-

Posts

2,033 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tlevine

-

Tom just brought to my attention a problem with the printed plans. The plans themselves are correct but the scale on Part 104 (and possibly others) is off. I will go back and double check everything over the next few days. The takeaway lesson here is that you need to build from the measurements, not the printed page. I can hear the four engineers who reviewed my work now...they did not want me to put any scale on the drawings for this very reason.

-

Paper wrapped around the bit works also.

-

NAIAD 1797 by Bitao - 1:60

tlevine replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Ouch! -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Thank you Alex. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

I am unable to give you any insight as to the purpose of the heavy rings. Sorry. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Please and thank you. -

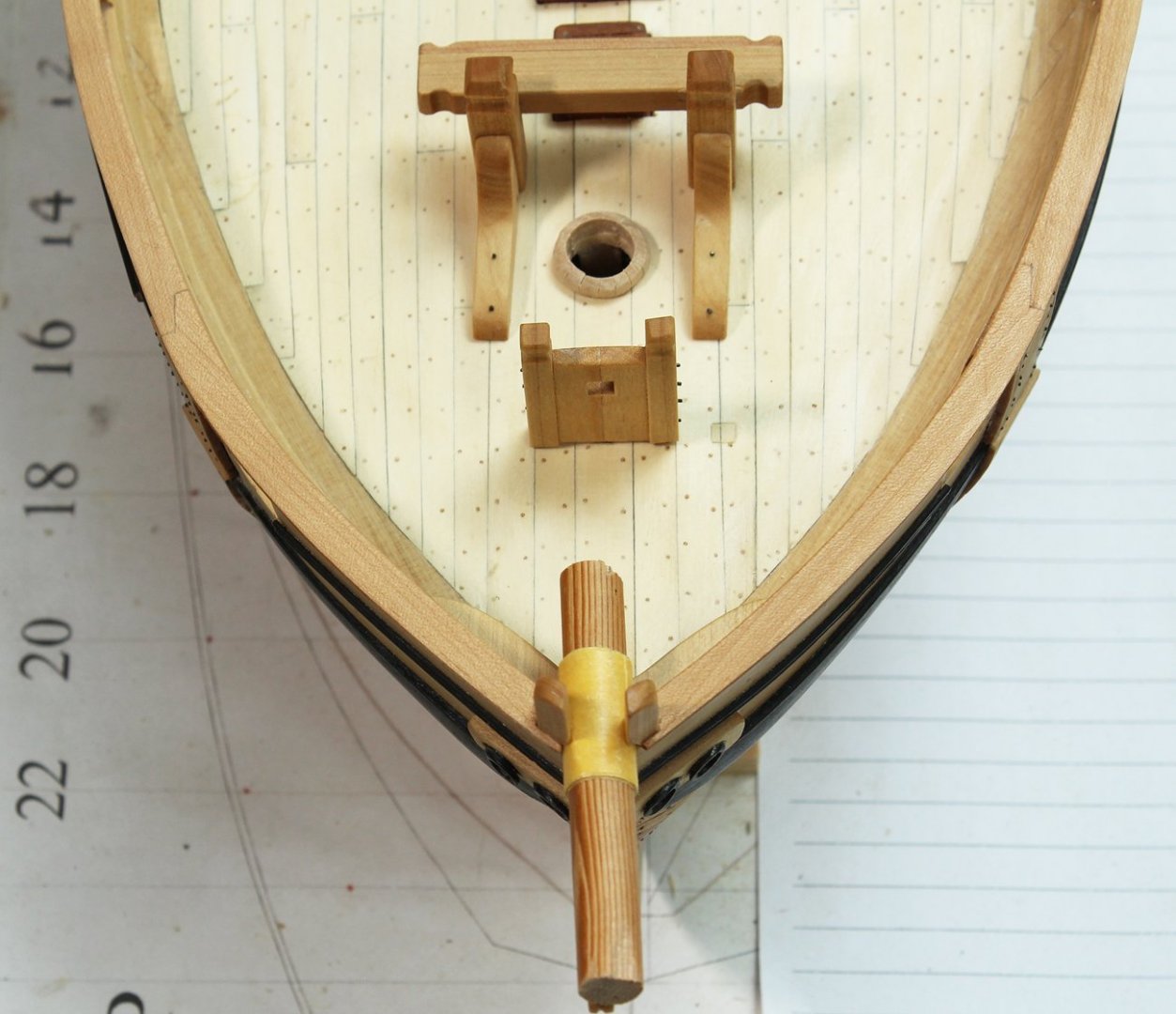

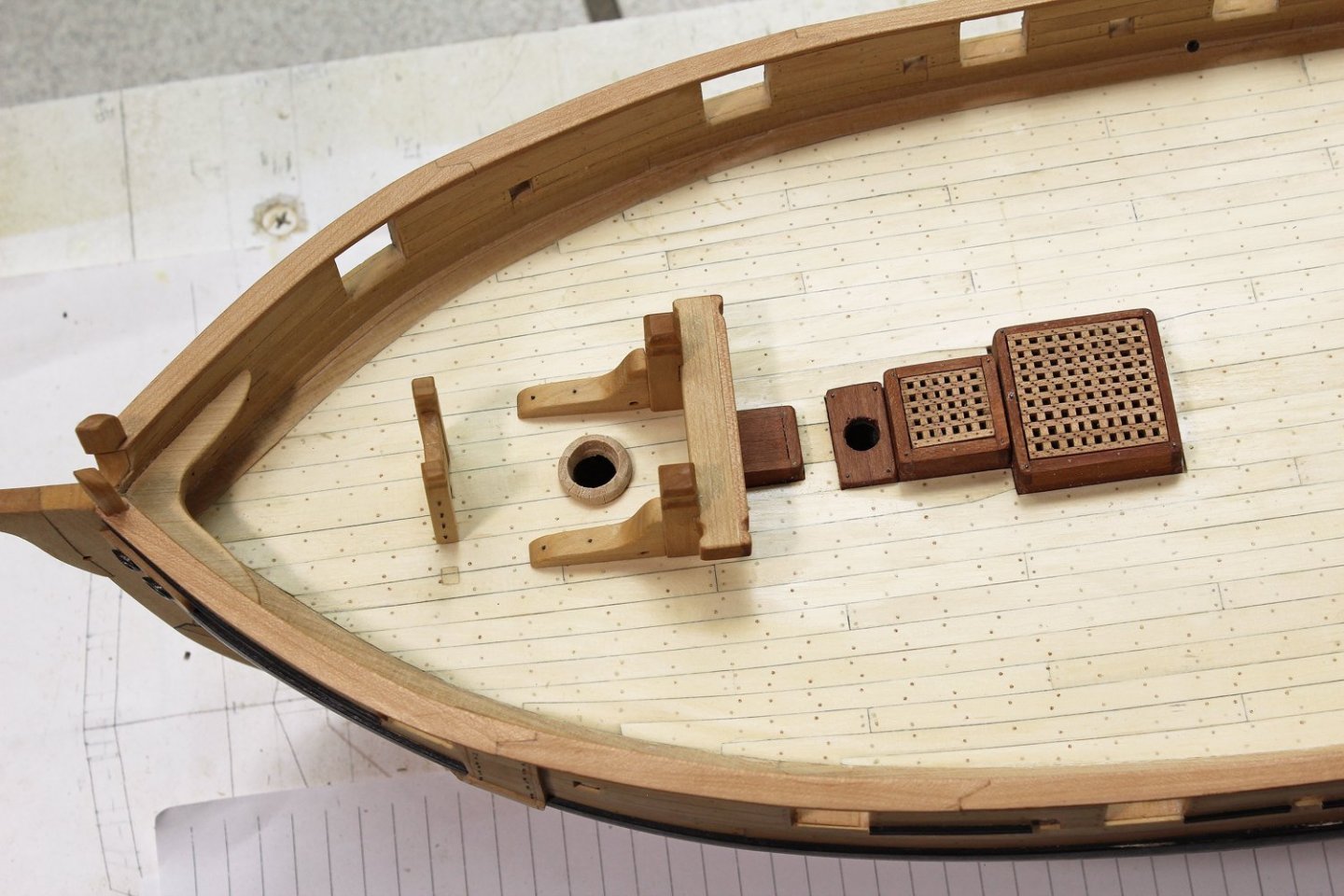

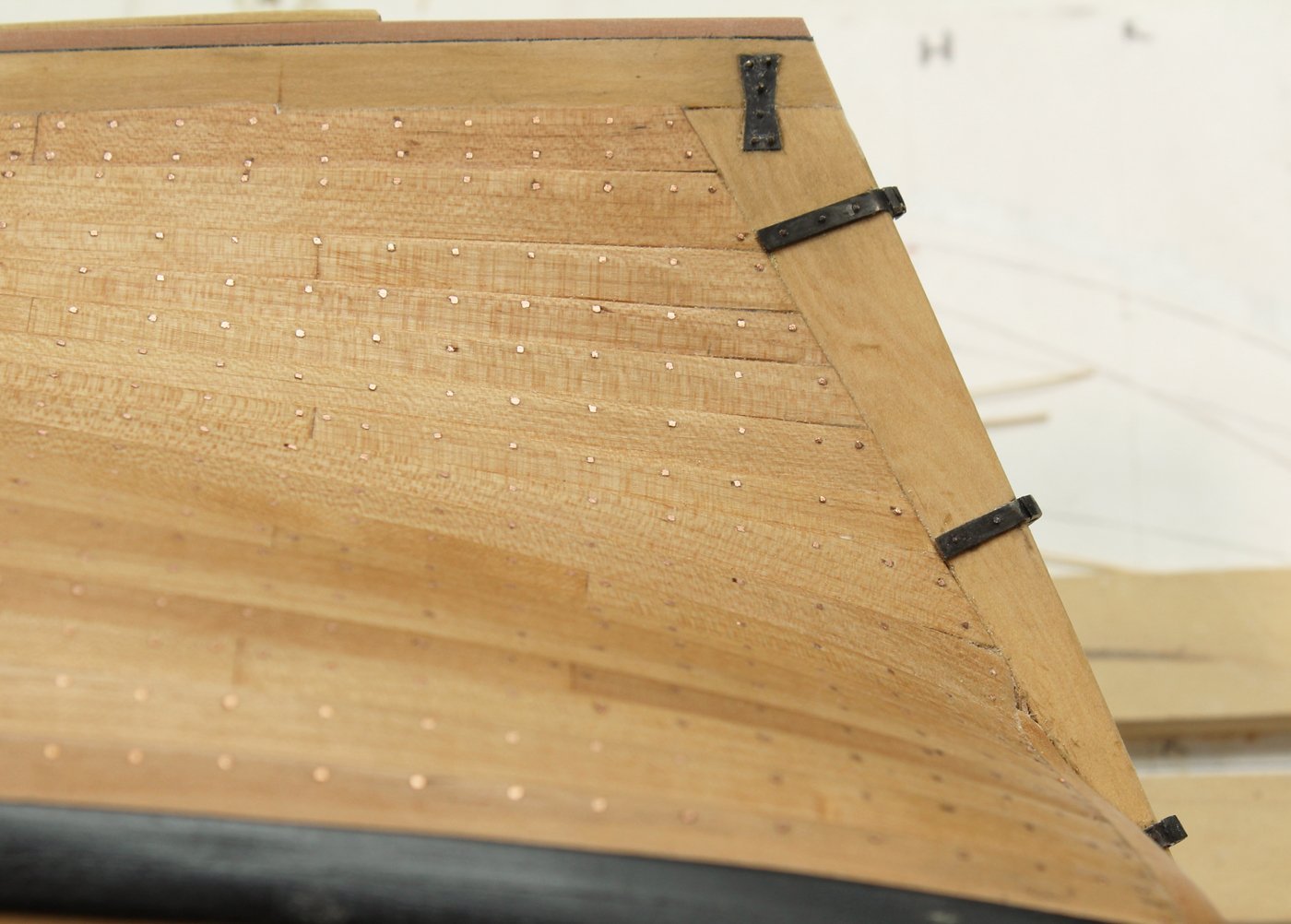

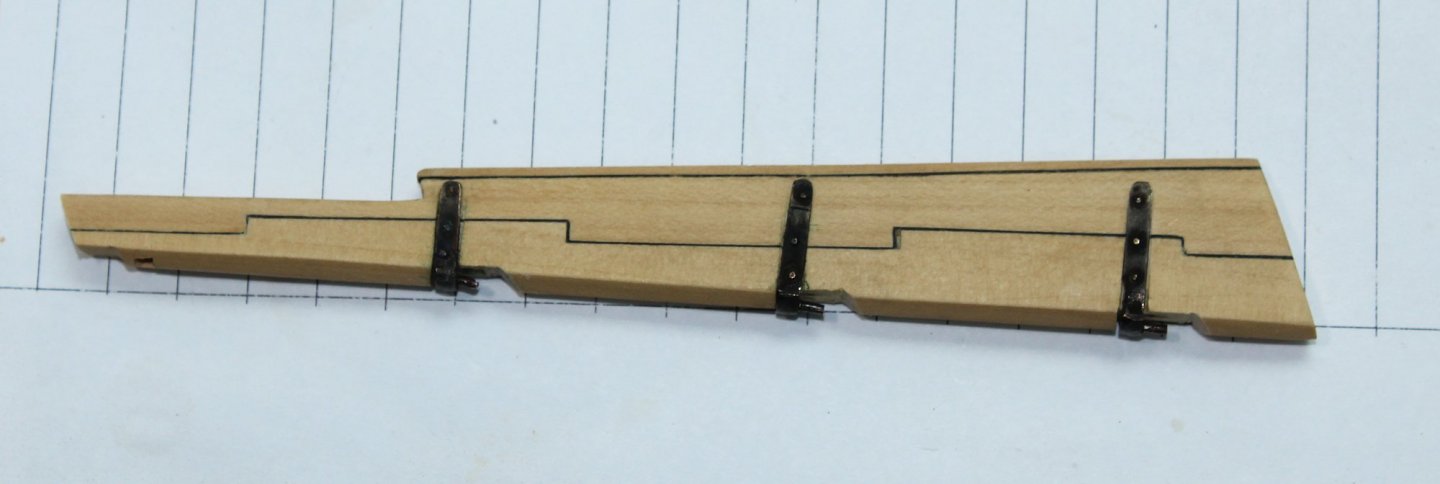

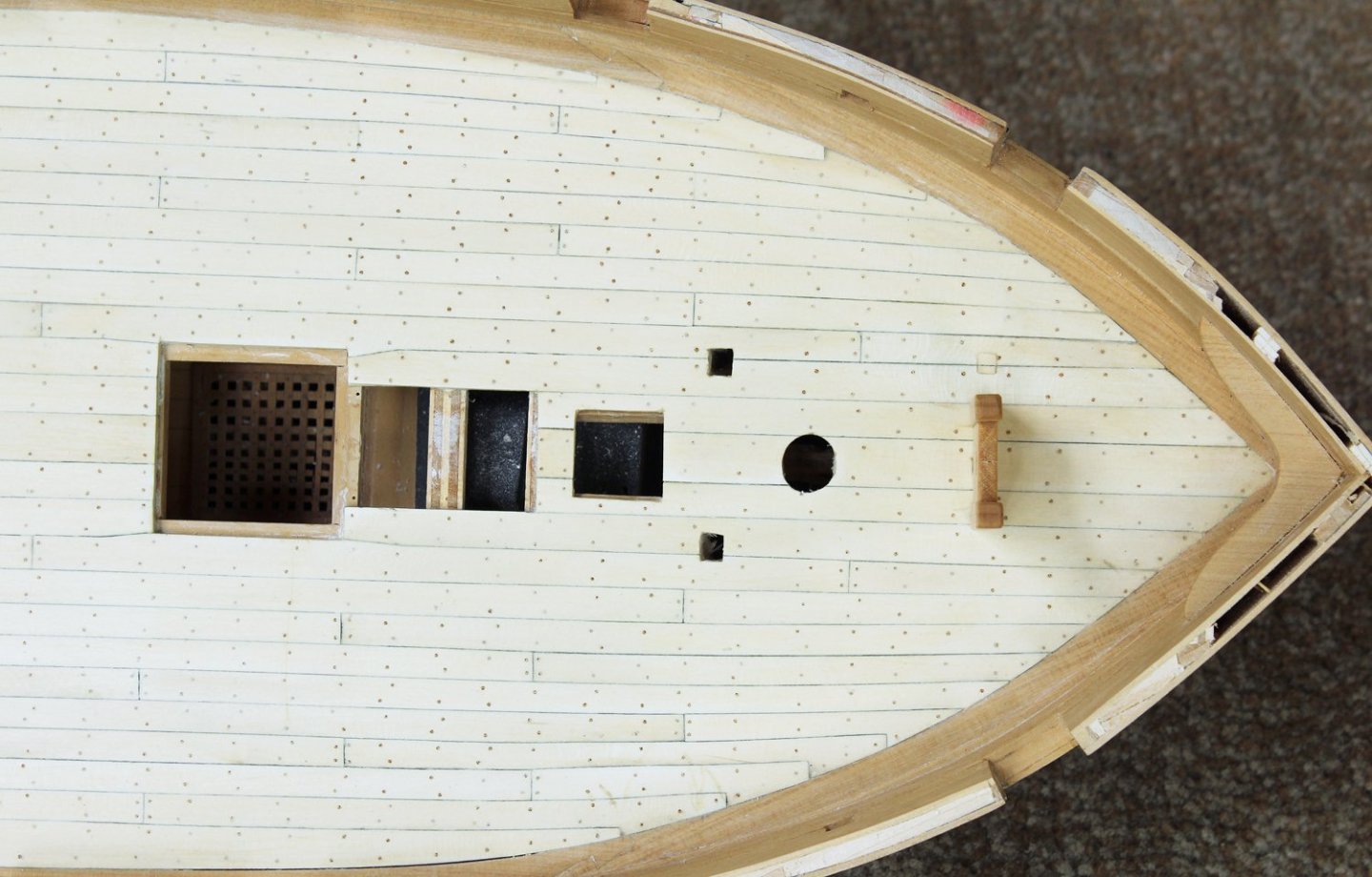

The bollard timber heads have been remade. As I was making version one, I knew there was something wrong but could not figure it out. As druxey stated, the inner and outer (athwartship) faces of the bollard head runs parallel to the keel. I have made an opening in the sheer rail for the timber rather than gluing it on top, as I did in version one. A thin piece of boxwood was bent around a dowel and used to fill simulate the bollard timbers alongside and below the bowsprit. Treenails in the grating were simulated with a punch. A pencil was twisted in the depression to represent the treenail. Bolts made of blackened brass wire have been added to the bowsprit step, bitts and anchor lining. Mast wedges for the fore and main masts were made up from four smaller pieces of castelo, glued together. These were turned on the lathe. The opening was made using a mill with a rotary table since I did not have bits the correct diameter. The multiple wedges were simulated with an 11 blade. The skylight was glazed with sheet mica. Most of the external details (other than the channels and deadeyes) have been finished. While it was still safe to hold the hull upside down, I installed the horse shoes, ribbons and gudgeons. The horse shoes and ribbons are left over from the photoetch sheet once sold by Admiralty Models. Recesses were carved in the stem, sternpost and keel for them. The pintles and gudgeons were made from brass square stock, strips and wire. They were silver soldered and blackened. I used the method shown in TFFM. The sequence is shown in the diagram. First the brass rod and strips are cut to length. Next, slots are filed into the brass rod to accept the strips. They are soldered and the face of the rod is shaped. A hole is drilled near the front. For the pintles, wire is inserted into the hole and soldered in place. Once I was sure that the rudder could be unshipped, I removed it for safe storage. Question: would a ship of this size have a spectacle plate or would some other way to secure the rudder been used? There is no spectacle plate shown on the plan or the model.

-

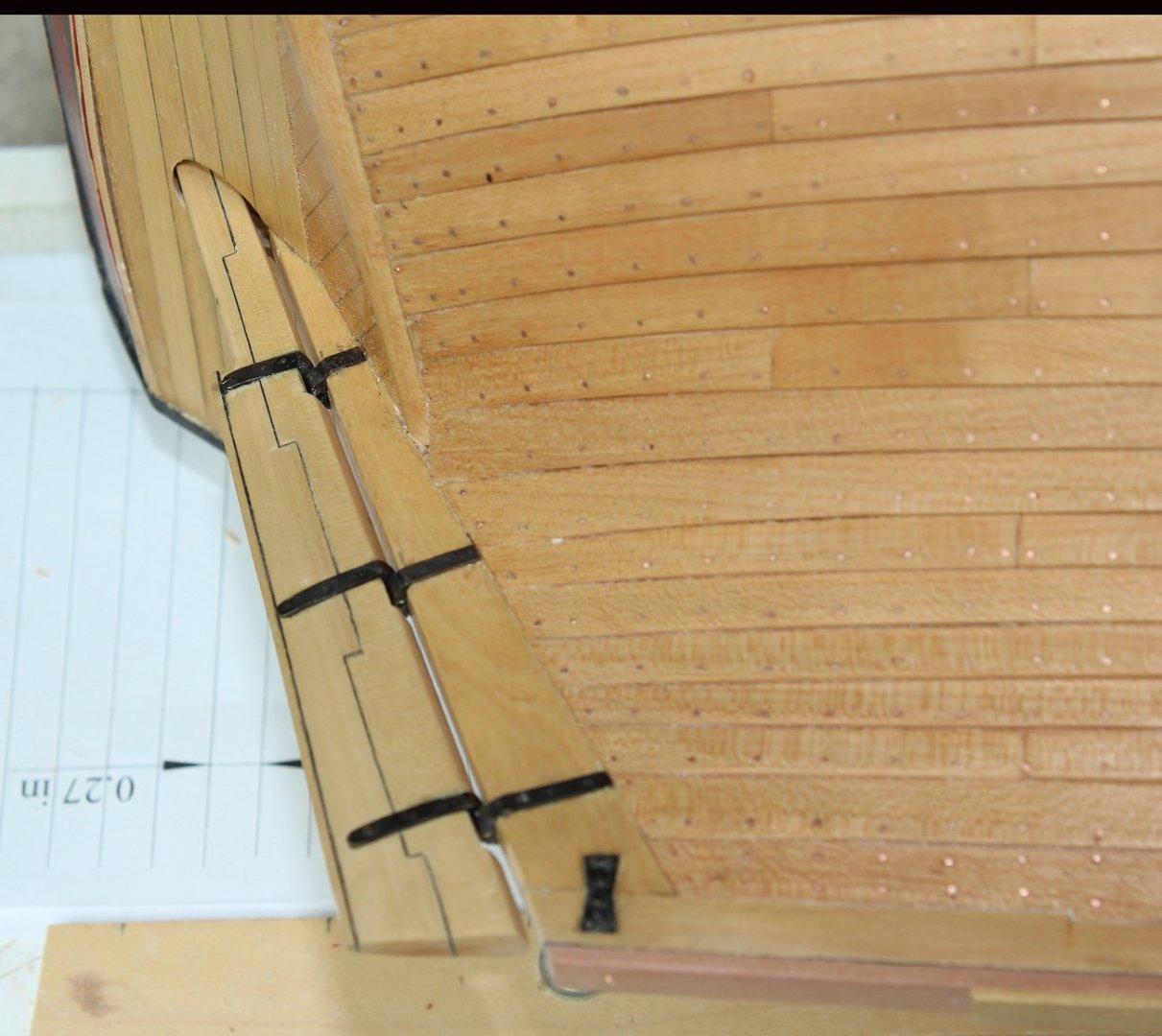

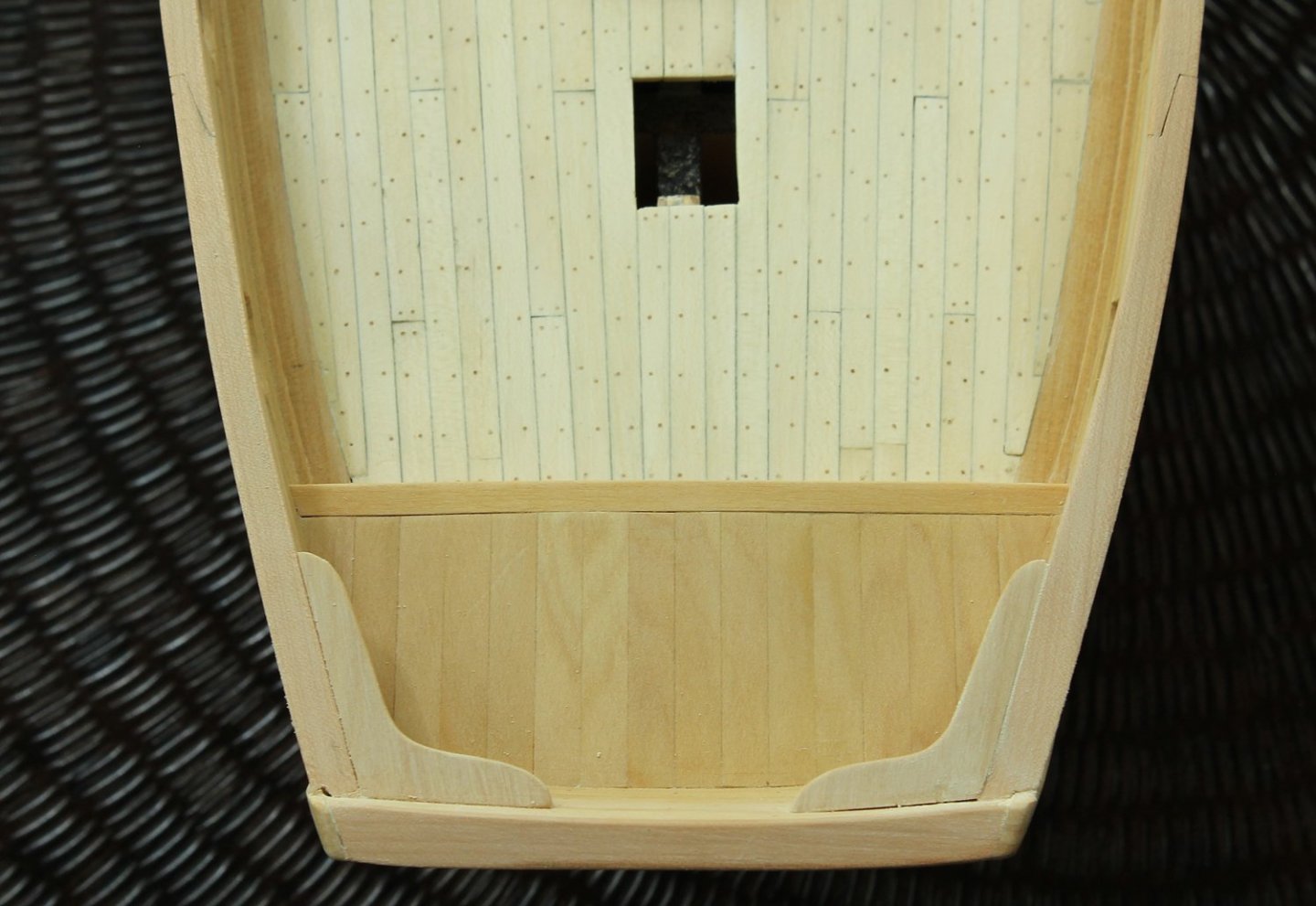

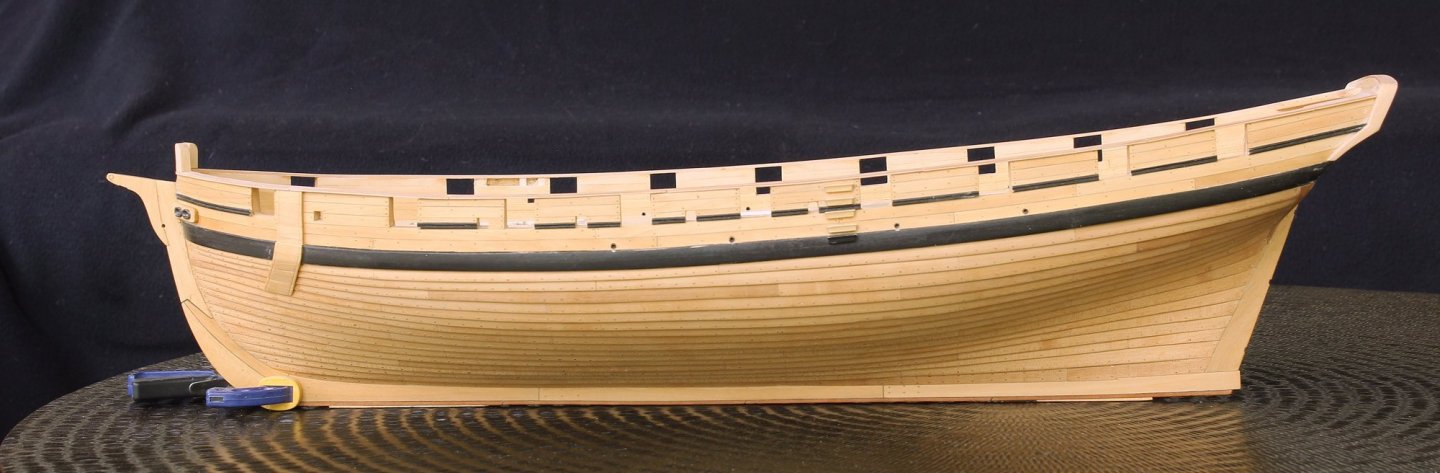

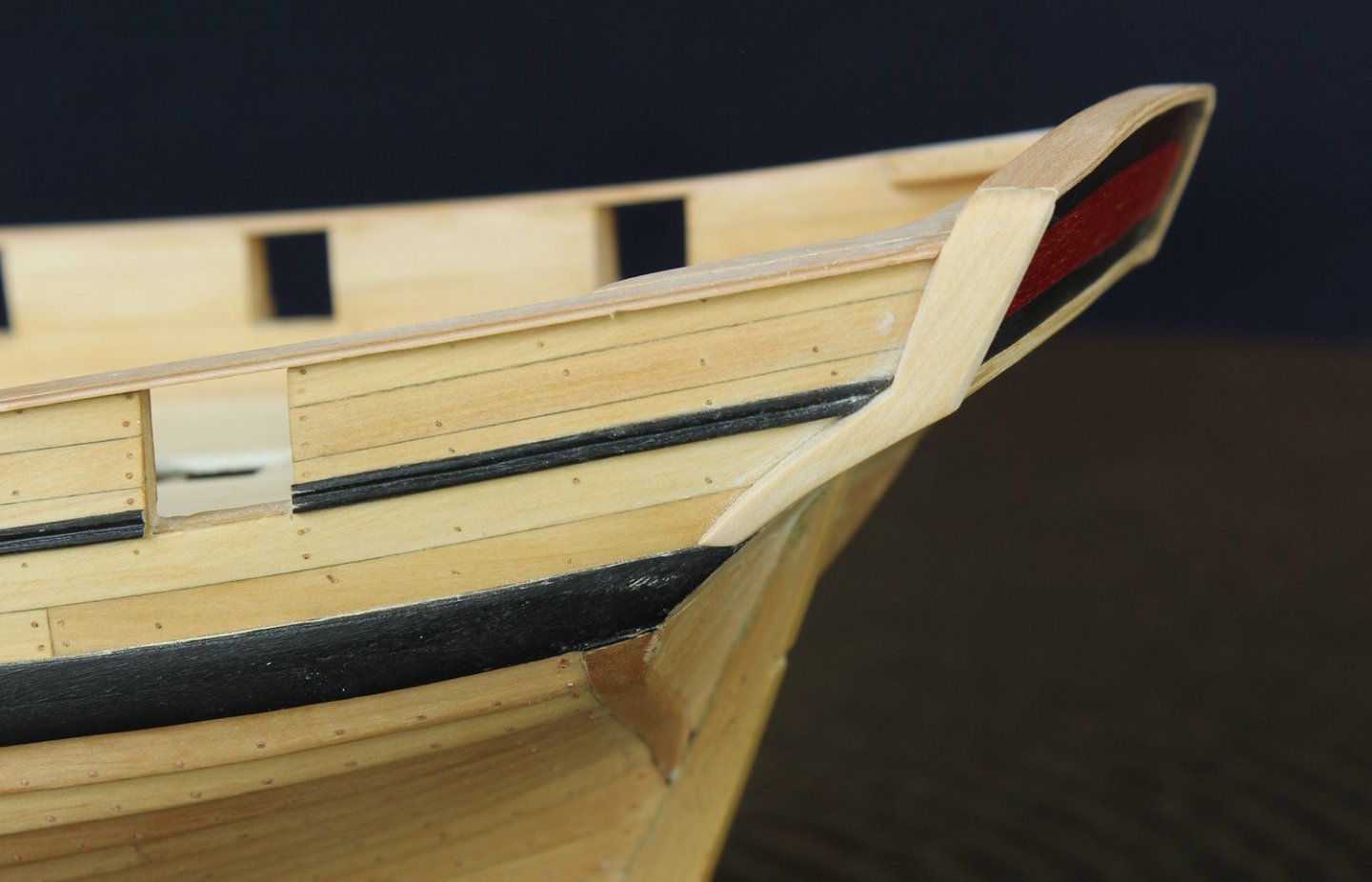

The plankshear was installed next. These planks are 2.5" thick, are flush with the inner planking and extend 3" beyond the outer hull planking. Each plank is approximately 15 feet long and ends in a scarf joint. A simple double-beaded edge was made with a scraper. I made them from pear, the same wood the lower hull planking is from, for a slight contrast in color. The knees at the stern have also been installed. The capping rail was shaped by wetting it and clamping it in place overnight. The edges were then shaped, putting the same edge treatment on the stern side. The fashion pieces were cut down to their final height and the corners rounded over. The bollard timbers help secure the bowsprit. A dowel wrapped in sandpaper (the bowsprit) was temporarily installed and the bollard timbers were sanded against the dowel to get the correct shape. I had been trying to decide on how much decoration to show on the model. The model in the RMG has a lot of fancy work, including gold leaf. Considering the type of ship, I thought a little bit of painting was appropriate but just at the stern. I wanted a pop of color and so decided on black edging with a field of red. The double bead motif was extended onto the aft end of the fashion piece. The mottled appearance of the red is the wood grain. I made this from pear. The black extends over the capping rail. The same paint pattern was put on the fashion pieces. Just for fun, I added red to the depths of the double-beading.

-

Mike, your cutter looks very nice. The purpose of the half hull project was to teach beginners how to plank a hull. Because the planking is a standard thickness, it can be removed and replanked a few times for more practice. Never say never but at this point I do not have any plans to produce another half hull project. If I do, the builder could choose between clinker and carvel planking. Swallow has spent too much time being ignored while developing the capstan project. She is a bit jealous and demands that I finish her before doing anything else.

-

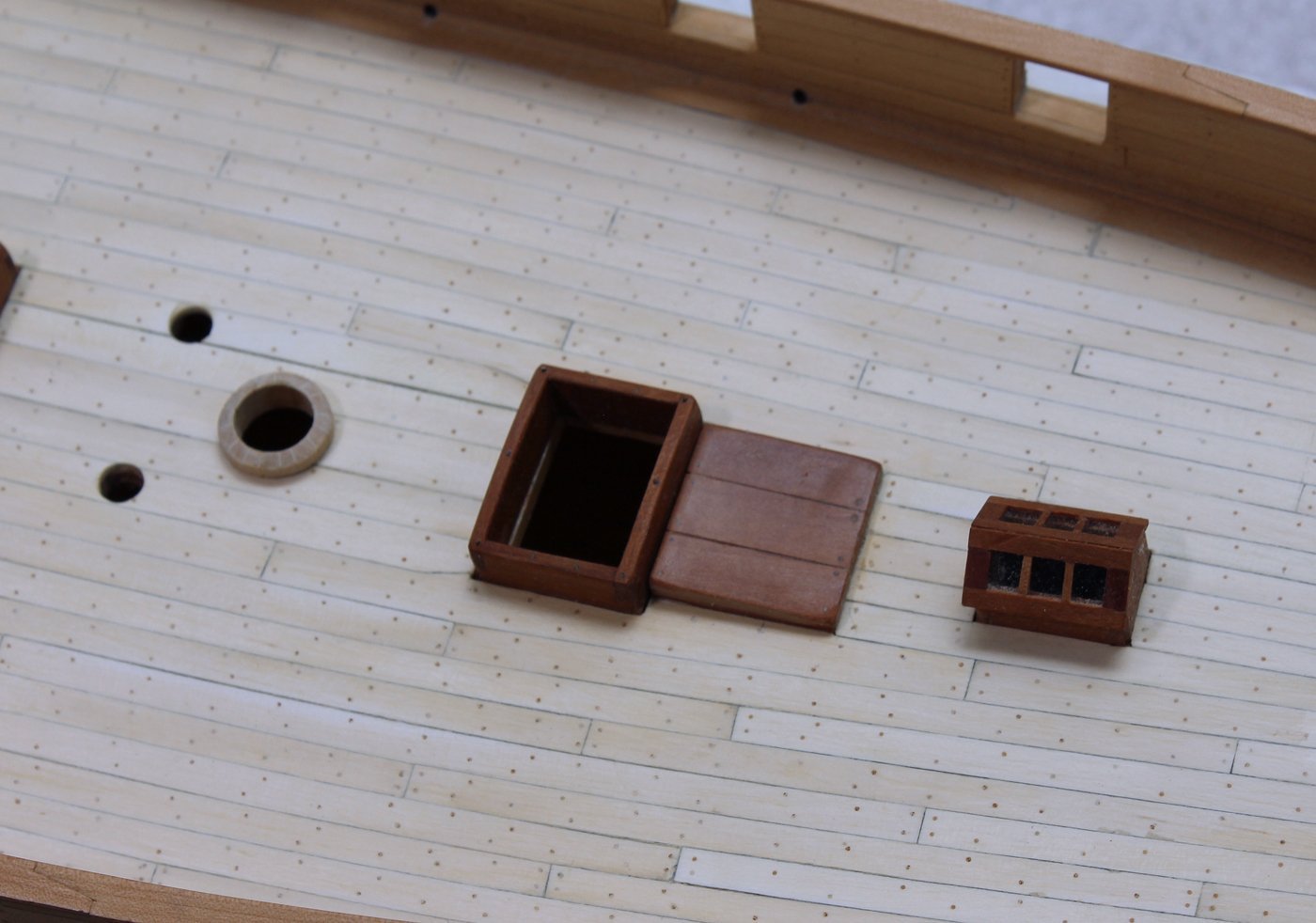

The anchor lining is a very prominent comma-shape on the model. The lining is not shown on the plan but I decided to follow the model. The upper part of the lining extends to the plankshear. It extends over the wale and continues down almost to the water line. These boards were added clinker-style but the outboard surface of the lining is smooth. There is also a smooth transition from the lower hull over the wale. Four scuppers are visible on the model but are not shown on the plan. They were lined with copper tubing blackened in situ with liver of sulfur (LoS). I have also started work on the fashion piece. Although the model shows painted scrolls and gold leaf, my model will be much simpler. I have not decided on its final appearance but most likely will simply paint it black. I have refined the top of the stem, narrowing it and incorporating the hances into the tip. As you can see, all the black paint will need touching up. The hawse holes are 10 inches in diameter. These were drilled out and then sanded to their final size. The pipes are copper. After the outboard shape of the pipe was determined, a piece of copper tube one size larger was shaped and soldered onto the end to simulate the rolled edge of the pipe. The inboard profile was then shaped. The hawse pipers were blackened with LoS after all of the excess solder was filed off. LoS will not blacken silver, only copper.

-

Would you like to see your model as a pinup girl next year? We are currently accepting submissions for the 2022 NRG/MSW Calendar. The only requirements are that the file is at least 5MB and that the picture is well composed. It does not need to be an entire ship; a close-up of an interesting feature (like the headworks) or a diorama is also welcome. You do not need to be a member of the NRG to enter. If you are interested, send me a low resolution photograph via PM. Everyone whose photo is accepted will receive a complementary copy of the calendar.

-

I would suggest that before you go any further, you look at build logs of other open boats from this era. There are several builds of the Model Expo longboat that will help you understand the construction of your model, since it is very similar. Syren's Medway Longboat is more complex but also provides good background information. An excellent rule of thumb in kit building is that if the instructions make absolutely no sense, they are probably wrong.

-

Thanks, Druxey. I forgot about the notch. I will try and develop the tip a little better. Thanks. And thank you to everyone for the likes.

-

Time for some modeling surgery. In order to position the bowsprit in the midline, the step needs to be moved. The holes were already made in the deck for the step. One of the holes will be hidden by the center part of the step but the port side one needed to be repaired. My options were: remove and replace the two deck planks where the hole passed or make a plug and insert it in the hole. My concern was that I would probably do more damage to the surrounding planks and waterway by doing so. Look at the June 5th post to see that these were not typical planks. I opted for a plug. The repair is not perfect, but I believe this was the more prudent approach. Next, the stem head was installed. This has a shallow mortise at its foot into the stem. A small scroll is carved at the fore end.

-

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

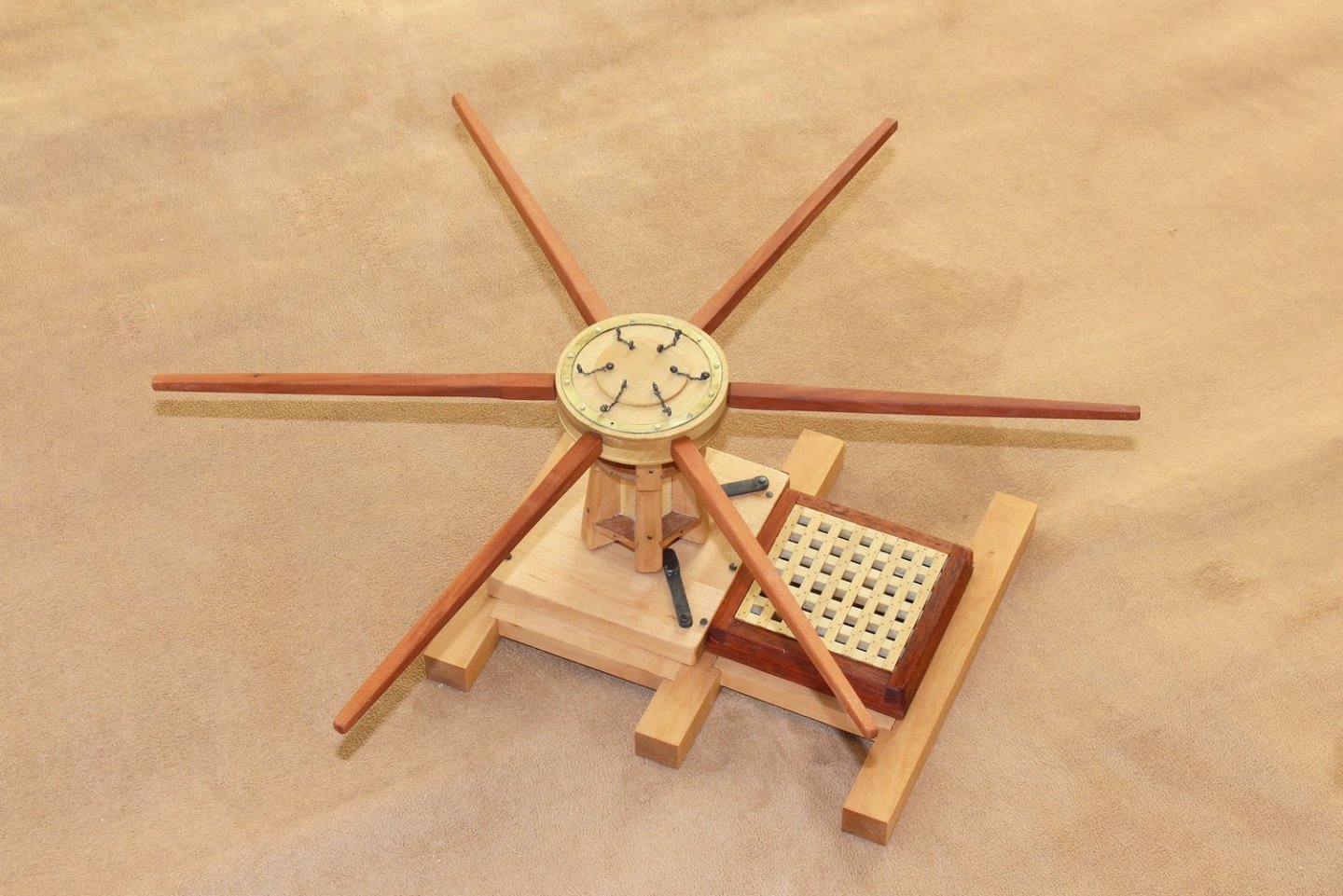

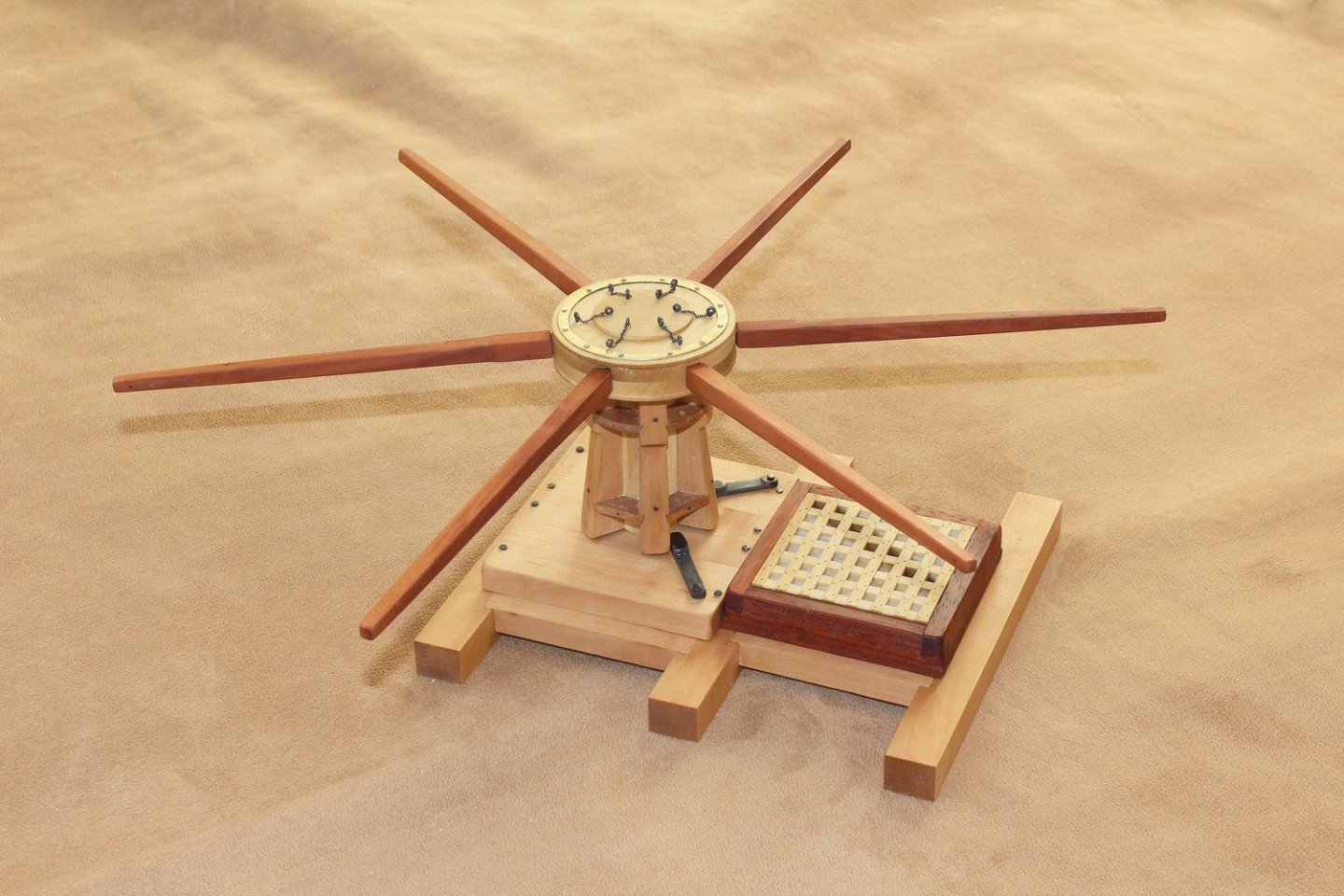

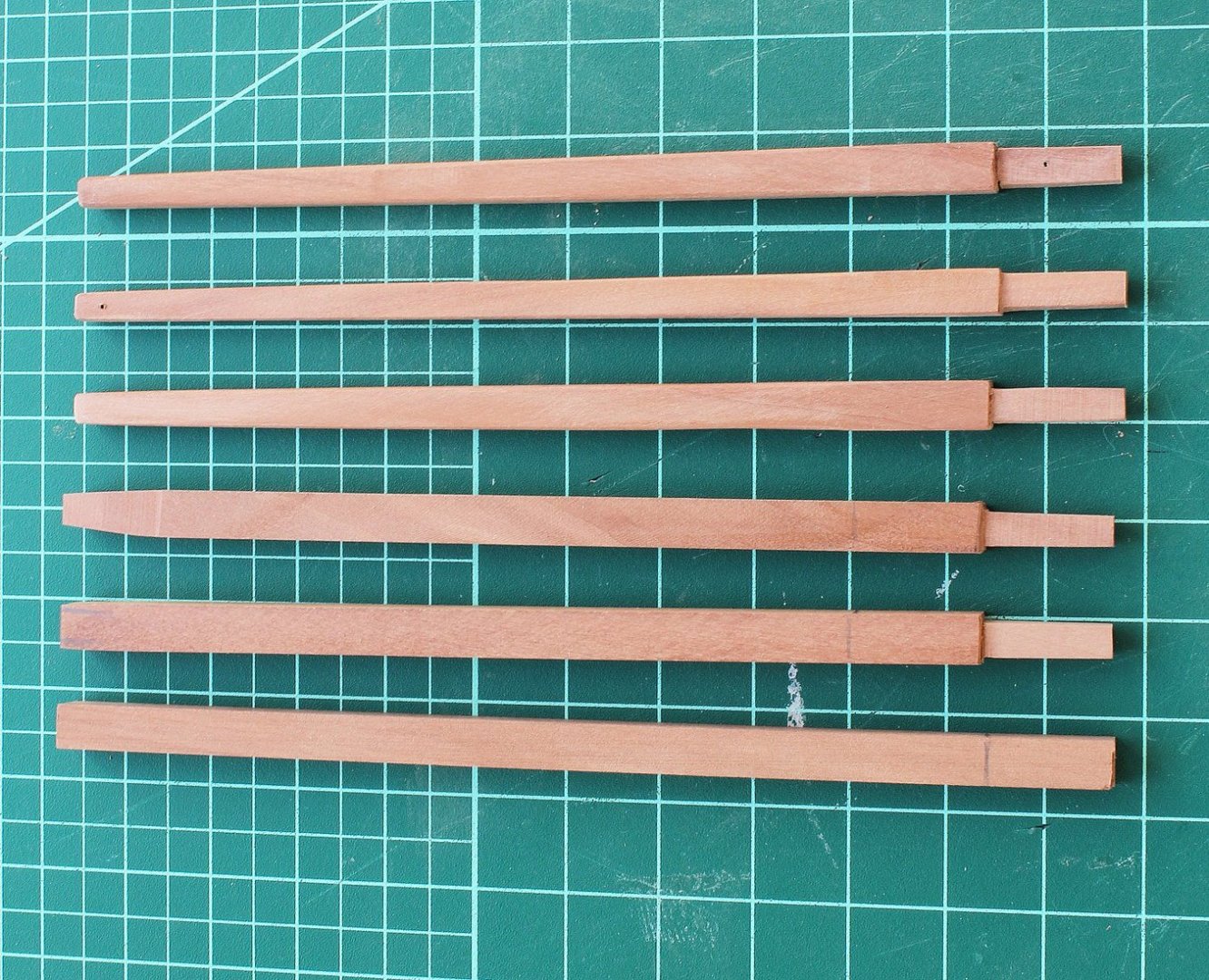

All that is left to make is the capstan bars and brakes. This was shown in the intermediate version and will not be repeated. Time to put everything together. This was a fun project to design and build. It does not take a long time to build and it makes a handsome desk ornament without the bars or in a display case with the bars installed. The project is available for purchase in the NRG store at https://thenrgstore.org/collections/plans-and-projects/products/capstan-project. It contains separate plans and monographs for the intermediate and advanced versions. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

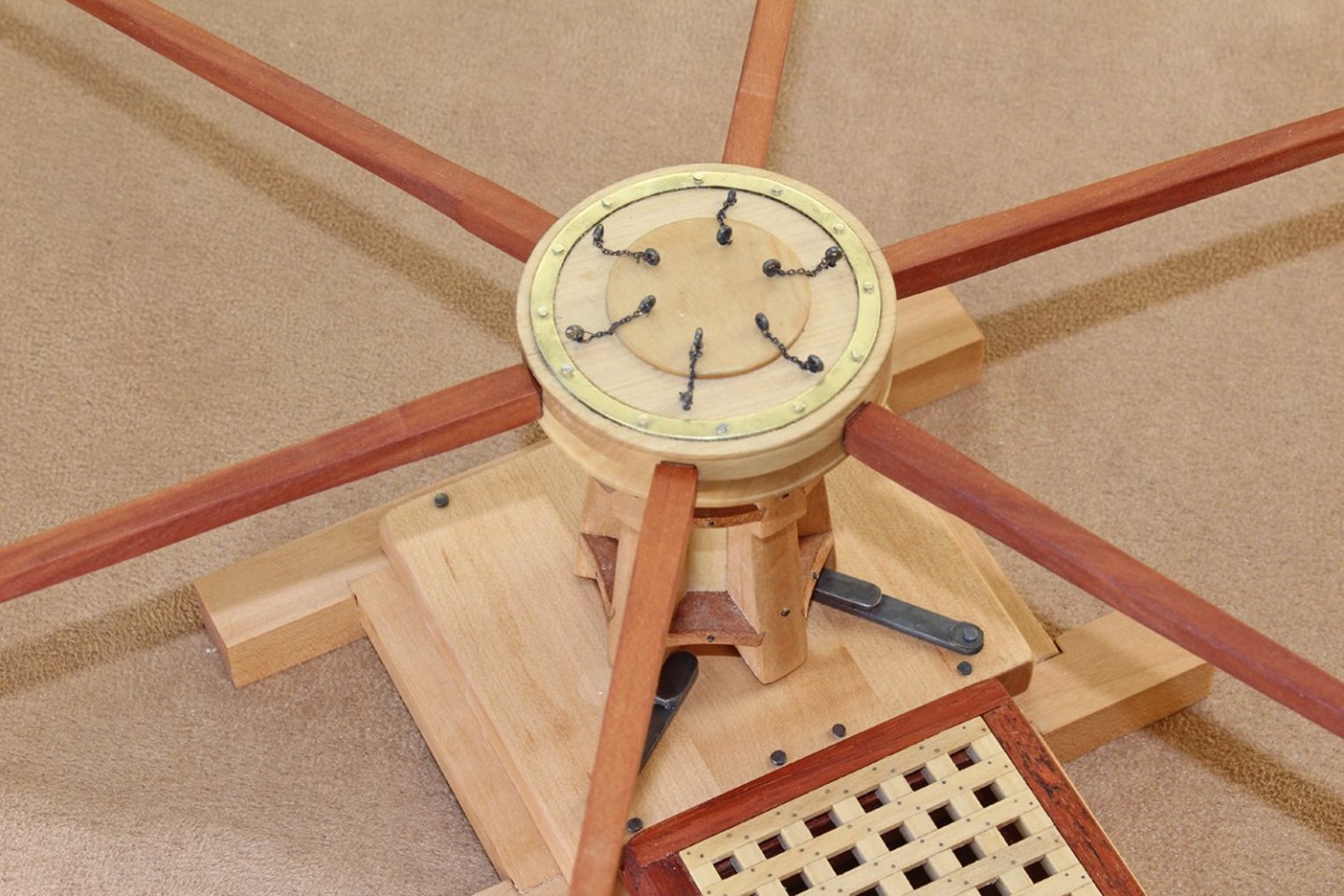

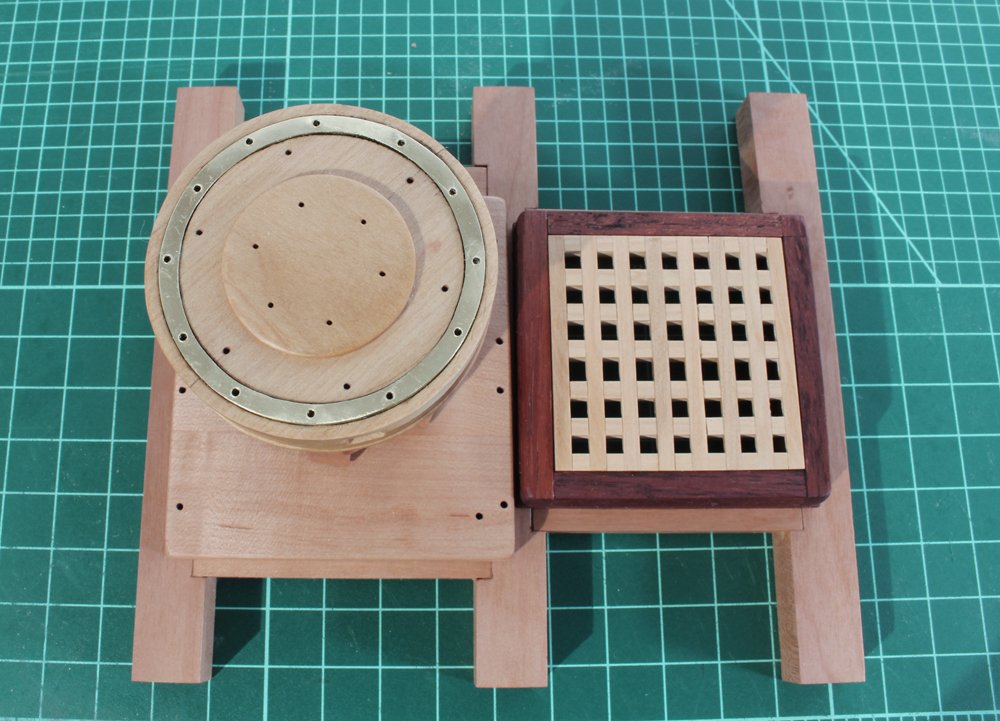

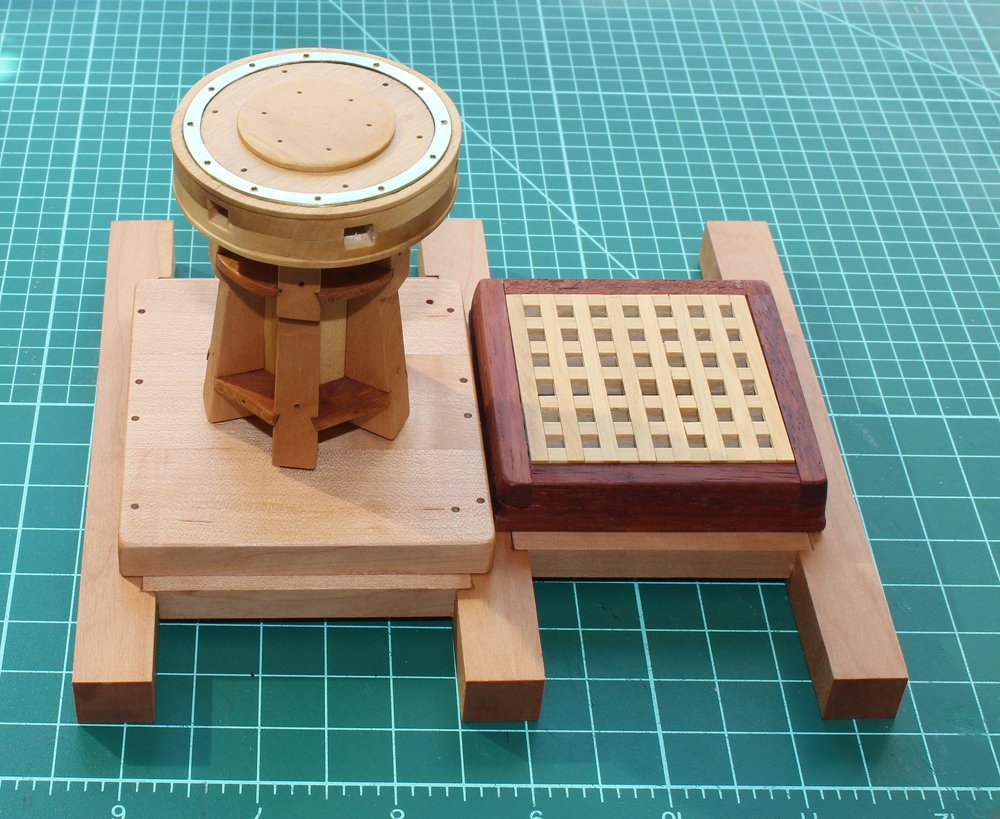

An alternate approach would be to use brass instead of wood to represent the iron ring. The bolts are brass nails with their heads filed flat. The holes for the capstan bar pins have been drilled. After a coat of finish, the capstan is trial fit on the step. Compare the appearance of the step and capstan in the next two pictures, showing the effect of a coat of Watco's. I used copper wire for the whelp bolts and they have not been blackened yet. This will be done with liver of sulfur. The eyebolts and capstan bar pins have been installed. Make sure the chain is long enough to allow removal of the pin. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

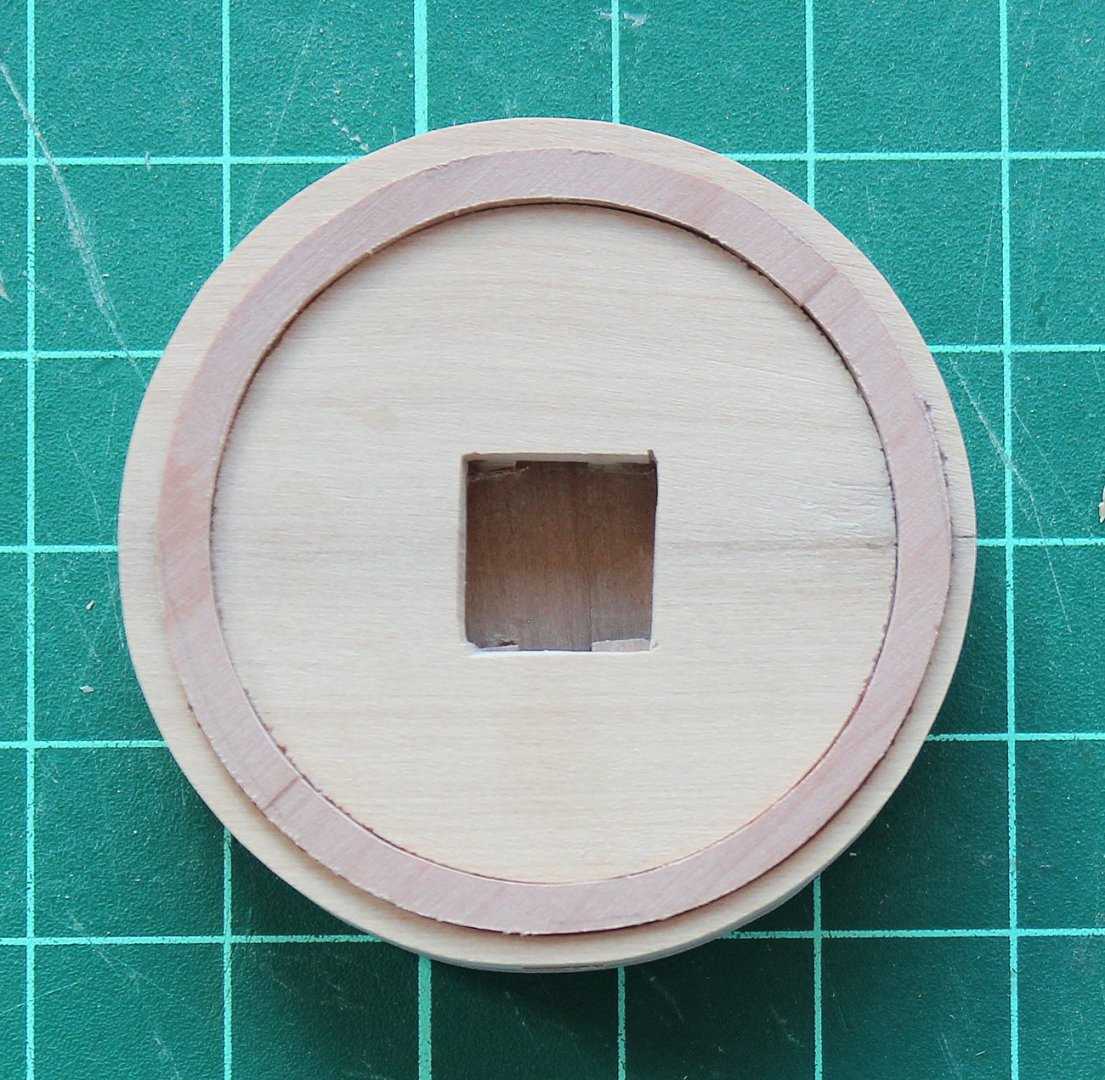

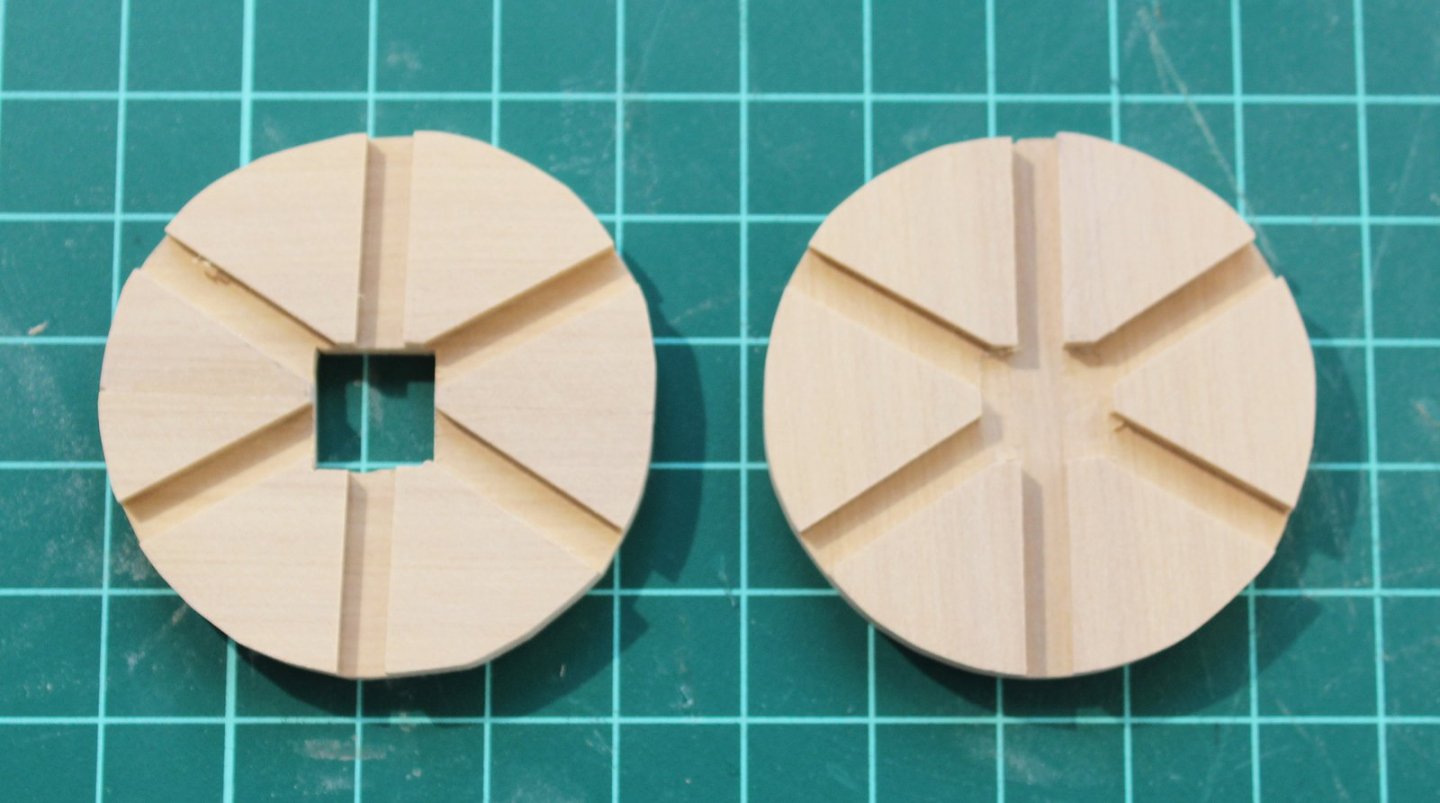

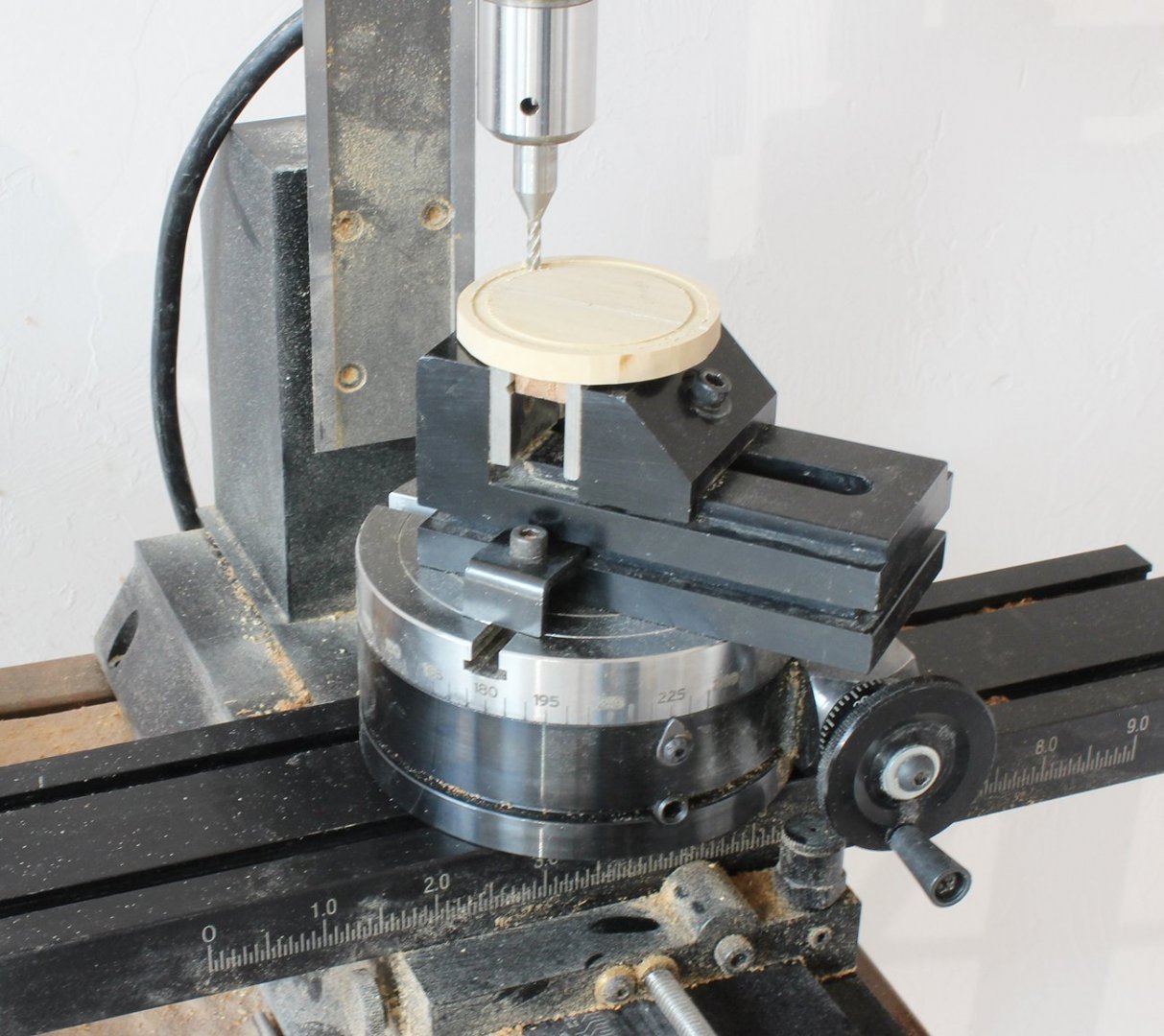

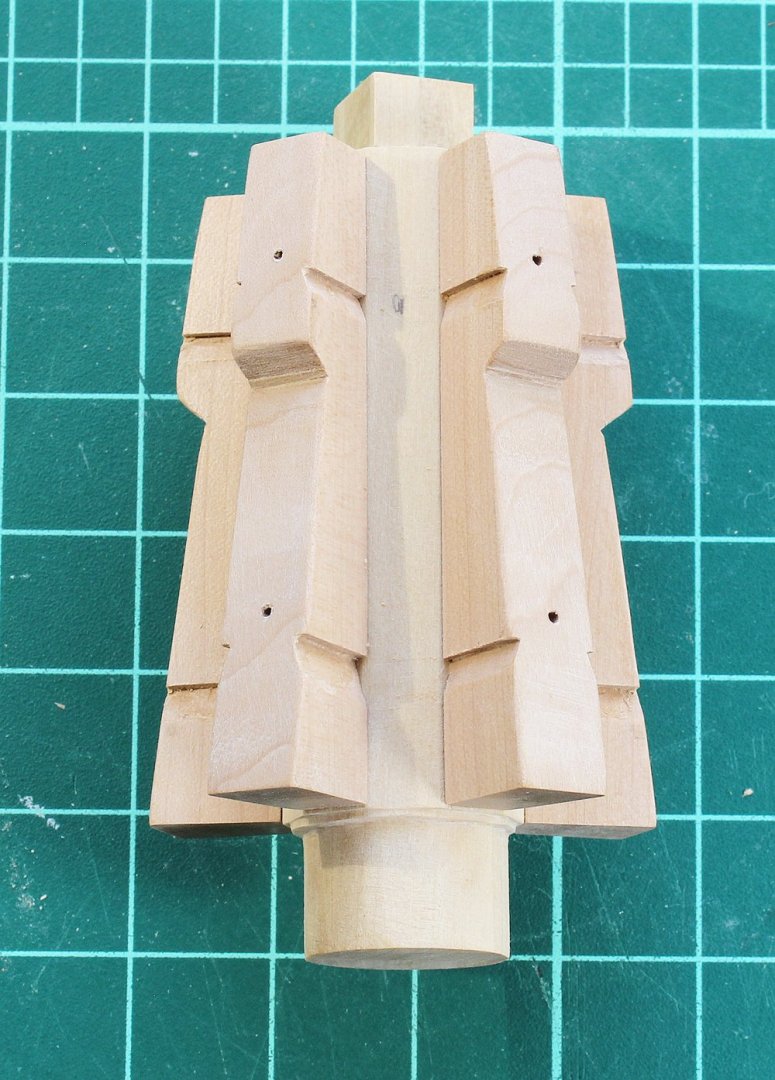

The barrel is complete except for bolts in the whelps and chocks. Just like in the intermediate project, the drumhead is made up of seven major pieces, two upper and two lower drumhead halves, two iron rings and the cap. There are also several miscellaneous bolts and fittings. After the two drumhead halves have been glued up and shaped (see the posts in the intermediate project), they are each glued to a block of wood. This block of wood secures the drumhead to the mill vice so that the recess for the iron ring can be milled. Do this on both the upper and lower drumhead parts. Debond the block of wood and glue it onto the other side of the drumhead to mill the slots for the capstan bars. The lower drumhead has a square opening for the top of the barrel. The iron ring is next. I made mine from contrasting wood, in this case pear. They are difficult to cut out without breaking because they are very thin and require cutting across the grain. I cut mine with a jeweler's saw. I made the rings thicker than necessary and sanded them flush to the drumhead. The cap was A block of wood was inserted through the square opening in the drumhead bottom. This was then clamped into the mill vise and the side recess was milled. I started in the middle and slowly worked my way out to prevent tear-out. The last bit was finished by hand with files and an 11 blade for the same reason. Finally the cap was glued in place. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Two thickness of chocks are required; the lower ones are thicker. Glue the whelps onto the spindle and then install the chocks. You can see the concave curve of the lower chocks and the convex curve of the upper.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.