-

Posts

220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jobbie

-

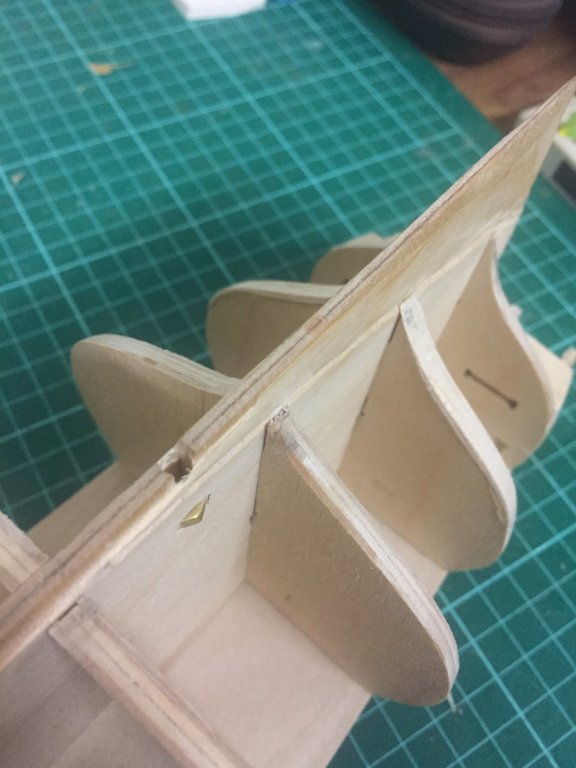

There are a couple of areas on the ship where holes in gratings, hatches and around the upper sternpost area where the plywood frame may be visible on the completed model. To help prevent this, I’ve employed one of my daughters to apply a bit of black craft paint to those spots. It doesn’t have to be neat, as it will all be quite dark in there later. Now the deck is ready to be permantly fixed in place.

-

Looking great, Rod. I’ll follow along as well.

- 108 replies

-

- endeavour

- caldercraft

-

(and 1 more)

Tagged with:

-

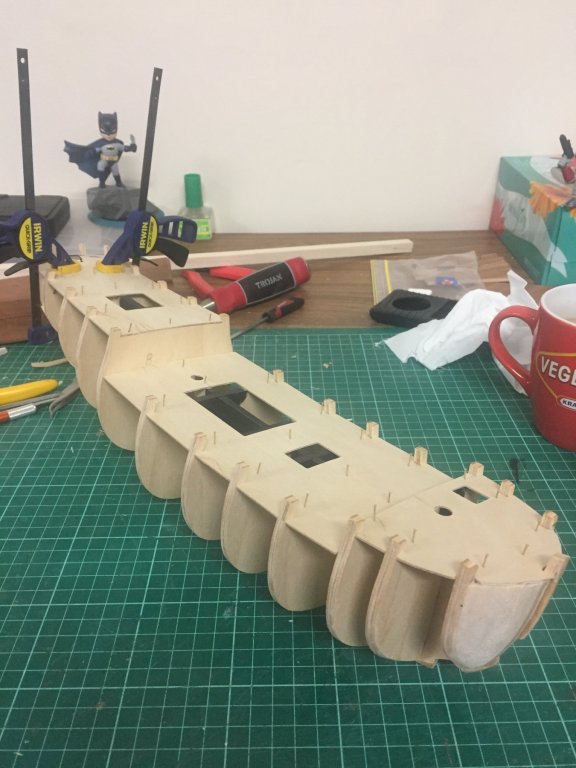

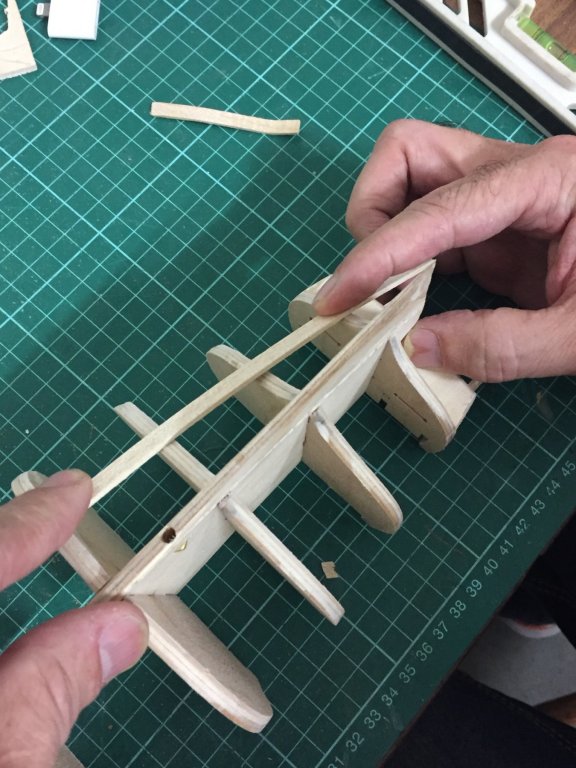

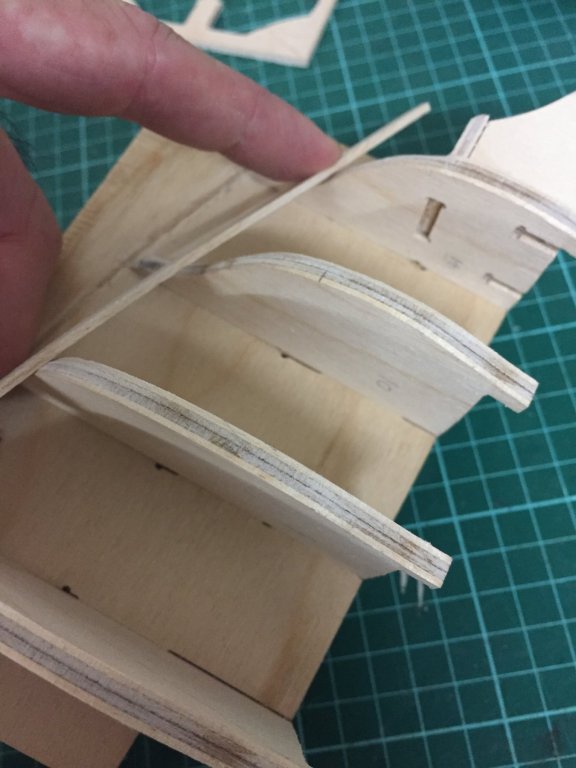

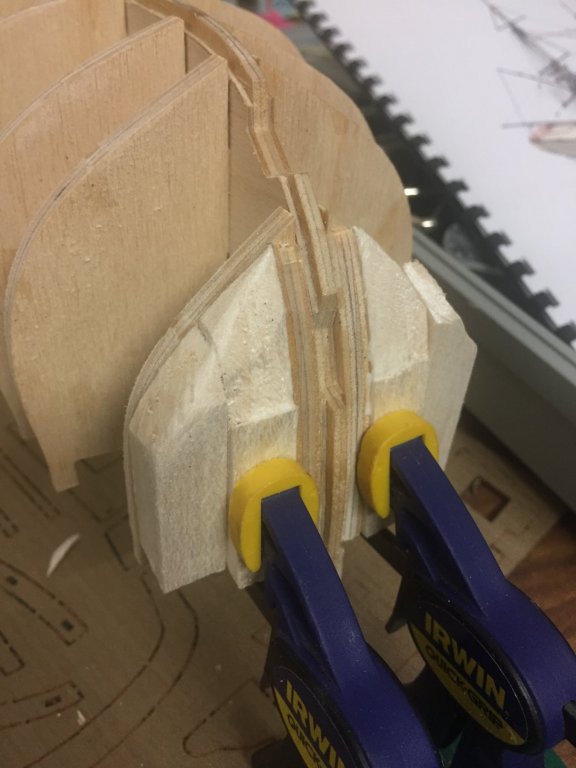

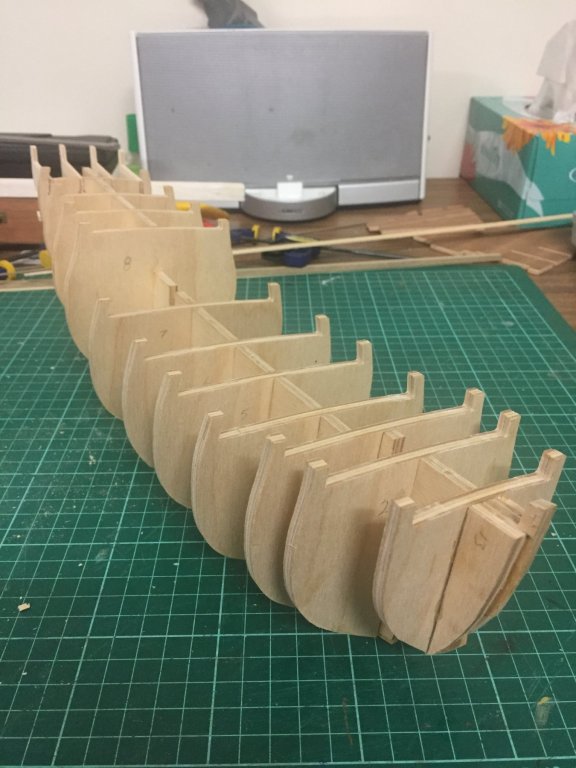

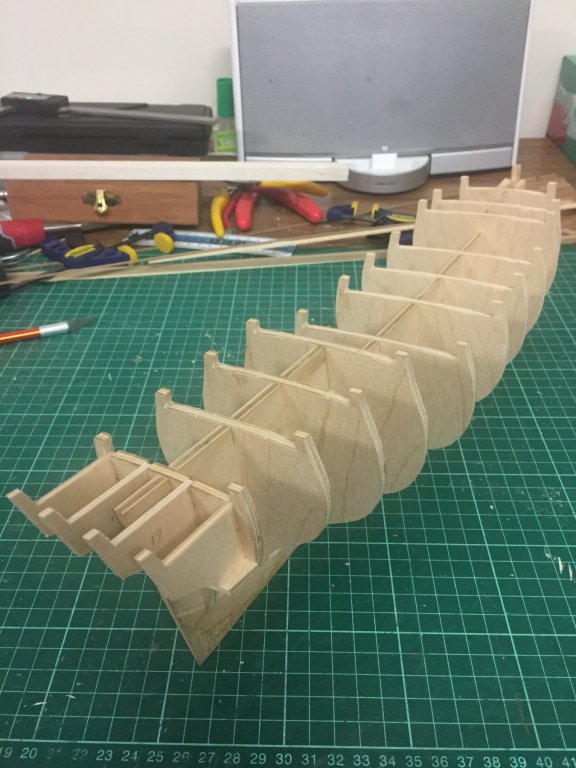

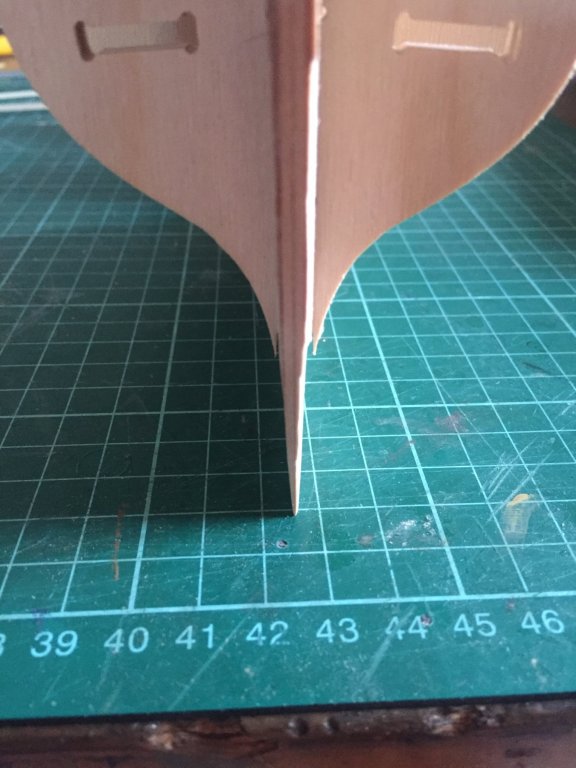

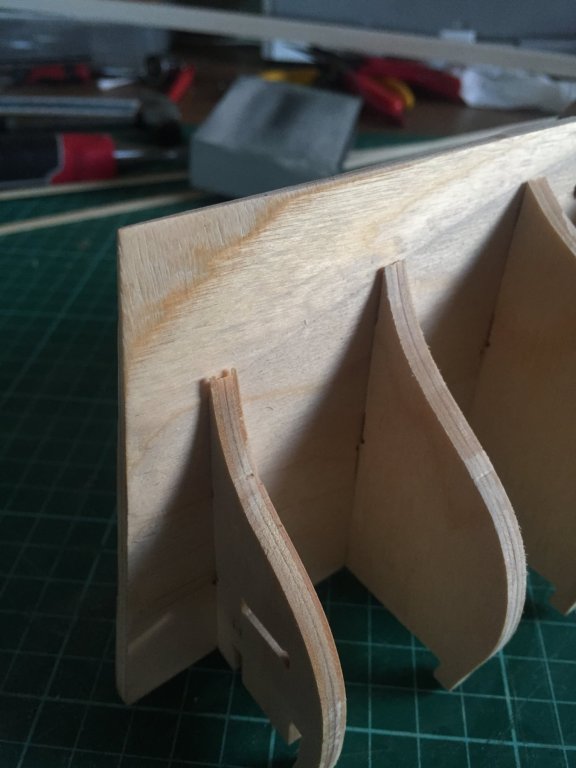

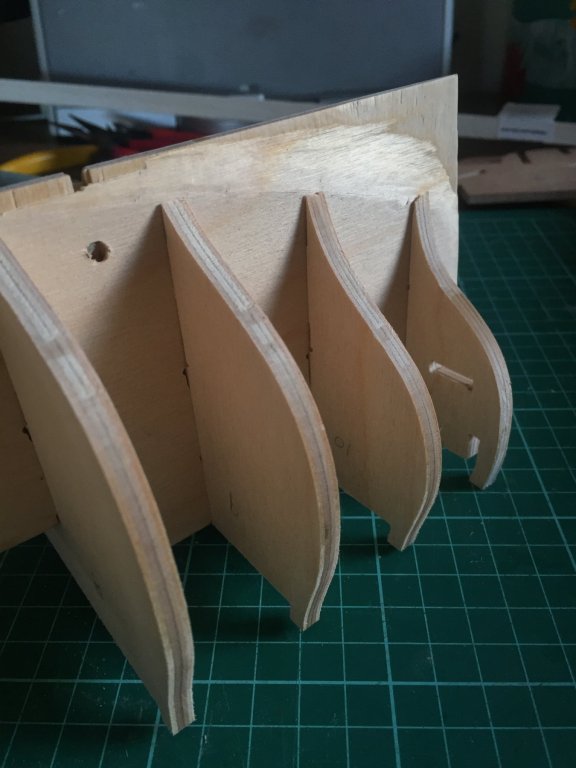

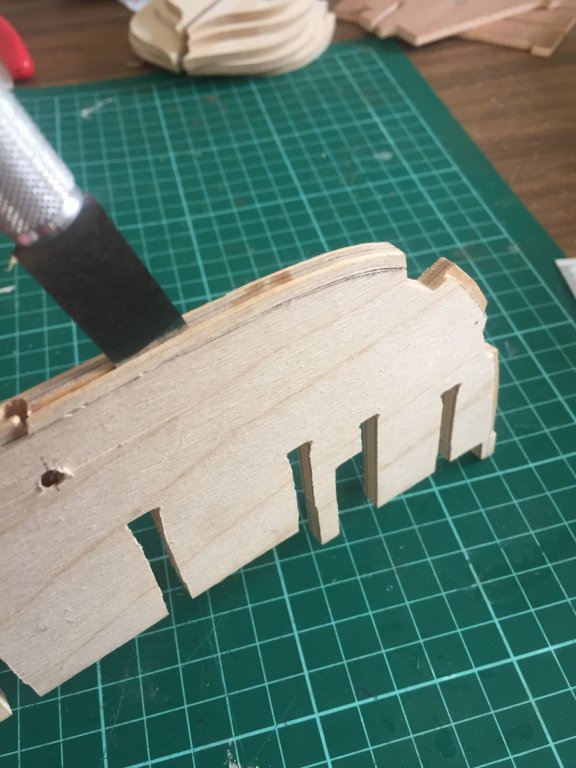

That was straight forward. Happy with that fit now. The instructions state “It is also recommended that you bevel the edges of the front and rear bulkheads as well as the plank termination patterns before gluing.” Yeah, nah. I’ll choose to wait until the skeleton’s assembled, glued and dried before profiling the hull.

-

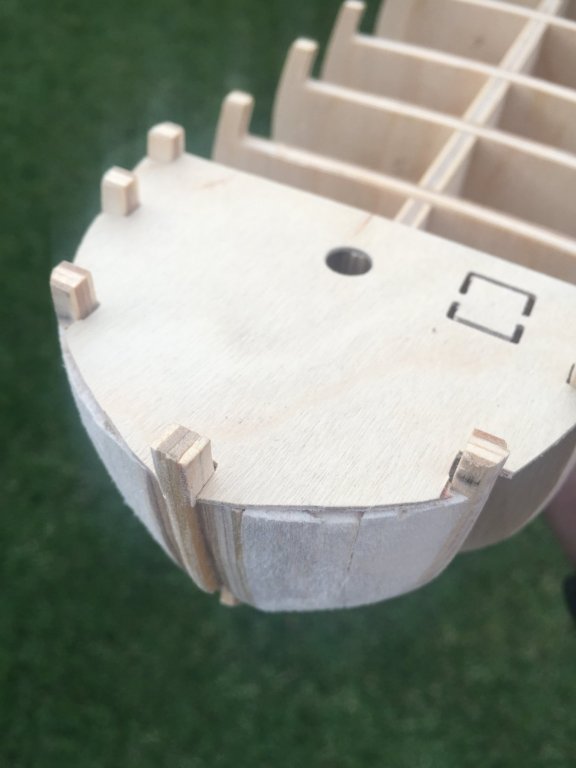

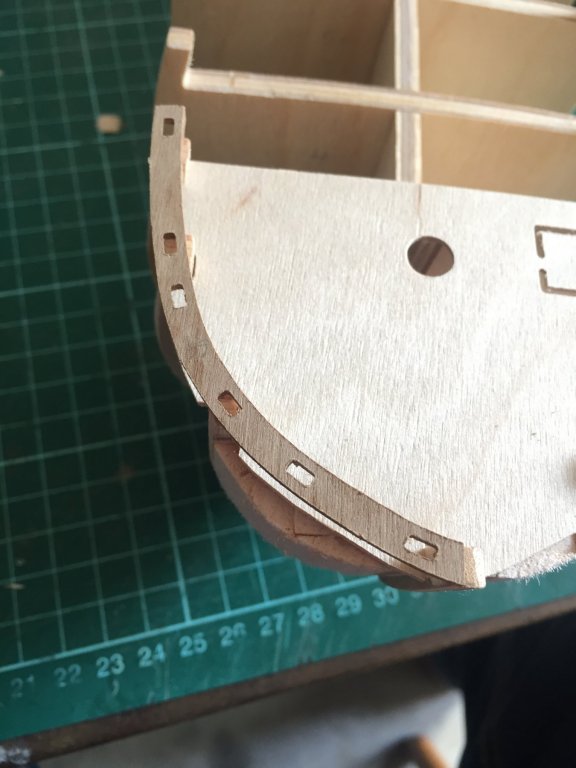

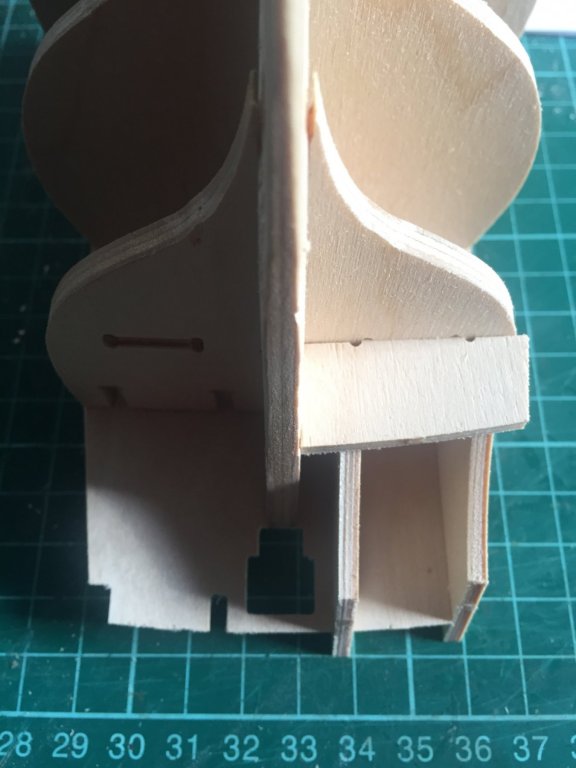

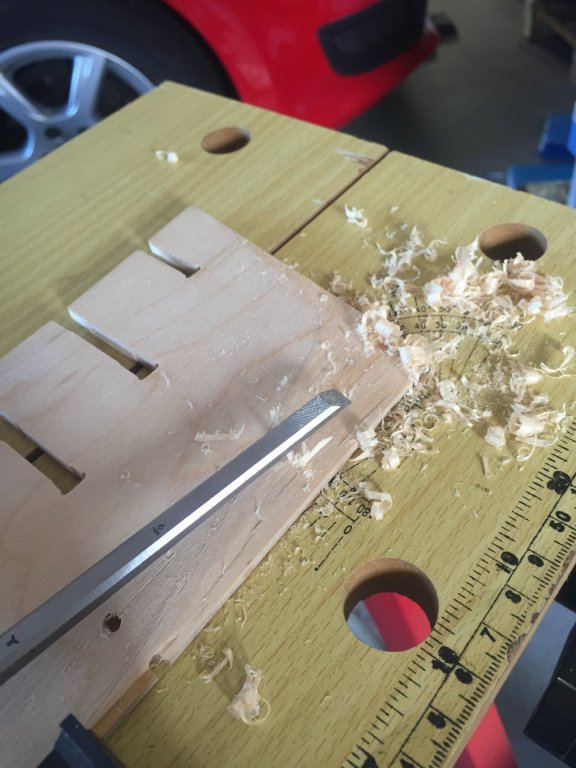

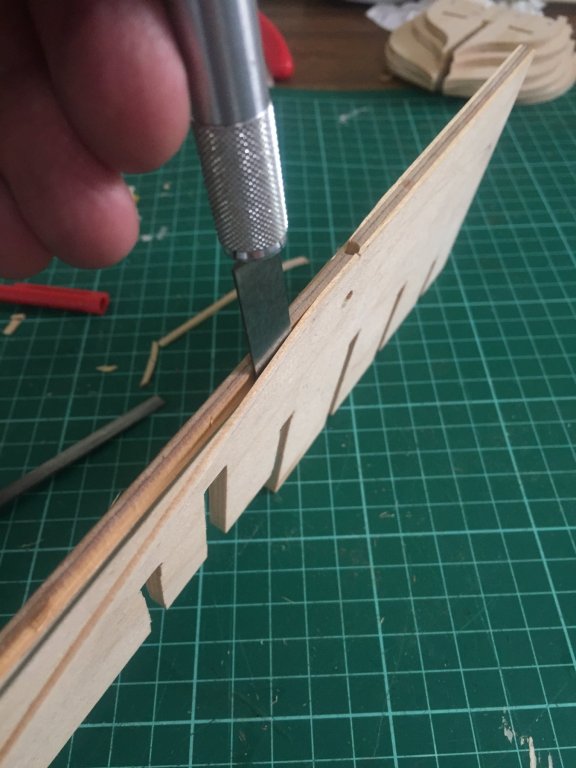

Ok, I’ve hit my first snag. As I’ve established the rebate to be the thickness of the first and second planking (2.6mm), the plank termination patterns (2x item 13) are now too large and need to be reduced by 2.6mm. I’ll use a finger plane and take it off the rear face to maintain the leading edge profile.

-

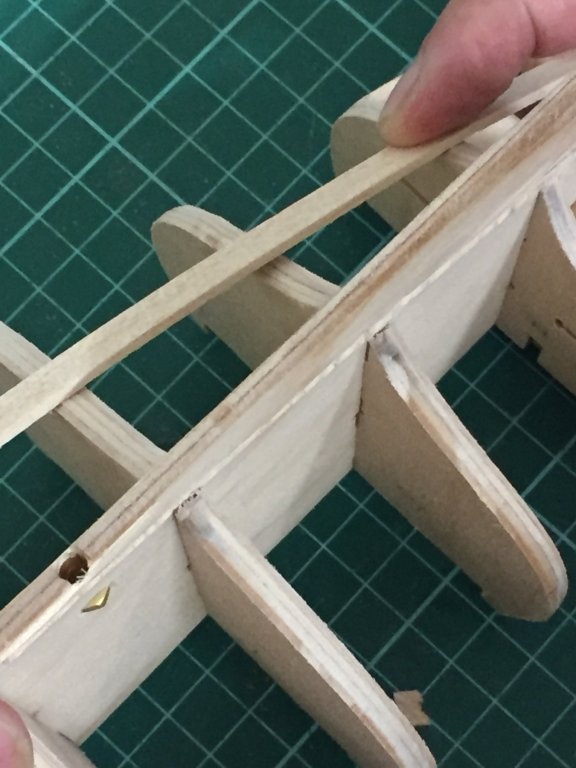

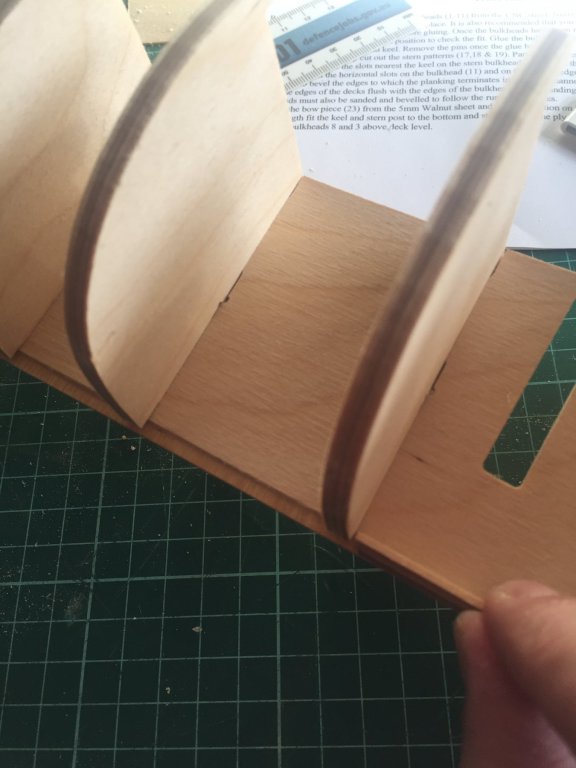

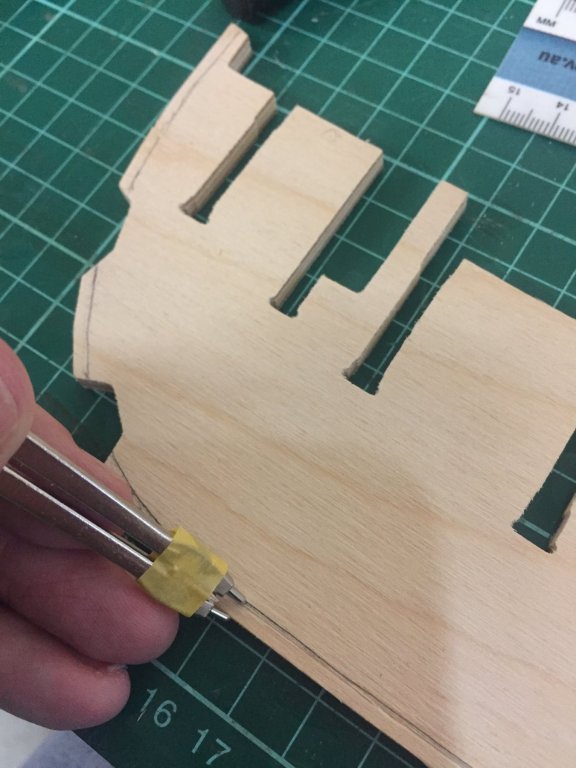

I press-fitted 2x 5/32 nuts for pedestal mounting later. I was going to Araldite them in place, but they’re not going anywhere. I don’t feel the need for a ply sandwich, either. Also, I’ve taken Rob’s advice to terminate the first planking at the bearding line, so I’ve formed a shallow rebate there.

-

This is seriously nice work, Rob. Lots of good guff, too. I'm very much impressed. (I'm a huge fan of the Aubrey-Maturin series, too.)

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.