-

Posts

1,716 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Modeler12

-

Geoff, if I were to start over again I would consider using the polyester threads. They are available in a lot of sizes. Have a look at http://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Store_Code=TTE&Category_Code=polyester-thread I have now used two different spools and both worked fine and gave some rope that feels good. I don't know yet what happens if I were to use my stain on it, but I will give that a try soon.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Carl. Actually I found that by having the little motor on top of the 'sled' helps to get a more uniform rope. When I used an electric hand drill on that shaft it was jerky and gave uneven tension. Now the whole thing runs while I watch for any defects or problems. Yesterday I made rope out of some thread that was .0055 inches in diameter and it worked smoothly.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Where do flag halliards go? Deck or top?

Modeler12 replied to Modeler12's topic in Masting, rigging and sails

I just noticed that the web site for Sea Flags did not come through. You might try http://mysite.verizon.net/vzeohzt4/Seaflags/seaflags.html#contents -

Where do flag halliards go? Deck or top?

Modeler12 replied to Modeler12's topic in Masting, rigging and sails

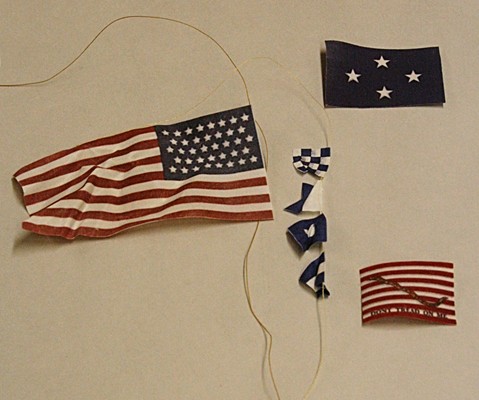

Thank you both Henry and Wayne. Things have a habit of changing, especially when it come to flying flags. I think we all know that back in the days of old Navy ships, the admiral dictated a lot of how flags should be flown, both from a signaling standpoint and perhaps his personal preferences. Even artists had their own interpretation, I am sure. For now I will eliminate the 'don't treat on me' flag since the ship is under sail, but I will add the call sign banners assuming it is close to port. I just like to have a bit of color to offset the otherwise drab black and white of the sails and spars. The admiral flag will be on the truck of the mizzen, but I am still curious about the 'banner' flying from the truck of the main. I might end up making one that is like shown in the web site I mentioned above. http://mysite.verizo...nal/fo.html#top Thanks again guys. Where the heck do you get all those great pictures Wayne? -

BTW Danny, I forgot to give you the final answer to your question. This took a long time, I know, and all those smart things, charts and apps would have done a better and quicker job than me entering a couple numbers that you gave me But I will survive without them. For those too young to remember, this 'smart thing' above was made by Texas Instruments eons ago and still works fine for me. It also allows you to program it (meaning that ones the basic formula is there, you can enter numbers up the gazoo and get instant return answers). Just remember that one inch is officially 25.4 mm.

-

I was brought up with centimeters, meters, kilograms, etc. I would love to convert this British inheritance of measuring in inches, feet and miles. All I am saying is that is not going to happen universally, not in mine nor your lifetime. Hopefully I will be wrong, but there will be lots of other businesses besides what is imported and exported to the US. I mentioned the building trades for one. I am still working from drawings that show my model in fractional inches and the first thing I do is use decimal inches (my vernier calipers and 6 inch ruler, for example). These kits are made in China or where ever, so why not change that first? We now have blocks and other parts that are listed in inches and some in mm. What size lumber do you use for planking? Now that is crazy for such a small market.

-

You are only considering socket wrenches? What about all the machine tools used in the USA, and the building industry's use of lumber, steel rods, aluminum extrusions, etc. etc. What about replacing all the nuts and bots,. taps and dies, rulers, etc.. Easy? I don't think so. Will it happen gradually? May be, but not completely in our life times.

-

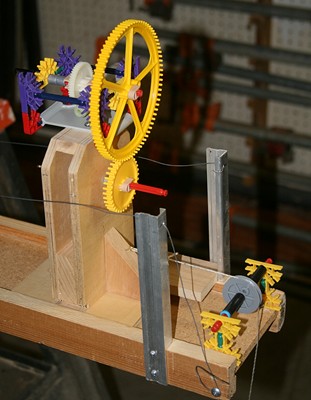

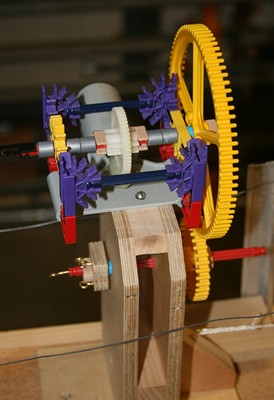

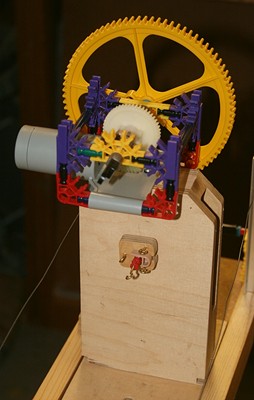

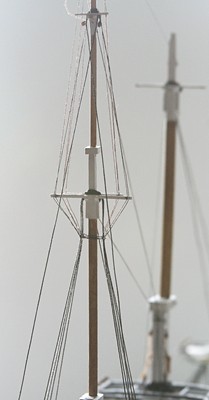

Geoff, I would like to know if the Byrnes ropewalk instructions suggest what kind of yarn or threads to use for the different rope sizes. The plans for the Conny call out dozens of sizes and there is no way that I wanted to follow that to the letter. I am using cotton that I bought in about five different thicknesses (it actually comes by weight). Then I used some of the thinnest #100, 80 and 50 to make rope. I also used the same threads as is. That gave me six thicknesses. But that still is not enough. As shown above, I also have made some rope with the very thin polyester thread, but I hesitate to mix that all into the bag. KNEX is an interesting toy for young kids and old men like me alike. My grandson has several pieces and I have some more he can use when he visits us. The idea is that the various shafts, connectors, etc can be used to make structures. It can also include electric motors and that is what I have installed now. The wooden platform of my ropewalk needs to move to the left inside the track, because as rope is made the length shortens because of the twisting. I keep tension on the whole thing by means of the white cord you see going around a pulley to the right and a tin can with weights down below. Before I would use an electric drill clamped to the red shaft in order to rotate the end of the three strings that are attached on the other side. Now I can simply turn on the little electric motor to do the same thing. To change direction of rotation I need to put in a switch to change the polarity of the dc motor. But that comes later. I can change speed by switching the two yellow gears. So far the whole contraption is working fine.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Where do flag halliards go? Deck or top?

Modeler12 replied to Modeler12's topic in Masting, rigging and sails

So, Henry, if I understand you correctly, I should not be flying the 'don't treat on me' flag while at sea. What about the location of this jack? I have seen a picture where the flag is coming down from the foremast yard. Are you saying that should be from the bowsprit? Yes, this was taken in Boston while the ship was moored. The admiral flag should be from the top of the main. I got the impression that it should be the mizzen from the following (but maybe I misunderstood this): The flying of a flag at the masthead to designate the vessel of a fleet commander is more than twice as old as the United States Navy, dating well back into the Middle Ages. The first known orders covering this subject in the English navy were issued in 1530: "the Admiral ought to have this order before he joins battle with the enemy that all his ships shall bear a flag in their mizzen tops . . . . . This came from the following source: http://mysite.verizon.net/vzeohzt4/Seaflags/personal/fo.html#top -

One part confuses me, though. The gun deck and the upper deck are on the same level on your built. Have another look and think about adding another level on top of what you have. Those gun ports are all below the top deck and the hatches are above that. That should not be a hard thing to fix, but it does take more time.

-

I agree Anthony. You are working with a very old kit and I was surprised to read that you had the gallery as a casting. That part is not easy to make, it is a challenge in itself, but certainly is worth doing it right from scratch. The shape of the hull looks very good. You did right as a kid!!! Your father did give you a good challenge and I hope you will live up to it. Keep up the good work. Are your plans in pretty good shape: detailed enough??? If not you might check here for more information and you can probably buy more recent plans if you want to. I am also doing the Conny. See below.

-

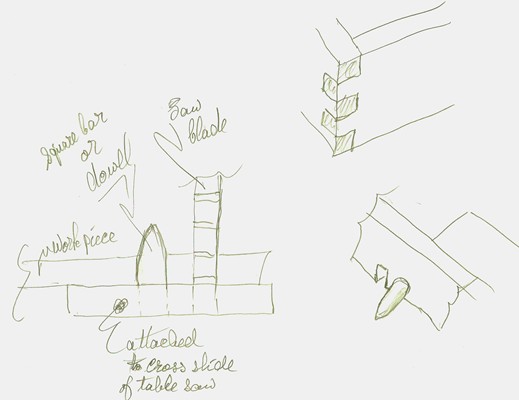

Making gratings

Modeler12 replied to marius's topic in Discussion for a Ship's Deck Furniture, Guns, boats and other Fittings

I don't know if this will help, but when I made some boxes with square finger corners, I made a fixture that allowed me to make repeated cuts. I tried to show that below but it may not be very clear. Assuming that you have a table saw and that the kerf of your blade is the same as the spacing of the grating, then you could go this way. The idea is that you make a plate that can be attached to the cross slide of your saw. The plate would have a dowel or square piece affixed as a guide. You start by cutting a slot in the plate, insert a piece of the dowel and glue that in place. Then you take a piece of wood of the same thickness and use that to align the dowel to left of the saw blade. Now you make another cut through the plate and that then becomes your fixture. I hope all of that makes sense. -

That is a pretty silly statement, Jan. I have to agree that if the whole world had agreed with Napoleon to only use the metric system we would not have to use inches. But can you imagine how much it would cost to convert now?

-

(7+13/16)x25.4 mm is the answer. I never said that I don't use a calculator, Danny. Mine is much easier to take out of the drawer right in front of me. I would have more problems finding a paper conversion chart and if you have a smart phone you have a calculator right there. That is no longer true. The 'standard' is 25.4 mm to the inch. It used to be based on the meter but a few years ago that was changed.

-

Using Blacken-IT

Modeler12 replied to fnkershner's topic in Painting, finishing and weathering products and techniques

The wire I used in the other thread here also came from Michaels and after I used steel wool on it the patina I use did a fine job. But just as I mentioned there, it does require a stronger solution than copper, britannia or solder joints. Even if the wire is actually low carbon steel or another zinc/copper alloy (other than aluminum or ss) it should work. -

Not only was mine cheaper but lots of fun to put together and much easier to use than the fancy Brynes model. Like you said, if it is for occasional use . . . .

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

My ropewalk is about eight feet long and requires the ends to be rotated independently. I use two hand drills and had to go back and forth. Sometimes the Admiral helped, but she was not always available. So this morning I said heck with this walking back and forth (yes that's why it is called a rope walk) and I got out my grandson's KNEX box again. You can see below how I added a couple gears and jury rigged the hand drill. A twister tie keeps the trigger in a position that gives me the right speed and I operate this one with a switch while holding the other hand drill during the winding operation. It works and now I can do it all from one place. Some day II will have to build a better arrangement, but then again I don't make rope every day.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

This may be a little late, but here is a good web site about tying knots. I show the clove hitch, but there are lots of others with a nice animated way to tie them. http://www.animatedknots.com/cloveend/index.php?LogoImage=LogoGrog.jpg&Website=www.animatedknots.com

- 64 replies

-

Where do flag halliards go? Deck or top?

Modeler12 replied to Modeler12's topic in Masting, rigging and sails

Thanks for all those suggestions. I will bring the halliards down to the deck and as far aft as possible. When I posed the question I was primarily thinking of the banner and 'admiral' flag that would be on top of the main and mizzen mast (perhaps also another flag on top of the foremast). I am adding six sails and the ship will be on a starboard tack. Hence the flags will be 'flying' with the Admiral on board. The large US flag will be attached far aft on the spanker gaff and belayed on the boom. Then there will be the 'name' banners and a 'don't tread on me' flag coming off the main jack (using the sheaves you mentioned, Kester). Any way that is my plan and I appreciate your inputs. -

I am working on rigging the USS Constitution and want to include at least two flags from the masts. It is a long way from the deck to the very top and I was wondering if the halliards are typically belayed on the first 'top' of the mast or go all the way to the deck. Should there be any blocks or thimbles on the way down?

-

Red Right Returning, history question

Modeler12 replied to Modeler12's topic in Nautical/Naval History

Please hold it guys. This thread was not intended to get involved with the history of wars. I simply asked about the history of 'Red Right Returning'. By the same token, I beg your pardon for mentioning the differences in the measurement systems used here in the US and abroad; it was by way of a comparison. Although, that in itself could be another thread or topic Again, I want to thank Wayne for clarifying some of my interests in the particular subject I asked about. -

After I got the ropewalk up and walking again, I had to practice using the thing. Making rope is not as simple as it seems. But I have a good whip, which helps with things that don't cooperate. Here are some results using polyester thread (Morope uses polyester): I have two spools of polyester thread seen below. One is 'heavy', the other 'all purpose'. That is all the information they could provide me. The first measured about .0085 inch diameter, the thin one was about .005 inches. I only made rope out of the thicker one and that measured .023 inches (but that was an average since it varied depending on the tightness of the wind). I found that the rope has a bit of sheen, some fuzz and too much 'chocolate' color. If I were to use it, I might give it a very light coating of my stain. I don't want it to be black. I'll try the thinner thread tomorrow, but I also have to make my cotton rope then. Sorry the picture is a bit out of focus and does not show the actual rope color nor weave. Thanks both Alistair and Jeff for your comments and help.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Jeff, I just about answered my own question. Here all along I have been using a spool of dark brown polyester for the very fine lines and making the whippings. It works fine, of course. This may actually be very timely for me. I just realized that I need more rope for the main and foremast shrouds. So out come the ropewalk from storage. After I make what I need out my cotton supply, I will try a few polyester ropes and see what they look like.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Jeff. I take it you have used Morope also. Do you find that the plastic lines tend to slip and are a bit harder to knot? I know that nylon does. Here is one more picture that I should have included above.

- 732 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.