-

Posts

314 -

Joined

-

Last visited

About ken3335

- Birthday 03/07/1947

Profile Information

-

Gender

Male

-

Location

Near Chester, UK

Recent Profile Visitors

-

DanielD reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

DanielD reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

catopower reacted to a post in a topic:

Royal William by ken3335 - FINISHED - Euromodel - Scale 1:72

catopower reacted to a post in a topic:

Royal William by ken3335 - FINISHED - Euromodel - Scale 1:72

-

Hi Kelp, For the ports I first drilled a hole then filed it out to shape, I don’t remember having an issue with the brass around the hull, it’s a while now since I built it but I’ve just had a look at mine and it seems to have gone around the bow neatly. On another note I don’t follow MSW site any more so if you could use the other site you will find my complete build log there. Regards, Ken

-

Keith Black reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

Keith Black reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

EricWilliamMarshall reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

Hi, I have never bought or built a Chinese kit of any kind and I don’t intend to, even those that are deemed acceptable, It is out of personal choice not because of anyone’s policy. The reason I stopped doing my log here was that there was so little interest and no interaction that it didn’t seem to be worth the effort, I tried SOS and there was a good reception and lots of interaction and advice, I now have many interesting people following my builds. I have also completed an Amati log and am currently doing another Euromodel build on SOS, not Chinese. If that excludes me from this site I am saddened, I am a modeller and don’t want to get involved in other peoples politics, it’s a sure way to put people off. Ken

-

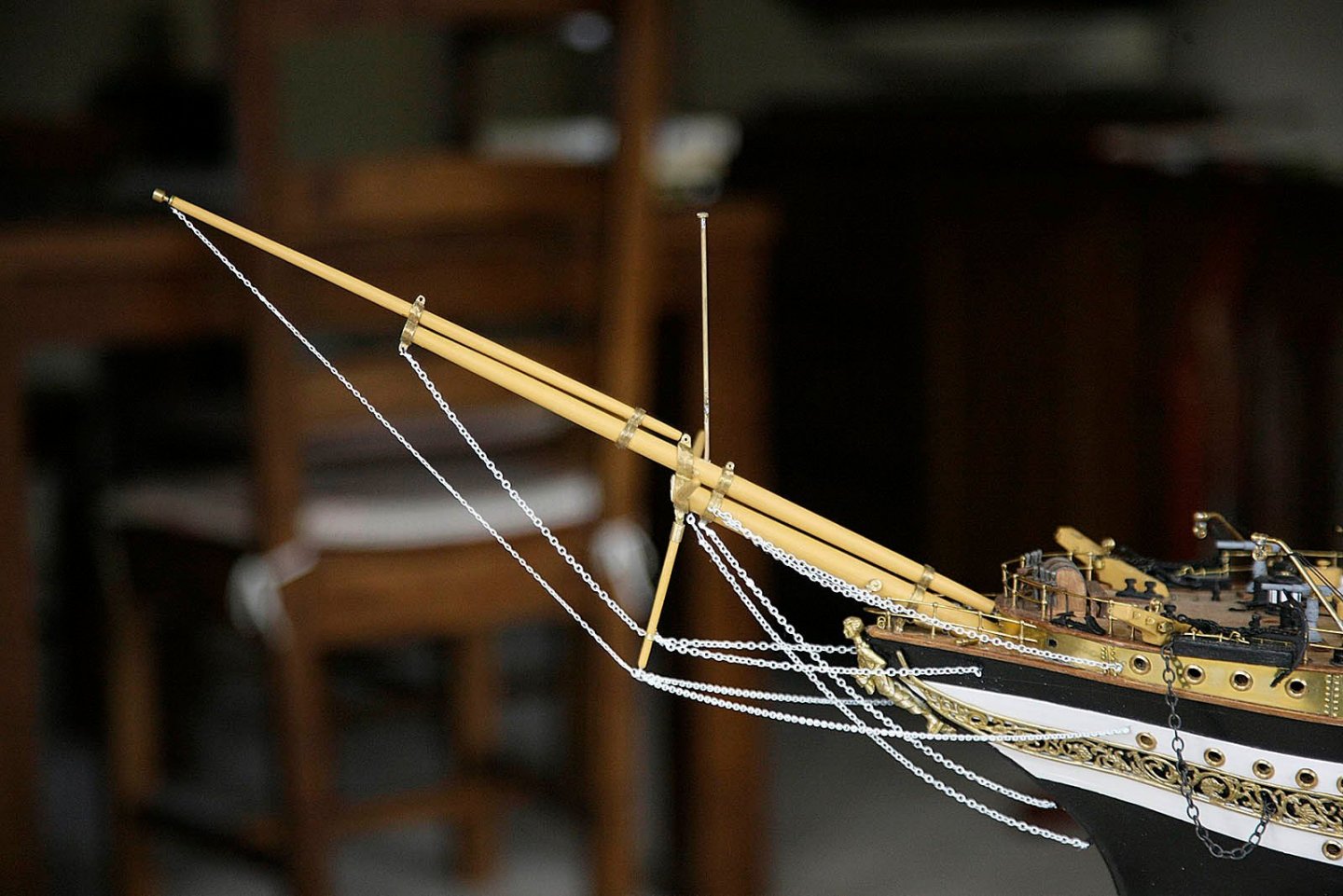

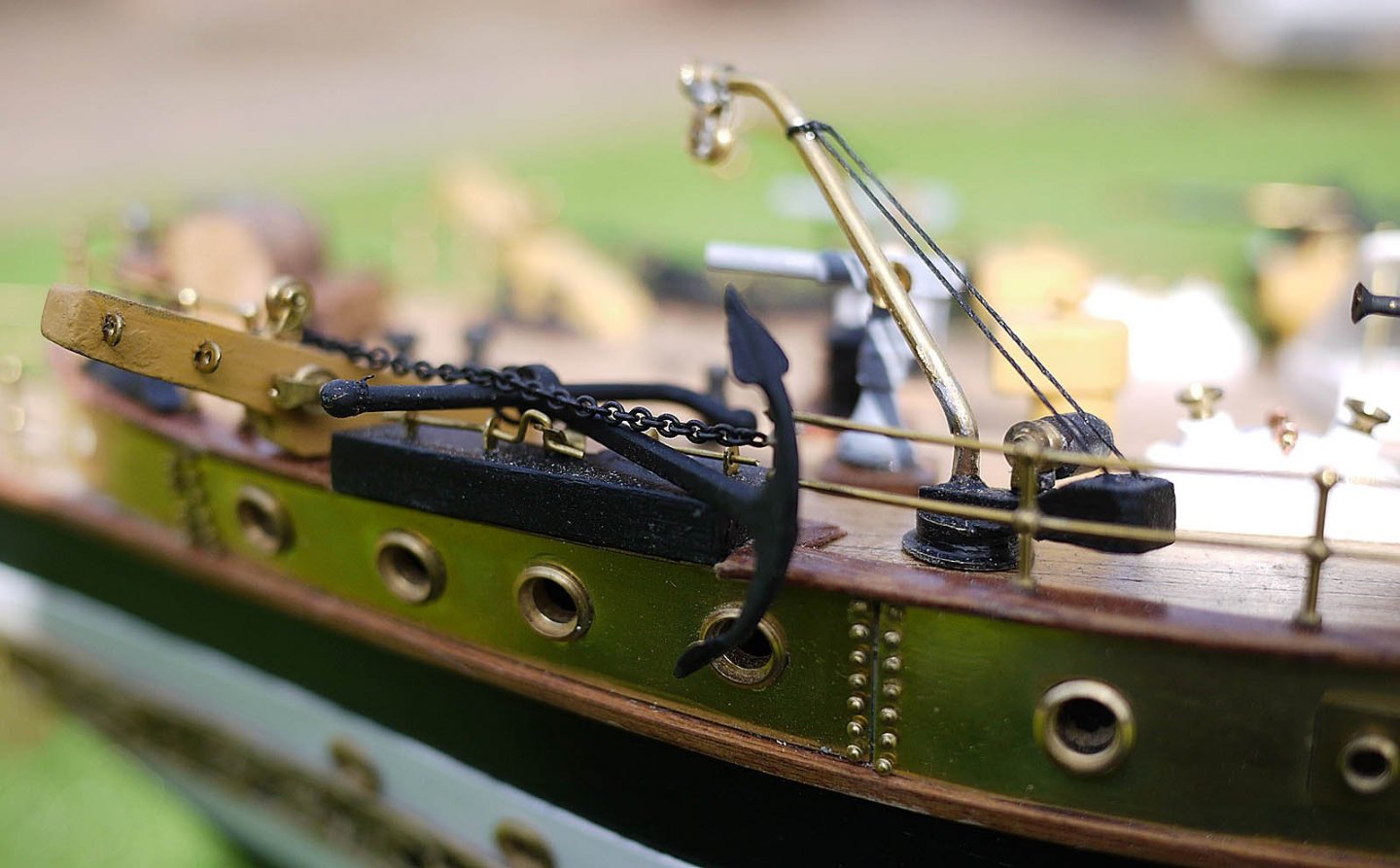

Hi, More updates, I’m really flying through this build, really enjoying it and can’t put it down. I’ve made, painted and fitted the bowsprit along with its bracing chains and flagstaff. It all went okay. The dolphin striker and side spars proved just a little awkward as they are attached on hinges which needed to be made up, the chains had to be just the right tension each side so as not to pull them out of alignment. The flagstaff was an afterthought which I made up from a welding rod topped off with one of the small portholes that were left over, I'll remove it when I do the rigging then paint it white when fitted. Ken

-

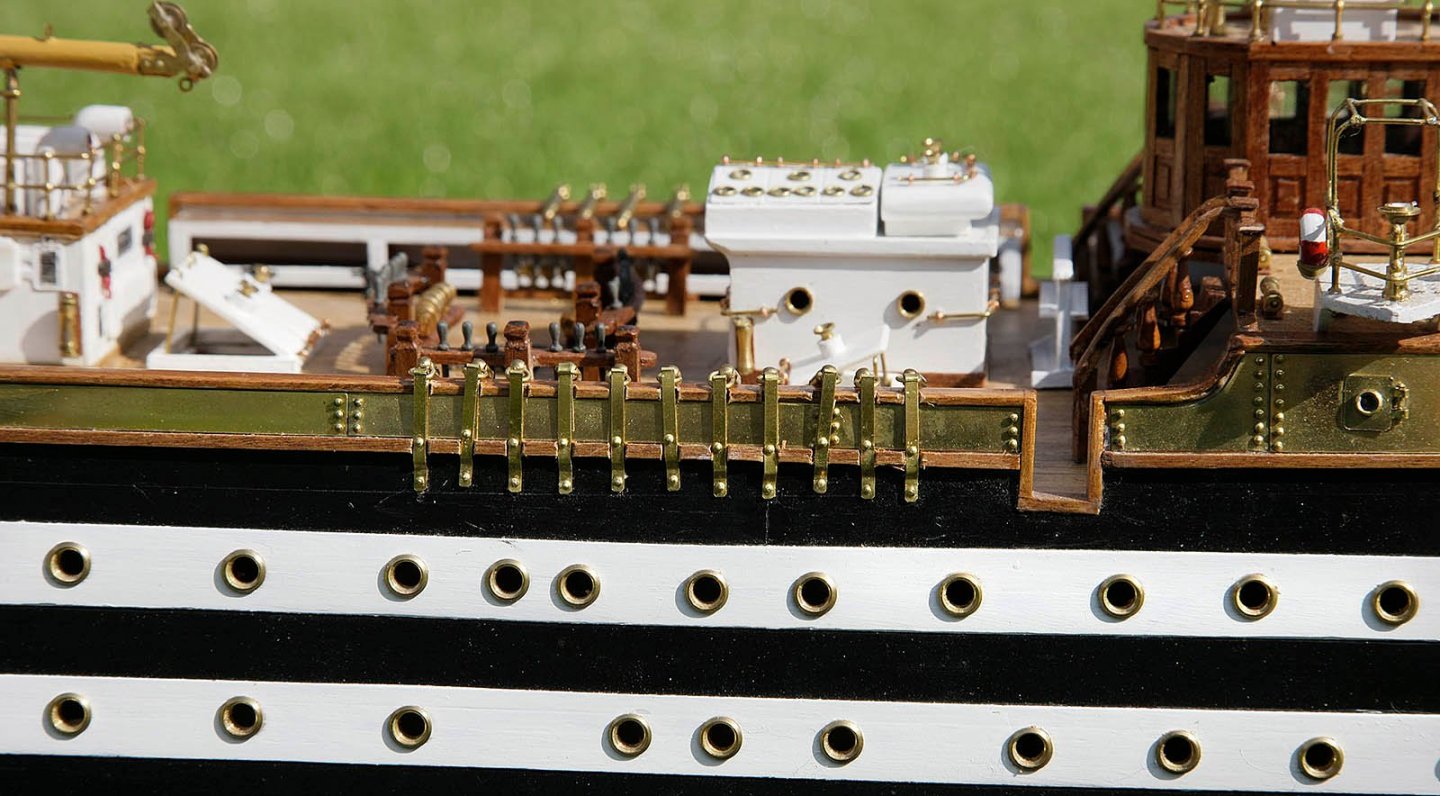

Hi, Again thanks for your likes, please keep them coming. Another short update on my progress. I have now finished and fitted the strops and turnbuckles along the sides. They were easy to make, just folded over brass strips trapping a brass ring in the fold with the turnbuckle attached then nailing them to the hull. The difficulty came with positioning and spacing them. You will see that there is no way of avoiding the portholes, most models of this ship that I have seen have the strops at what looks like unrealistic angles to keep them the same length and avoid fouling the ports, they didn’t look right. I decided that I would keep the angles all the same and just cut them short where they would foul. I think that they came out well and even if they are not right they look more aesthetic. Ken

-

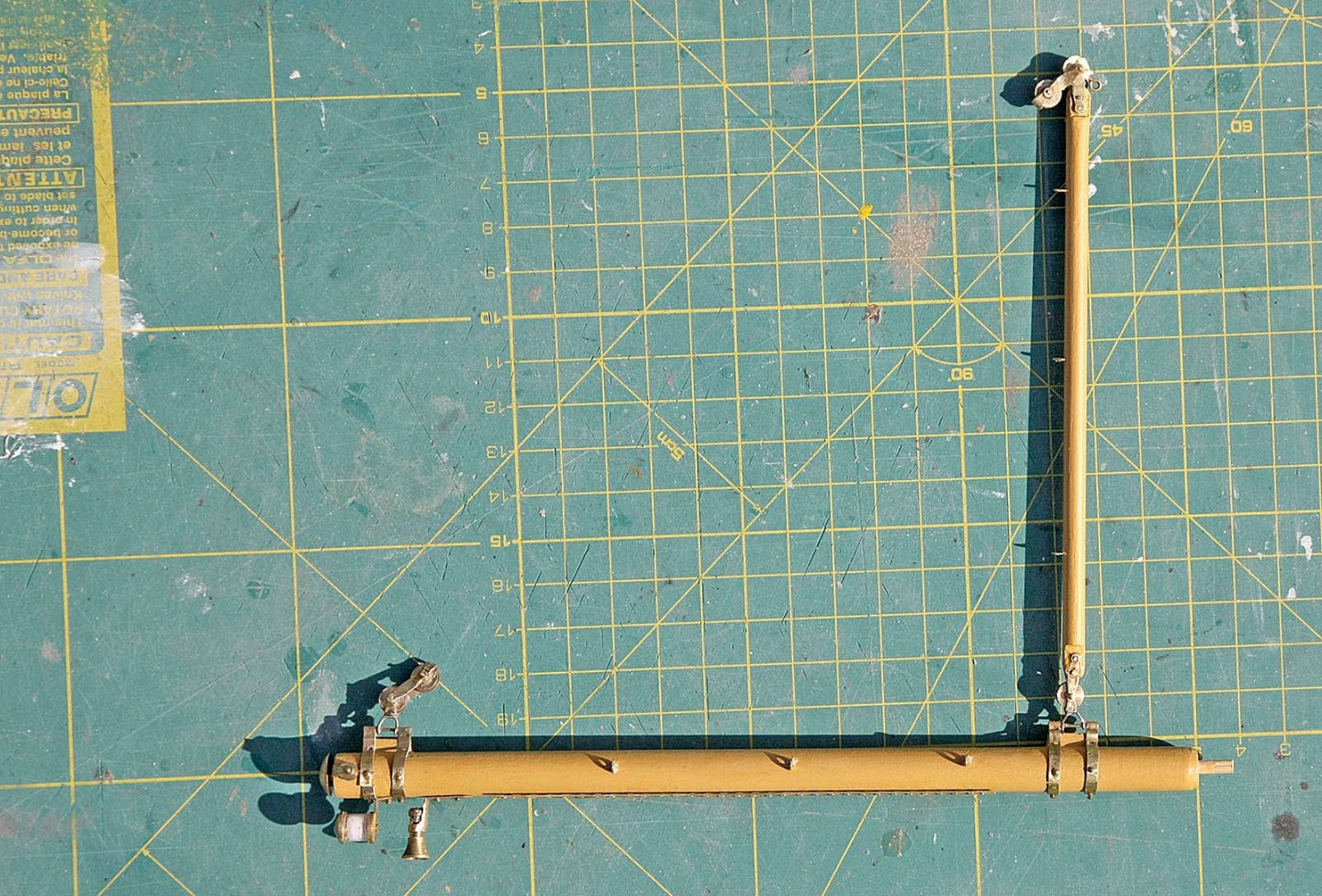

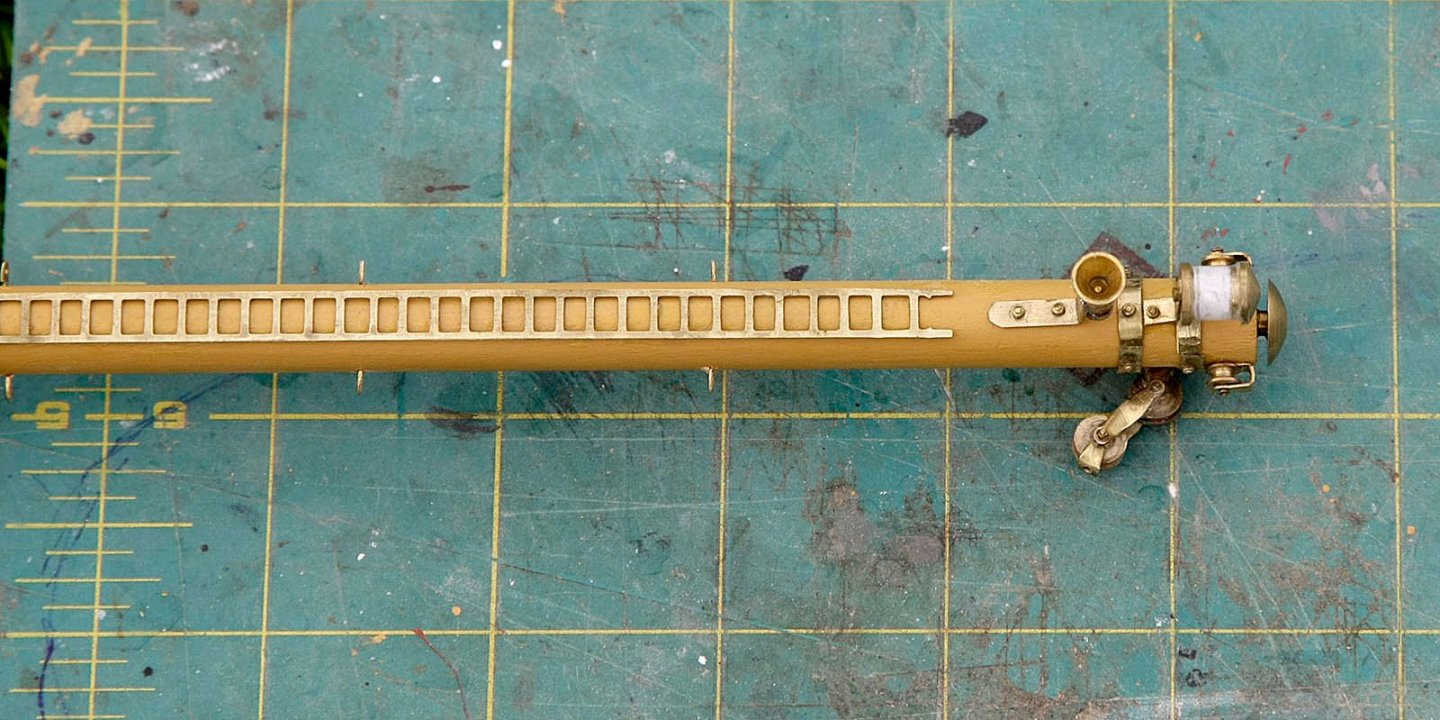

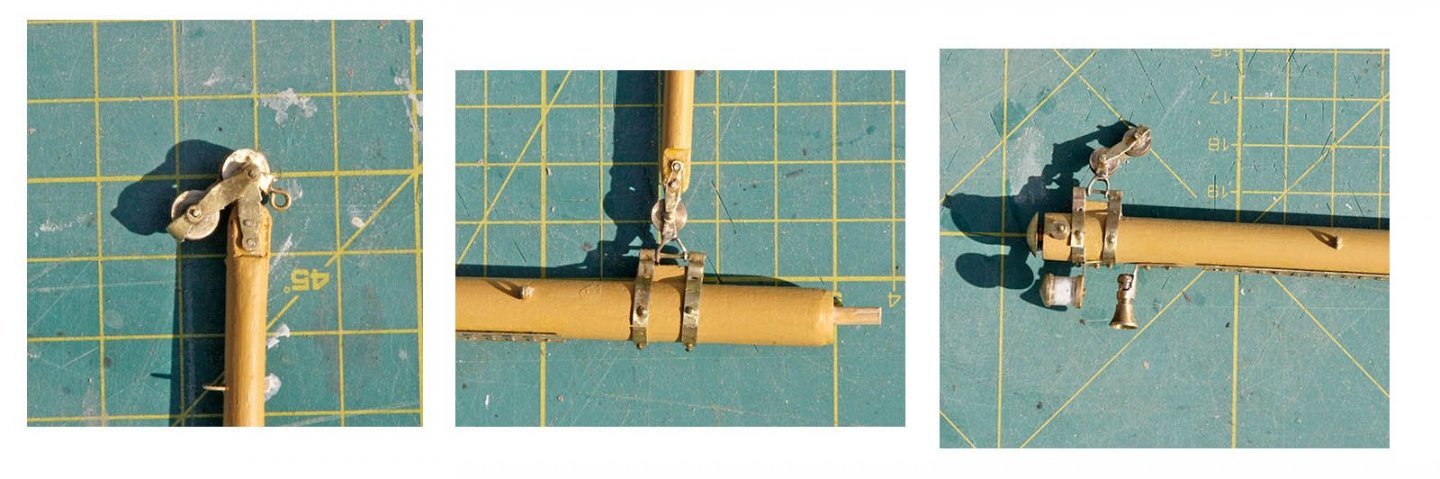

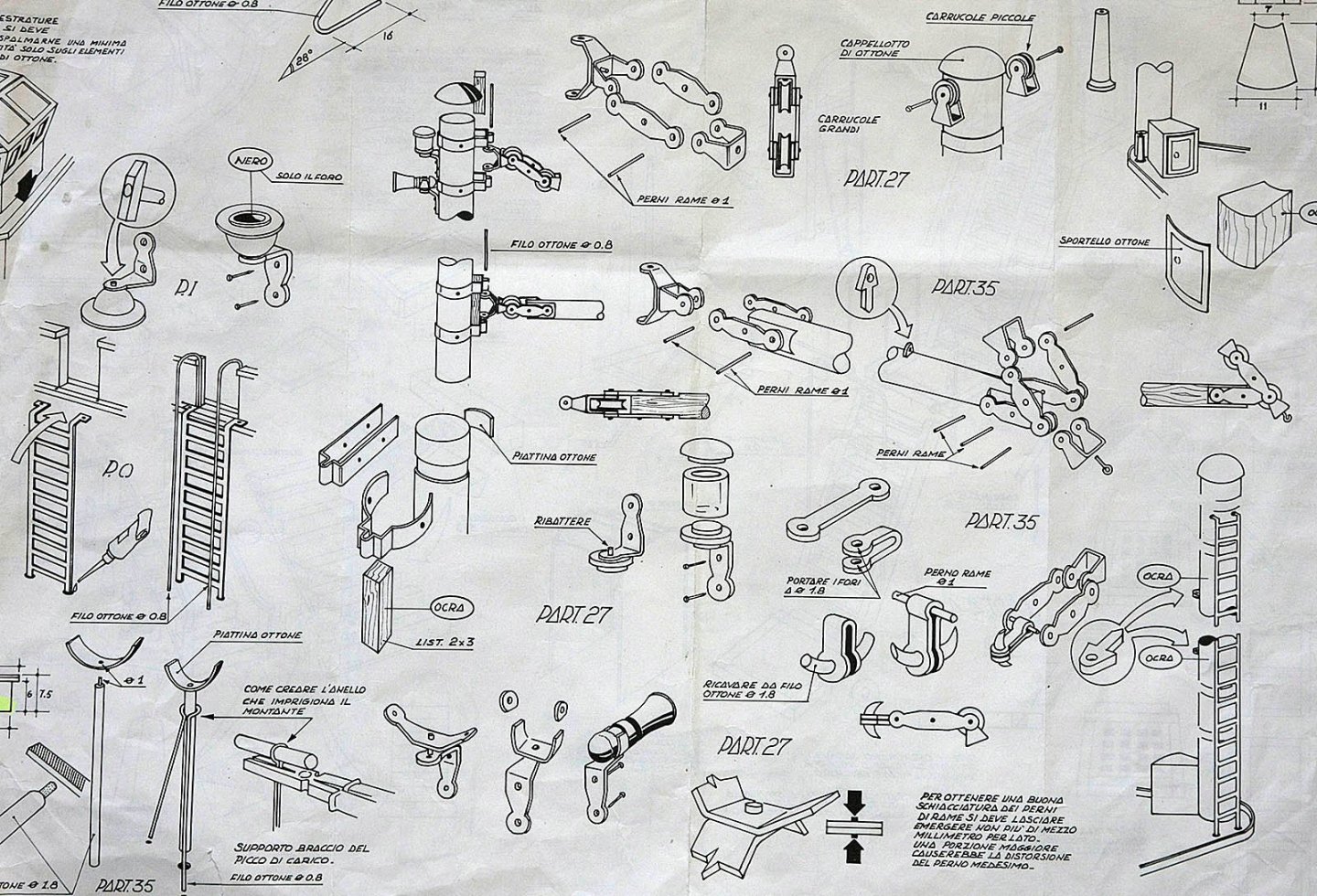

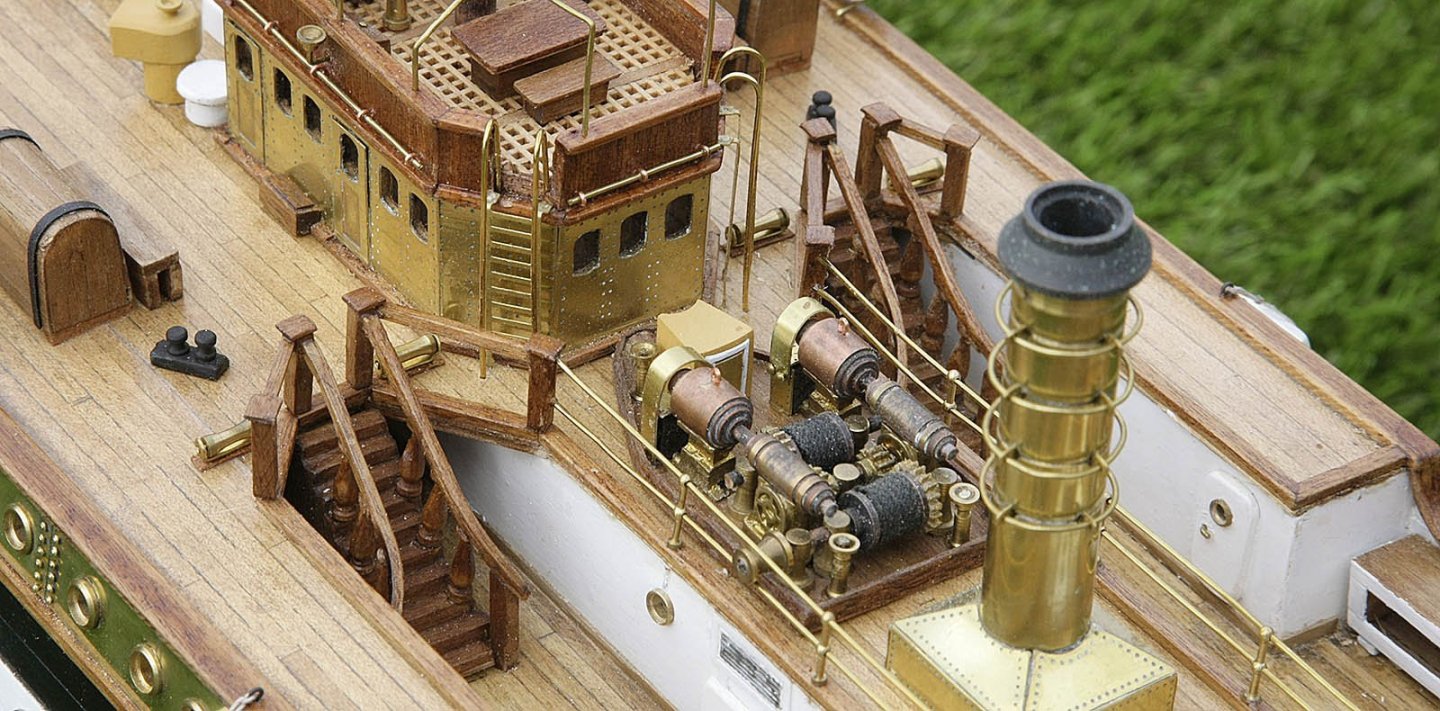

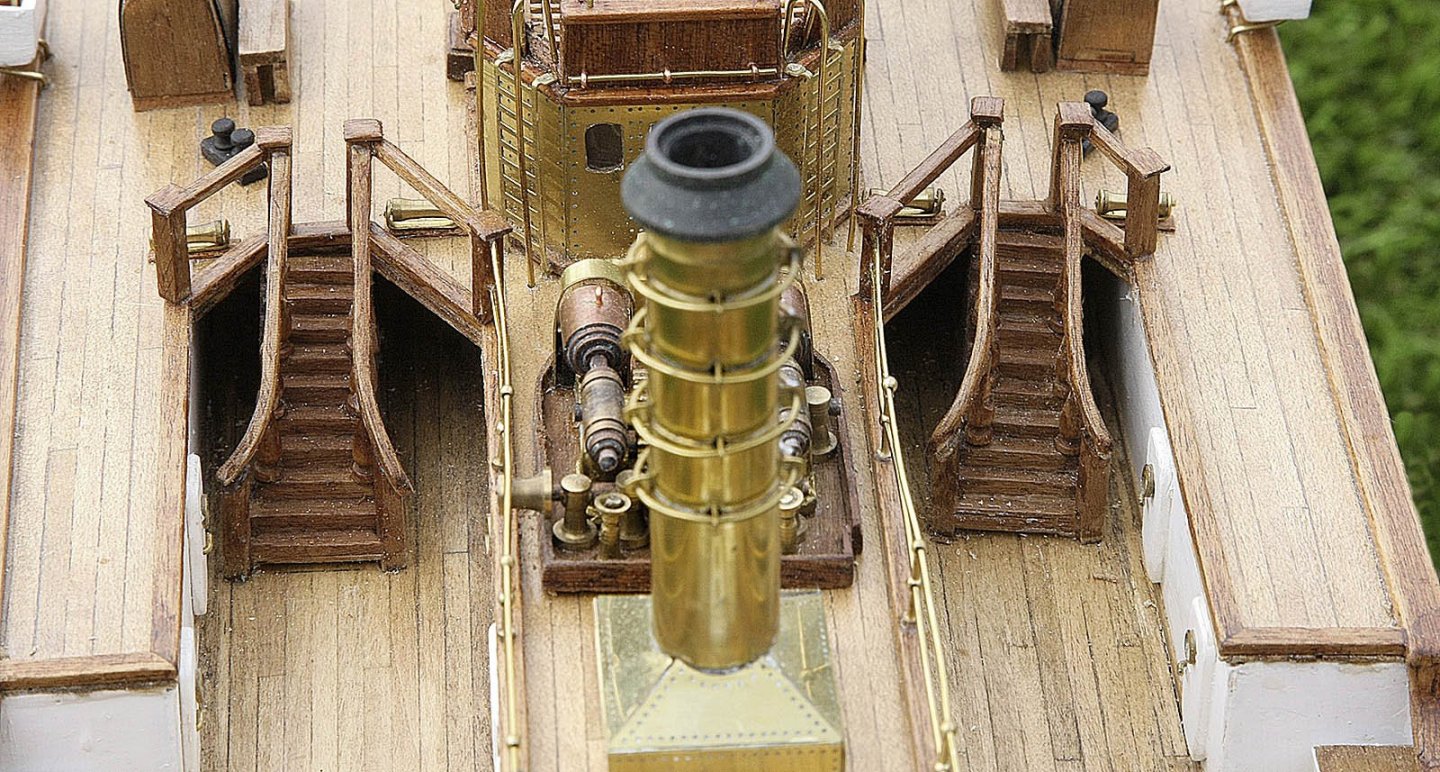

Hi, Once again thanks for your likes. Next I decided to make up the large derrick that’s used to lower the ships pinnace and motor launch from the midships. The plans for this at first glance looked easy enough but they were like a Chinese puzzle, almost impossible to interpret. First problem was that the plan was not to scale and only the diameters were given, there are three different size rollers supplied but no indication as to which size went where. There is no rigging guide for it so it was difficult to understand how it would work which would have helped understand how it all fit together. It eventually came together and I now understand its concept. At times there were up to seven pieces that needed to be held together so that all the holes for the holding pins lined up, all of them very small and tricky to hold, I had to get my wifes help with this as I just don’t have enough fingers. I completed the unit by painting, adding lights and horn and the cable guides, it is now ready to mount and rig, but I’ll do that in another session. Ken

-

Hi. Carrying on from my last post I continued making up the stern davits. I’m getting quite a bit of soldering practice on this build and improving all the time. The davits were made up of thirteen pieces of brass rods and wire of various sizes, shaped and soldered together, again not to be painted. I won’t do the other davits just yet as I think that they would get in the way of the rigging. You will notice that I have also made and added the brass boom support. I also made and attached the reserve anchors at the stern and the lifebelts. Next week I’ll be doing the strops and turnbuckles for the shrouds ready for the masting. Ken

-

Hi, Thanks again for those likes. This is just a short update on my progress. Only the rails at the stern to show, but progress is progress. You may notice that I've started the rear boat davit, one of many, there are eleven ships boats on board, something to look forward to building, ( or not ) Ken

-

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

-

ken3335 reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

ken3335 reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

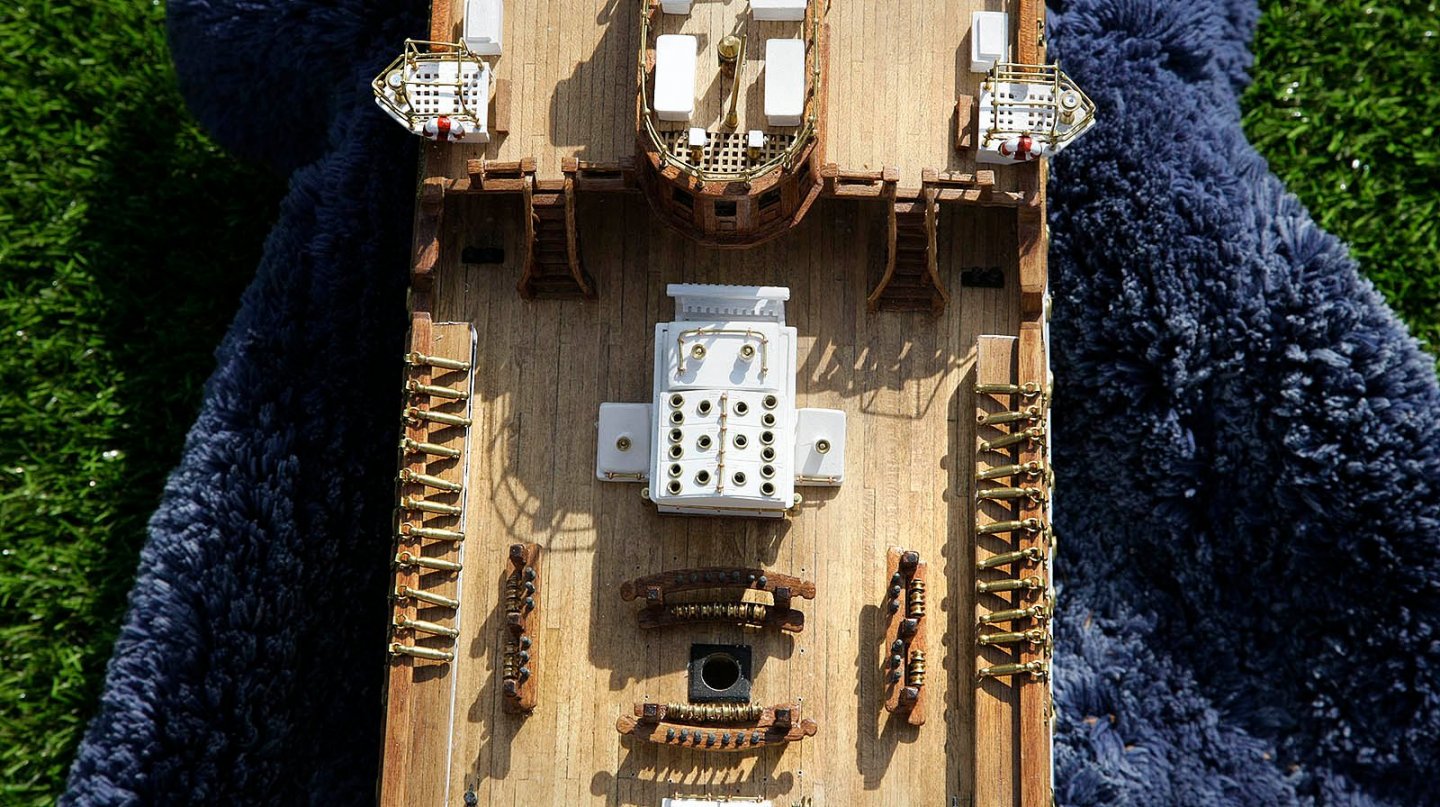

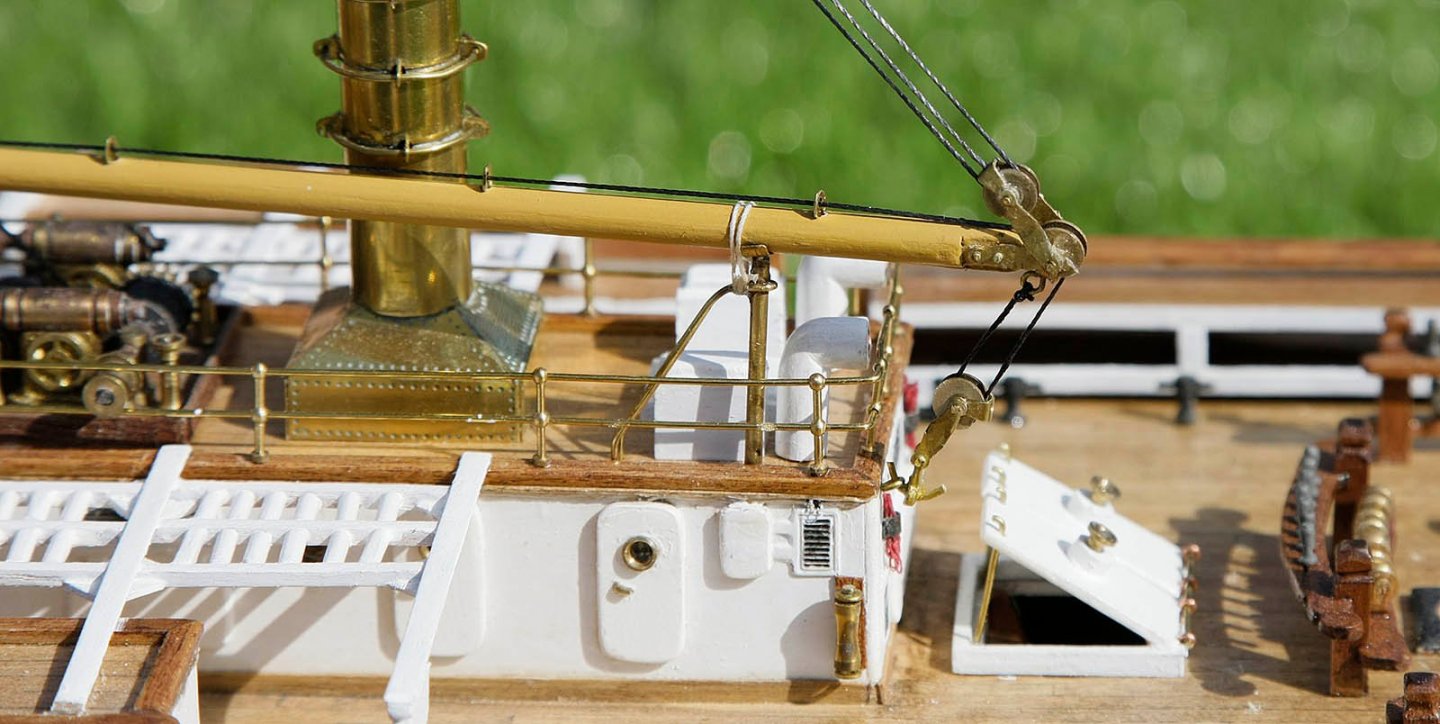

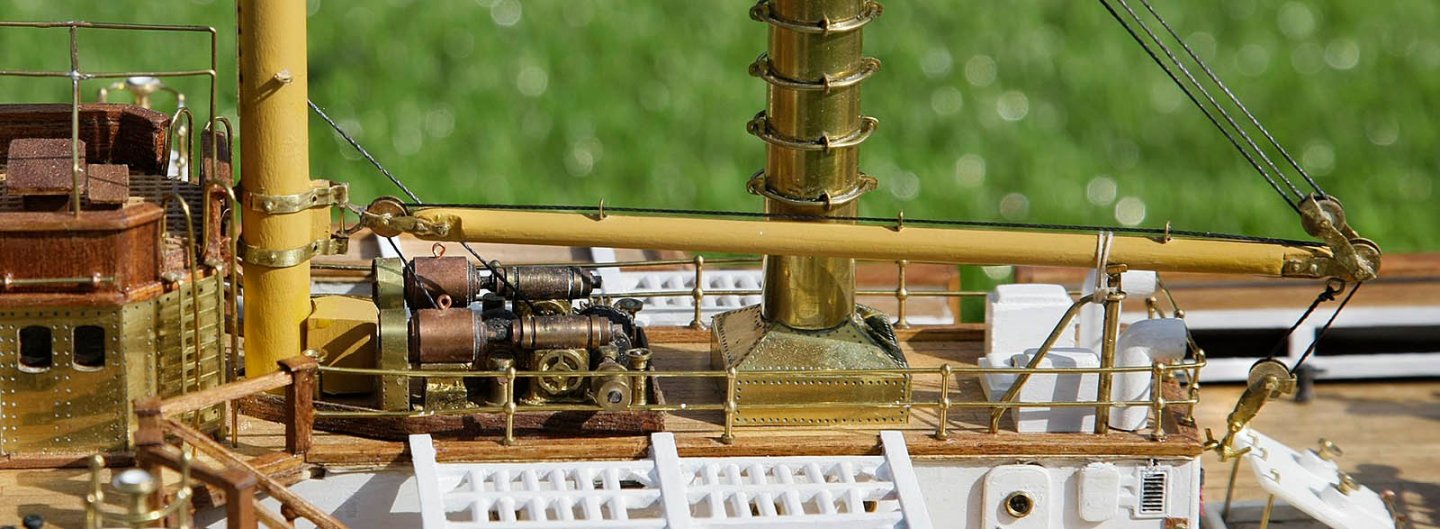

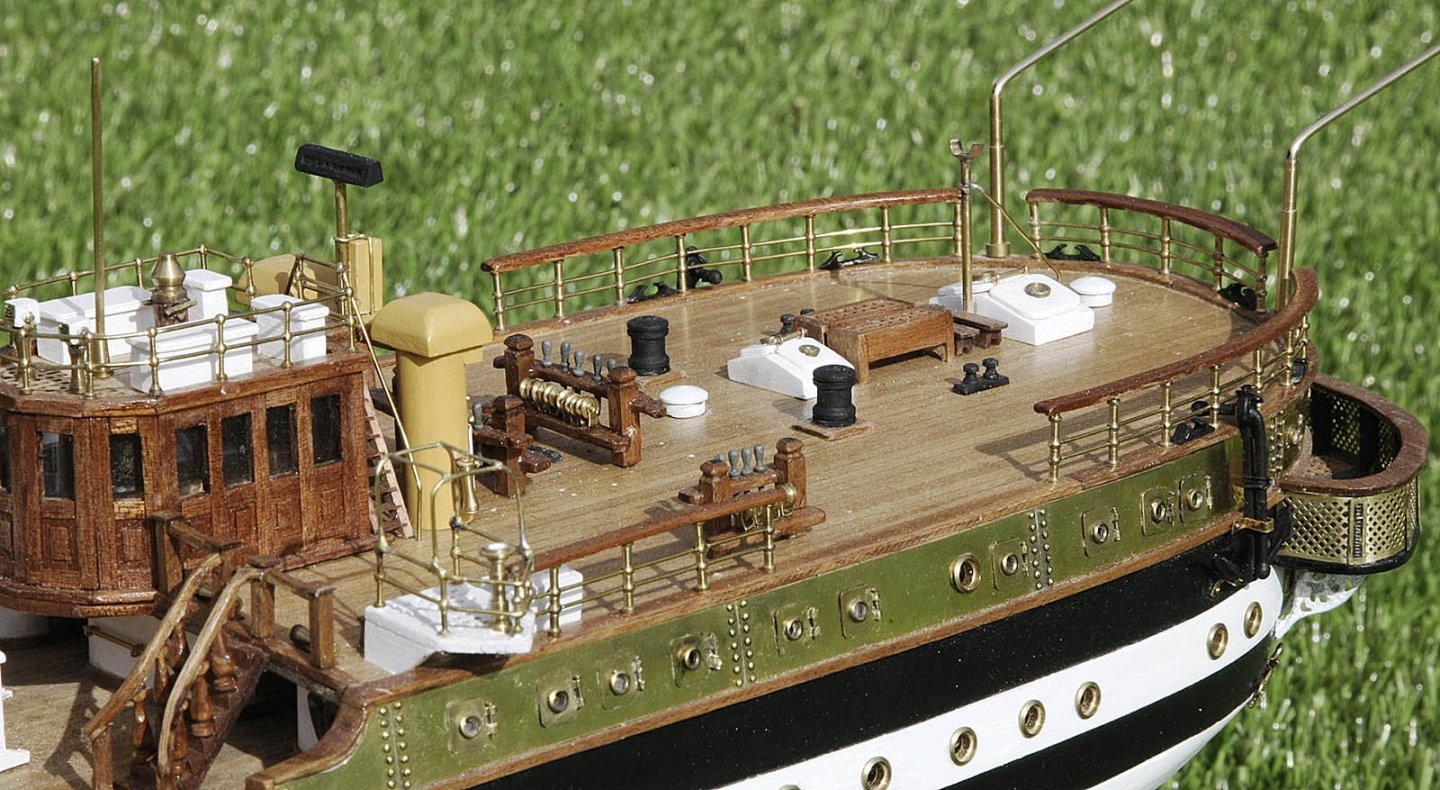

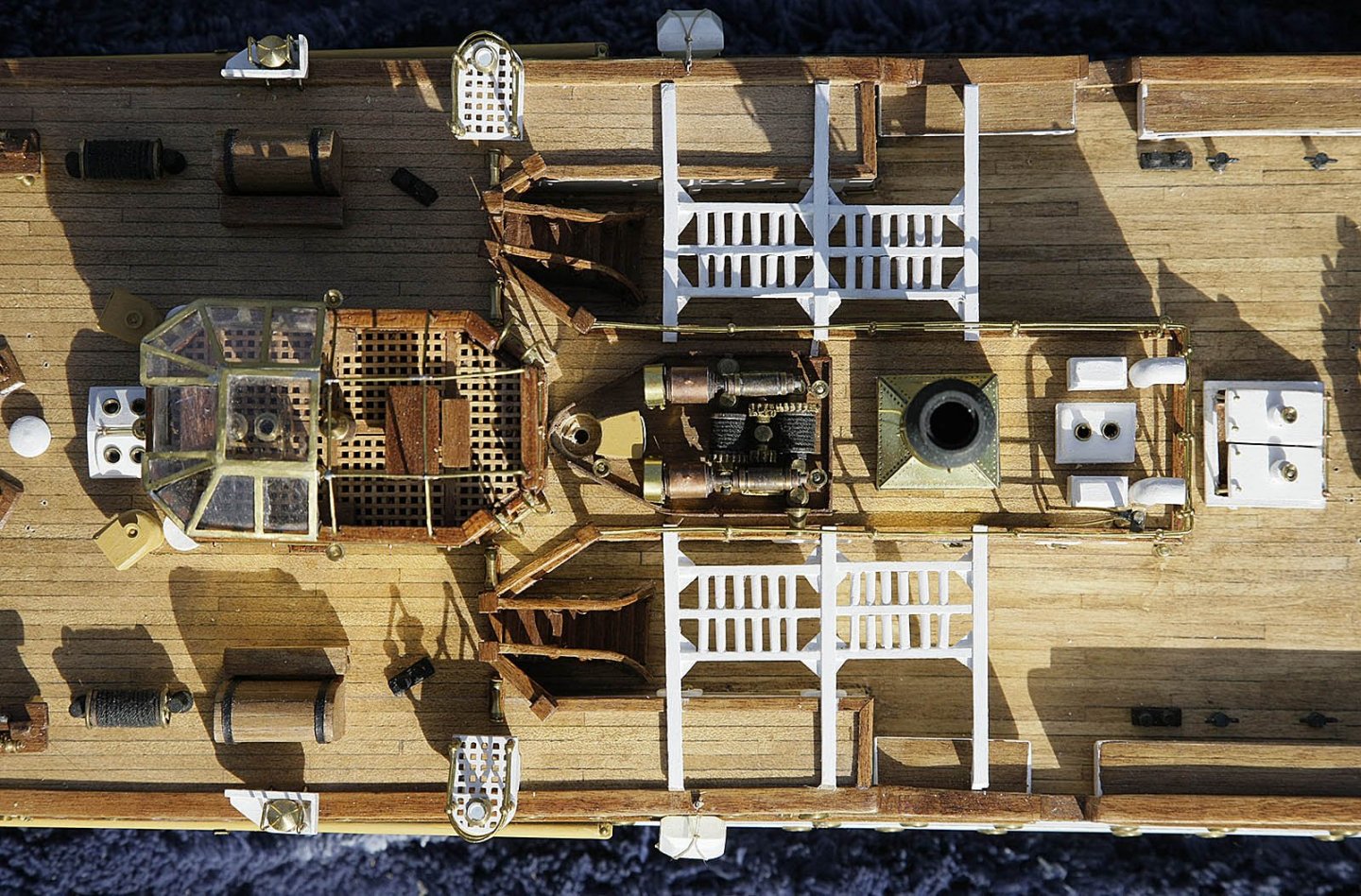

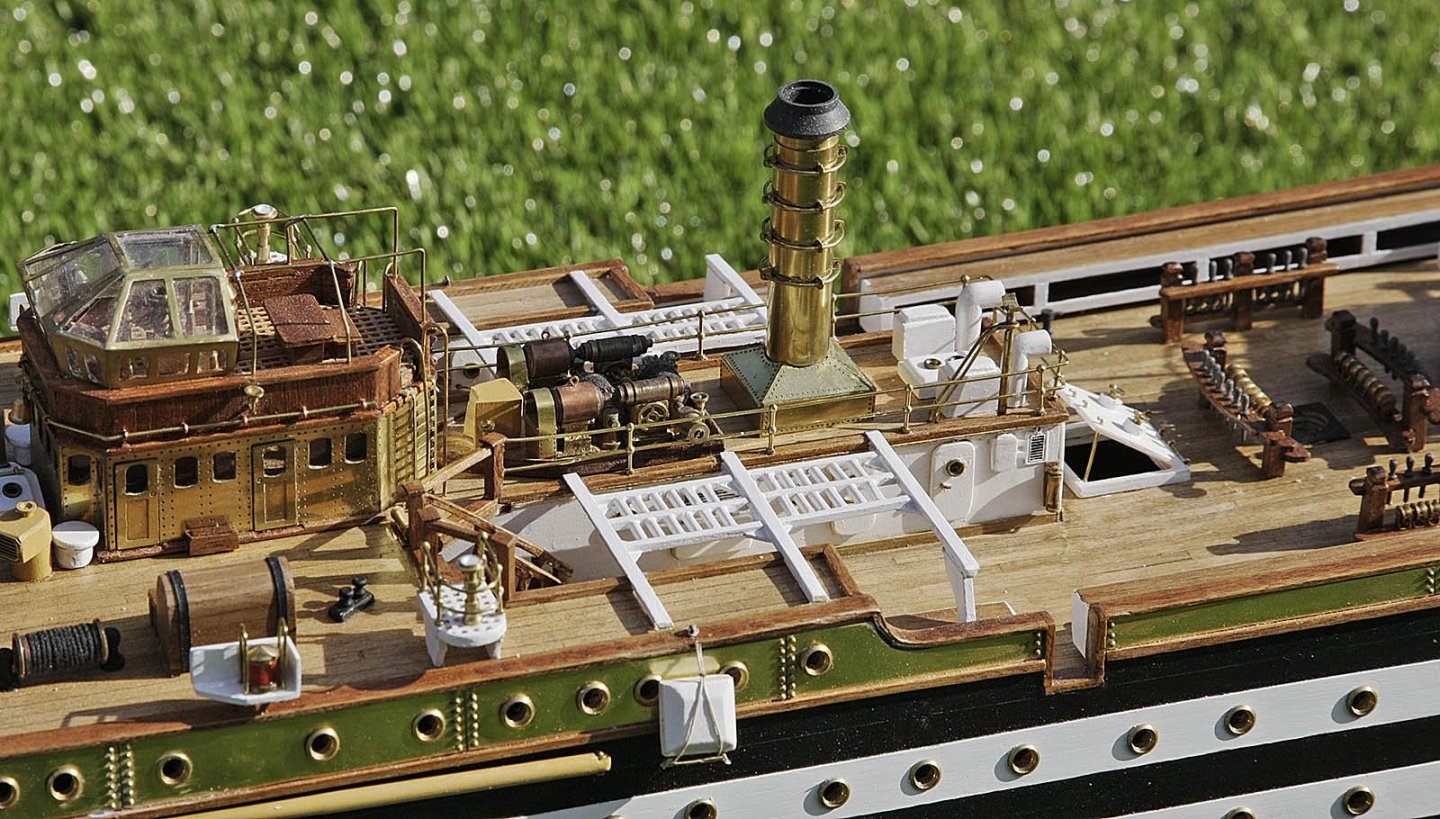

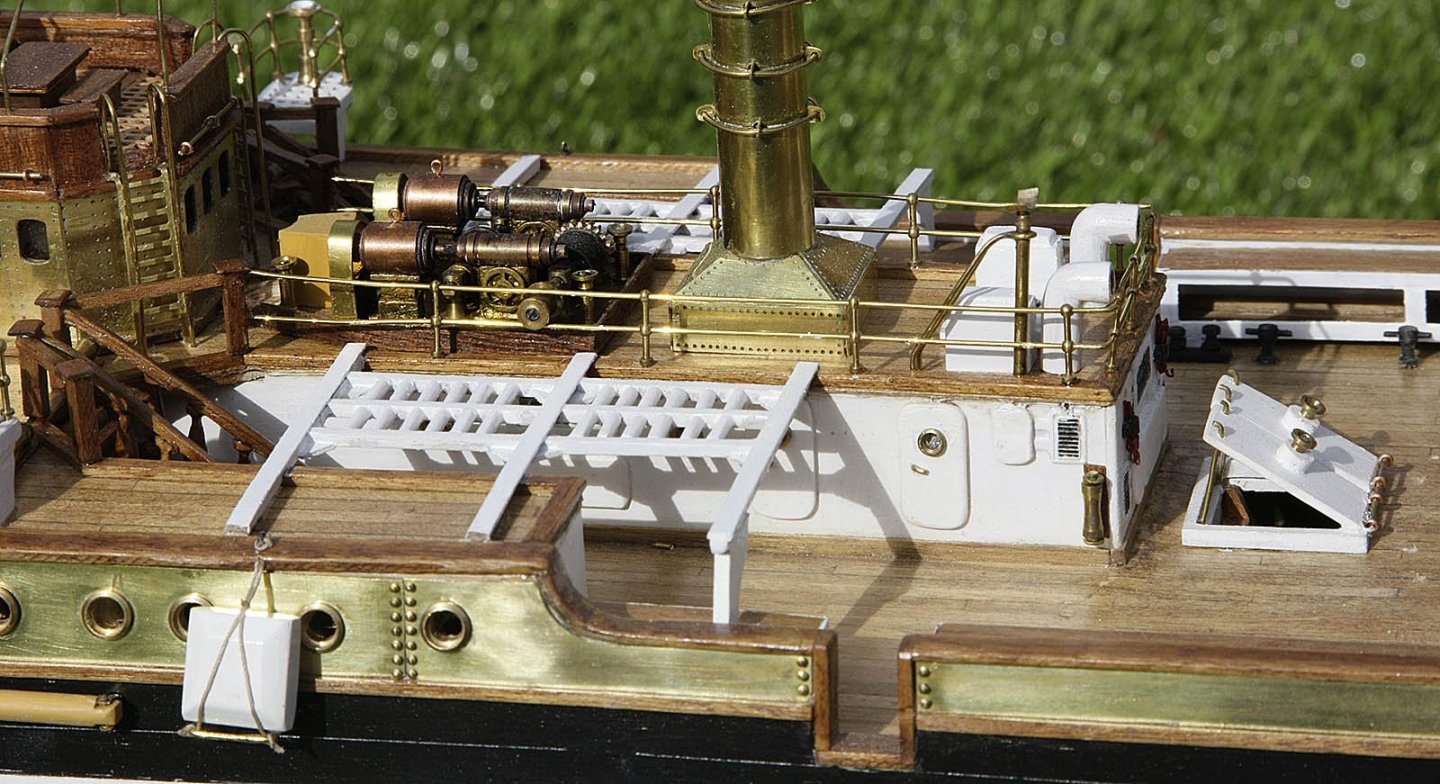

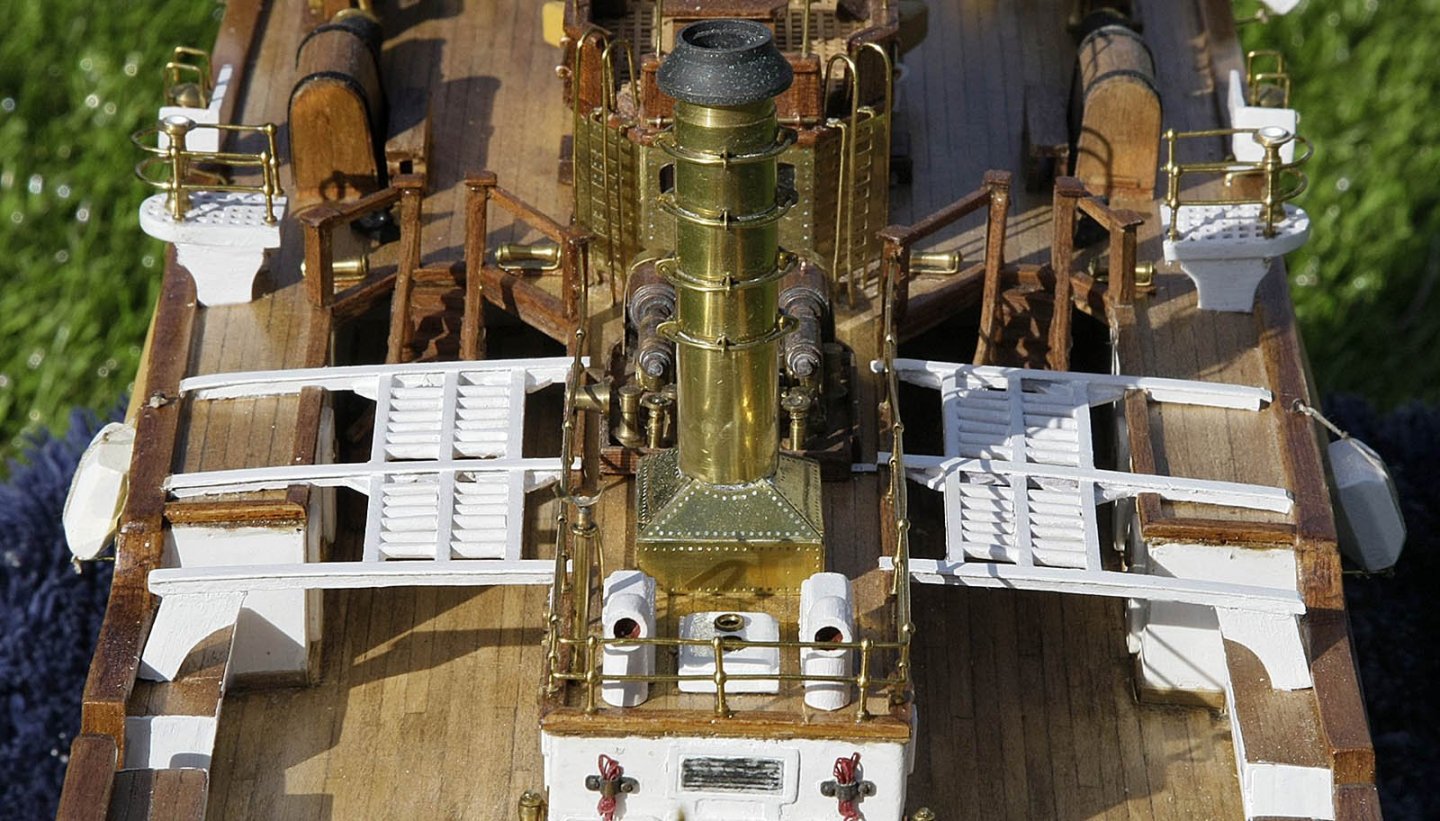

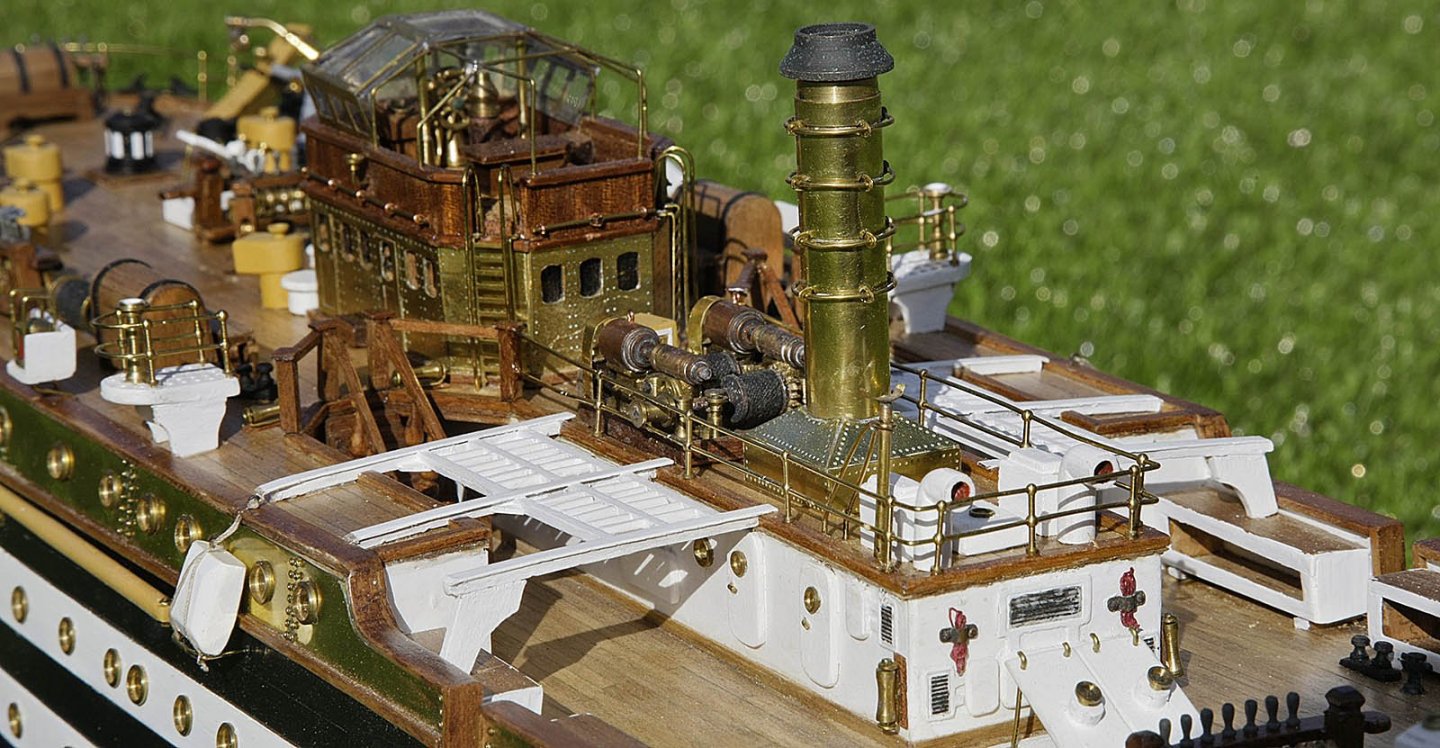

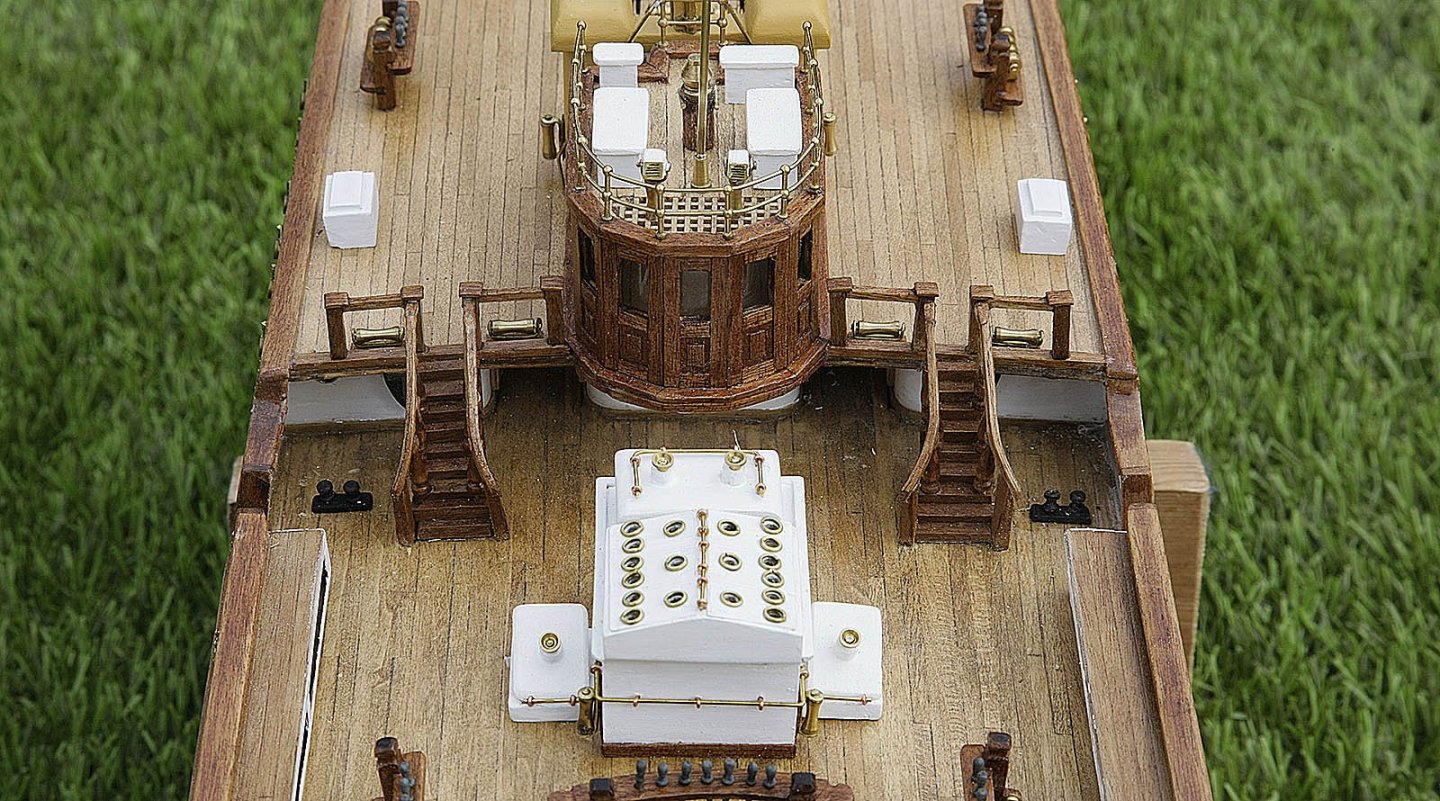

Hello again. Progress is being made fairly quickly, this build gets addictive once into the small detailed bits. I’ve now completed the rails at the bow end and around the funnel deck and a few other bits, the forward decks are now completed. You will need to look closely at what’s been done as I’m losingo track of the sequence of, build, photo, log as I’m doing bits everywhere at once with no particular plan in mind, a bit like a mad woman’s diary. Ken

-

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

-

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

ken3335 reacted to a post in a topic:

HMS Enterprise by Kevin - CAF - 1/48 - August 2020

-

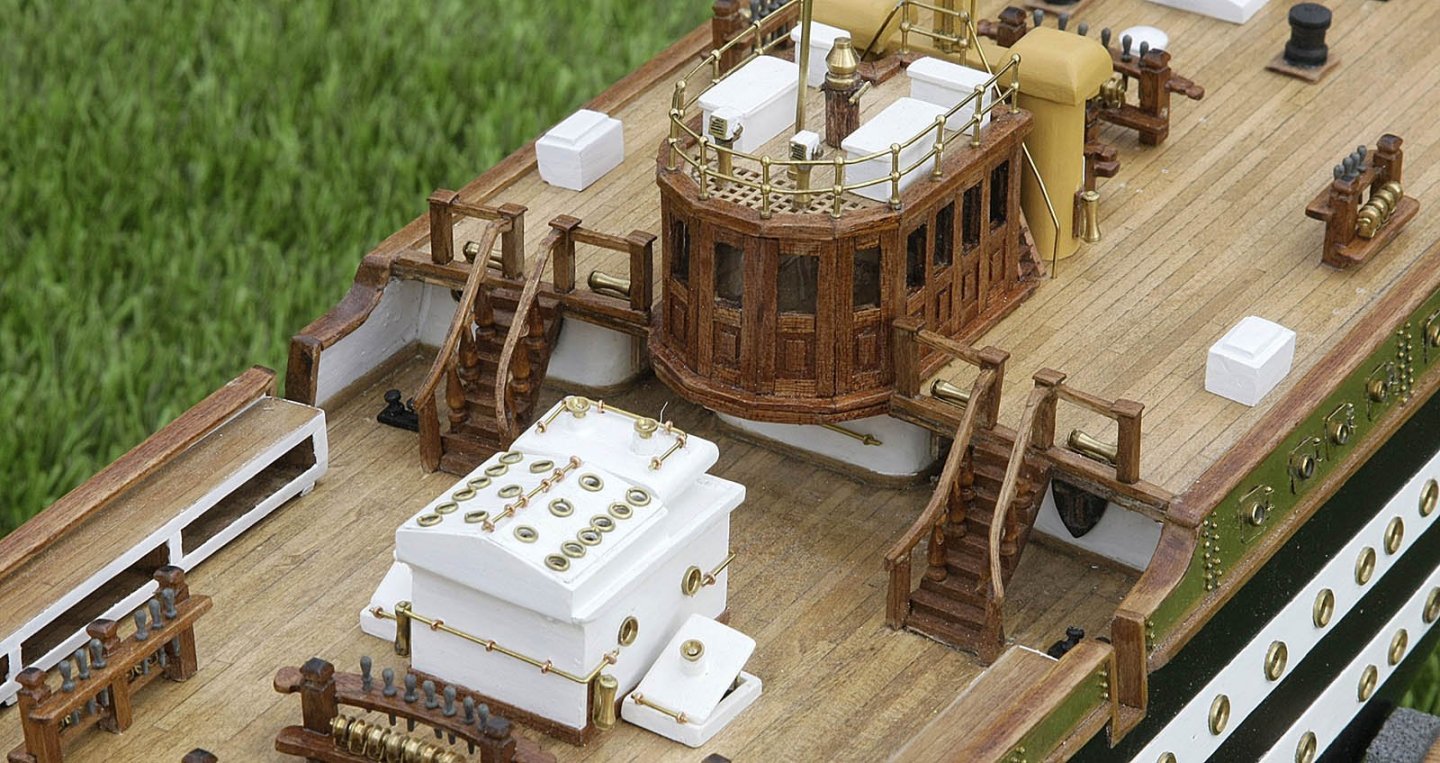

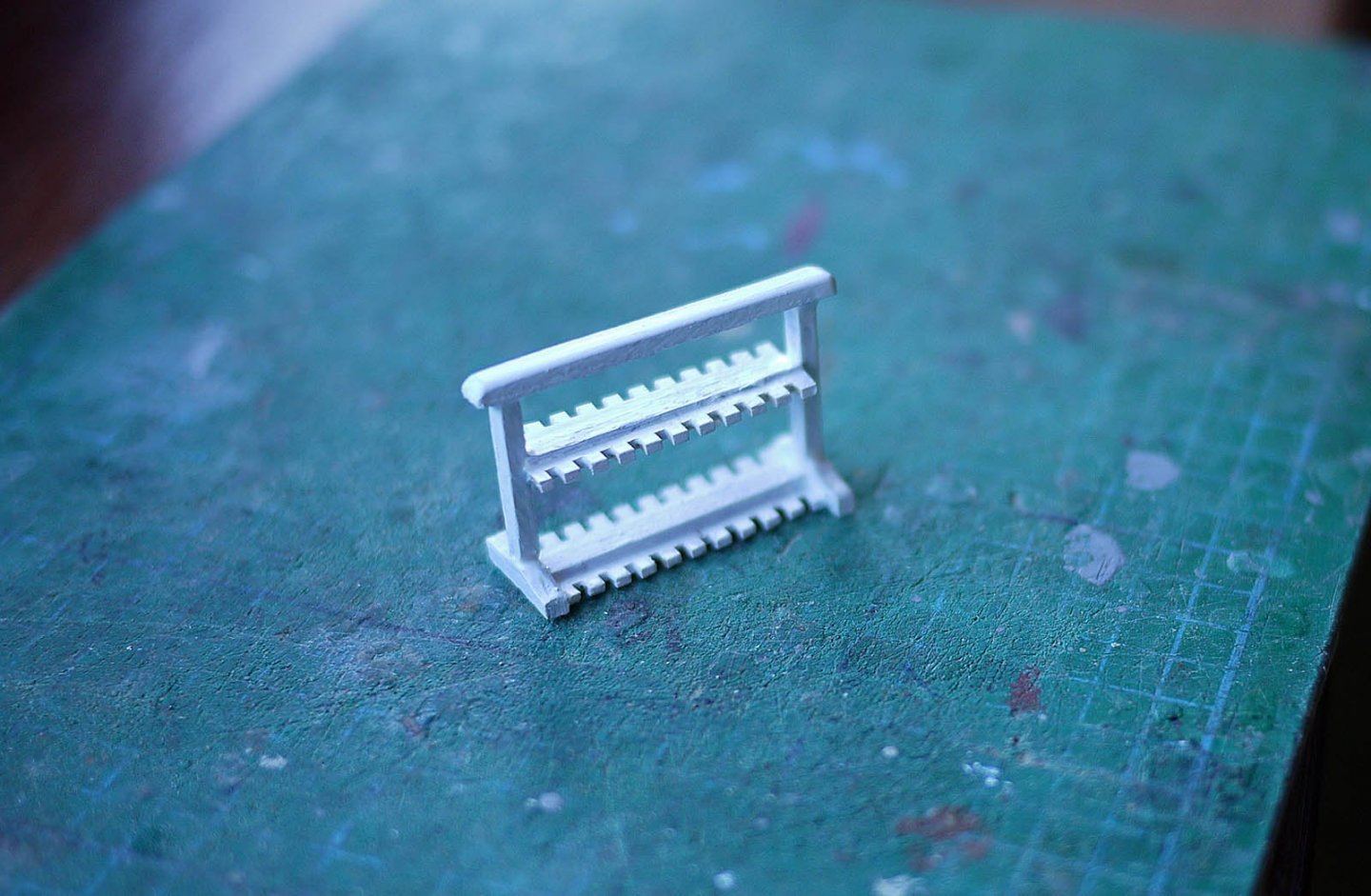

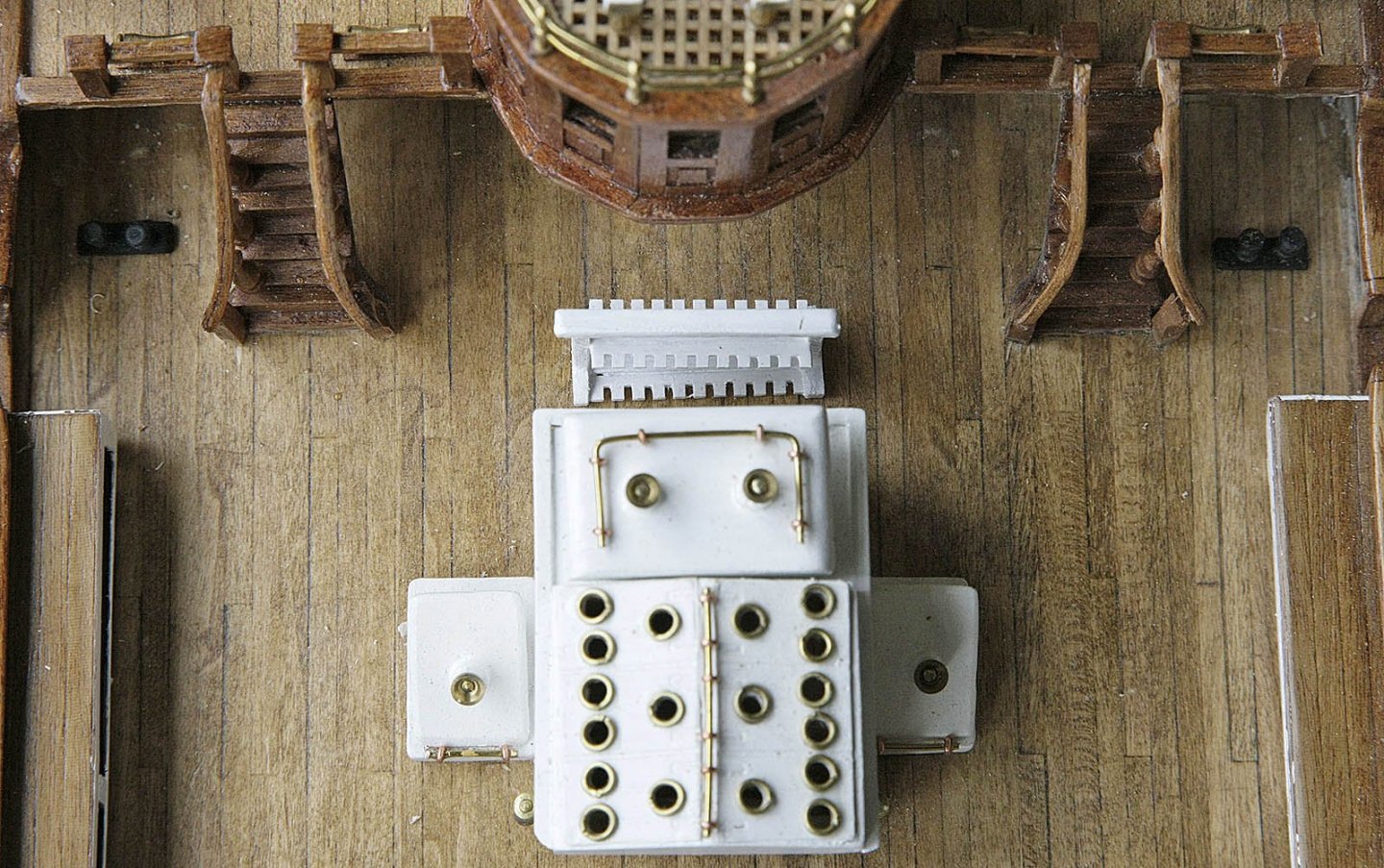

Hi. Again thanks to all who gave their likes to my build, and welcome aboard Tom, Mad Dog. It’s still progressing well, here’s the result of the next session. You will know that I had built the staircases earlier, now I have glued them into place and built up their rails as well as the rails on the upper decks. I have also started to make up the brass rails around the funnel deck, you can just about see part of them in the pics, again I’m pleased with the result. I’m also still making up the smaller parts which add to its character. I have made up pike racks before but never a riffle rack so this is a first for me and I think a nice touch that you wouldn’t expect. Ken

-

ken3335 reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

ken3335 reacted to a post in a topic:

Amerigo Vespucci by ken3335 - Panart - 1/84 scale

-

Hi. Again thanks for your many likes. Welcome Chris, thanks for taking the time to view and like my build, it really gave me a boost to have your approval. I promised a few shots of the overall state of the build so far, well the sun shone and I was able to photograph outside. The foredeck looks finished but that’s deceptive, quite a bit to do on it, even a couple more guns which I hadn’t noticed earlier on the plan. There’s the rails, some life rafts, platforms nav lights etc. After these I’ll start on the staircases so still plenty to do. Ken

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.