-

Posts

77 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by FrozenRabbit471

-

-

-

Popeye, Anton and Jan,

Thanks guys. You're all correct. I decided to use parchment paper, as thats what I've been using atop my wooden slab. It helps move everything around easy, also easy to sweep dust and wood off and great resister of glue.

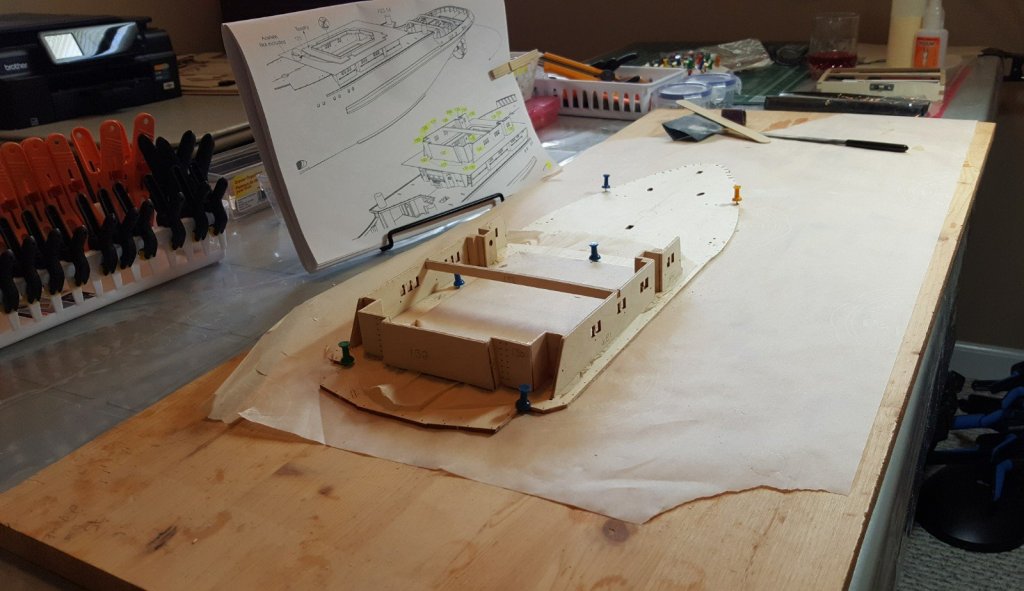

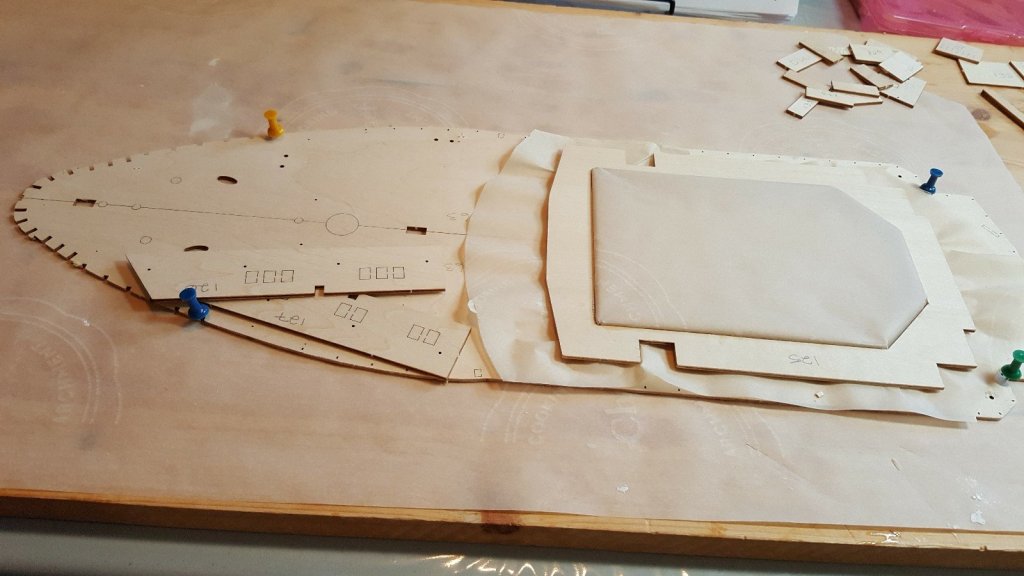

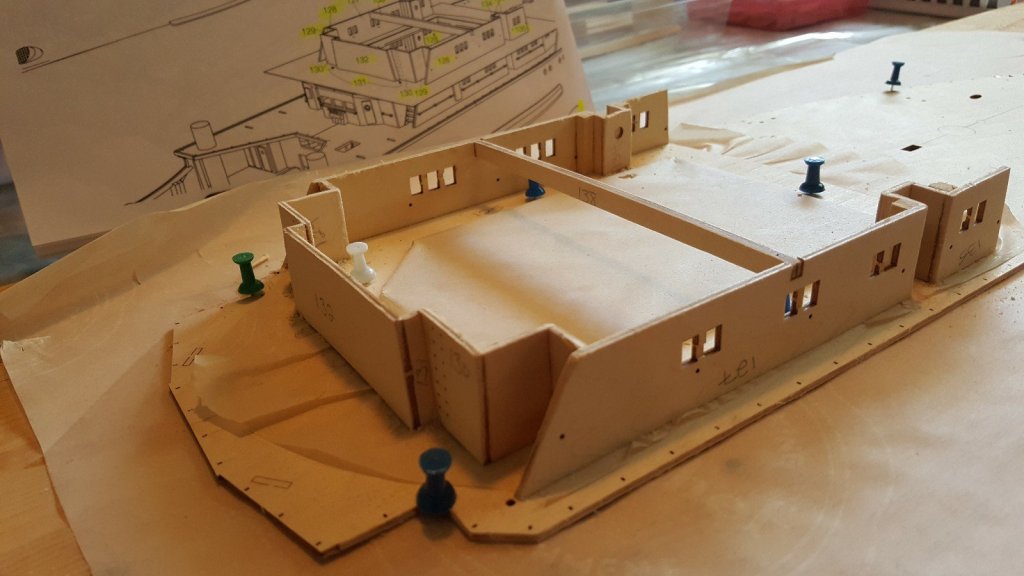

So today, while waiting to collect more information accross all the forums and groups regarding what filler to use, I started on the 3rd deck cabins. 😁

- maddog33, amateur, Steve 12345 and 4 others

-

7

7

-

Hi all,

I couldn't decide where to place my query as the margins for the subject are so wide. The answers are so vast, it almost becomes complex.

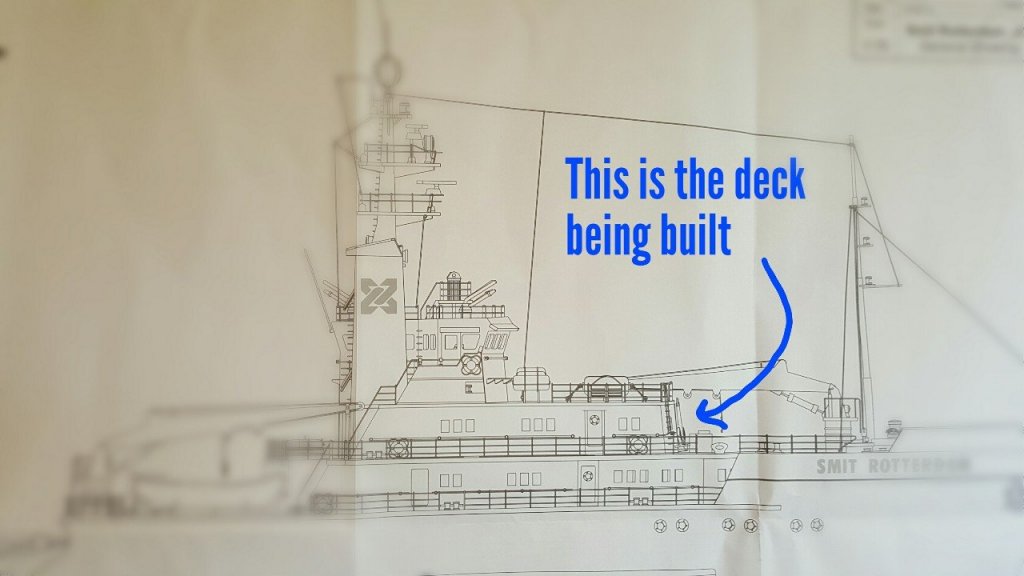

I'm building the Smit Rotterdam by Billing Boats 1:75 scale. I am about to start sanding. I have applied non-polyester resin and 3/4 oz fibreglass cloth to the inside of the hull. Solid as a church! Looks great.

Most builders share either home made ideas or suggest fillers by brand name. This serves well if you're near the same county, province, state or country.

I want to fibreglass the outside of my hull after I have it all filled and sanded smooth. I'd like to know what type of filler is compatible with the type of resin / fibreglass I am using?

Much appreciated mates.😊

-

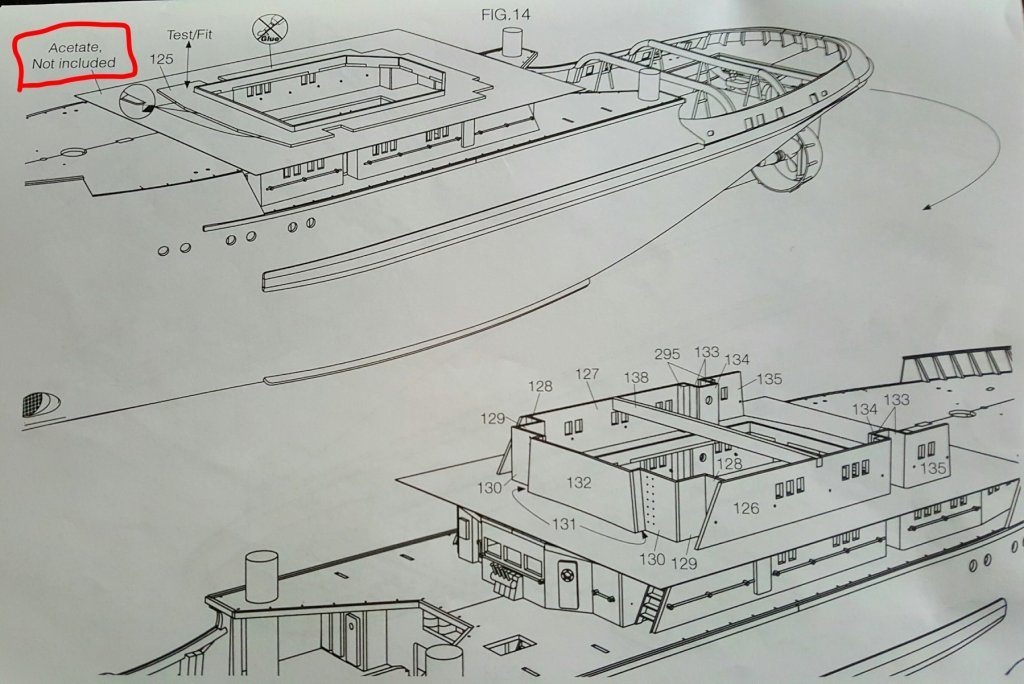

Question guys, the acetate indicated here, is it merely used as a test fit sheet? A couple guys suggested thick paper. This would allow the superstructure to go on and come off the boat easily.

In the diagram, it shows a a pretty big piece, that eventually disappears in further diagrams.

Just a wee stumped.- maddog33, popeye the sailor, cog and 1 other

-

4

4

-

Well, to that note, ill start on the superstructure. thanks aton and jan

- maddog33, Tallshiptragic and CDW

-

3

3

-

2 hours ago, Tallshiptragic said:

This is a perfect time to finish the outer hull. If you can avoid fitting the decks, get the hull finished so when you add the RC gear you can also ballast the ship, I use lead sheet and ball bearings (in bags) to get the model to the waterline. With the open hull it's the best time to be able to get to all the areas. Once you have the correct trim with your ballast those can be epoxied into the floors of the hull also. Keep in mind the batteries the large 12v or 6v kind are quite heavy so will make up the most of your ballast.

Anton, I have to order a few more RC components next week. Could a guy start the superstructure in the meantime or would you advise against it?

- Tallshiptragic, CDW and maddog33

-

3

3

-

Got it all done now Carl. Nothing wrong with a bit of extra stength. You're right though, it was a pain in the ♤$$.

Popeye, thats what i used to dab it all on. 1/2" Brush. 4 of them cheap ones. All worked out. No worse for ware.

- CDW, cog and popeye the sailor

-

3

3

-

Well fellas, the inner epoxy and glass cloth application is not elegant that's for sure. But, It's done.

When it's all dry and fully hardened I'll cut off the excess and i guess thats it for the inside for now.

Unless you all have anything to add?

While I'm waiting for the RC components to show up, I'll start in on the outside.

Terry

- maddog33, CDW, Steve 12345 and 1 other

-

4

4

-

1 hour ago, Tallshiptragic said:

Pour some resin into the space below that flat piece to coat or fill if needed. Is that for the rudder or prop nozzle supports?

yes it's the rudder compartment. I can just pour some resin in there and swish it around.

-

Sjorseye and Passer, thank you very much for dropping by my warf!

I agree I have alot of sanding to do. I think I'll pick up a mini mouse or palm sander and sand it gently with that, then obviously by hand after filling some valleys. Before I start all that I intend to epoxy the inner hull with strips of glass cloth as best I can.

The deck is only lightly tacked on and will be taken off tomorrow morning after the last few hull planks are dry.

All your input is genuinely appreciated. Stick around. Lots of fun left yet.

-

-

-

That cloth and resin is messy $#!+ I dont care how experienced you are. 🙃

That cloth and resin is messy $#!+ I dont care how experienced you are. 🙃

-

Hey Keith. Thanks for the much needed tips. The tips, tricks and critiquing I get on this and one other ship build forum are like gold dust to me. Though 90% of it being too late, is created a well fitted dry-dock for a future build. I plan on studying all my threads before the next build.

This of course is not to say I still cant use the advice on some current applications. By the way, I hope you don't send me to the gallows, your pics are stunningly crisp and bright. I have saved them in my "Rotterdam Build" file on my table, so I can refer to it to get that mental picture. The pic on the box must have been taken in 1973. Gross!

Thanks Keith

-

thanks a bunch guys. to be honest to the 3 of you, i intended to resin the inside first and maybe dab on strips of cloth.

Regarding the horrible outside, I was going to give it a rough sand, use filler, rinse and repeat.

Im going to pick up a mini plam sander. If I had ended up with a perfect hull I would not have bothered, but I think it may save my hands.

On another note, I have posted these pics and texts to several other groups and forums. I can honsestly say, this group and NRG are amazing. The support is top shelf. I opened one of my facebook threads in a boat building group this morning. An experienced builder had told me I was rushing and that's not what model boat building was all about. He said I should be buying #ready-made-boats / rc boats.

I was heartbroken, crushed, woundedm choked......... for about 11 seconds.

-

1 hour ago, Tallshiptragic said:

Hi frozen, with the fiber glass resin I would suggest once the hull is sanded and smooth the give the outer hull a couple of light coats of resin first. Let dry properly and a light sand in between coats, this will make the hull nice a solid and then resin the inside of the hull. This is how I build my large RC ship hulls. Also when the hull is done and you lay the decks down again give these a coat of resin also especially at the joins with the hull. The resin will ensure better chance of the deck and hull not parting after years of use on the water as well as ensuring its waterproof. If you're patient you don't need to use cloth just a few light layers of resin. Below is a photo of my 1:72 Australian AWD HMAS Brisbane and my 1:72 Arleigh Burke class DDG in progress.

Hey tallshiptragic, The ship is beautiful. Damn fine job. What you've suggested is the way I will go. The inside seams have been wet finger glued with good wood glue. I hope that wont hinder the epoxy bonding.

- Tallshiptragic, CDW and maddog33

-

3

3

-

2 hours ago, Steve 12345 said:

Hi frozenrabbit I caught your build yesterday I assume the progress from removing the kit from the car didn't happen in twenty four hours , is the log up to date now

ps looks like a very nice kit will follow with interest

Hey Steve, I was late coming to this group. I had already completed the frame and hull floor and just starting the planking. I am up to date. I wanted to be sure to post in chronological order.

- Steve 12345 and CDW

-

2

2

-

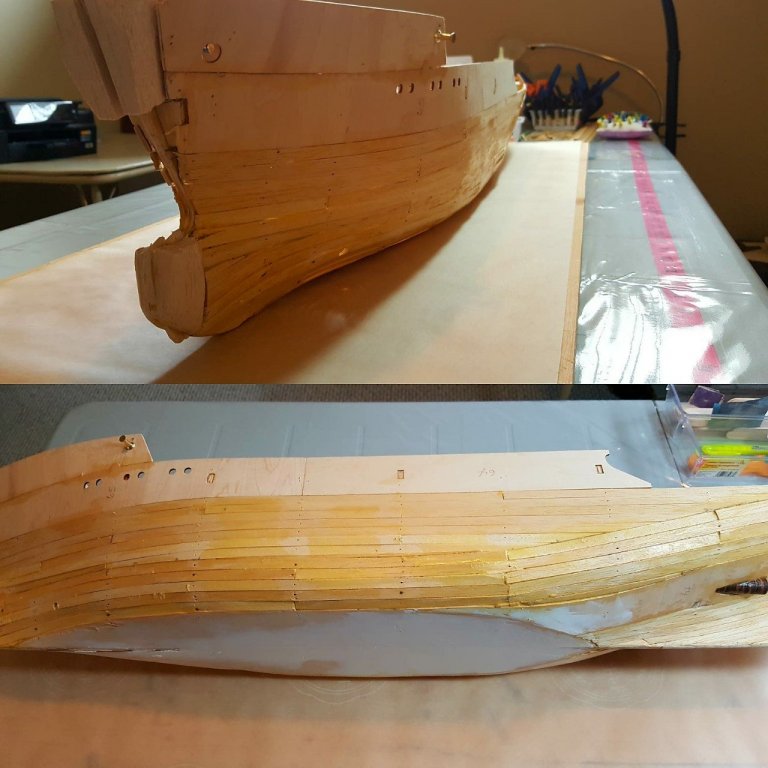

Ahoy

I have a few pics here. You will all throw pie in my face on these pics. Keep in mind, I am a perfectionist, for real!

I majorly messed up on the starboard side planking. In comparison, you can see I did quite well on port.

Before you all make me walk the plank, just know, I'm am still not discouraged in the least. I worked a hard a possible to compensate fir the horrible placement and lack of keeping true.

My wife came in the room, as she often does to show interest and cheer me on. When she seen it, she give me "a look".

The jig was up. I stood up, stepped back and briefly lost all confidence.... briefly.

I strongly considered no posting them as it would have been easy to just post the port side etc. Then I thought about it and concluded that this is a forum to help everyone. I another builder is searching for how not to do planking, well I have toes pictures posted here.

So have a look and Post your honest opinions and reviews, for me, and future builders. -

Sjors, Popeye and Passer, thank you very much for dropping by my warf!

I agree I have alot of sanding to do. I think I'll pick up a mini mouse or palm sander and sand it gently with that, then obviously by hand after filling some valleys. Before I start all that I intend to epoxy the inner hull with strips of glass cloth as best I can.

The deck is only lightly tacked on and will be taken off tomorrow morning after the last few hull planks are dry.

All your input is genuinely appreciated. Stick around. Lots of fun left yet.

-

- popeye the sailor, maddog33, RGL and 2 others

-

5

5

-

-

-

-

(2).thumb.png.08e26c1b7271617455d04b102a2b4077.png)

Smit Rotterdam by FrozenRabbit471 - Billing Boats - 1:75

in - Kit build logs for subjects built from 1901 - Present Day

Posted

well, not easy for me. But fun.