-

Posts

1,344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtbediz

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Greg. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you so much Peter. As I mentioned before, my model is actually 1:70 scale, so it is slightly larger than yours. The reason is that I could not fully match the scale of the kit plan. But I'm glad it happened, it gave me some relief while working. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

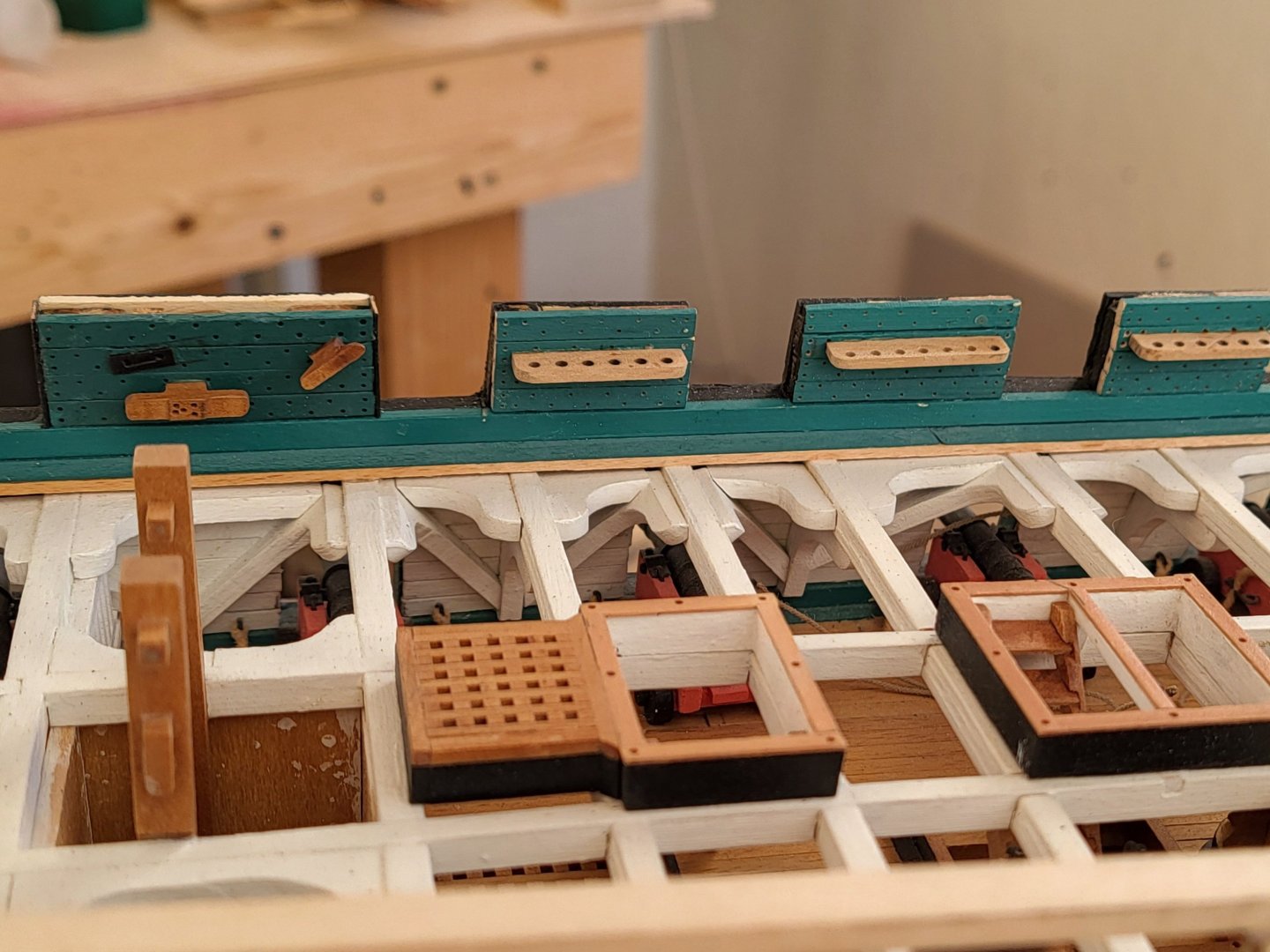

Friends, thank you for your nice feedback. I use this method often in deck planking of my models. It's a bit of a lazy job, but it's an effective method. In this case, I drilled all the planks which are going to be laid in the same space by stacking them on top of each other, which ensured regularity. By the way, Jon's bolts are much more realistic. Even if I could find the material he used, I'm not sure if I would have the patience to make it. Below is an example for the deck. I did this on my Alert model. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

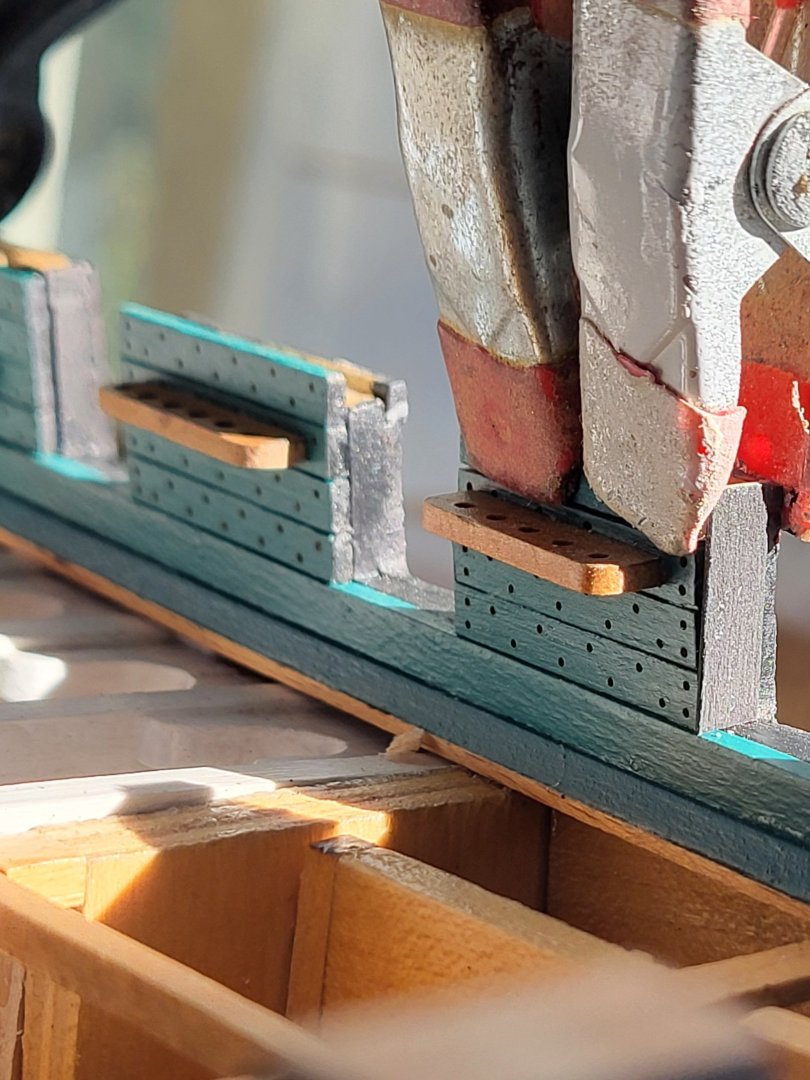

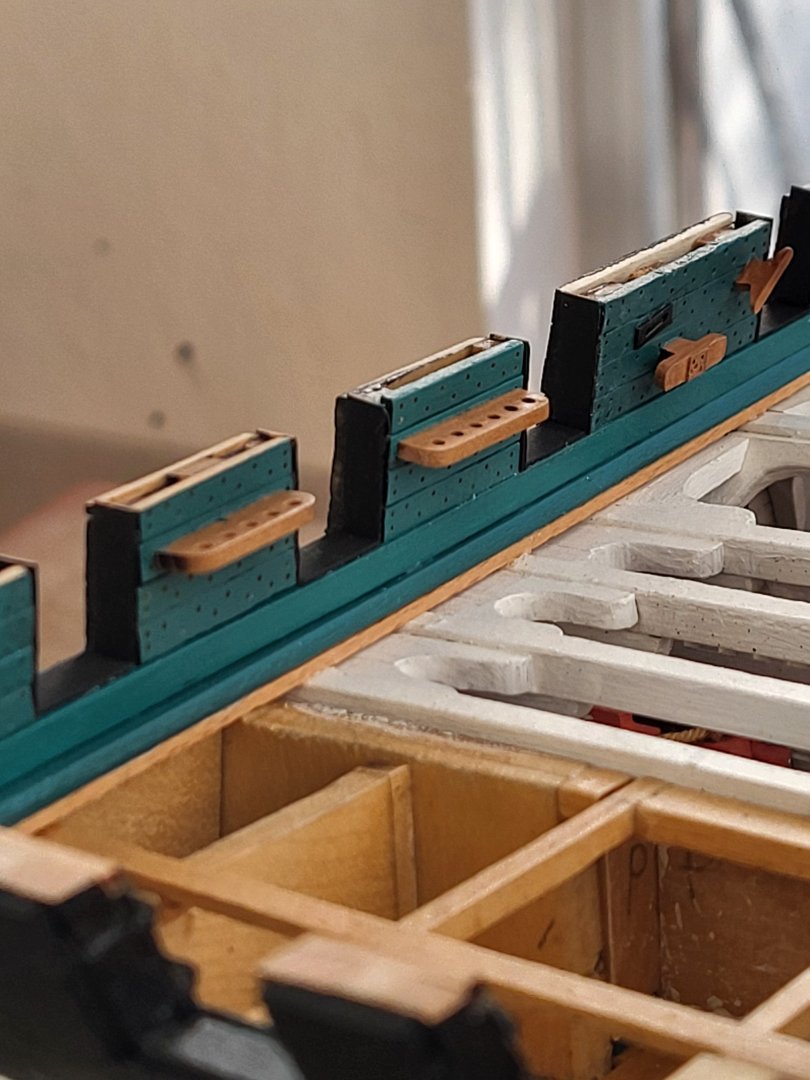

I have started planking the spar deck bulwark and adding the pin racks and other detail. I drilled 0,6 mm diameter holes into the planks to represent the bolts and was happy with the result. For the bolts, I didn't feel the need to struggle for a more realistic look at this scale. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

You are so right, Phil. I actually experience that happiness at the end of every working day. Sitting in front of the model for a while and watching what I did makes me so happy every day. That is the best part of this hobby. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you Peter. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

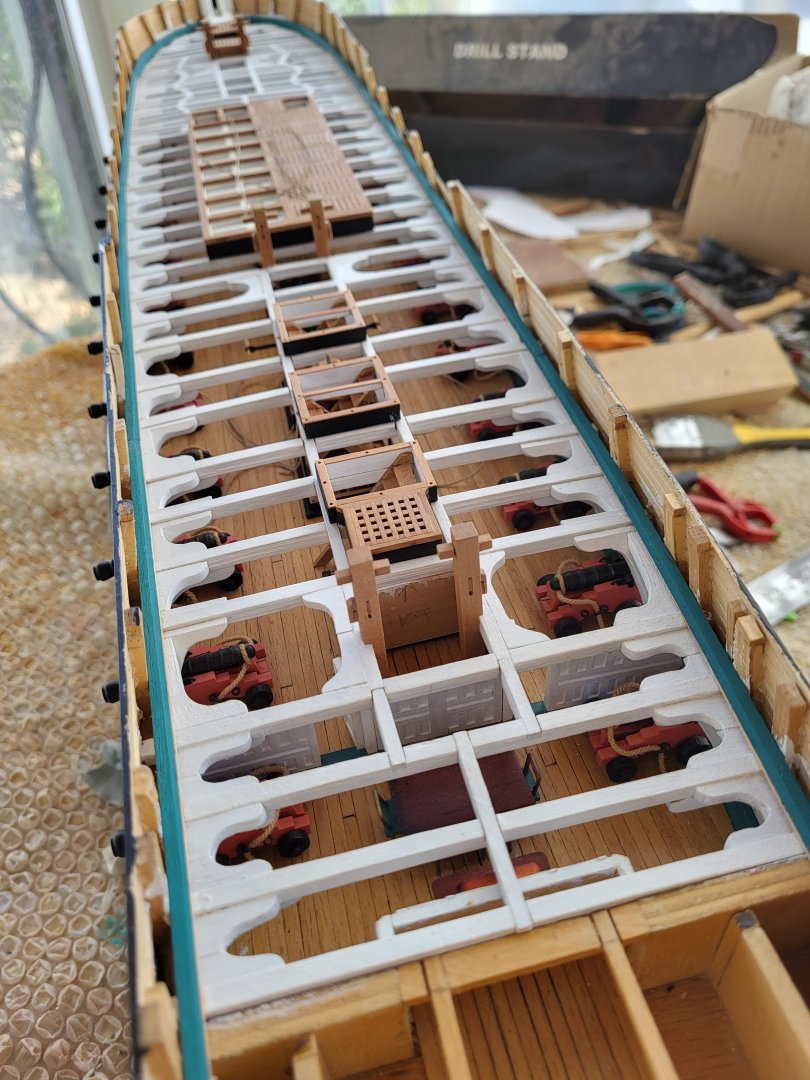

Thank you Greg. Yes, the gun deck detail and spar deck beams are complete. It was a real marathon for me. Especially building the beams and knees was a lot of repetition and hard work. Thank God it's over. I think it'll be more fun from now on. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

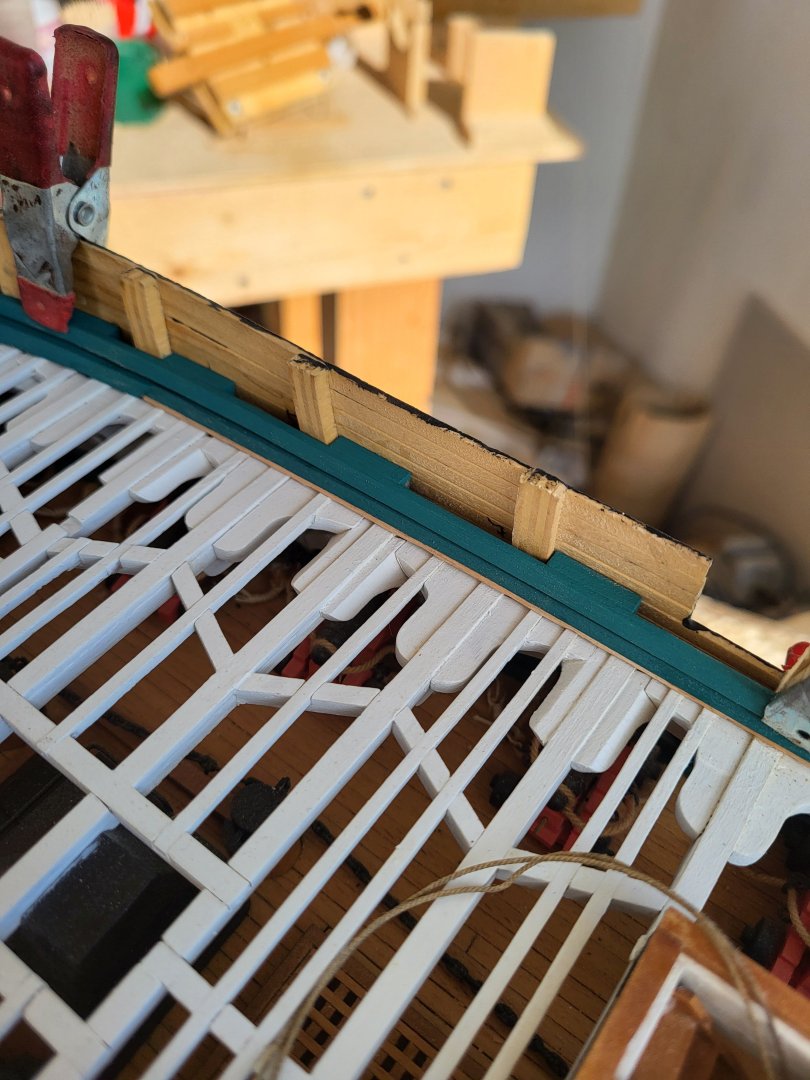

I completed the frames of the spar deck gunports and cut the gunports. I protected the sills with a brass jig to prevent damage during cutting. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Yes, there is such a risk if I don't take measure. I have some measures in my mind and I will try to implement them. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I have started making the gun ports in the front. I glue the bottom sills of the gun port frames to the planksheer and mount it on the waterway. I will cut the gun ports after the frames are completed. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I think the reason is that it makes the hull of the ship stronger against lateral forces. Like zigzag braces on lattice electric poles. If there is an expert on the subject here, maybe he/she can contribute to the reason for this. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

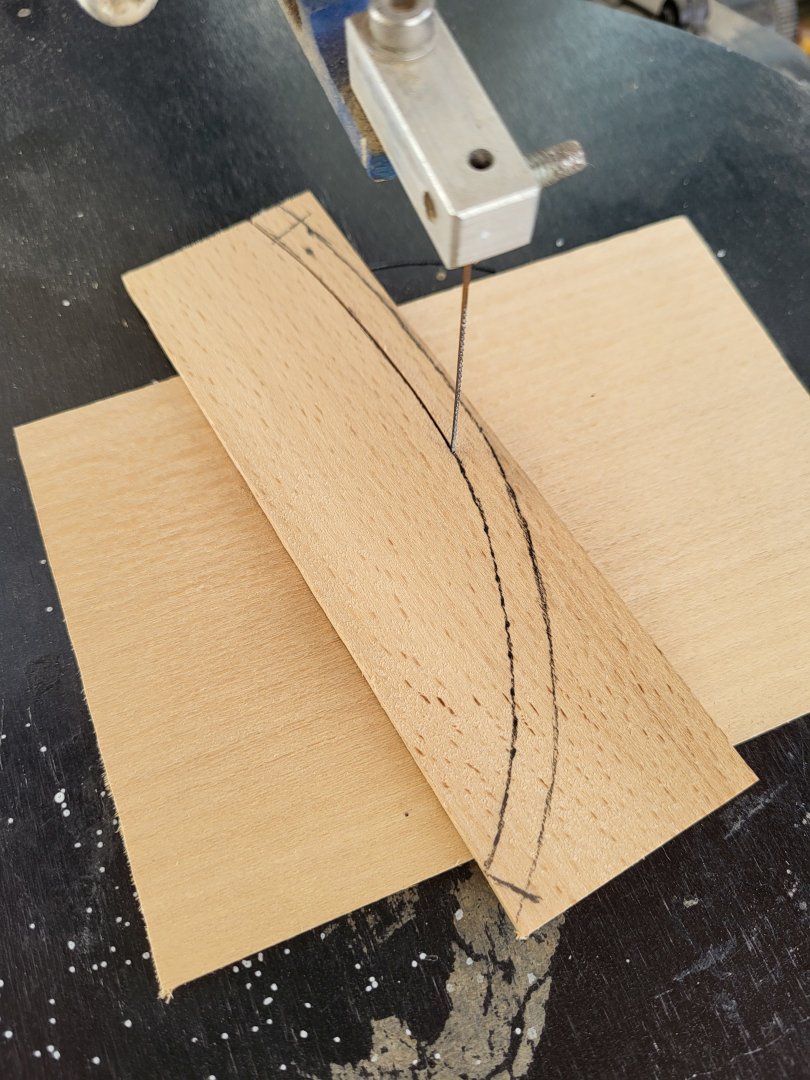

Actually, I did not use a file when chamfering the curved bow waterway on the port side. I thought about how I could do it better. I attached a drum sander to my hand drill mounted on my drill stand and made an inclined table in front of the drum. Thus, by sanding the waterway at a fixed angle, I achieved a more regular chamfer and completed the job in a much shorter time. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

-

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi Jon, actually there aren't many ways to do this. I do what most modelers do. First, I make a template and transfer it to the wood. After cutting it with a scroll saw, I chamfer it with a file. Finally, I make corrections with sandpaper, that's all. -

USS Constitution by mtbediz - 1:76

mtbediz replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.