-

Posts

2,033 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tlevine

-

Swann Morton chisel blades.

tlevine replied to harlequin's topic in Modeling tools and Workshop Equipment

There is nothing magic about SM. My blades are brand X. More important is the handle. The cheap ones do not hold the blade as well. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

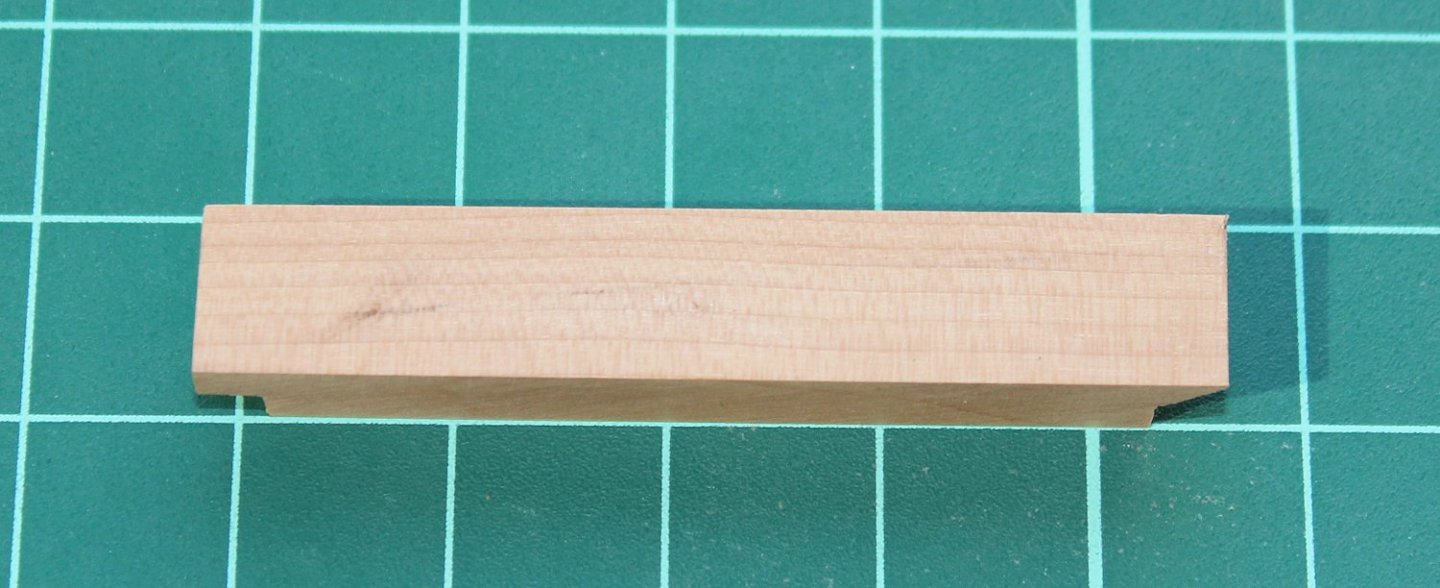

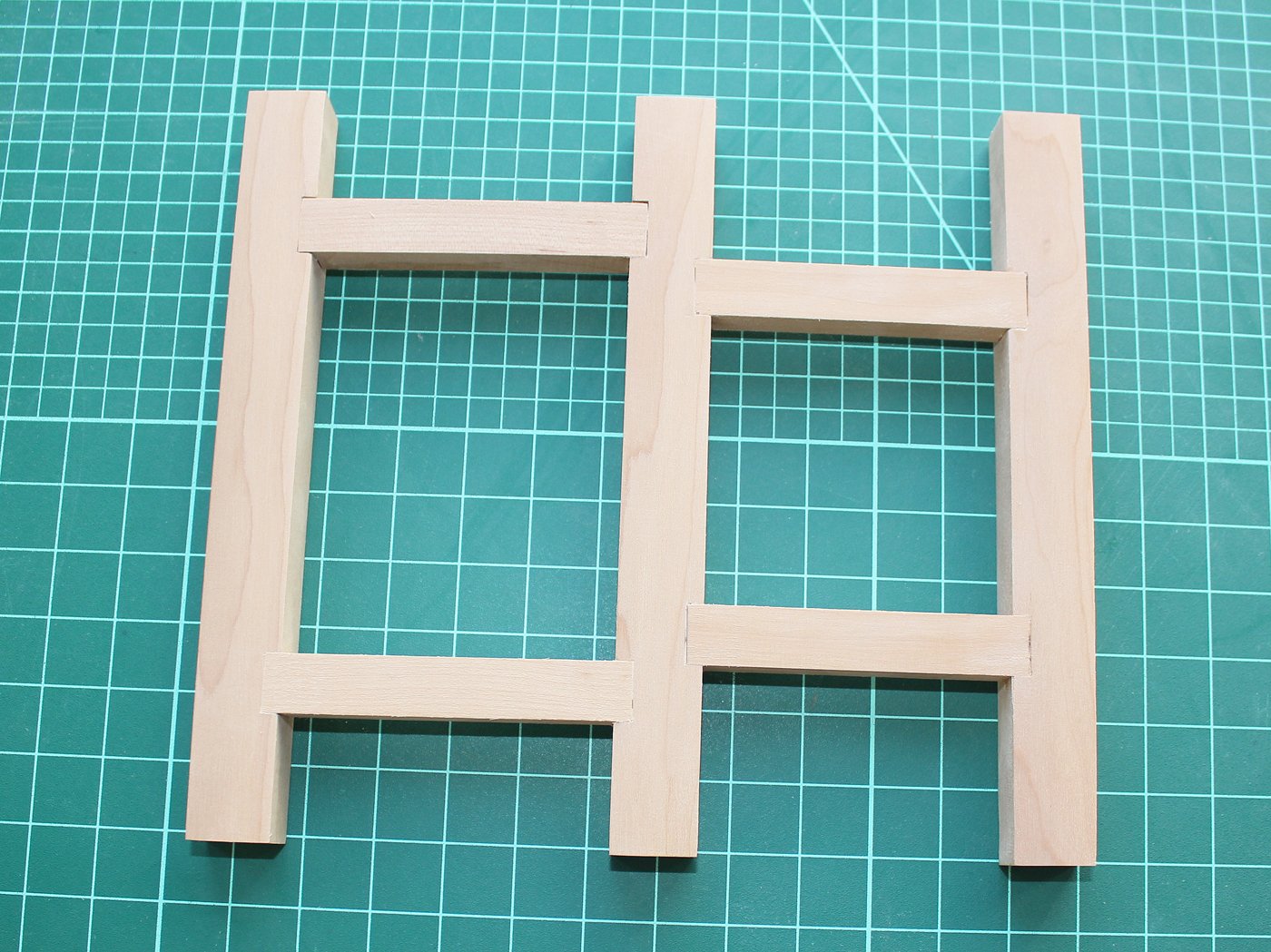

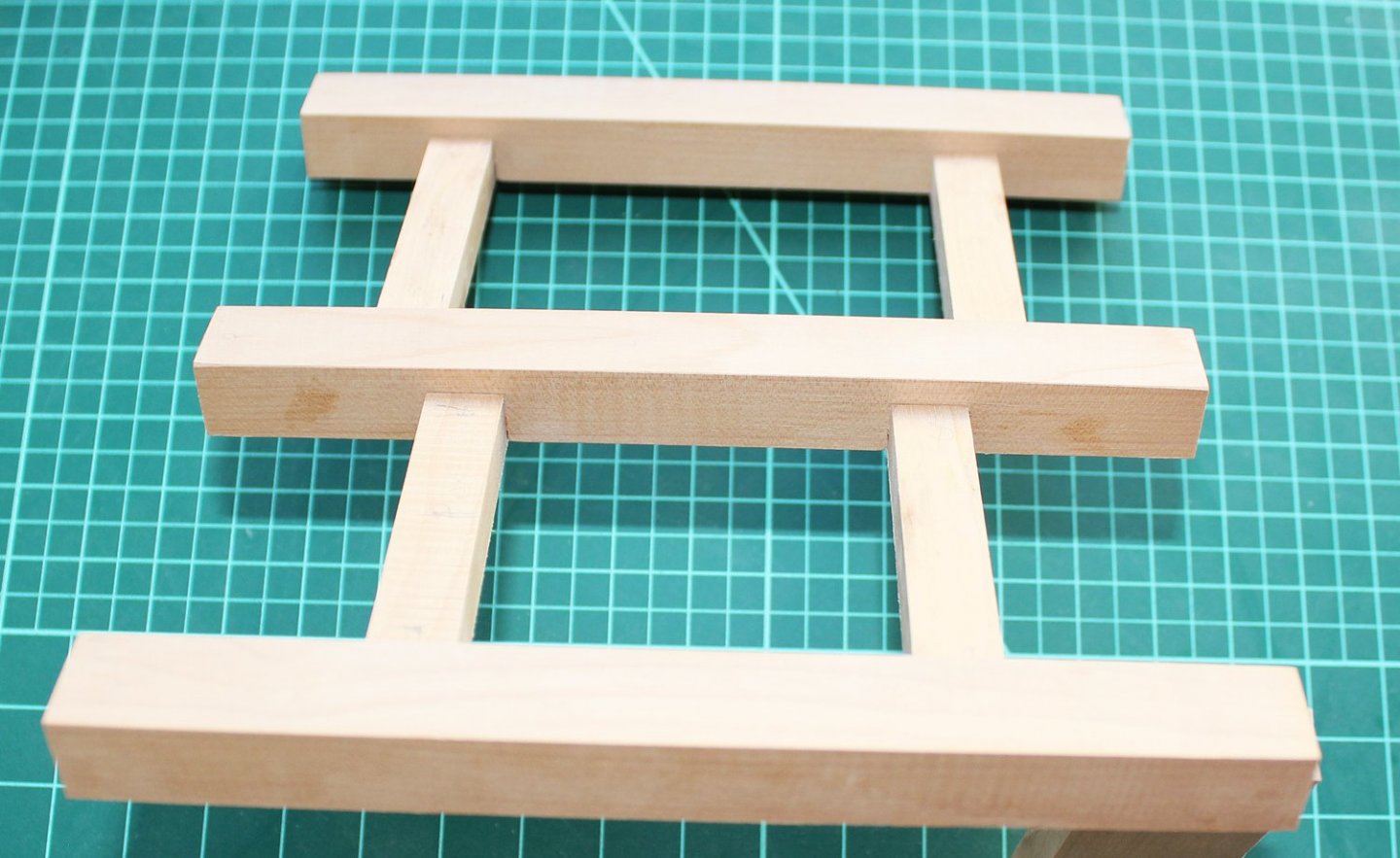

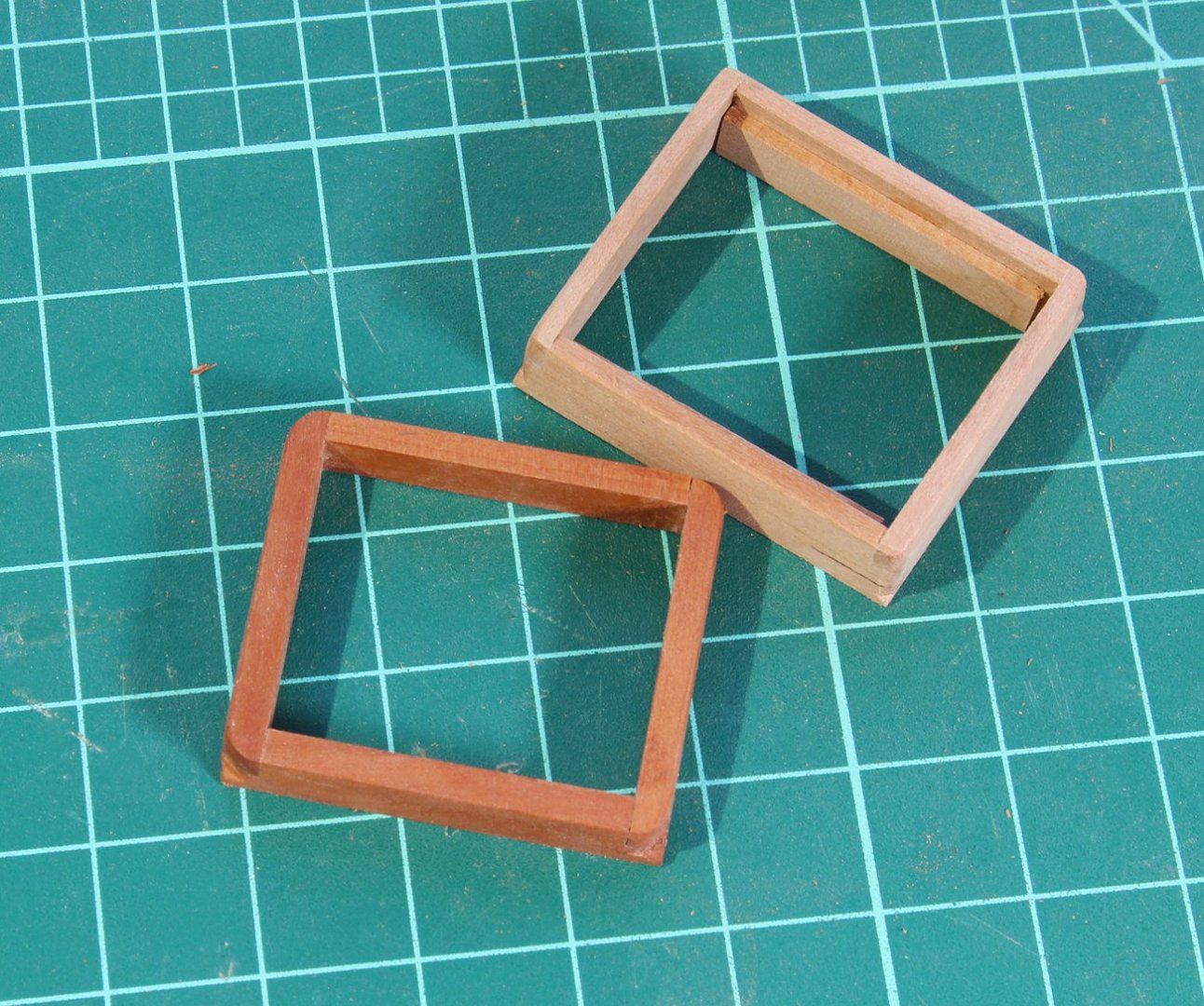

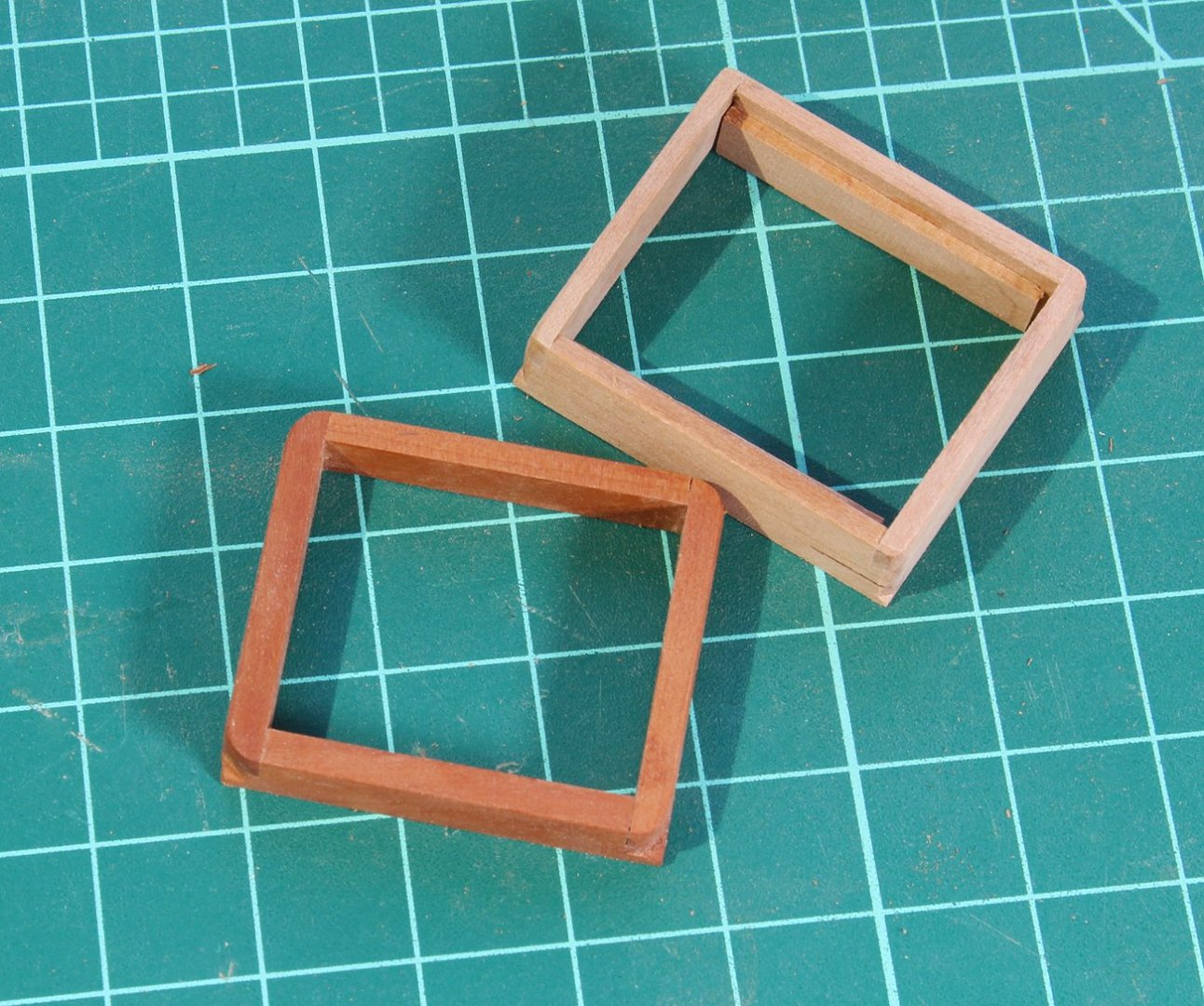

The hatch and gratings are next. The coamings and head ledges will be connected with half-lap joints. These are easily made with hand saw and chisel. There is a rabbet on the coaming to support the grating. The hatch may appear overly tall but keep in mind that the hatch sits on top of the beams and carlings, not on top of the deck planking. This is also a top deck hatch which would be taller to prevent water from entering through the hatch. Glue up the head ledge and coaming. Once dry, install the rabbet for a tight fit. The outer edges and corners need to be rounded off to the level of the deck. The lower two inches is left square for a tight fit with the deck planking. The upper half of the hatch is also chamfered 1/2". In the picture below you can see the rounding of the edges and the sharp corners at the deck. Please make your rabbet nicer than mine! The picture also shows the relative height difference between upper and lower deck hatches. Both of these hatches are made from the same sheet of cherry. I did not apply a finish yet to the upper one. There are a few things on the weather decks that draw the observer's eye. One of them is the gratings (of course, the capstan is another). Once you learn how to make your own grating, you will never go back to kit-supplied ones. What makes kit gratings so bad? They are almost always out of scale. A prototypical grating would have battens and ledges that are approximately two inches wide with similar sized openings. Remember, sailors walked on these gratings so the openings need to be small enough to prevent a foot or shoe from getting caught in it. I measured leftover grating parts from two kits. The first was from a 1:96 Victory. The blanks were scale 3.5" wide with openings over 10 inches square! The other was from the 1:62 Prince. These blanks were almost five inches wide with similar sized openings. The next problem is that they never fit the opening. You always end up with gratings that do not have solid wood on all four sides. Well, I always did. Finally, they are made from soft wood, so the teeth break off easily. Choose a hardwood for these. They are incredibly easy to make if you have a hobby circular saw. And you only need enough toothed slats for the ledges; the battens are narrow slats of wood that fit into the the recesses of the ledges. Here is another "trick". Even though I make my hatches first and fit the grating to them, if you have any concern about sizing your grating correctly, make it first and then build the hatch around the completed grating. Take a look at the picture below. There is a solid slat of wood on all four sides of the grating. If you look carefully you can the the difference in thickness between the battens and the ledges. The openings are the same size as the width of the slats. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

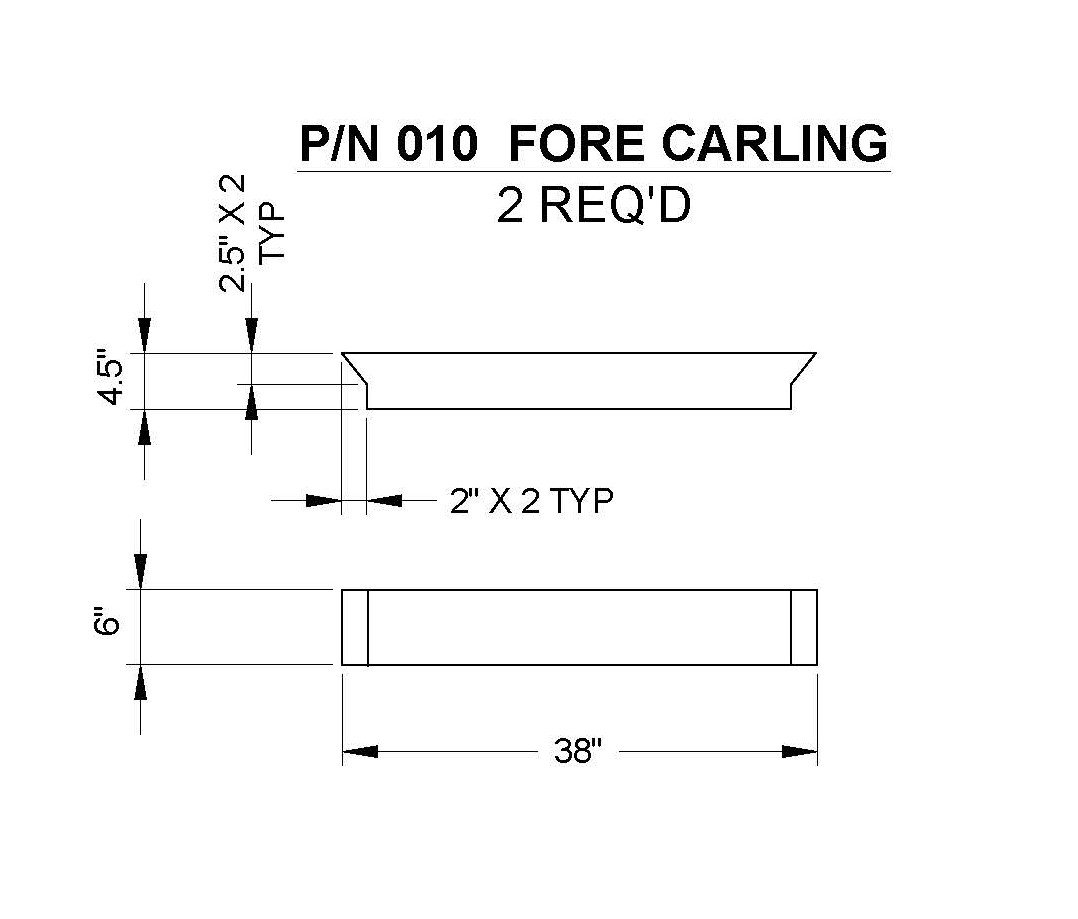

Absolutely, Chuck. The plans are fully dimensioned. The following is a sample from the carlings sheet. -

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

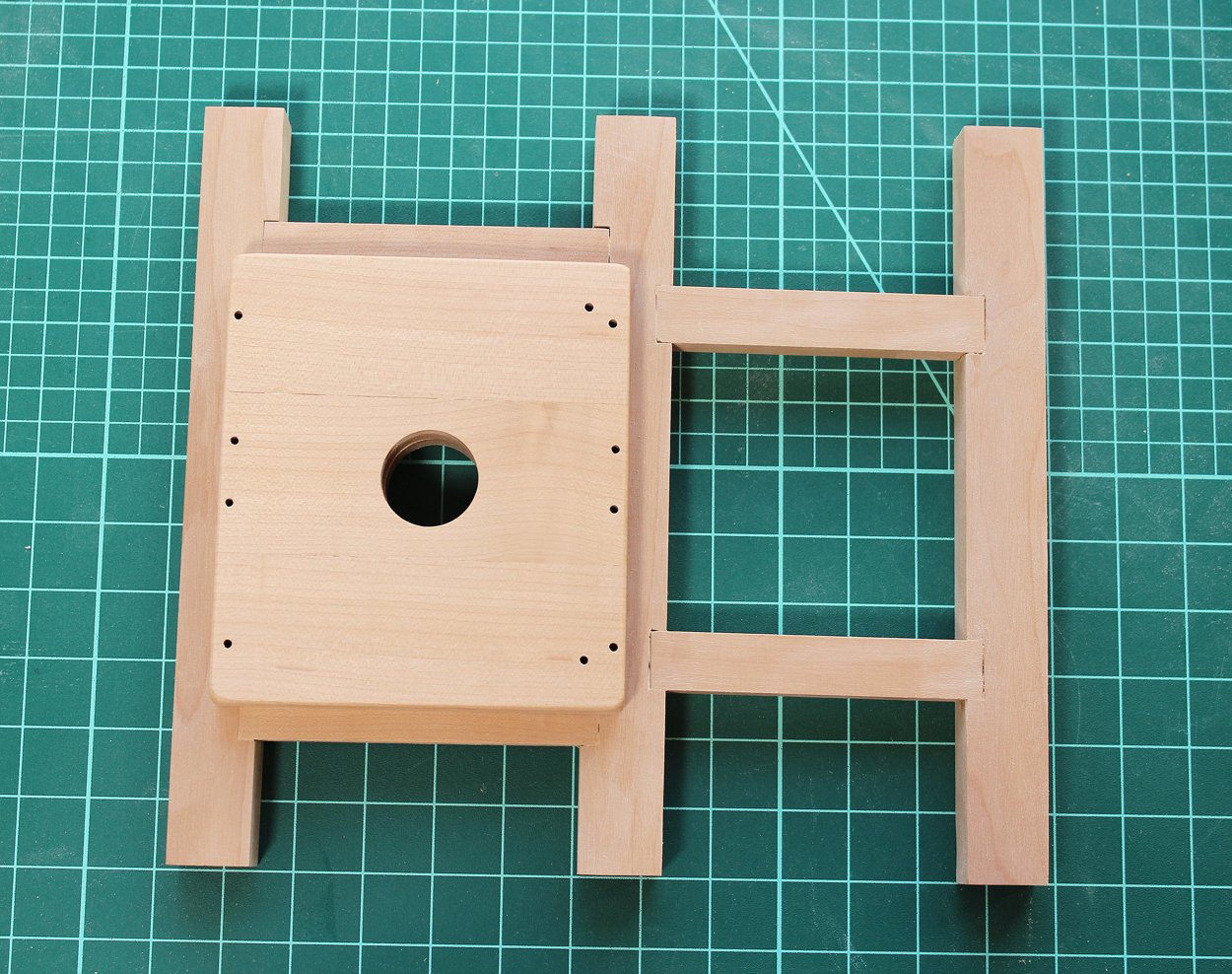

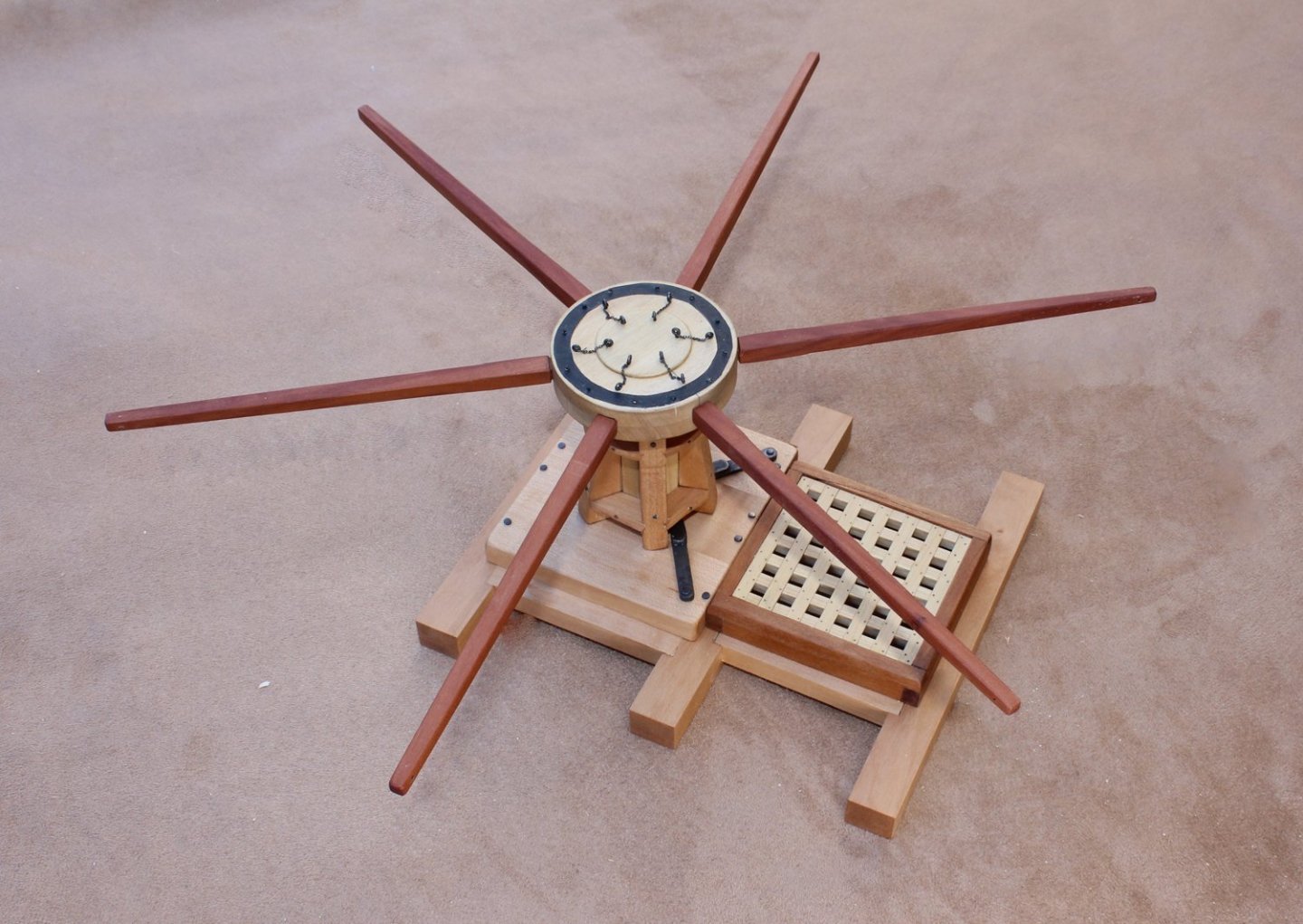

Now that the deck structure is complete, it is time to build the capstan step. There are three parts to the step and in real life they would be connected with half lap joints. To keep things simple, on this model they are glued together side-by-side. The middle piece is thicker than the outer pieces. This adds strength to the area where the capstan spindle extends through the step. The extra thickness is added as a separate piece. Items 6 and 8 are the outer pieces and 7a1 is the upper part of the middle piece. 7a2 is shorter because it fits between the beams. Throughout the build log you will find discrepancies with the instruction set. This is because, as the build was progressing, I sometimes discovered better ways to accomplish a task. The following picture shows the step glued up, with holed drilled for the bolts into the beams and the bolts for the brakes. It is easier to defer drilling these holes until the step is mounted on the beams. All sharp edges are rounded over. The hole has been drilled for the capstan spindle. This was done with a standard drill because of its size. The last picture shows the step temporarily installed onto the deck assembly. -

Drill Bits Unlimited and Drillbit City sell essentially the same bits. If you have a tremor, stick with HSS bits unless you are using a drill press. Using a carbide bit in a Dremel is not a problem as long as you Have a steady hand and do not put any lateral pressure on the bit. I would never put a carbide bit in a pinvise.

-

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

As Kurt said, we will have it available in the store Monday or Tuesday. This really is a fun project. It does not take months to build and the final product is quite sharp looking, granted I have a vested interest... -

I cannot believe it has been over three months since I posted on Swallow. I promise you, I have been busy on her and a few other things. Take a peek at the Capstan Project. Also, I was unhappy with the appearance of the upper planking. It has all been removed and rebuilt. Trunneling has started and pictures will be forthcoming soon.

-

NRG Capstan Project

tlevine replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

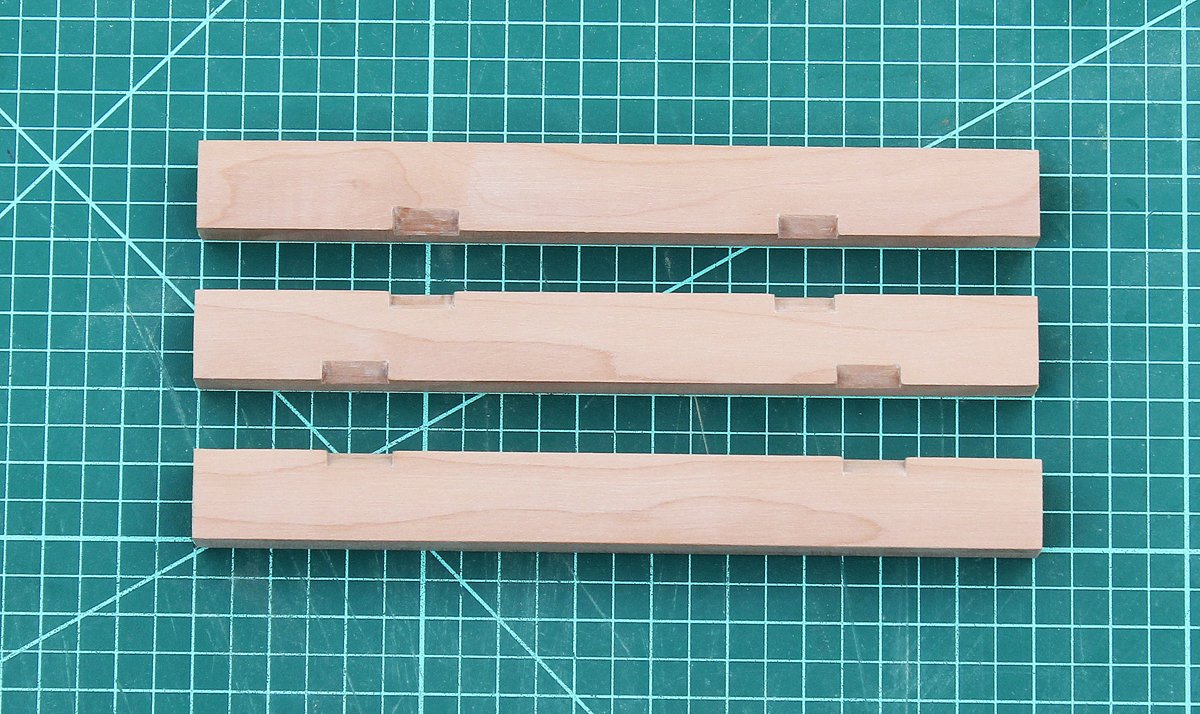

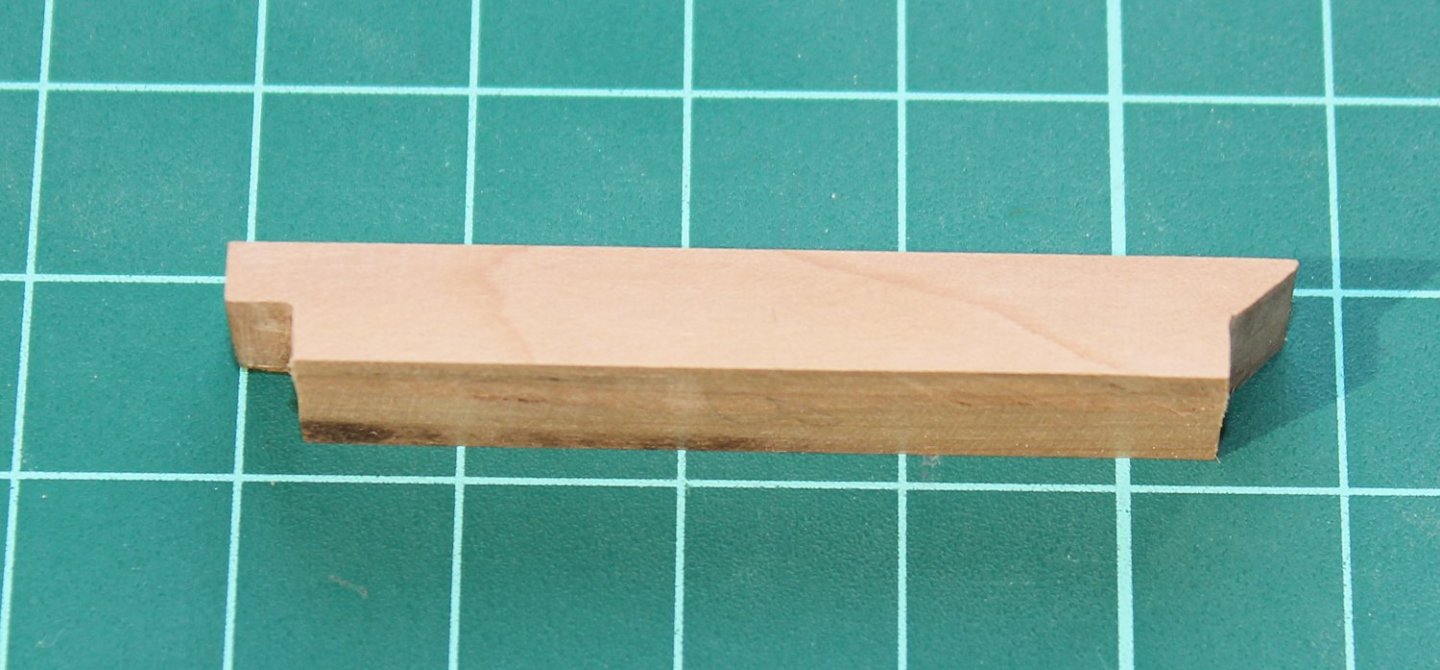

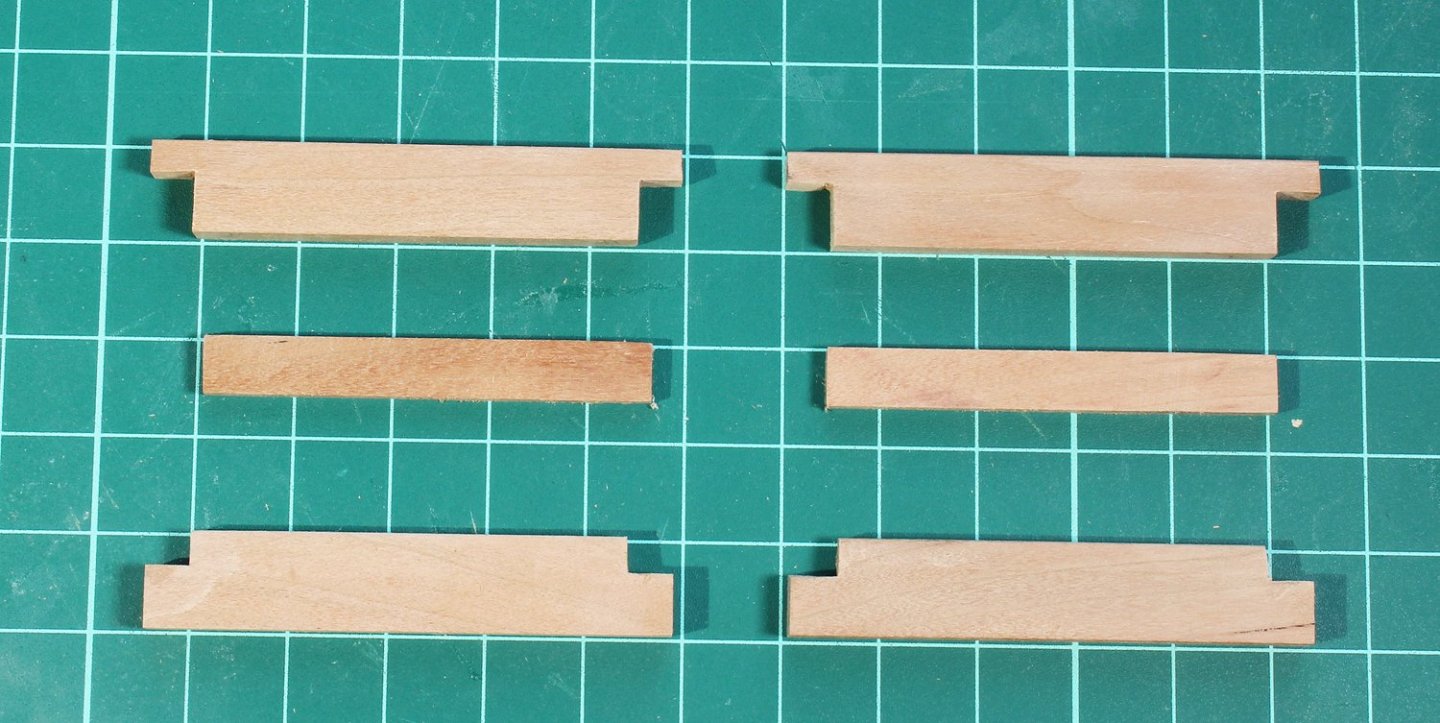

The first thing any builder should do is read the entire instruction set for both intermediate and advanced and look at the plans. This will help in two ways, first you will be less likely to make stupid mistakes. Secondly, you may want to build one part from the intermediate and another from the advanced project (for example, you own a lathe but not a mill and want to build the advanced barrel but the intermediate drumhead). Make sure you understand the plans. Most of us are not used to looking at engineered drawings; kits typically include perspective or distorted drawings to prevent copying. Decide on your scale, develop a materials list and gather your lumber. If you are using contrasting species of wood, buy a lot more than you think you need. I had to change species for my advanced hatch coaming because I ran short and could not color match replacement wood. Except for the capstan barrel, do not attempt to build this with soft woods. Now to get started. The individual subassemblies (deck, barrel, drum head, hatch and grating) can be built in any order; they are assembled as the last step. I started with the deck. There are three beams and two carlings between each beam. The carlings support the capstan step and the hatch. For simplicity, the mortices in the beams are cut at an angle. This is readily accomplished with a razor saw to make the cuts and an 11-blade to remove the wood between them. Once the carlings are installed, no one will know you "cheated". The carlings are next. Again, the tenon has been simplified. On the right, you can see the simplified tenon and on the left a proper one. Looking from above, there is no difference. And here is how it looks with the beams and carlings assembled. Make sure everything is square. -

Two years ago, the Guild started selling the half hull kit, a project designed to include modelers who had no access to power tools. The purpose of the kit was to teach modelers how to plank a hull by spiling. The Guild has a new project, actually two projects, designed to expand your modeling skills and develop confidence in the step towards scratch building. As you know, the Guild’s logo is a capstan. Our next project is construction of a capstan, shown on its step, with a hatch and grating. The first project is designed for the builder whose only power tools are a Dremel-type rotary tool and a hobby circular saw. The second is for the builder who has all the “toys”, including a lathe and mill. This is a picture of the completed intermediate-level capstan. Because this is an introduction to scratch building, the project will be sold as a download which will include a monograph and fully dimensioned plans for both the intermediate and advanced projects. No wood is included. The builder will choose the scale of construction and develop their own lumber list. Most of the plans are drawn at a scale of 1:16 (3/4 scale). At this scale, the completed model measures approximately 6” x 6” without the capstan bars and 12” x 12” with them installed. Let’s get started…

-

Vacuum (or Suction Pick-up Tool

tlevine replied to Will Ferris's topic in Modeling tools and Workshop Equipment

The cheapest price I could find was here: https://www.micro-tools.com/products/mp $5.95. Much less than Micro Mark. -

A few minutes in the oven (250F) melts the wax into the rope. Loosely loop it on a paper towel that has been placed on a pre-heated sheet pan.

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

tlevine replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

I also used a flex shaft and right angle attachment for my Dremel with a sanding disc for the initial sanding. Looking good, even if you are frustrated.- 475 replies

-

Looks great! I cannot tell from the pictures but if you have not faired the inside of the frames, now would be the time to do it while access is still easy.

- 30 replies

-

The key is to treat the copper before it is on the hull, not after. Things to consider... Are you using copper tape or individual plates? What was the original intention of the product, i.e. is there a protective finish that needs to be removed before the "weathering" can occur? What is the look you are after? At launch, just pulled out of the water before cleaning and in a drydock after cleaning and repair will all look different.

-

Dockyard Carving Tools

tlevine replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

I bought some 2 mm chisels from the Carving Glove Guy a few years ago. I already had 3 mm "original" Dockyard chisels that are probably 25 years old. The physical appearance is identical and their cutting and sharpening characteristics are also the same. The sharpening set is also a great help for the V and U chisels. -

Talk on Missouri River steamboat design & history, March 9, 2021

tlevine replied to Cathead's topic in Nautical/Naval History

Great talk! And thank you for mentioning the NRG and MSW. -

Sometimes things look better in photographs; the fastenings look better in real life. I was afraid it would be garish looking but the bolts are scale size (#77 drill bit) and so blend in nicely with the planking.

-

The coppering on the starboard side is now finished. You can see the difference between the port side with a finish applied and the starboard with none. I have decided to delay applying the finish until the wale has been redone. While doing research for another project, I discovered that the coamings were built several inches too short (8 inches instead of 13). You can see the difference in the picture below. Time to rebuild them all.

-

Miniature Drill Bit Chuck for Dremel Tool?

tlevine replied to turangi's topic in Modeling tools and Workshop Equipment

If I am drilling holes smaller than #75, I want that hole to be the correct diameter and with a crisp outline. Most of the smaller drill bits placed in a Dremel with a micro chuck or Proxxon have some "shimmy", resulting in oversized holes. For this reason, I almost exclusively use resharpened carbide drill bits for the smaller sizes. I have been using Drill Bit City https://drillcity.stores.yahoo.net/ for years. They are located in the Chicago area.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.45468af1e192d07b4a7abcb9bbf0a231.jpg)