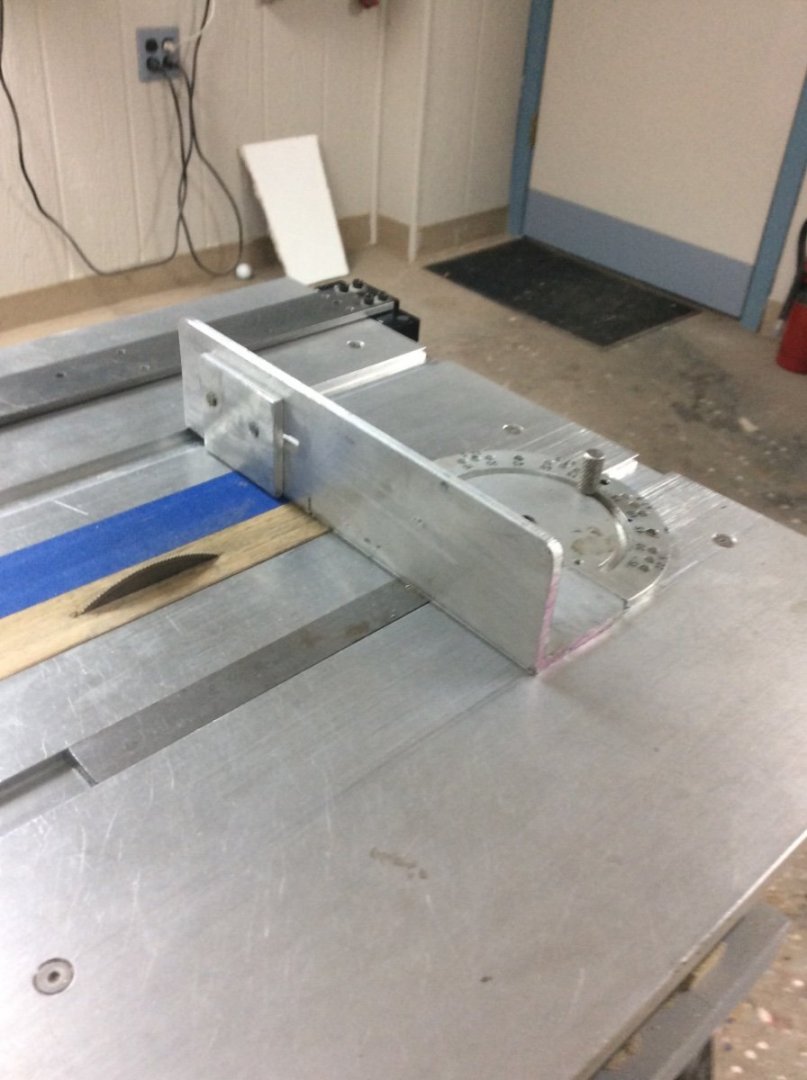

Byrnes Saw Mini Sled

Roger Pellett replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

The finished version of my mini sled. The two thumbscrews make setting the stop accurately easier for me. The sled works well. I recently used it to cut a piece of 3/32in dia brass tubing into multiple slices each 3/32in long. -

A well kept secret is that models of steel ships can be hard to build. First of all the real things are much larger than the usual wooden sailing ships. This means that unless you have a huge display area, small scale is required. Simulation of hull shell plating is a roadblock for many. There are also a lot of fittings, each of which becomes a separate model in itself. Valeriy’s model is built to a scale of 1:75, smaller than the customary 1:48 dockyard model scale. Accurately producing the wealth of metal fittings at this scale would be a daunting challenge for most of us. Roger

-

Want information on a model kit.

Roger Pellett replied to Bill Hudson's topic in Wood ship model kits

Congratulations, Bill I hope that you do build it. I’m sure that you will do a great job. -

Hello from Northern Wisconsin

Roger Pellett replied to RobMann79's topic in New member Introductions

Welcome aboard! Not a Wisconsinite but almost! Duluth is just across the bay. I’ve been to Hayward several times. Nice town. Roger -

Air Compresser

Roger Pellett replied to Guyuti's topic in Painting, finishing and weathering products and techniques

It depends on your living/ modeling accommodations. If you live where you have space and the noise will not bother others, here in the USA Home Improvement (DIY Stores) sell inexpensive portable air compressors with integral air tanks. Air tanks are usually 2-5 gallons. Maximum pressure is usually about 125psi. These compressors are fitted with pressure switches that turn the compressor on and off to keep the tank full. Mine also has a regulator that allows you to “dial in” the pressure that you need. Air brushes usually operate at 25-35psi. These are usually “store brands”; made in China and labeled with the store’s trademark. Mine cost about $100 US. Most airbrush brands sell adaptors to connect the airbrush hose to a standard compressor outlet size. See what your DIY store offers. Roger -

Seeing models of Japanese lanes here on the forum, i’ve wondered the same thing.

-

Hi Krisan, Thank you for contacting us. My advice is different from others and is based on my own life experiences. I am old enough to be your grandfather. I have been messing around building model ships and boats since I was 7 years old. My first models were based on looking at pictures and were building using my father’s tools and scrap lumber in his workshop. They were very crude! My interest in model boats led me to improve my school grades to the point that I was accepted into a college program to learn how to design and build real ships. My interest in ship models changed my life! My advice to you is: Decide what kind of ships you are interested in- there are 100’s of choices. Read some books about the kind of ships that interest you. See what your library has, or perhaps your parents can help you find some. Once you have narrowed down your choices, ask us. We can probably give you some ideas. Try building some examples using the pictures in the books. These can be very simple ones that just show the important features. A good idea might be waterline models that just show the ship above the water. Try to learn why ships look the way that they do. Your first models might be crude and you will make lots of mistakes. That’s OK!! We all do. Ship and boat model kits are expensive. By using materials that you can find at home, if you mess something up, it is not costing money. The only mistake that you can make is not trying. Do not get discouraged. Your skills and knowledge will improve as you keep trying.

-

Want information on a model kit.

Roger Pellett replied to Bill Hudson's topic in Wood ship model kits

Bill, With a few notable exceptions, most of us building ship models are old enough where time is more precious than money. A related concern is “What am I going to do with my models when I am no longer able to house and care for them?” For many, the dumpster awaits. If I were considering this kit, I would ask myself a few questions: Does the subject matter really excite me? Do I want to commit time to building this model that could be spent building something else? Is the quality of the kit such that it will produce a model that I will be proud of? Do I have space to display it, or do I know someone else who would like it? If the answer to any one of these questions is no, I would advise them to list it on eBay. Roger -

Your model just keeps looking better and better. Strictly speaking those are not paravanes. Paravanes included the depth control, splaying out, and mine cable cutting functions in one unit. They were used to protect ships not engaged in minesweeping in waters where mines could be present. The short, fat, item is a “hammer box.” Towed behind the boat, it created noise to set off acoustic mines. The other two are floats that were attached to the ends of the sweep cable when sweeping contact mines. These floats would have performed two of the three functions of paravanes; depth control and splaying the sweep cable outboard from the vessel doing the sweeping. They often were had little flags on top to give those conning the vessel a visual reference. As I posted earlier, the actual cutting of the mine’s mooring cable was performed by cutters fastened along the sweep cable. Roger

-

I generally don’t like to see religious doctrine on non related subjects, but I believe this could apply to any religious belief, and I find these words comforting and timely: ”For everything there is a season and a time and purpose unto heaven........” Good to see you back, and am glad that you were able to buy the water tank plate. Yes, I believe that builders plates were included on ships. Roger

-

Ras, The ones that you show look that they would not be difficult to make from brass. Nicerand closer to scale.

-

Byrnes saw fence advice sought

Roger Pellett replied to geneinmurphy's topic in Modeling tools and Workshop Equipment

Go to the Byrnes Saw Reference thread. It is “pinned” and is right above your post. It is on page 2 of the thread. Roger

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.