-

Posts

1,825 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tkay11

-

Wonderful to see your work on this. I also appreciate the shots of a similarly-sized boat to show just how big it is. Thanks! Tony

- 15 replies

-

Nicely executed. I'm impressed by the speed at which you have been able to work. Congratulations! Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

There are some very simple jigs you can make to ensure the deadeyes are all in line (though on real ships they quite often were not that straight, so this is more of a model-making convention). I made mine with paper clips. See the following, a few paragraphs into the post: By the way, I strongly recommend the late Hubert Sicard's site Wooden Ship Modeling for Dummies. This is now maintained by his family. A lot of it is free, but you can get a lifetime subscription for $40. I used it extensively. It has plenty of free videos and focuses on using the most basic equipment with the minimum of power tools. Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

I based my own rigging of the Sherbourne on Petersson's book, and found it very helpful. However, I did augment it with more precise details from Steel, Marquardt and others. The original plans in the NMM came with no rigging plan, so it really is up to you how you rig it, within the various options that these different authors and paintings portray. Not only were there many different approaches to the rigging of a cutter at the time, in terms of number of yards, positioning of the topmast, and belaying plans but every shipyard had its own way of doing things, and captains would often change the rigging to suit their own requirements. Finally, I do recommend that you go with the sail plan, and therefore the rigging plan, that pleases you most -- especially if you plan to show the model with sails. It should be noted that the kit differs from the original plans in some details, notably the windlass, so you also have to decide whether you want to attempt to go for some original recreation (which to my mind is impossible) or whether you see this as a generic reconstruction of what these lovely ships used to be. There's a huge amount of discussion on most of these aspects on this site, either in detailed build logs or in discussions of each of the different details. You are doing a really nice job so far, and whatever you decide, it's going to end up as something deeply satisfying to you and to those around you. Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

It's been a pleasure to watch. Congratulations! Tony

- 84 replies

-

- sherbourne

- caldercraft

-

(and 2 more)

Tagged with:

-

I think every builder has problems with boo-boos. There's an entire topic devoted to just this aspect of a modeller's life. Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

Nice progress. Normally the hull planks would go over the edge of the transom timbers as they would be nailed from the outside to them. However, if you are going to paint the hull, you should be able to hide the fact that they are lying on the inside of them. Even if you don't, I don't think it would be worth tearing off your planking to re-do it as it is quite neat. You can check this with some of the build logs of the Sherbourne. Tony

- 14 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

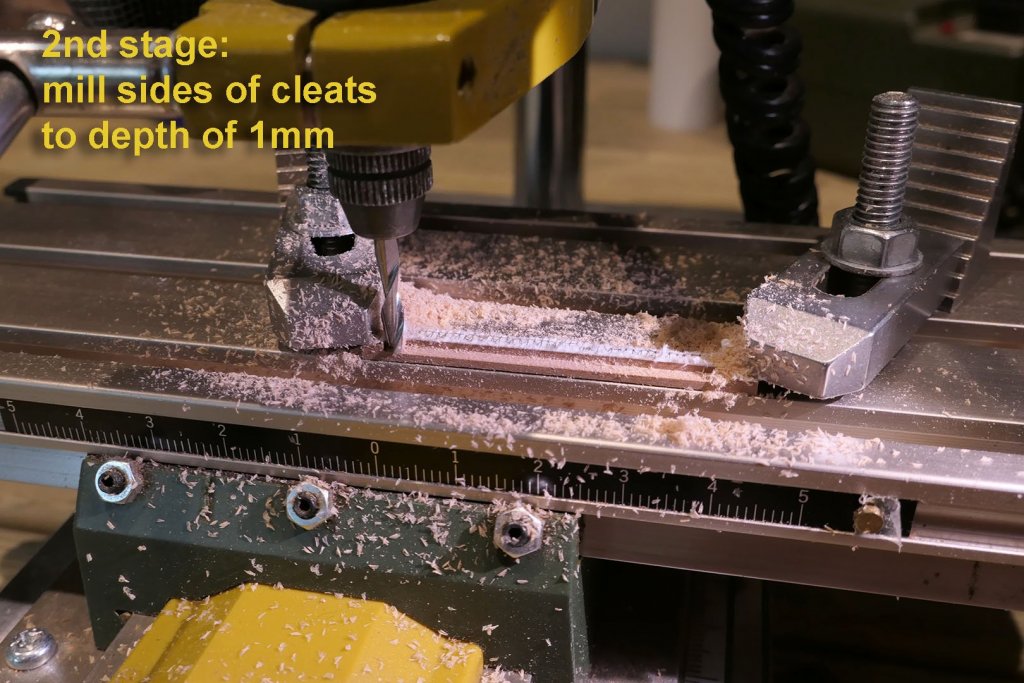

@mjh410: The machine I use for milling is a straightforward adaptation of a 50W Proxxon Micromot drill, which I made in 2013 for my earlier builds and is discussed with photos at the beginning of this build log. The only essential adaptations are (1) a clamp for the drill stand made of wood which has an old tuner knob glued to a 6mm bolt to act as a height adjuster, and (2) a dial gauge on its own stand. You can see this in the section on Stem, Stern and Keel on the first page of this build log, and the link to the post is: You'll find my instructions on making the clamp on this site at: Many people have said that these small Proxxon drills are not made for milling as the bearings are not designed for lateral thrust. However I have not had any problems so far as I keep my cuts shallow and I only use it on wood. The advantage of these Proxxon drills is their high speed (up to 20,000 rpm) which is ideal for using small diameter milling bits (1-3mm) in wood. A key problem is ensuring that the drill clamp on the drill stand holds the drill truly vertically. I had to insert a strip of wood between the drill clamp and the stand as the stand I have is the cheapest possible and not build to such good tolerances as the Proxxon MF70 mill (the standby for a vast number of modellers working with model ships). Tony If you want to know more, please do ask.

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

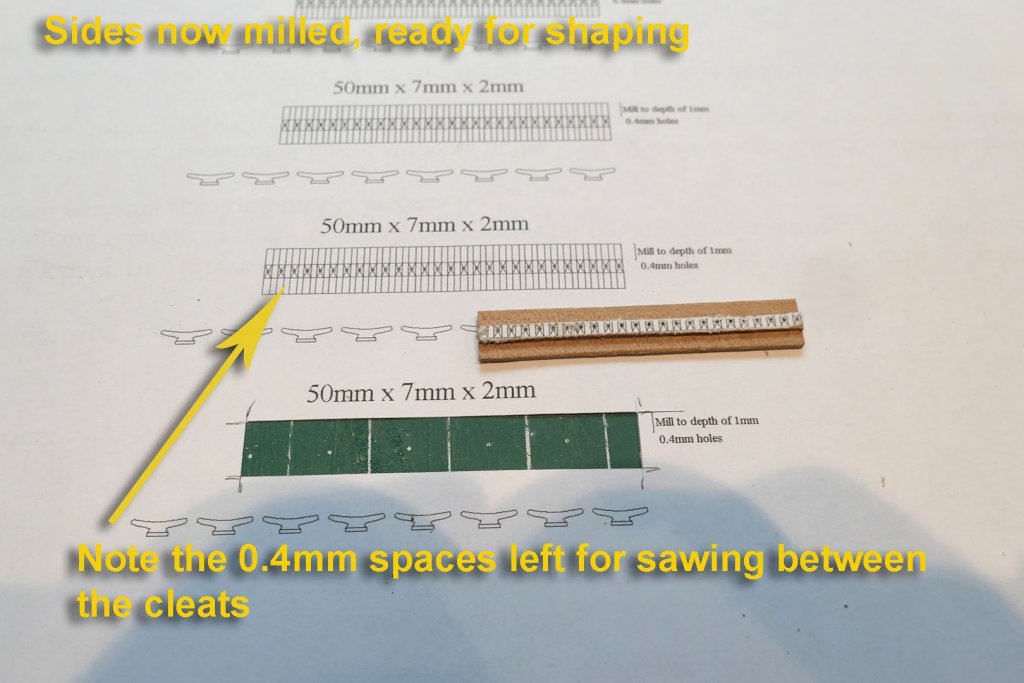

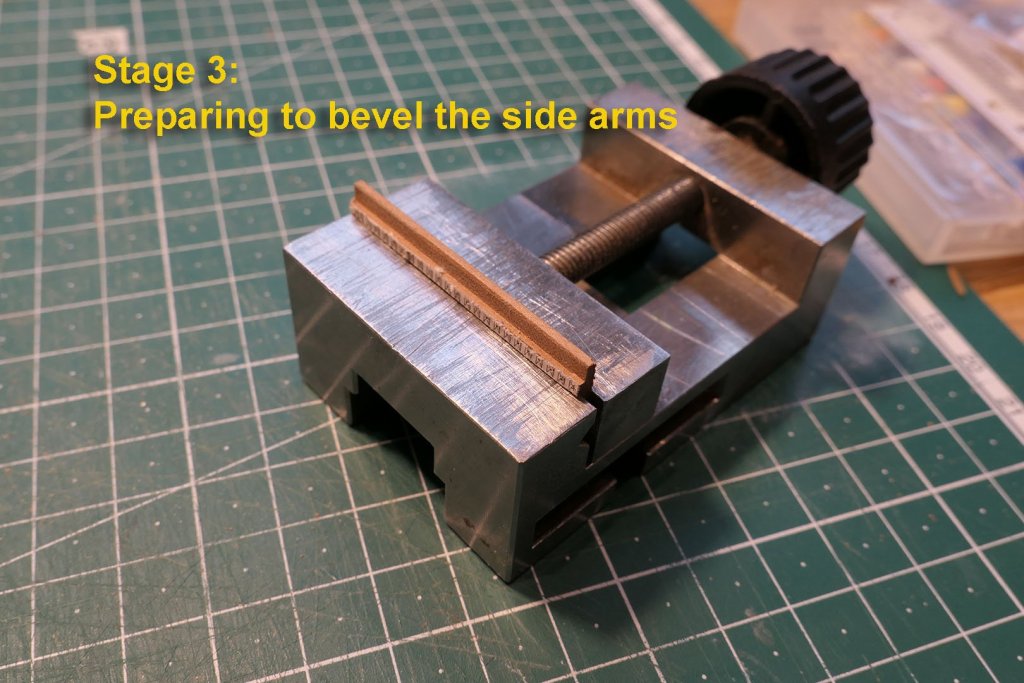

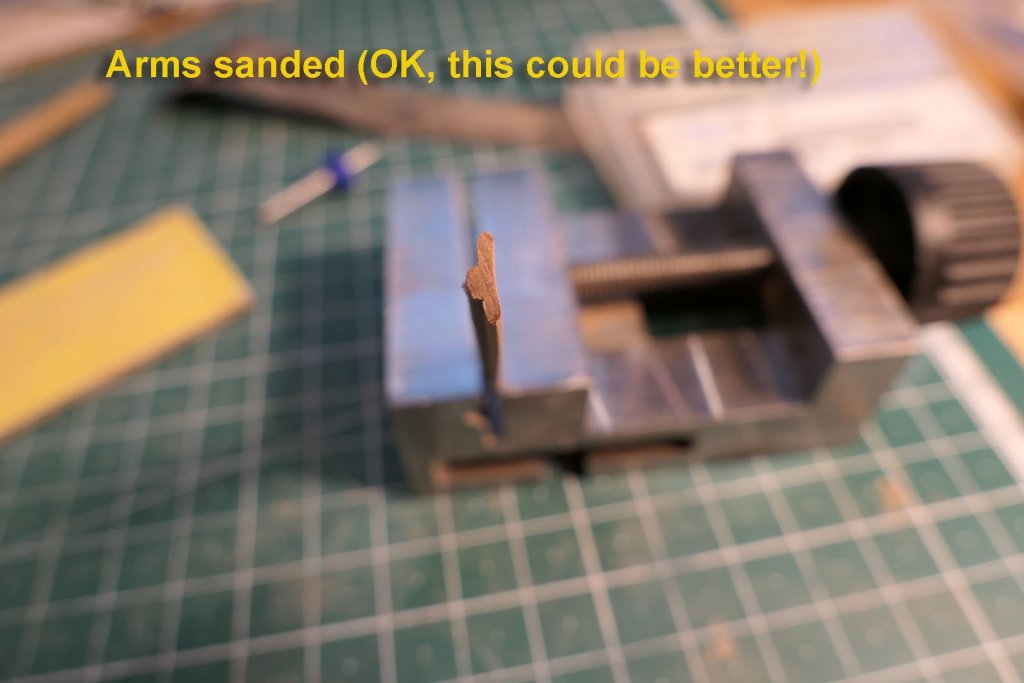

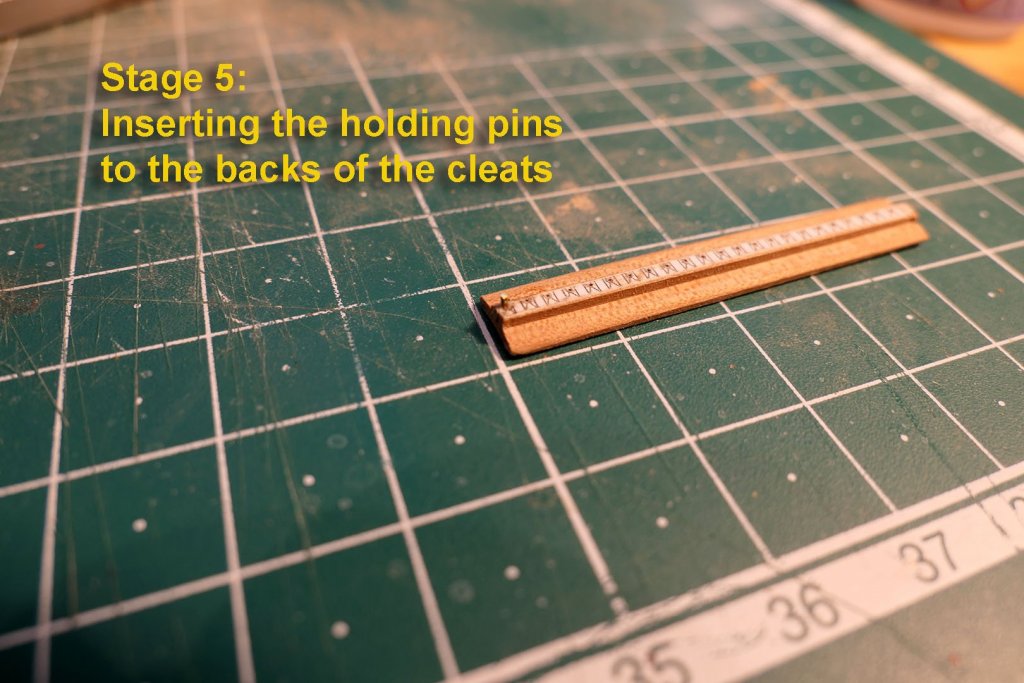

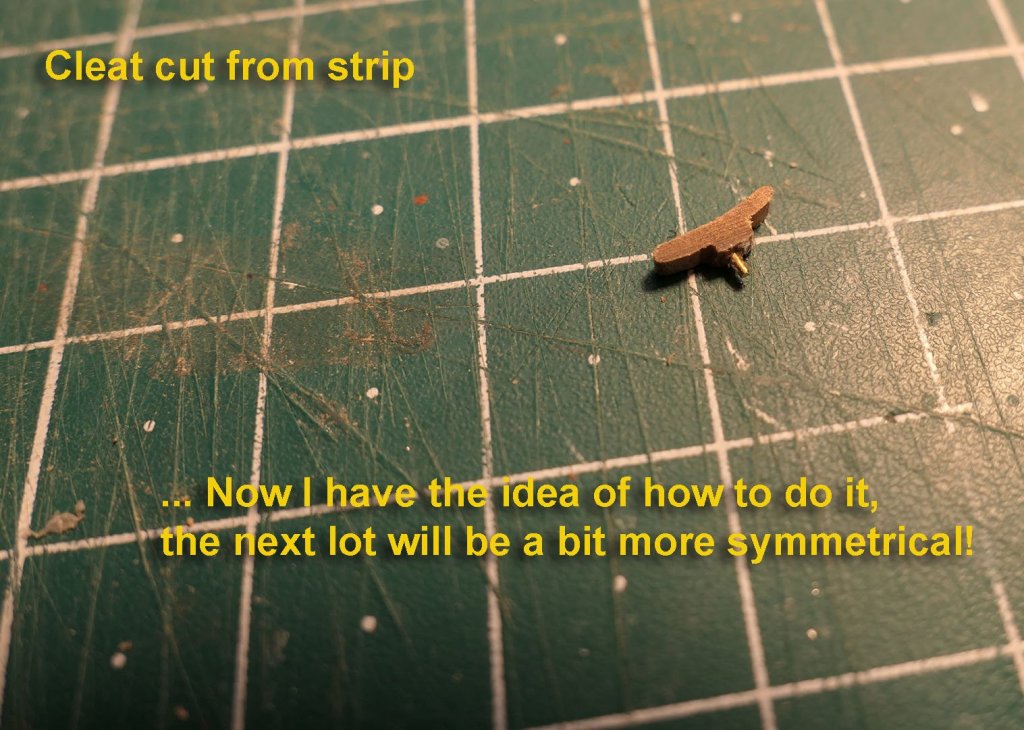

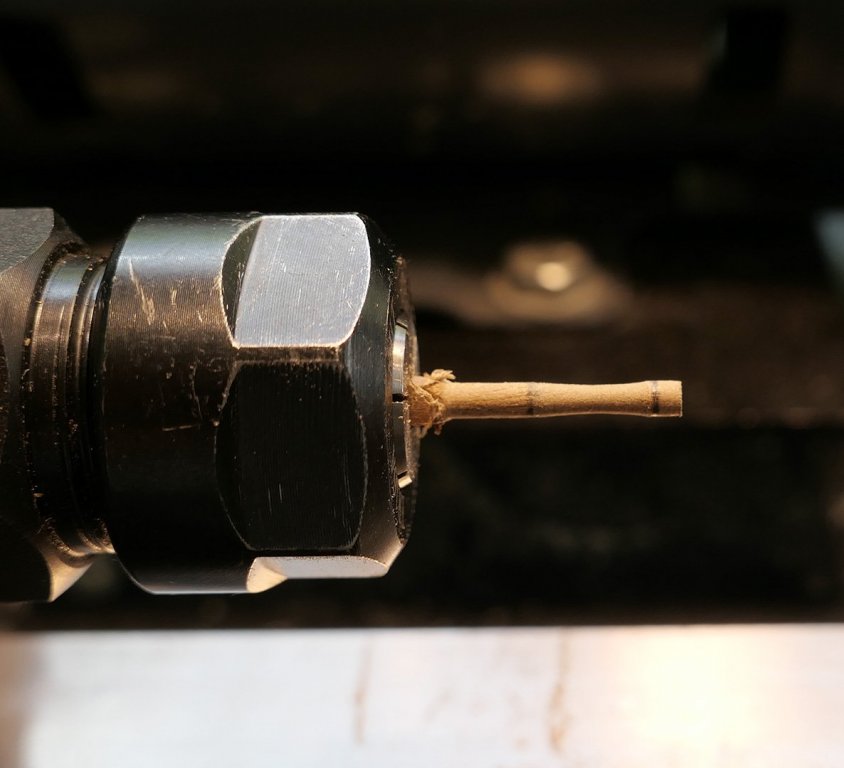

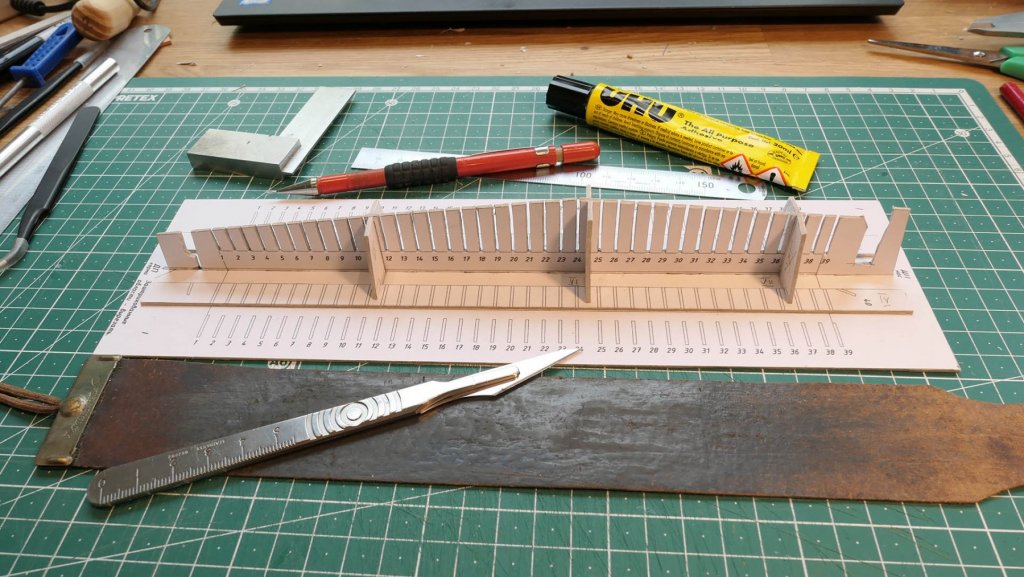

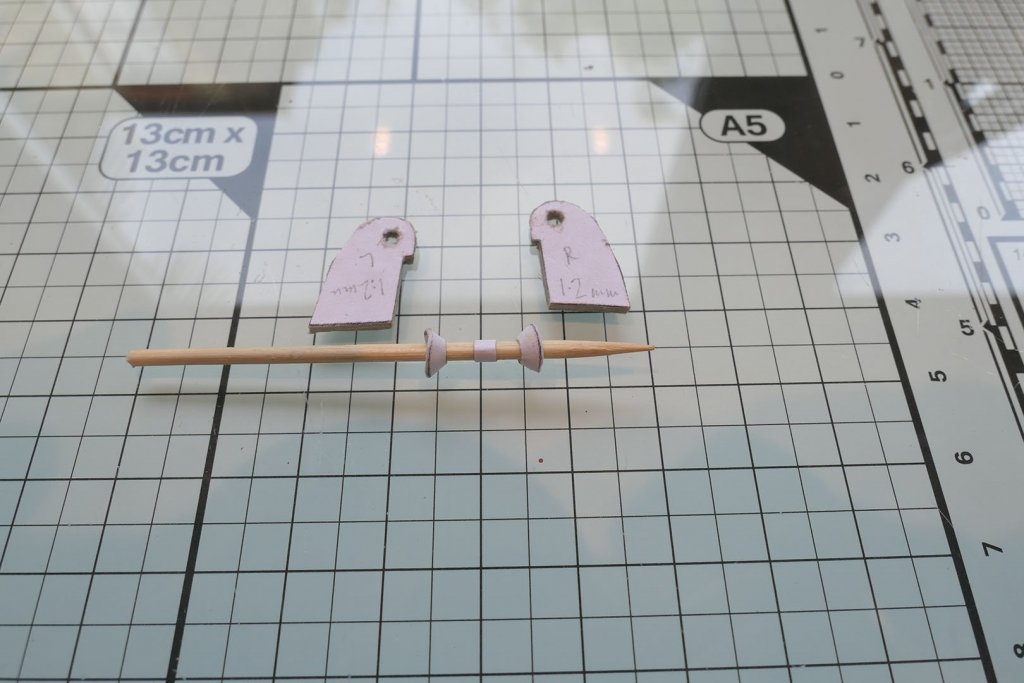

Cleats While I’ve been involved in other work, I’ve been pondering how to make the cleats. I read several other articles on this site and elsewhere, but wanted to do this in as labour-saving a way as possible. I eventually figured that the easiest way would be to start from the rear of the cleats by milling away the underneath of the two arms. I used my TurboCAD programme to draw up the outline for the strip to be milled, using the dimensions of the cleats shown on the plans. This was placed on a strip of pear wood 7x2mm in section, this being the overall face dimensions of the cleat. I left 0.4mm spaces between the cleats on the strip to allow for the width of my razor saw (0.3mm) -- you'll see this a few photos further down. After clamping the strip to the compound table I drilled the holes for the supporting pins at the back of the cleats. The backs of the cleats were then milled to a depth of 1mm on the 2mm thick strip. I then took the strip, and, holding it in a vice, sanded the underneath of the arms to a curve with a sanding stick. I then sanded the front faces of the cleats to a curve on an old bit of brass tube. I then inserted and glued brass rod into the holes on the backs of the cleats on the strip. As this was my very first attempt, it is all a bit rough. However, now I have the idea of how to do it, I’ll be able to perfect the technique for future belaying pins. I only need 14 of them for the chaloupe, so it’s no big deal. Tony

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

I used square mini files or jeweller's files for the small square ports. They come very cheaply in sets of six or so on eBay, Amazon etc. You can also make your own square punches for smaller squares (e.g. on the windlass) by squaring off nails. Then there's the option of making your own mini-chisels 1mm or so in size using allen keys and suchlike. There's lots of advice on the web on how to do this. Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks for the nice comments, druxey and G.L., and to all who posted 'likes'. That's the nice thing about logs. Every time I read someone else's log I, too, learn new things. Above all, they make me think, as well as wonder often at the ingenuity displayed. And thinking's the main pleasure of this game for me. It demonstrates that there can never be a simple guide to how it's done for any model, as so many variables will always intervene. Skill seems to me separate, and comes with practice and experience. Tony

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

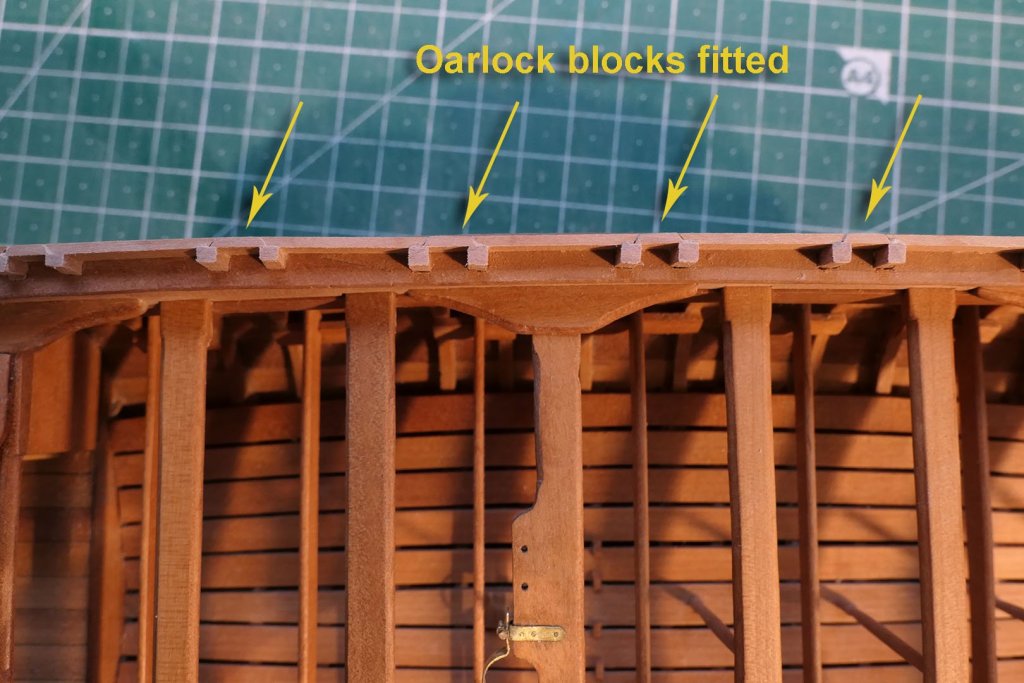

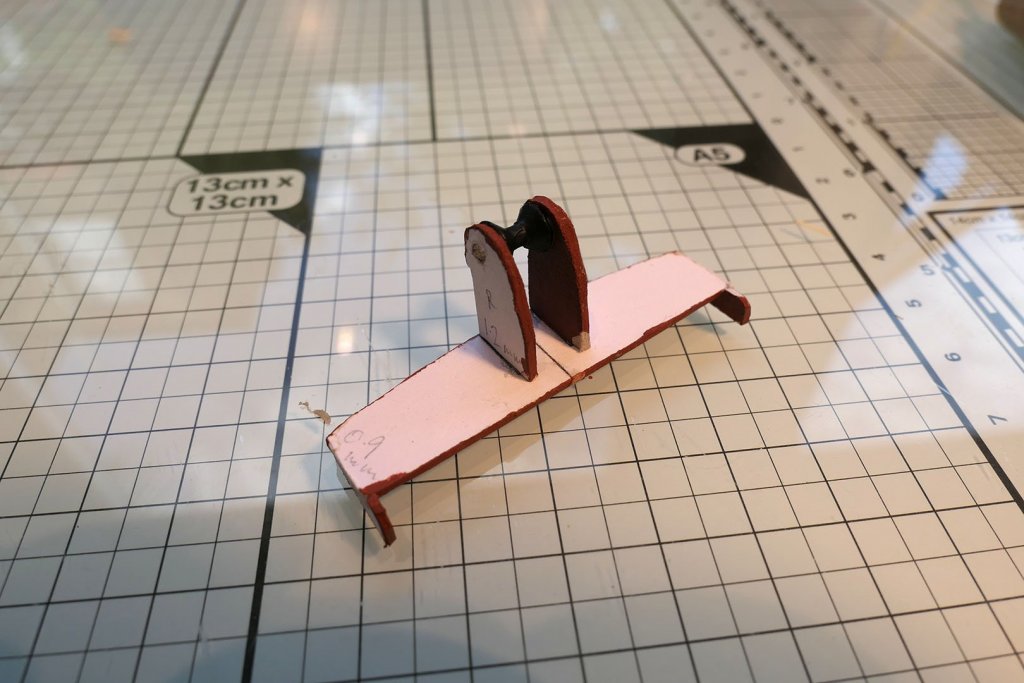

Rear Roller This was relatively easy to do. I cut a 3mm square length to a 2.6mm rod on the lathe, then tapered the central area with a file It should be noted that the roller is not fitted in line with the transom top timber, but between that and the transom. Ideally, a little axle would be fitted, but I just cut the roller to size and glued it in the appropriate position since the axle would be impossible to see and I wouldn’t want people to start rolling it just to prove a point. Washboards I had a nice load of offcuts from the 2x2mm frames which could be used for the washboard supports. The washboards at the bow needed bending, so I laid the wet cuts on a jig. I then had to build the blocks for the oarlocks. This proved to be a little tricky. I started doing it by hand, but this was hard on the fingers and didn’t produce a straight line easily. I soon found the answer with a vice. This turned the process into something very rapid indeed. Next up will be the bow roller, followed (I hope) with a whole load of the hull fittings for the rigging. This may take a while as I am involved in other work for the moment which is very time consuming. All the same, keep watching this space! Tony

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

Looking forward to this build. I like your Ballahoo. Tony

- 104 replies

-

- sherbourne

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks, Moab. That's a nice compliment. I do like these longboats and inshore craft too. I use TurboCAD DeLuxe 21. It was about £30 when I bought it. I can't really give an opinion on the learning curve. I did spend time looking at the tutorials on the web and asking questions on the TurboCad forum. My approach was to define the problem I needed to solve (e.g. loading a jpg, or tracing, or drawing a curve) and looking up how to do it. As a result, I found the process painless and cumulative. That way you don't have to set about learning everything at once. There's a wonderful set of tutorials on YouTube by Paul Tracey at https://www.youtube.com/playlist?list=PLbIC1X9V7KK9ayIcOfzdYm0h1AQOOTSKa, which I strongly recommend. I've tried quite a few CAD programmes, but the one I keep coming back to is TurboCAD. Other programmes might suit you better. You can do quite a lot with a photo-editing programme such as Photoshop, or an illustration package. If you work in Linux, there's Gimp and FreeCAD. I hope this helps, but if you want to know more, don't hesitate to ask. Tony

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

Thanks very much, Paul and Karl. I'm beginning to feel improvement in being accurate in my cutting. I just wish I'd been more careful with the start of the build, but then that's how we sometimes have to learn. I especially love the feel and look of the wood and the boat itself. Paul, I very much liked the pictures of your earlier Cutty Sark. That's a model I made from the Revell plastic kit when I was a teenager, and the memory of that stimulated me to think of taking up wooden ship modelling in my retirement. Your longboat, too, is beautifully finished. Karl. you'll see that I've posted a link to your absolutely superb build of the Chaloupe at the beginning of this log, and I am simply amazed at the level of craftmanship and precision you bring to all your builds, so I'm even more grateful that you give me a kindly nod in my early and novice attempts. Builds of such beautiful workmanship serve as great ideals towards which I can strive. Tony

- 124 replies

-

- longboat

- Chaloupe Armee En Guerre

-

(and 1 more)

Tagged with:

-

The simple way to obtain the length of the rope would be to pull your cannon as far back as you want and measure the resulting length. Tony

- 84 replies

-

- sherbourne

- caldercraft

-

(and 2 more)

Tagged with:

-

Just to add to Druxey's comment, have a look at these photos of the cutter Hawke I was shown in the Chatham Historic Dockyard (the same Hawke, I think, that was shown in a better state in the AOTS book on the Alert). The curator thought it must have been the result of a handler knocking the model against something and then hurriedly trying to 'repair it' in what he thought was the correct way. He groaned when he saw it brought from the store. However, I don't think anyone seeing this would think of it as historically accurate because of being contemporary. You can see the remaining photos in the gallery at Tony

-

I agree with Frankie that there are many inaccuracies in Petersson's book. However I found it invaluable as a simple guide to the names and principles of rigging. The reason is that it separates each aspect and its function which, for a beginner who has never sailed, is really helpful. Of course, as soon as I started rigging I went to Steel and Marquardt as well as others to make it more accurate, and I received really helpful criticism on this forum when I made mistakes, but without this beginner's guide I would have been lost in the complexity of drawings and explanations that are so often provided. Tony

-

Thanks, ragove. If you search for 'CARD' in the scratch building forum, you can see what can be done using card for ship models. Try Doris' posts, as well as GrandpaPhil, Ab Hoving, Chris Coyle, and several others. Then there's lots who do wonderful kits from card in the kit building forum. They're all way ahead of myself and their builds stimulated me to try a card model just to see how it is done. I might well come back to it once I've improved my skills on wood. I don't want to reach ahead of myself! Tony

-

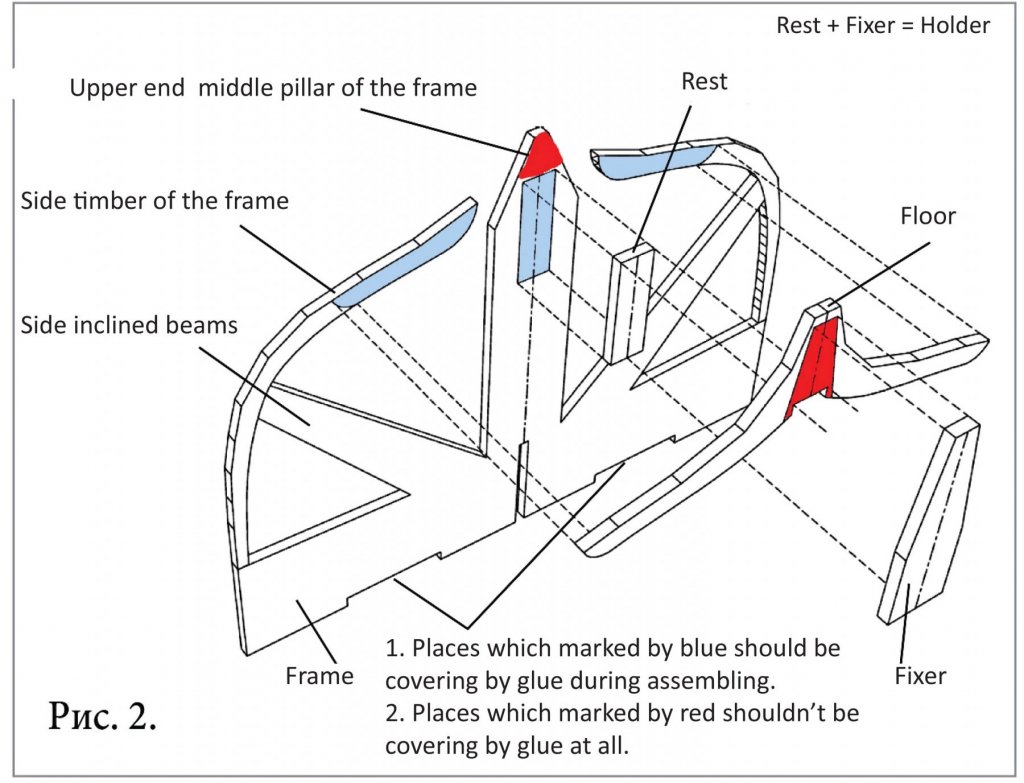

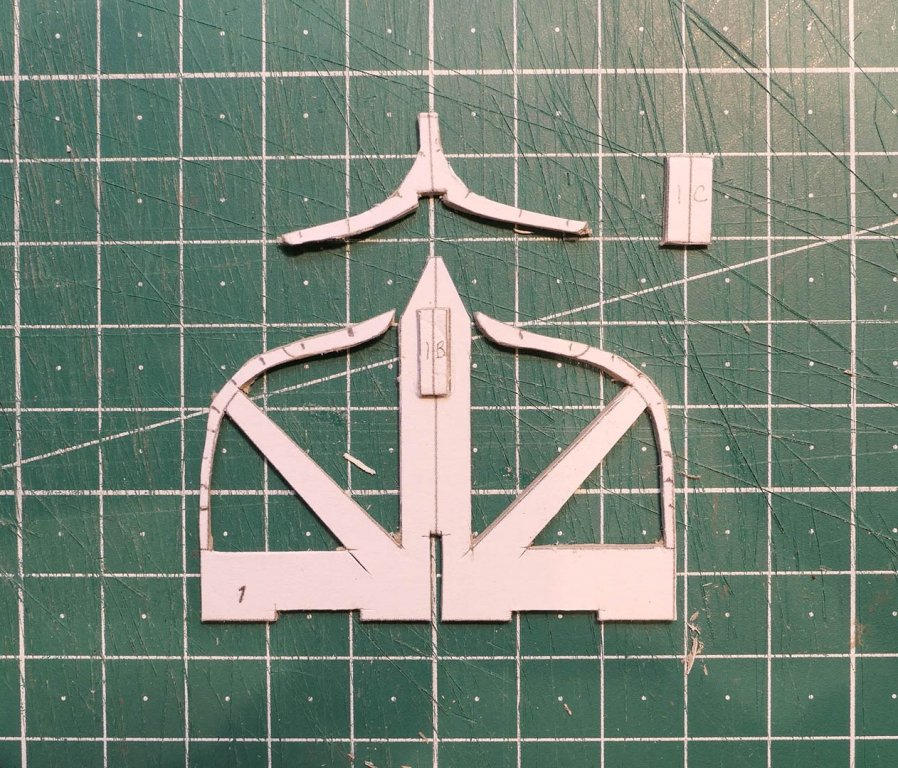

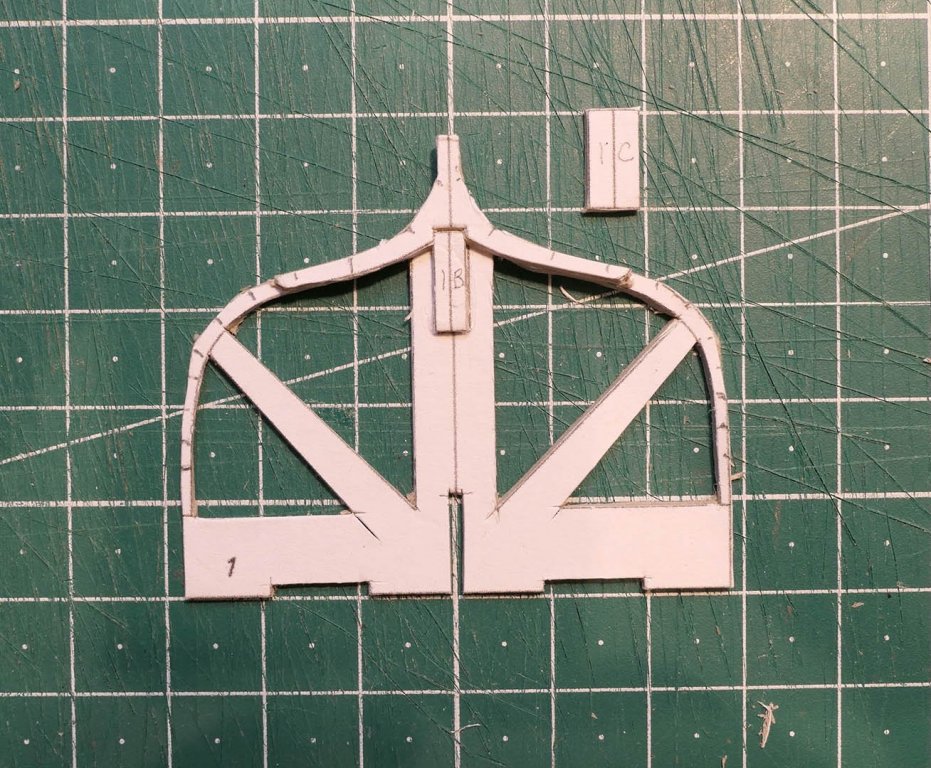

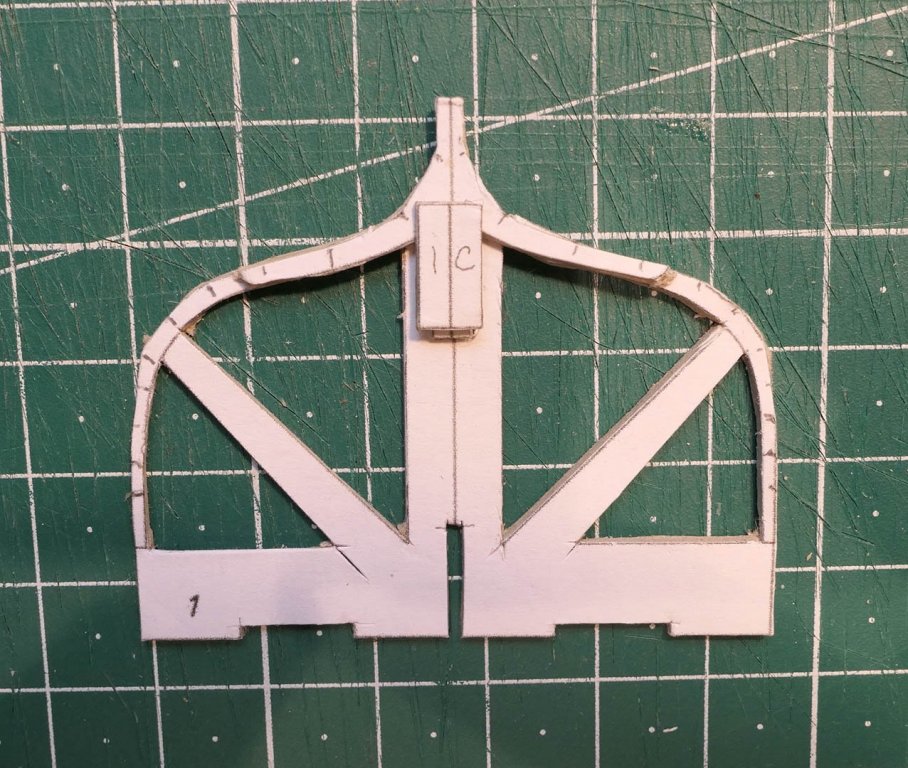

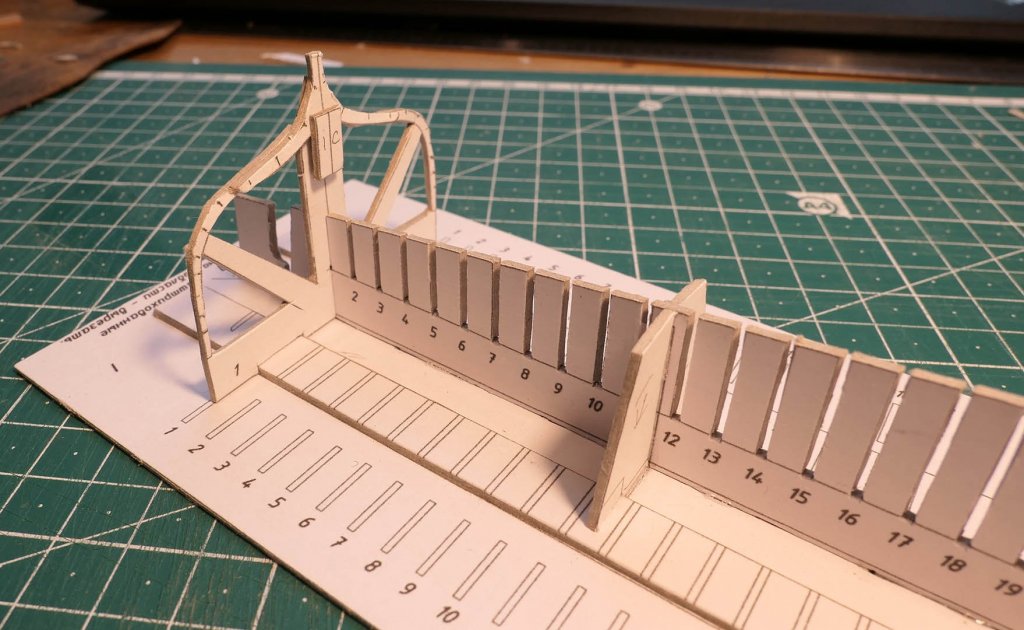

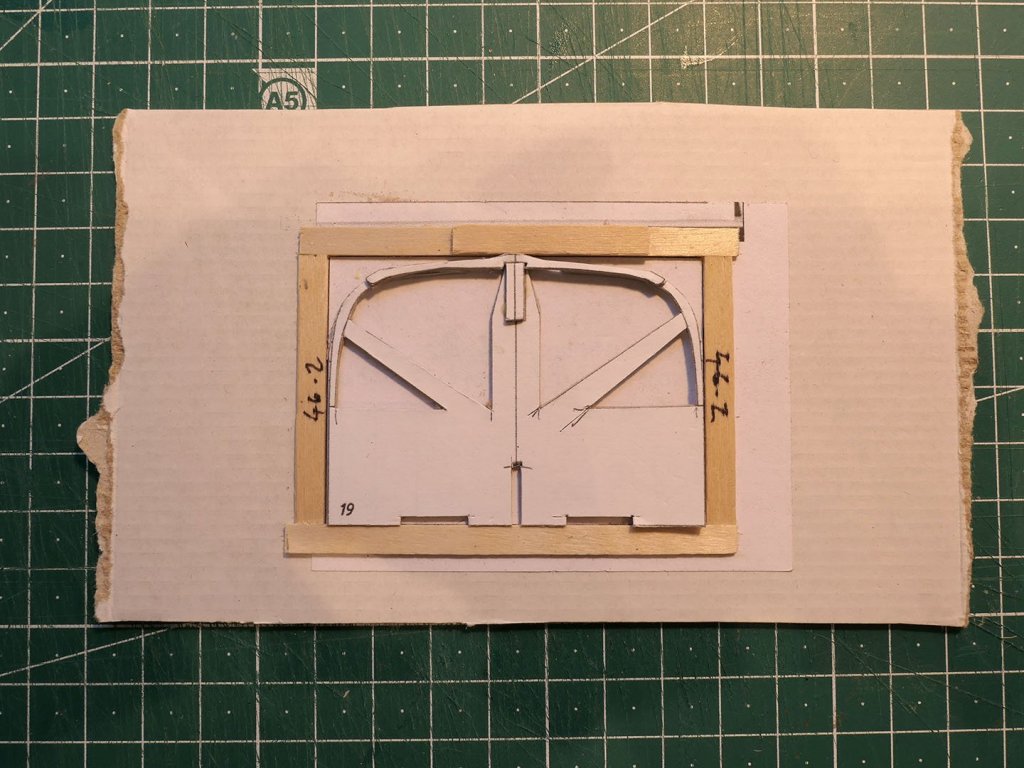

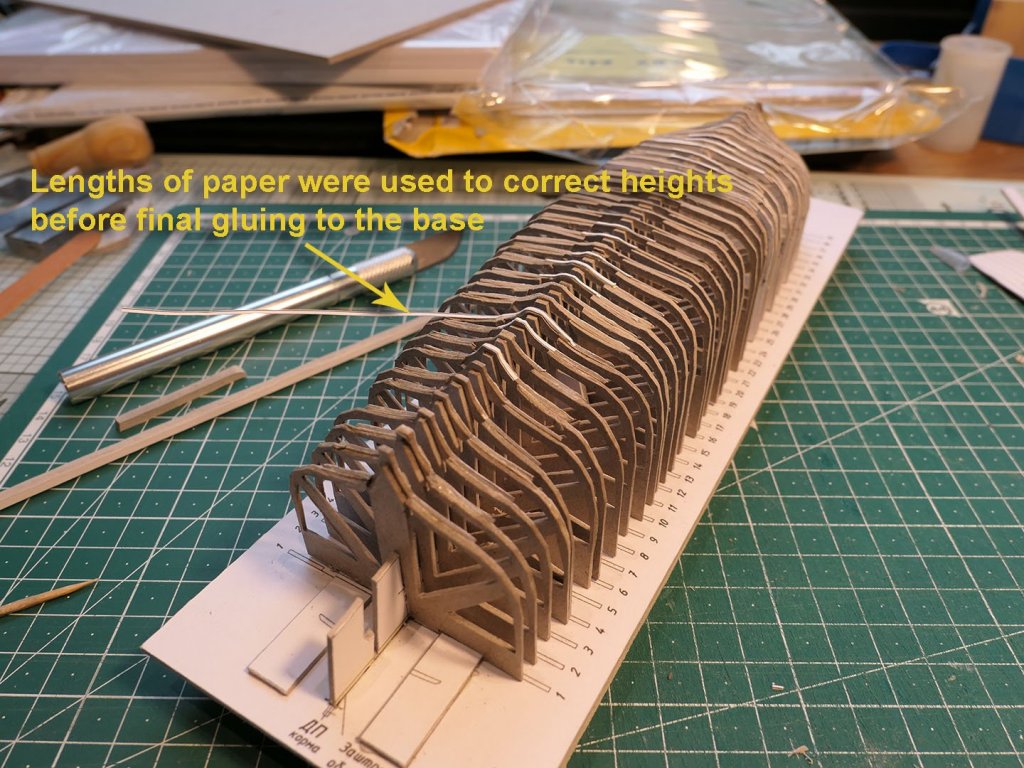

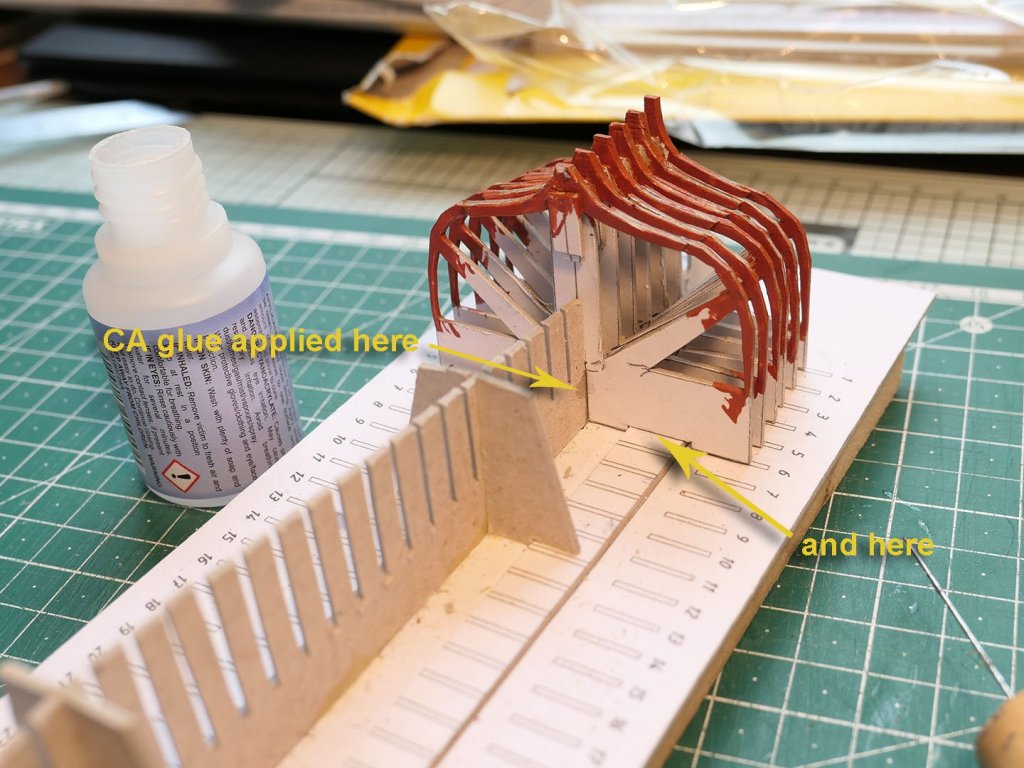

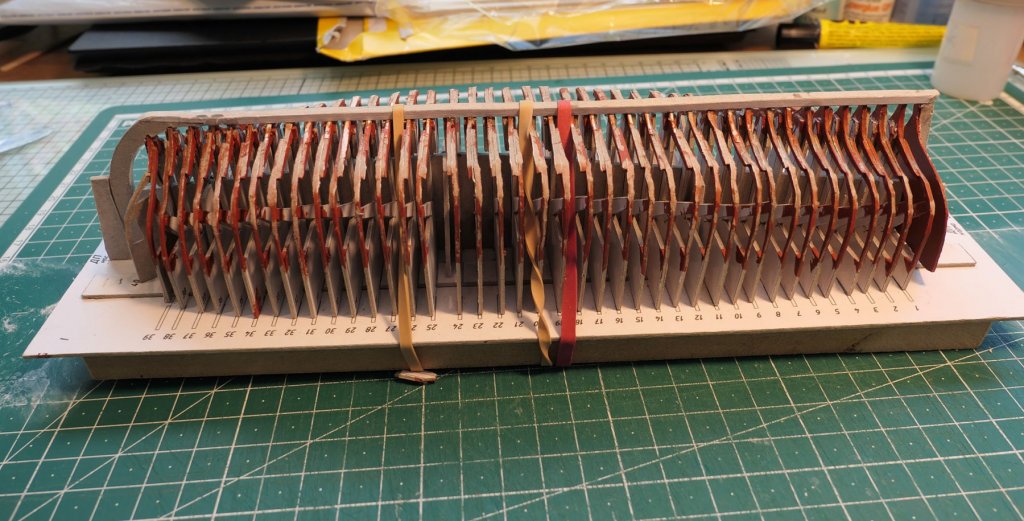

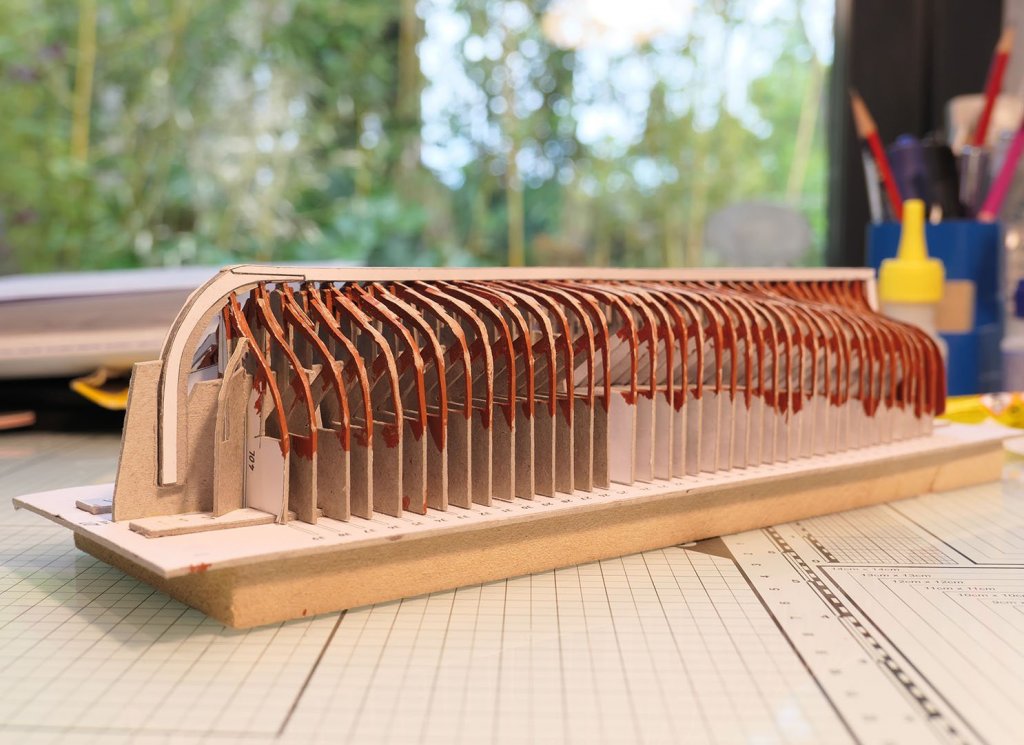

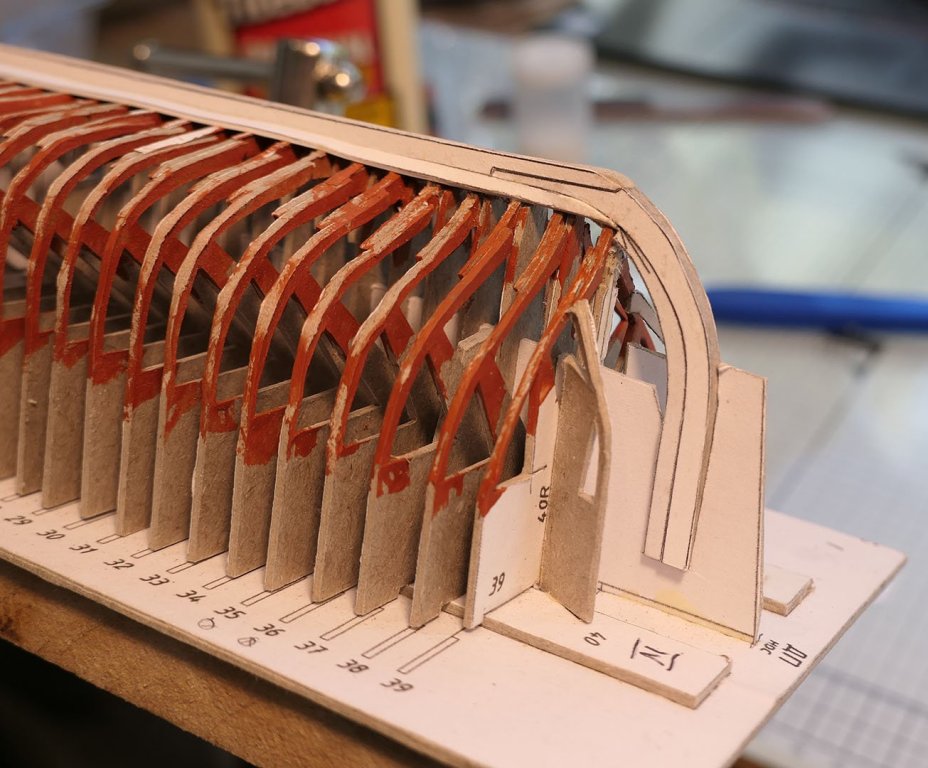

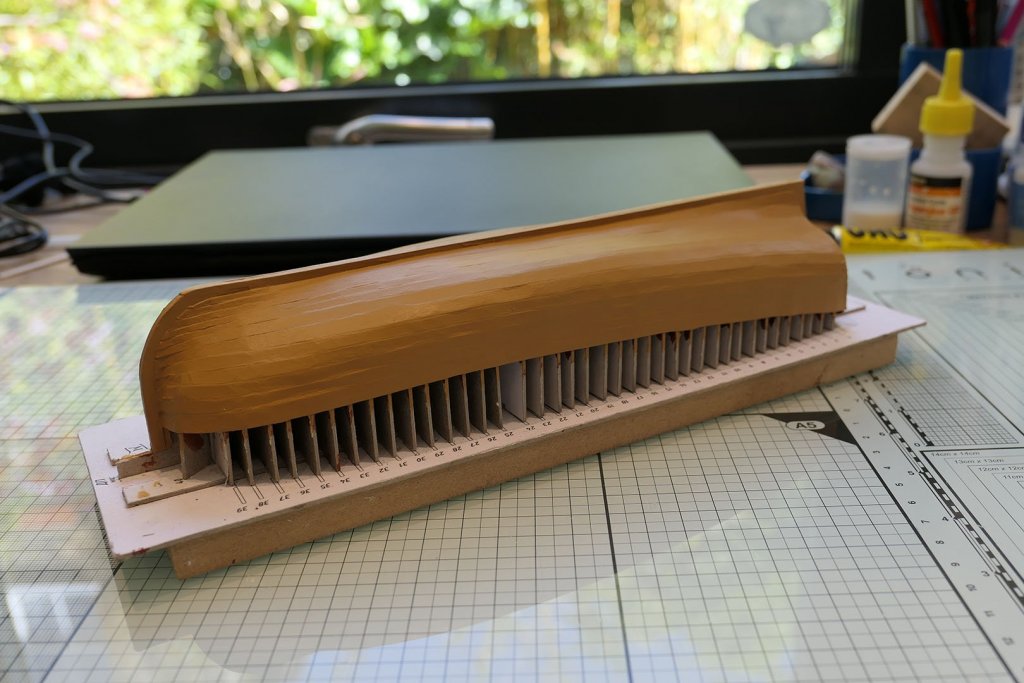

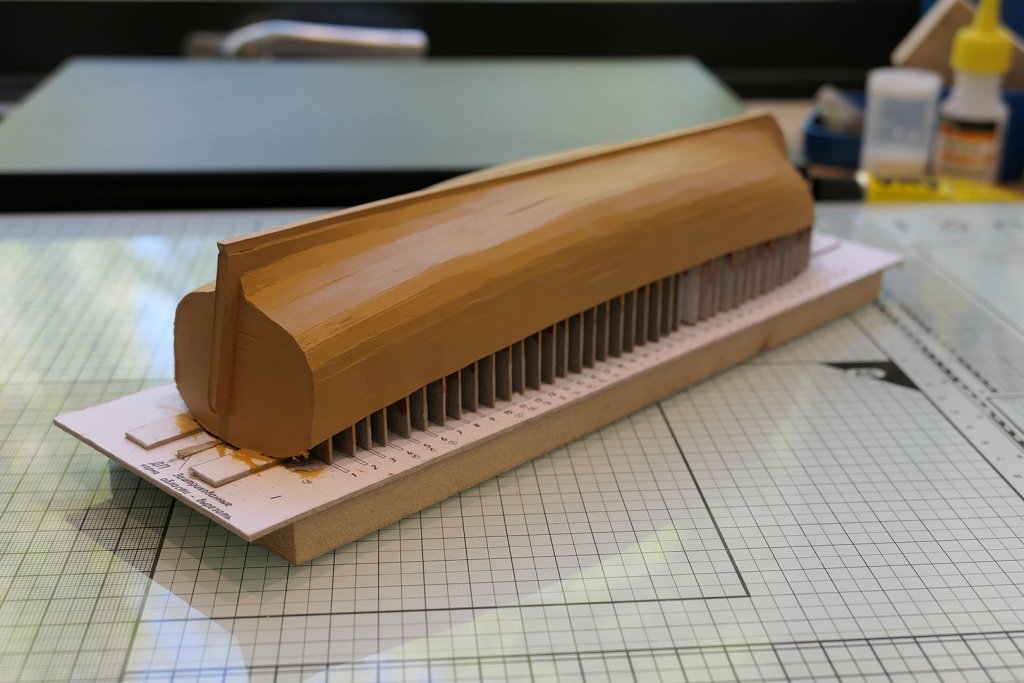

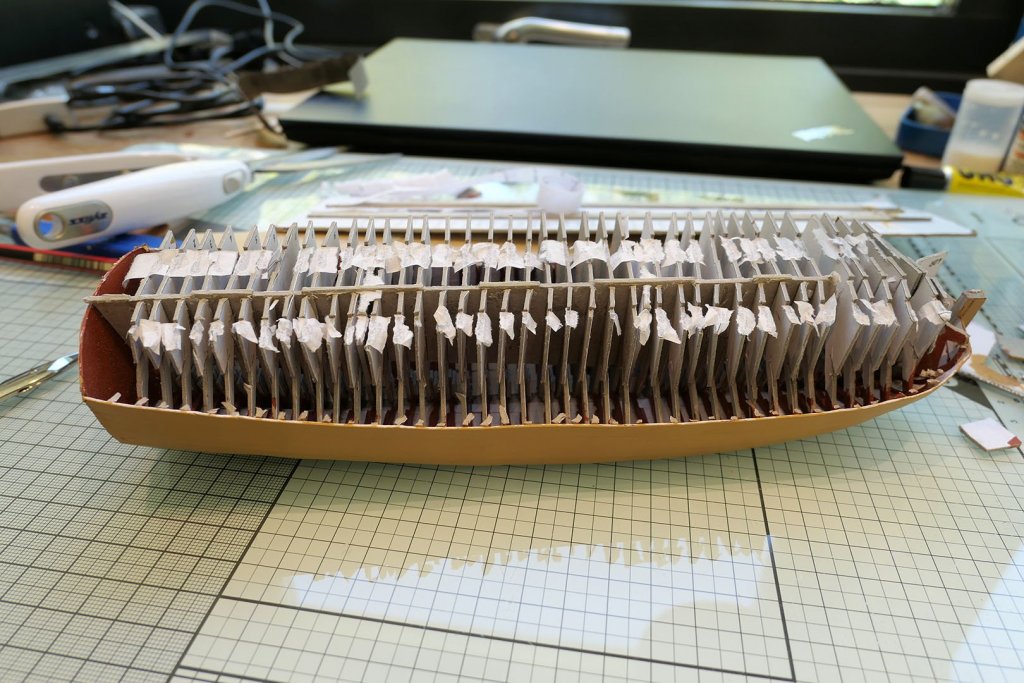

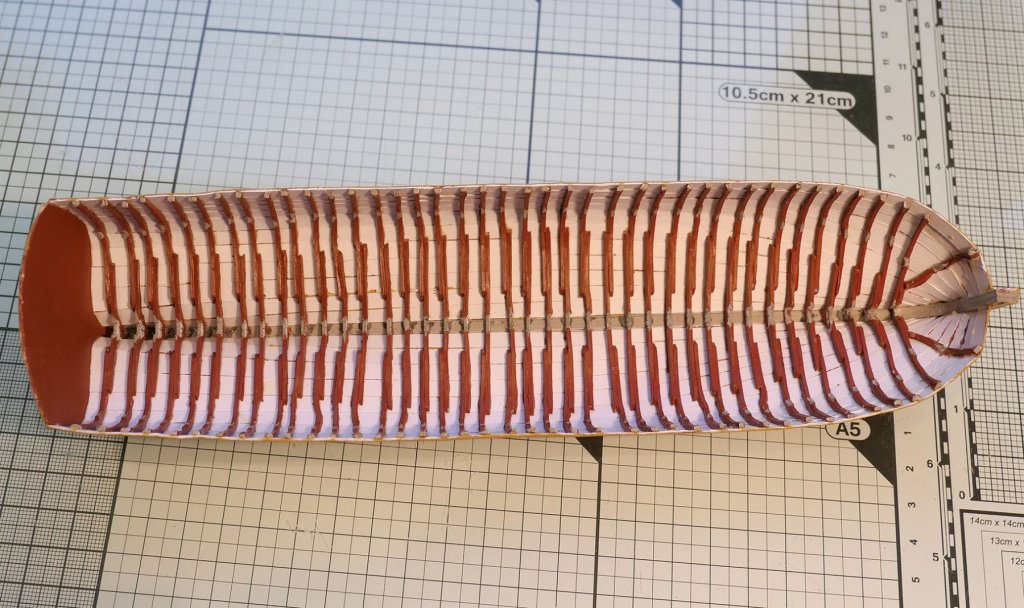

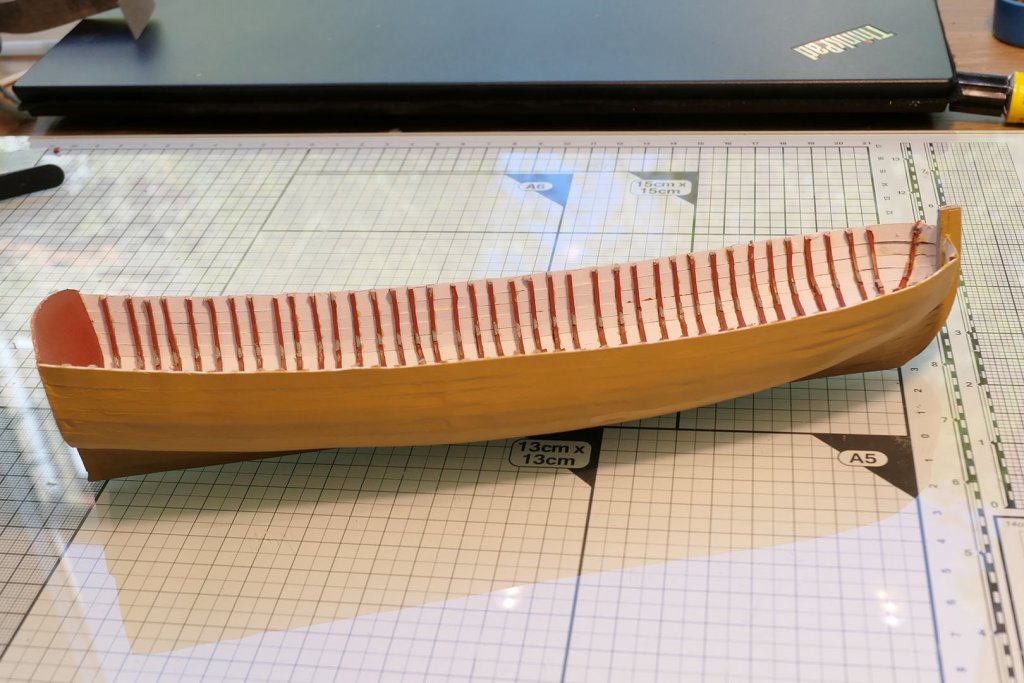

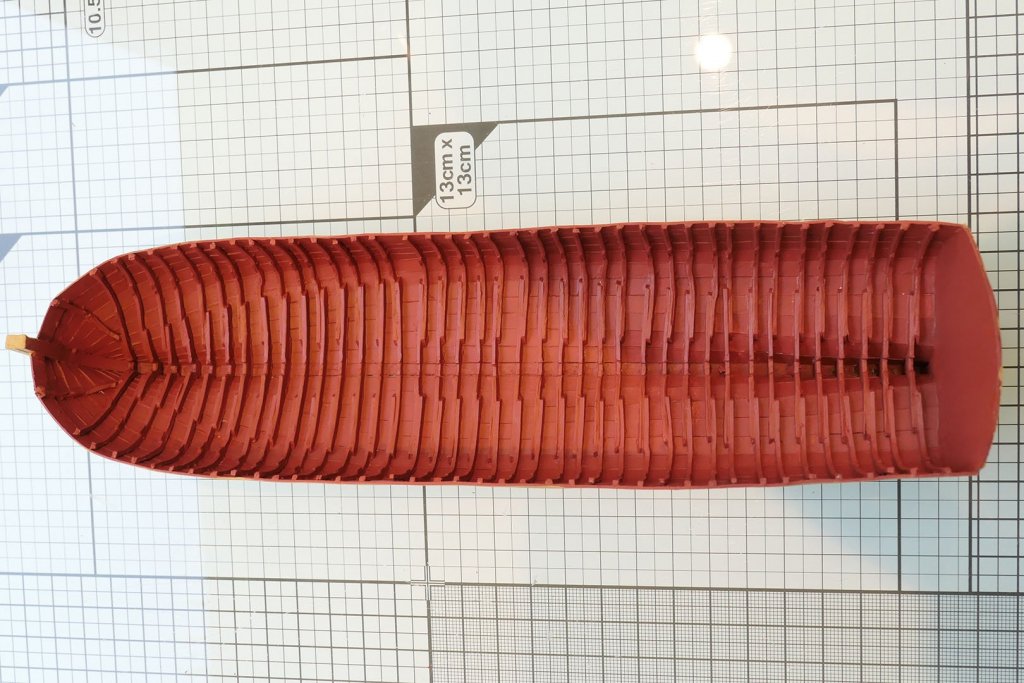

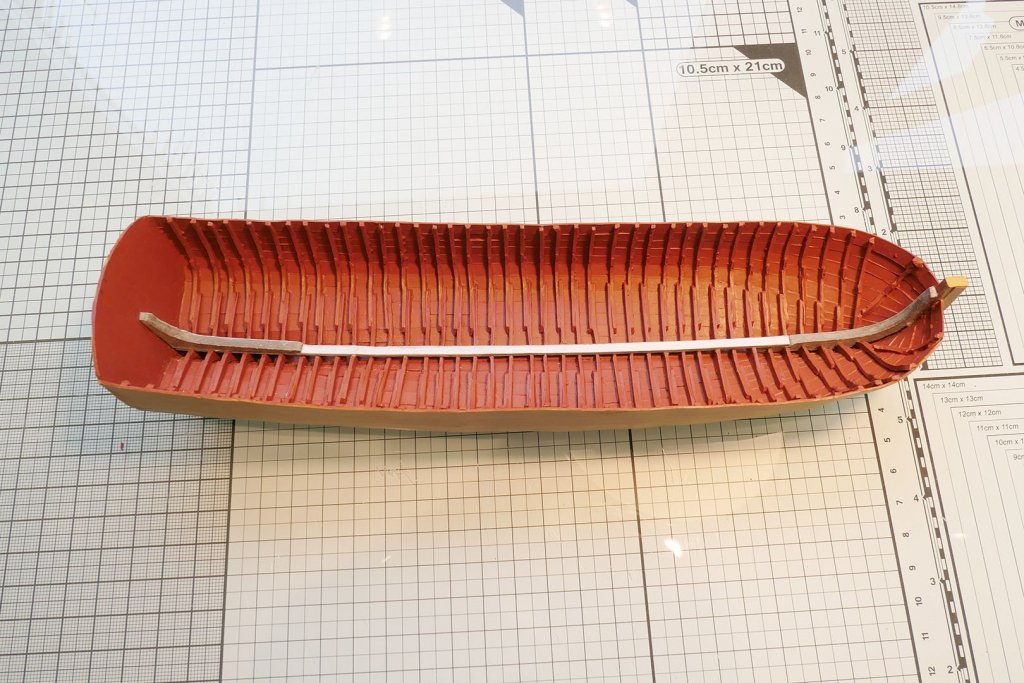

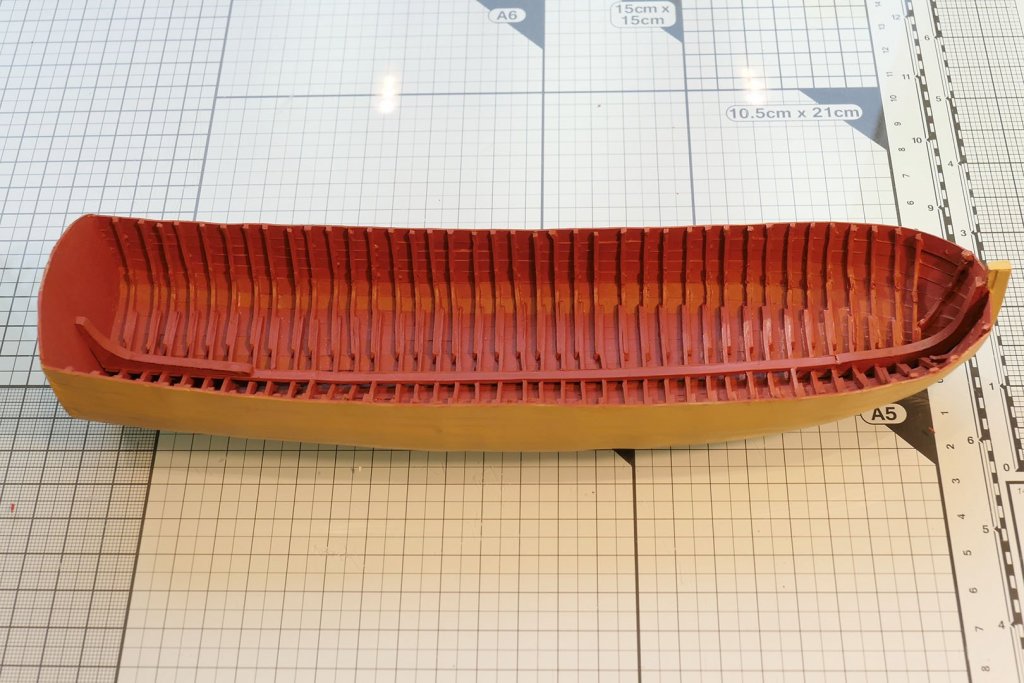

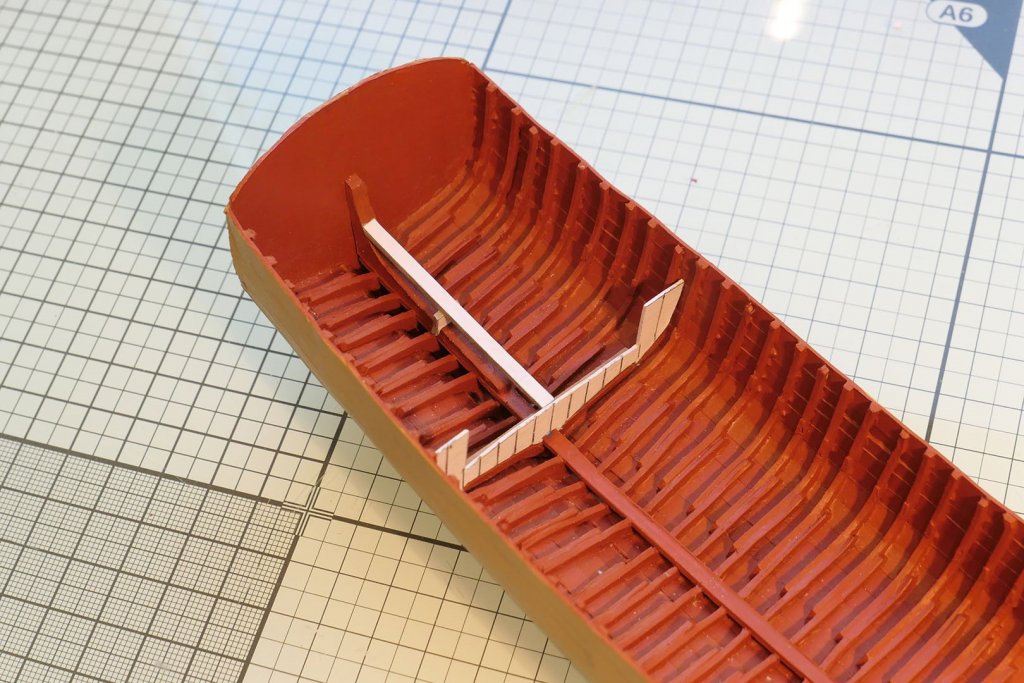

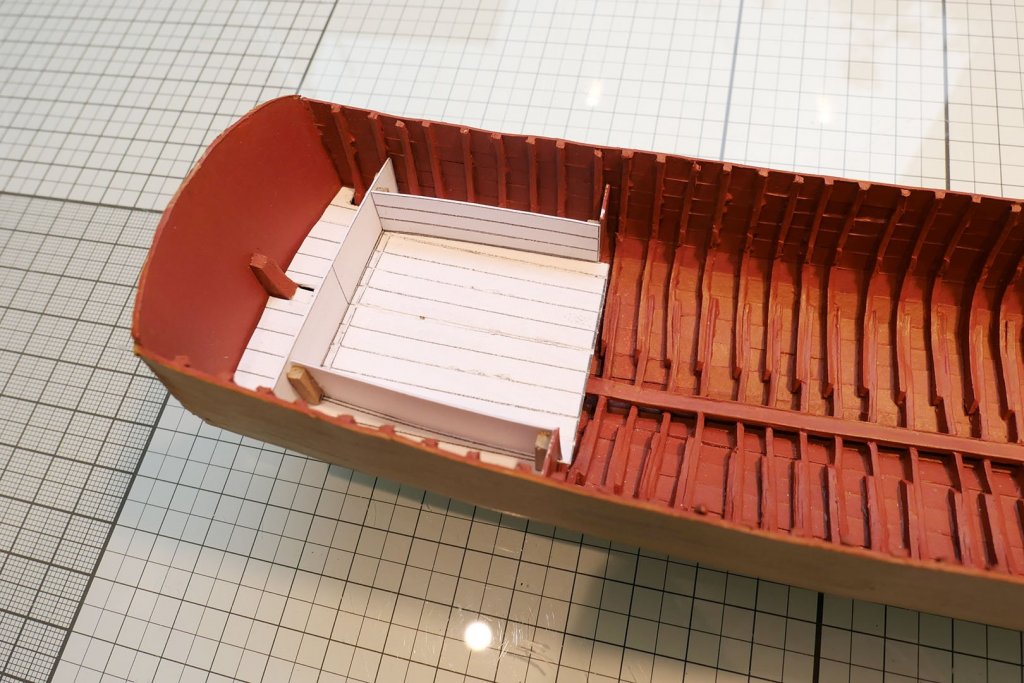

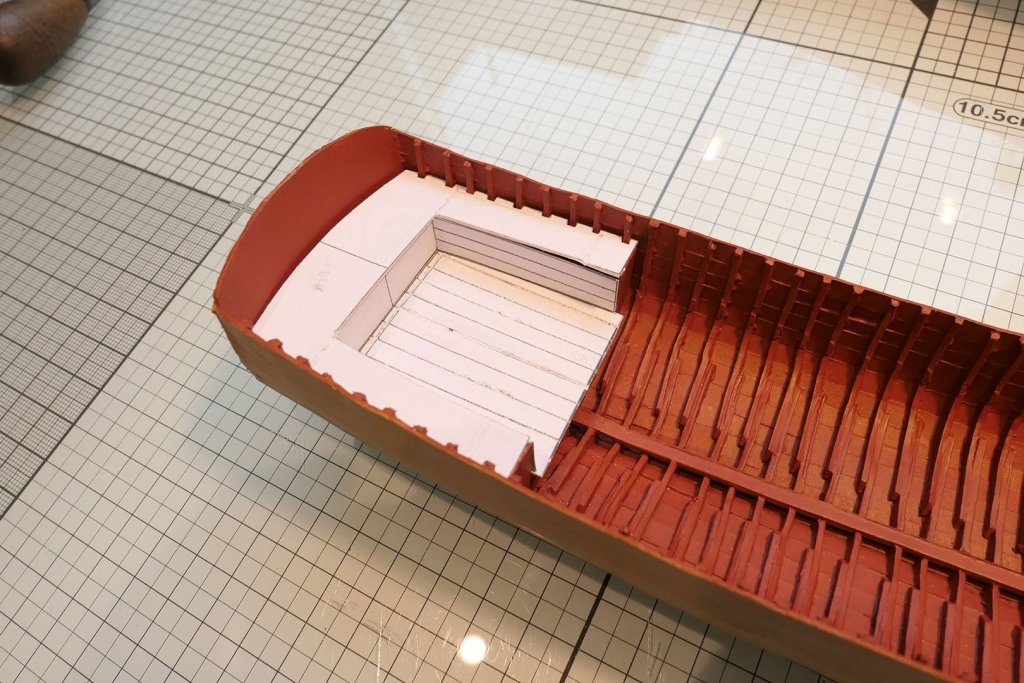

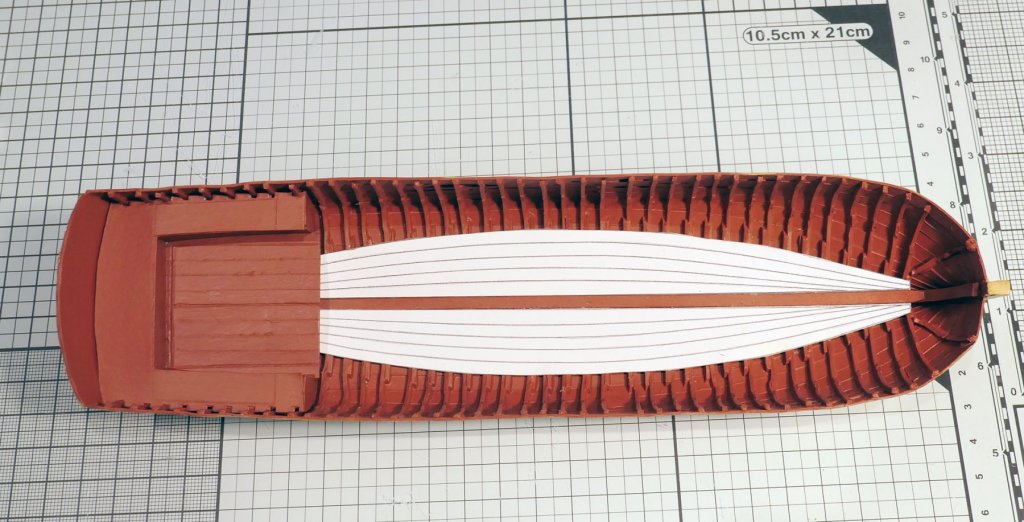

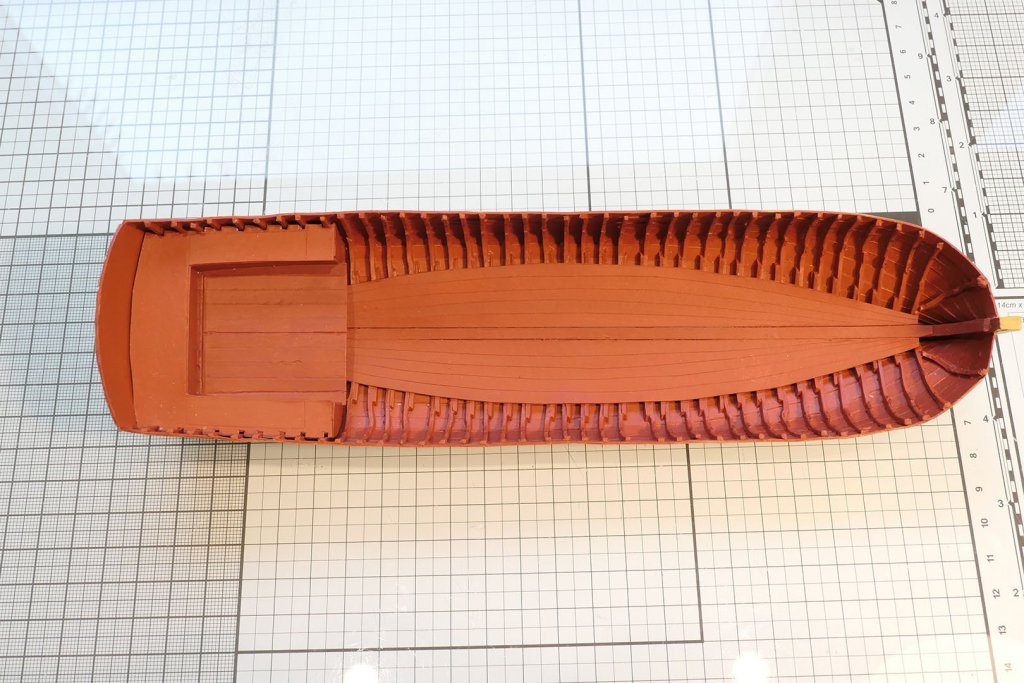

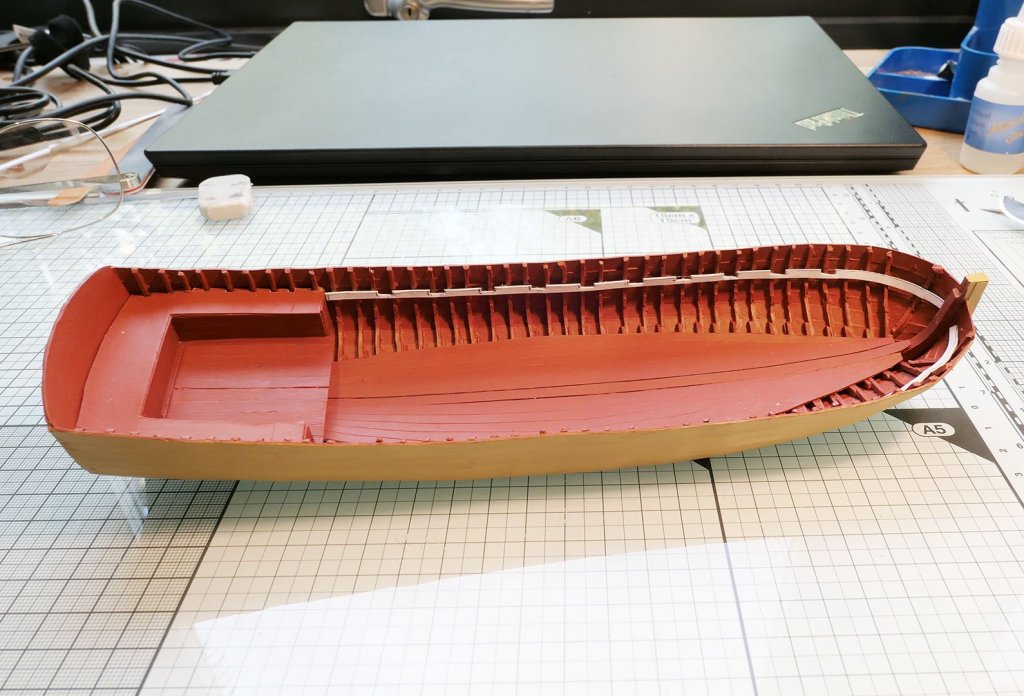

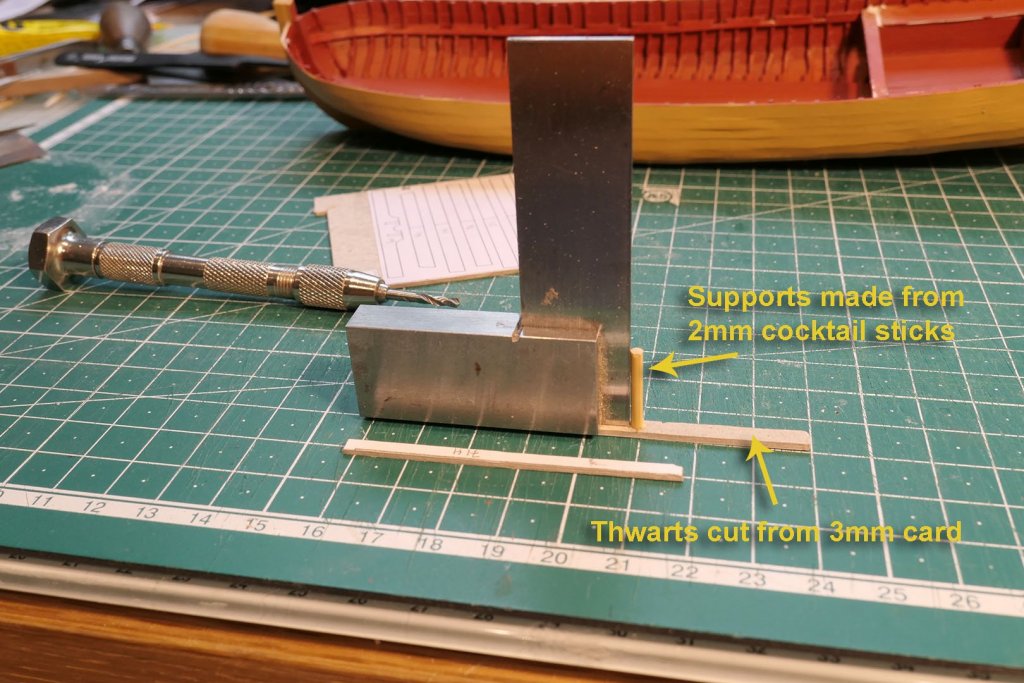

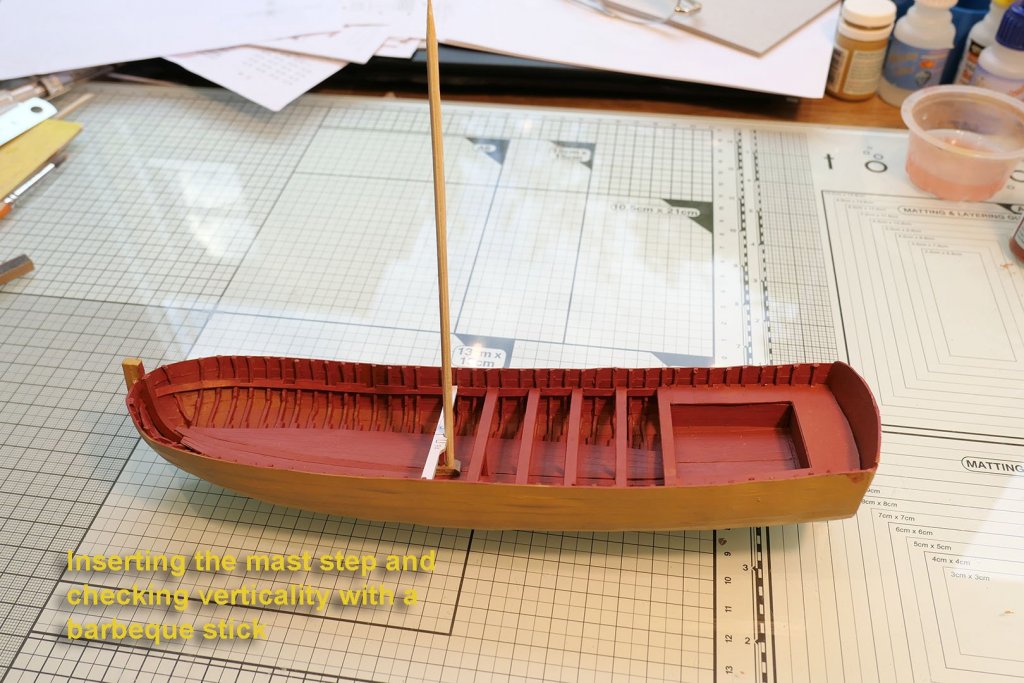

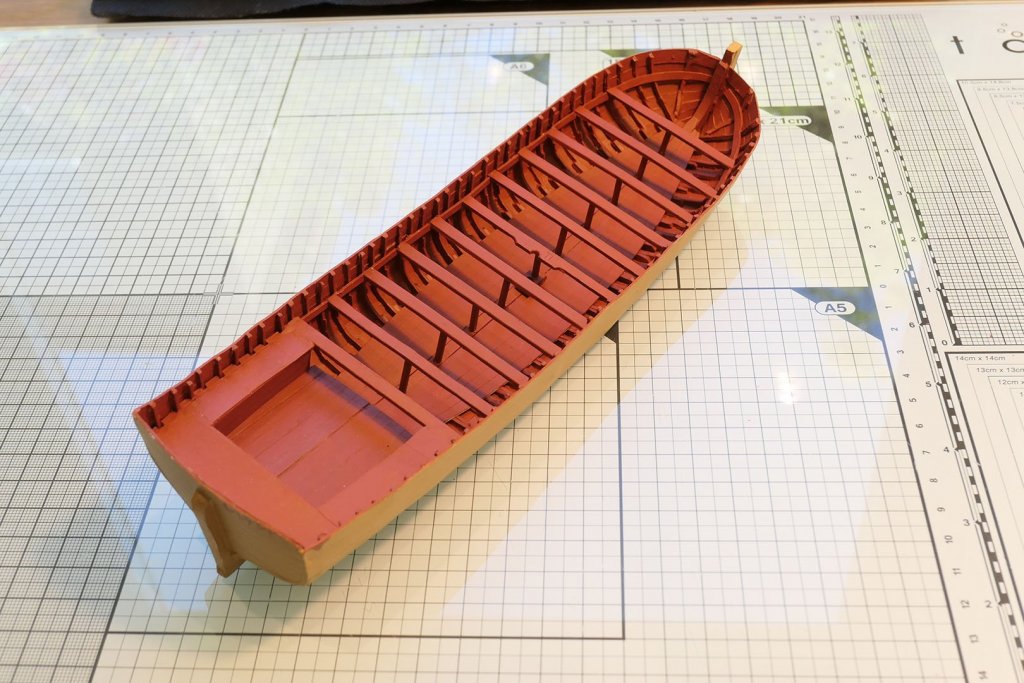

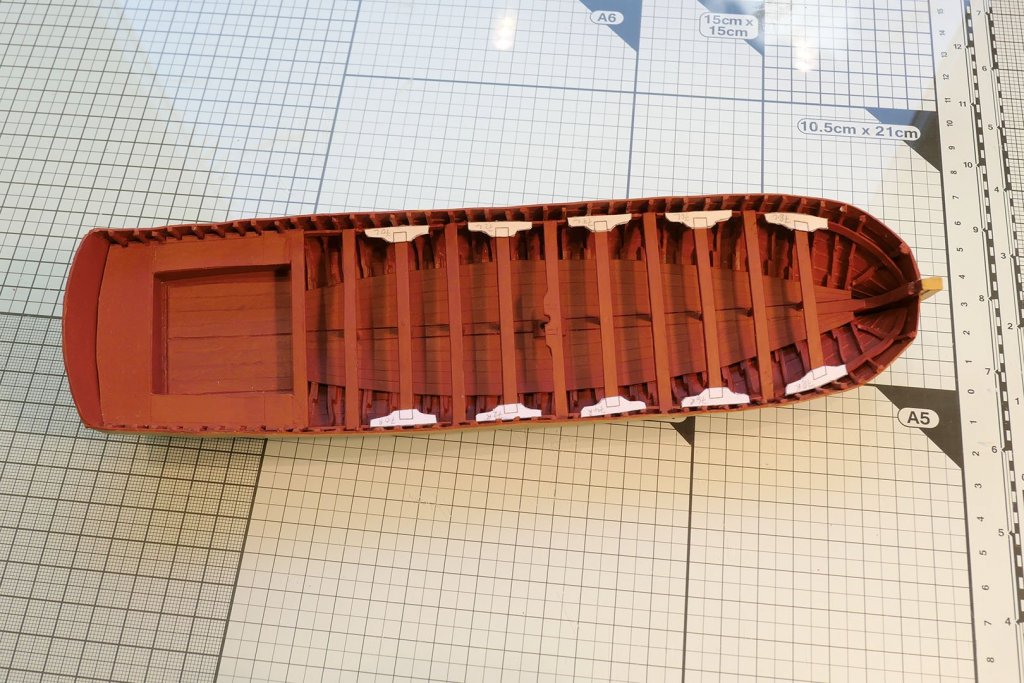

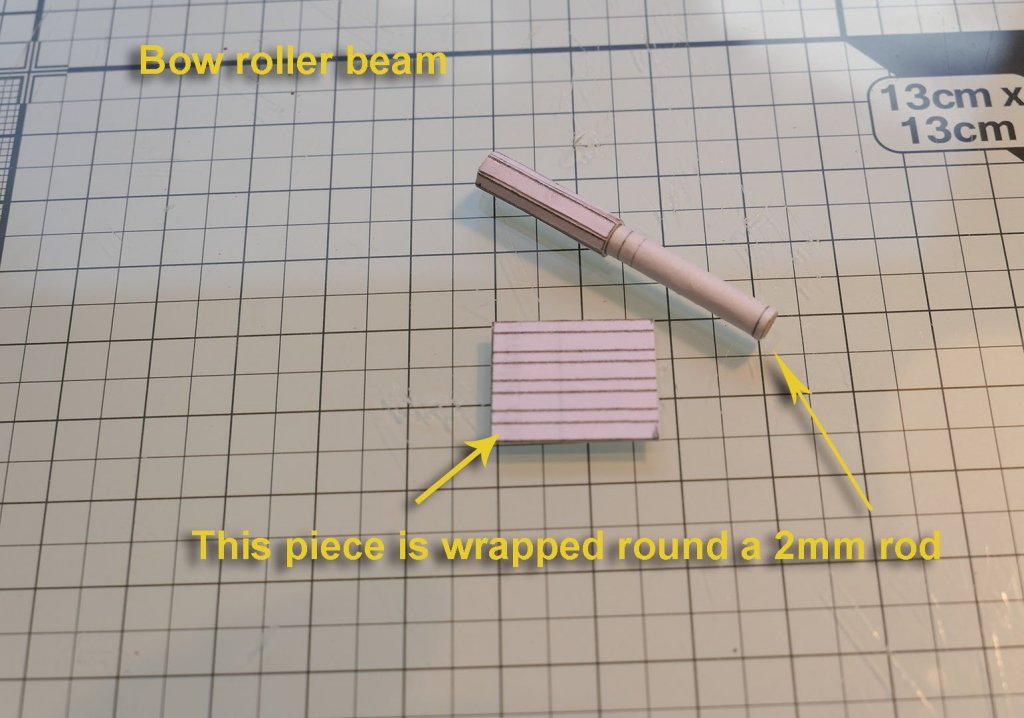

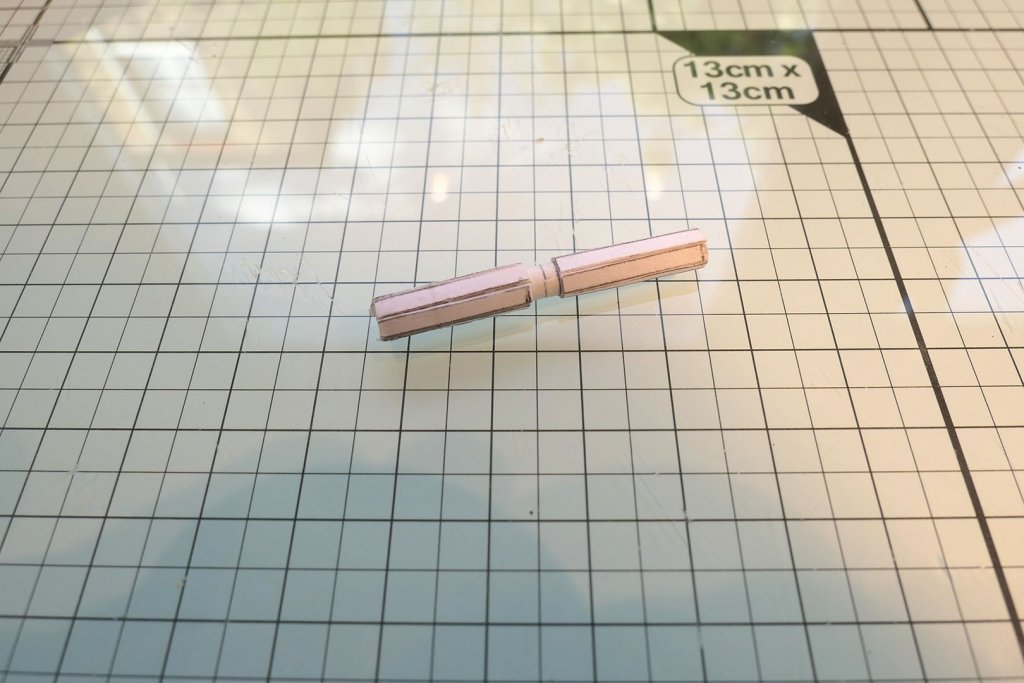

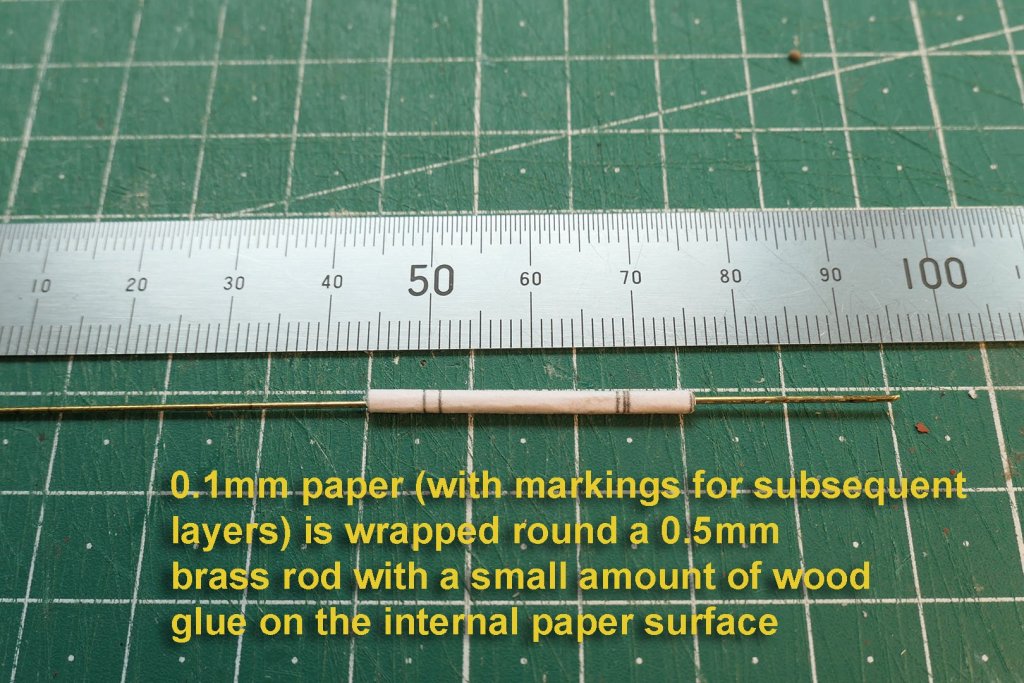

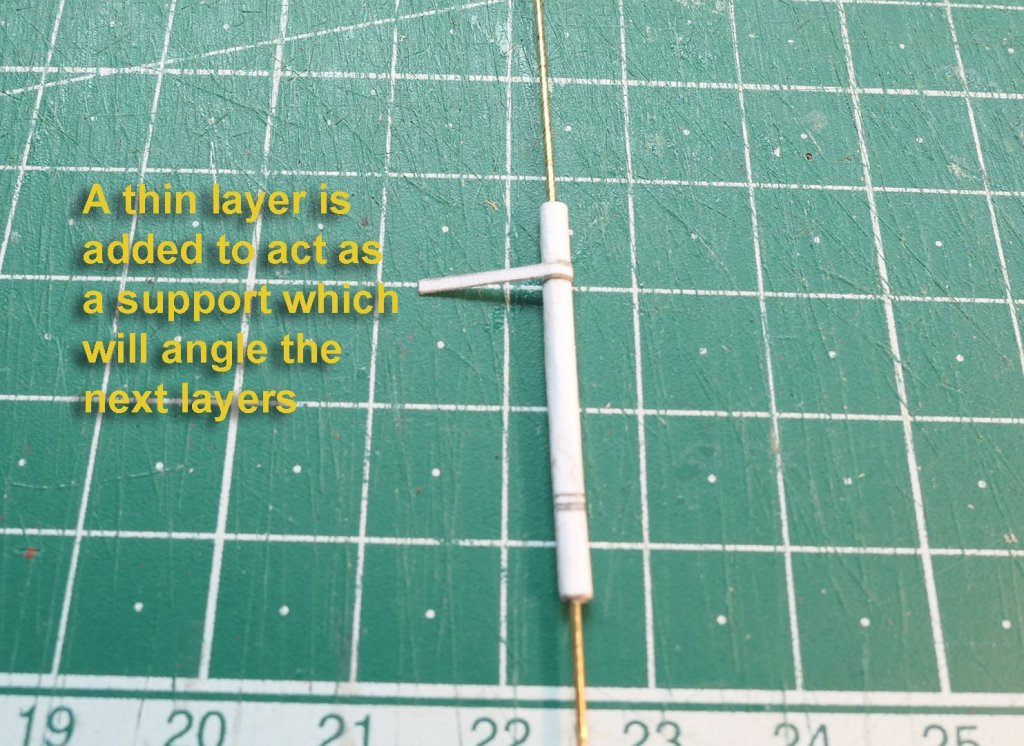

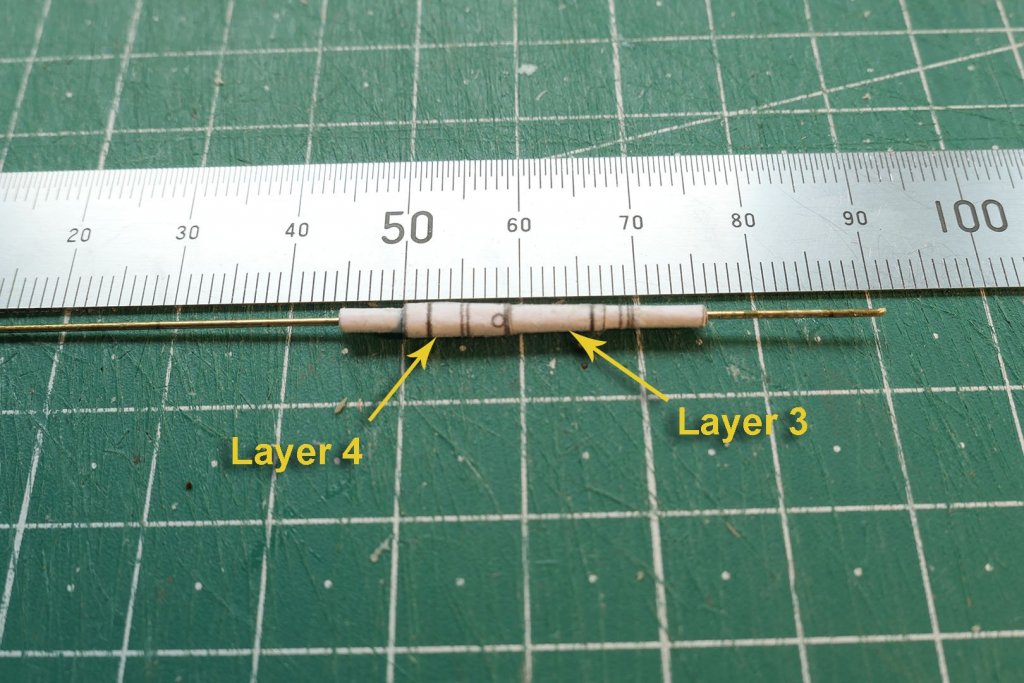

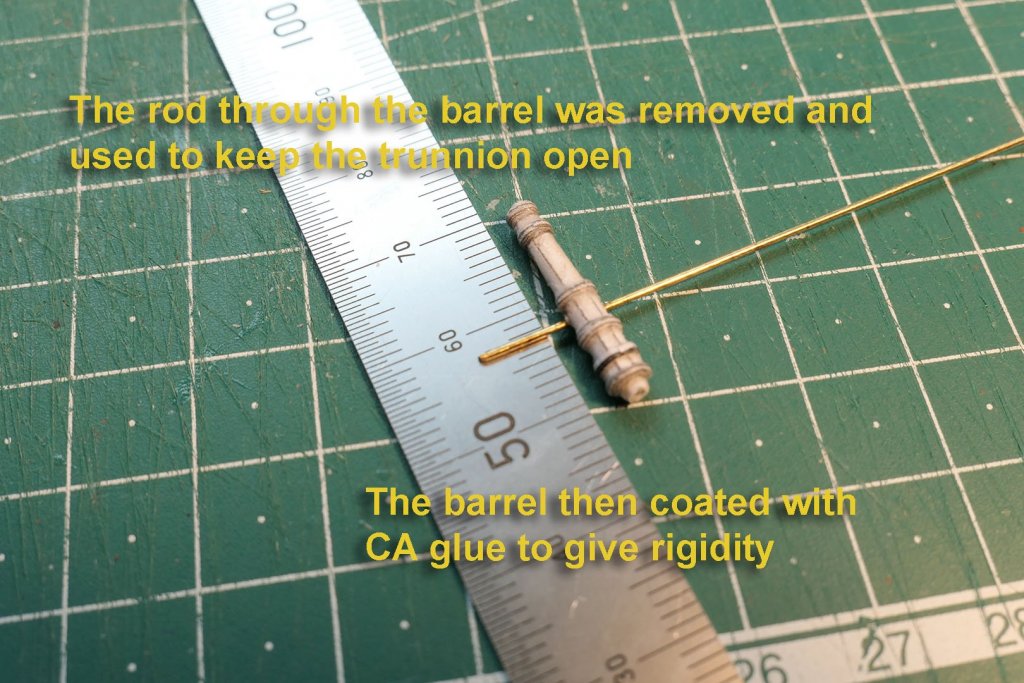

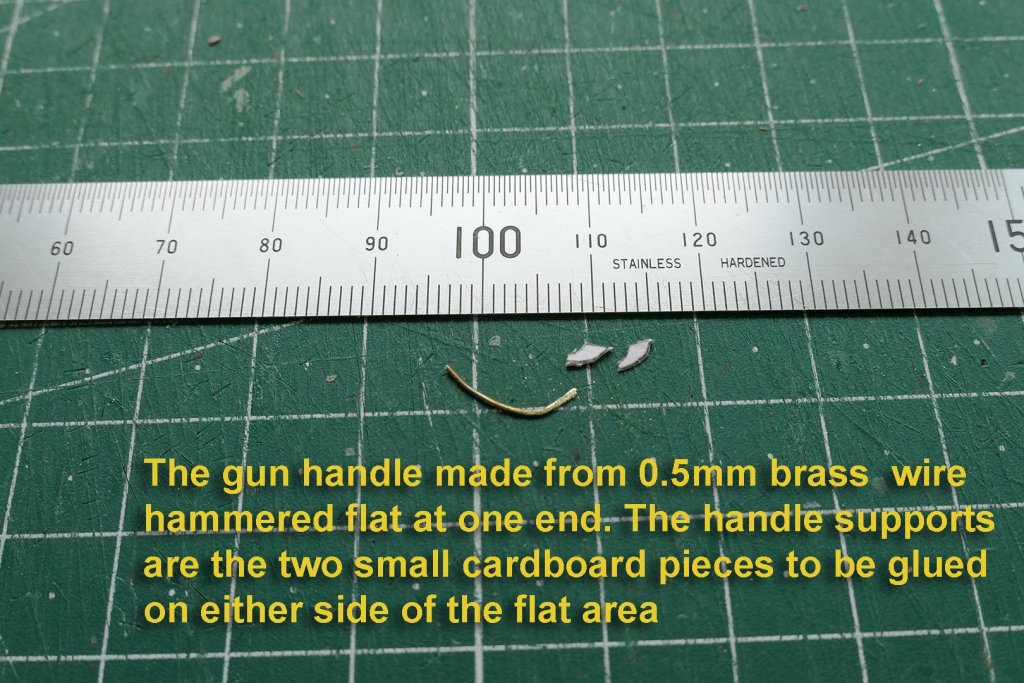

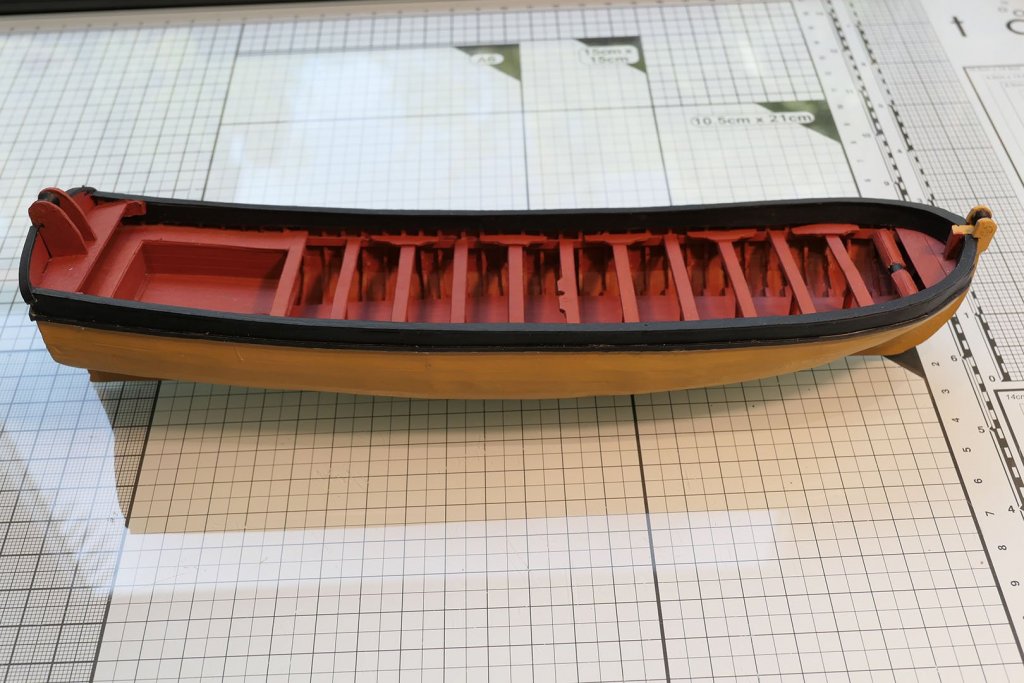

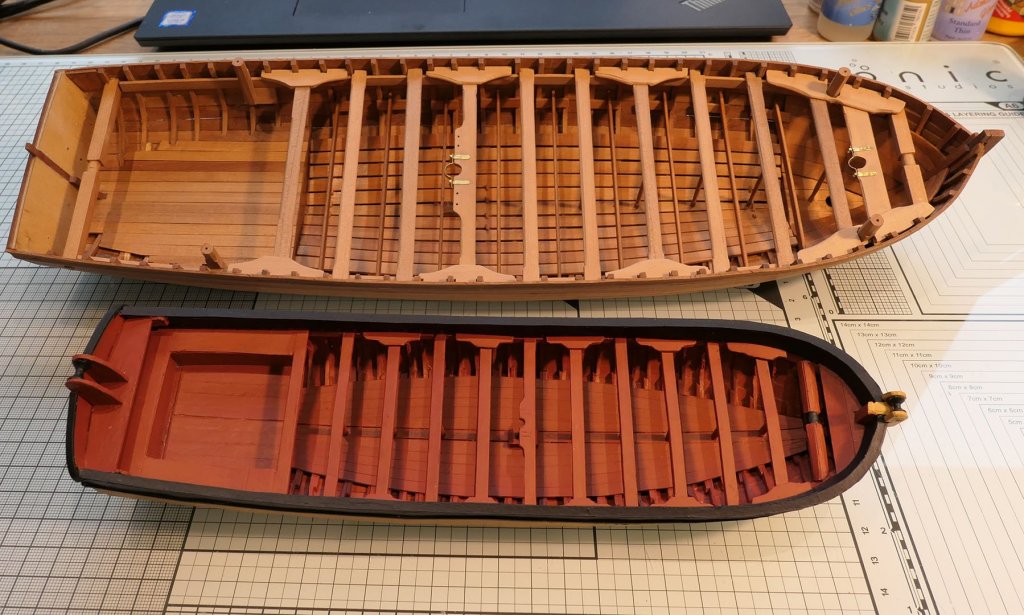

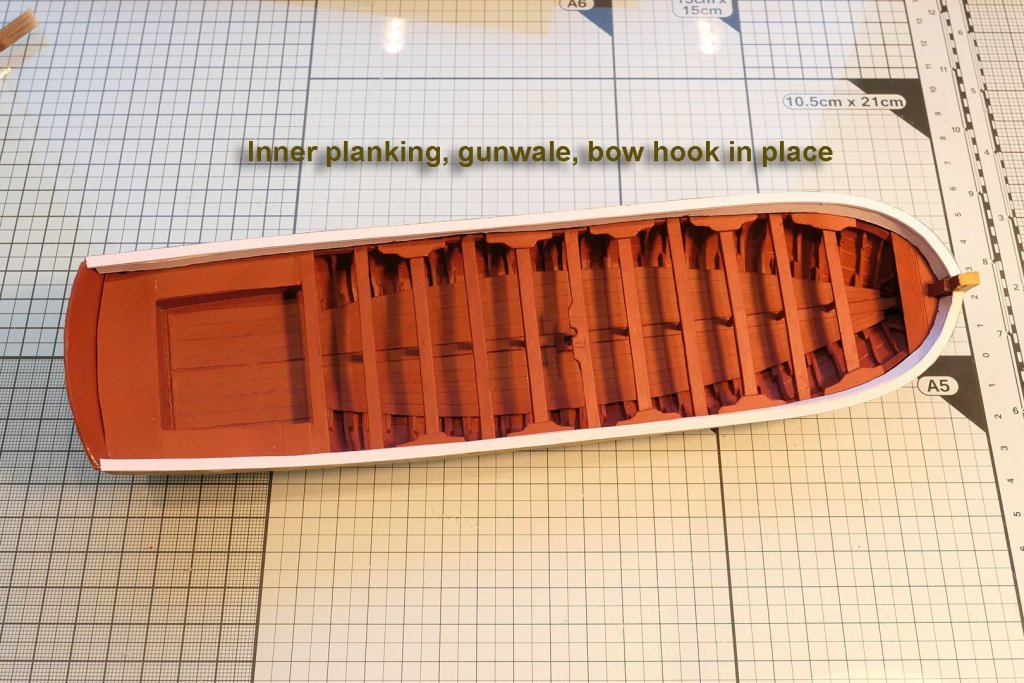

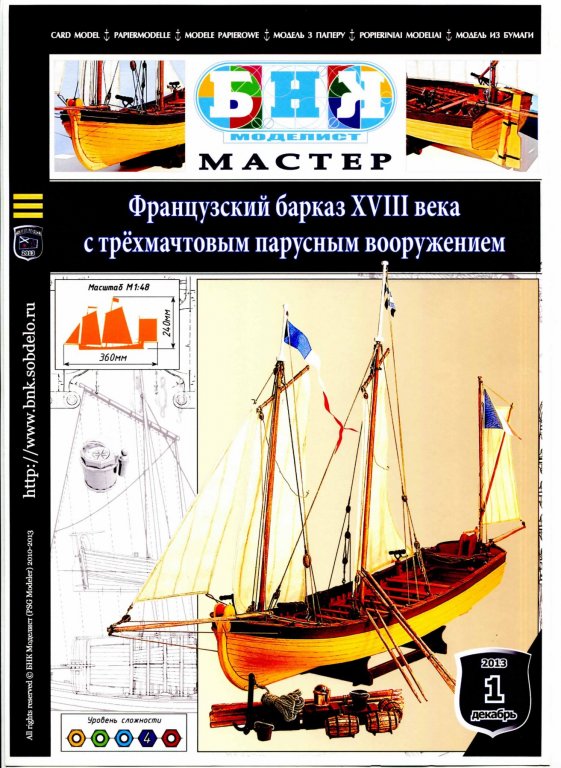

I bought this kit after seeing completed builds on this and other sites. It is a model designed by Daniel Dayn Vishnevsky-Karlskhagen and I was intrigued to see how a longboat with its small frames could be built from card. It uses the same principle as the wood kits for longboats: frames supported by an internal plate which is removed after the external planking has been applied to the frames. The kit is low cost (I spent about €25 which included postage from Russia to the UK) and has excellent instructions. The only problem is that the instructions and guide are all in Russian (albeit with very good and useful illustrations), so I had to work hard using a variety of sources to translate it all into English. See my post on Russian translation and the resources used at and previously in my Chaloupe Armée build. For those who buy the kit I will be very willing to send them the translations of the instructions with the parts list. I have done the translations as a table with the original Russian in the left column and English in the right-hand column. I also have made a table or dictionary of Russian nautical terms used in the guide which goes with the parts list. I think you can only buy the kit from the author, whose email address is bureau.k68@gmail.com. You can see his full build of the original on the Russian forum at http://only-paper.ru/forum/85-12867-1, and you can see his discussion about it (in English) on the papermodelers forum at http://www.papermodelers.com/forum/ships-watercraft/27125-french-longboat-xviii-cen-most-large-pinnace-tree-masts-sails.html?highlight=planking . Because my interest was mainly in the method of construction, but also because I was prevented from continuing with my build of the Chaloupe by recuperation from surgery, I only built this model as far as completion of the basic boat without any masts or additions such as anchors and cleats. My main purpose in providing this Review/Log is to bring the attention of a really interesting kit to others on this forum who are proficient in card modelling or who just wish to probe it (as I did). I would rate it as fairly tricky but very rewarding. What’s in the kit? In addition to the guide and parts list, the parts themselves are printed on standard A4 photocopy paper. There are several sheets of 0.3mm card which can be multiplied to provide various thicknesses. The list of parts also details how thick each part should be. An interesting aspect of this kit is that the card comes in three colours: white, yellow ochre and red ochre. This is to allow you to make the model with a minimum of painting. A really nice feature of the kit is that plans are also provided for you to make all the masts, yards and fittings as well as accoutrements such as barrels, buckets, cleats, hooks, belaying pins and oars. A full rigging and sail plan is included, with directions for the varying rope thicknesses. Finally, the author has a practicum with colour photos which he will send you (in Russian). The base The first thing to make was the base. This is really sturdy, and, as with all the pieces, requires accurate cutting out so that the frames, when inserted, fit exactly. You’ll note in the photo the Swann Morton scalpel with a no 26 blade I use which I keep sharp by stropping after every few cuts. You can get the idea of the frame assembly with the following diagram: It is clear that you have to be very careful with where you place the glue if you want to remove the shell from the assembly later. But you can see that it does replicate very neatly the framing structure of the boat with floors and futtocks. You can see the assembly sequence in the photos below. The guide points to the fact that all but three of the 40 frames have the same height, so it is important to have a method of making sure that the height is correct. I built a small jig to build most of the frames, but later on just used a slide rule to check the heights. Despite all this my measurements were frequently incorrect and I had to adjust several frames by filing or gluing on various thicknesses of 0.1mm paper. Because the frames were made from grey/brown card, the instruction was to paint them with red ochre. This I did, but regretted because (a) I painted it on too thickly and (b) later on it interfered with the gluing. You can also see how the paint covered the holding frame – which I then had to separate from the floor with a scalpel in order to ensure I could remove the frames from the mould. Actually, after finishing the entire 40 frames, I was so dissatisfied that I made the model again, base and all, to this stage again, but being more careful with glue and paint. I don’t have photos of the second frame and mould, so you’ll have to make do with the photos of the first attempt! Stem, keel and stern timbers were then cut from 3mm card, glued and the assembly held in place with rubber bands. Planking I then laid the planks. I could have used the coloured card supplied in the kit, but I elected to use my own card which I then painted with yellow ochre. The spiled planks were beautifully accurate as printed, so I did not have to make any further adjustments when cutting from the plans. As you see, the big problem for me was laying the planks so that they would be completely flat. Mine turned out in a rather wavy fashion! Once the planking is complete, the shell with its frames can be cut from the mould. First there’s the rough cut using curved scissors to cut around the edges at the level of the rubbing strake and then to cut the areas attached to the base floor. The frame supports can now be cut away. Because I had used my own card, I had to paint the interior with red ochre. Finishing the hull The keelson, stemson and sternson are then put in place. The counter and timbers for the cuddy can now be added. With the cuddy finished, the main floorboards can be inserted. The thwart stringers are placed. The thwarts were made from 3mm card, and the supports made from 2mm cocktail sticks. The mainmast step was made from wood, using the plan in the guide. Now the thwart knees. The davit timbers and their roller are now constructed and assembled. The front davit with its roller were made in an identical way. The main remaining piece of the hull was the roller beam at the front. Swivel Guns Having done the main hull (without the swivel gun mounts, cleats, mast straps, belaying pins etc.) I thought that even though I wouldn’t arm the boat I would still see how cannon were made with paper alone. The instructions in this regard are excellent. I started with a simple roll of paper, marked with the positions for the subsequent layers of paper. Final result So, at its current stage, the model looks like this: In comparison with my ongoing 1:36 build of the Chaloupe Armée: I won’t be going any further with this build as from now on I will concentrate on finishing my build of the Chaloupe Armée. It is just possible that at some future date I will continue, but don’t hold your breath! The purpose of this review/log was mainly to bring the potential of this very nice model to the forum, and especially those who wish to explore card modelling – which, as you can see, offers up its own delights, techniques, thought processes and problems. Tony

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.