-

Posts

220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jobbie

-

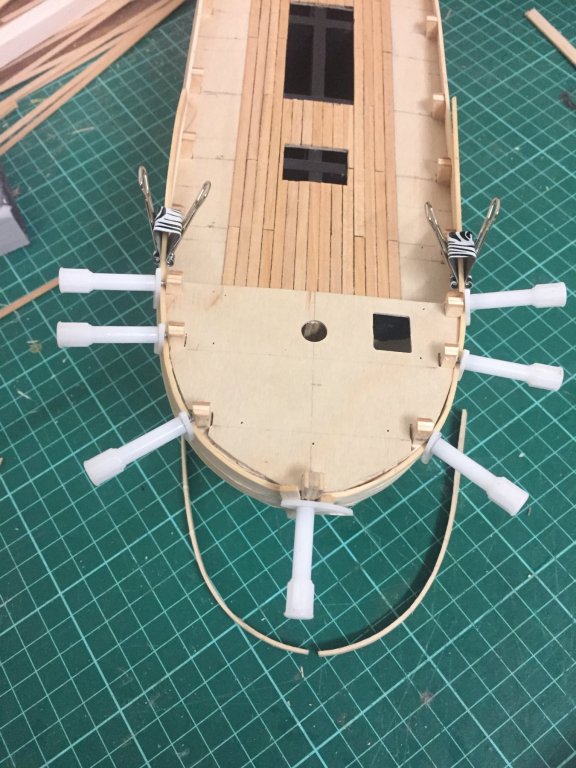

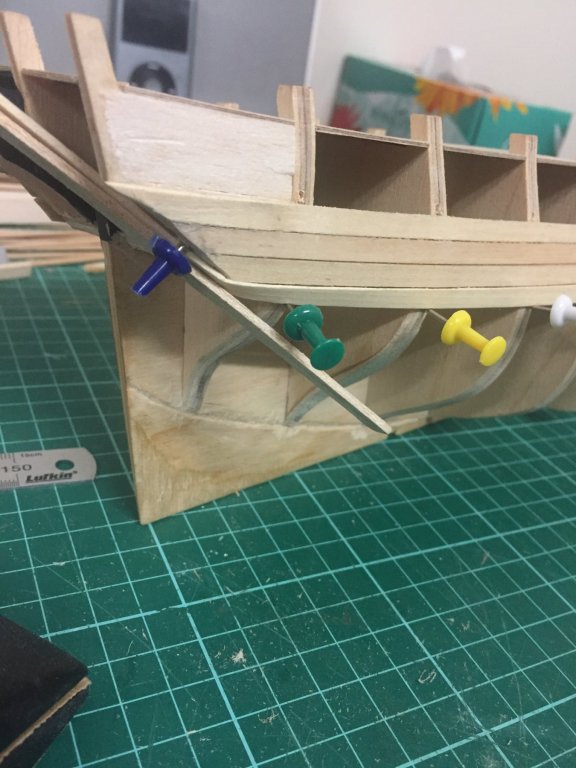

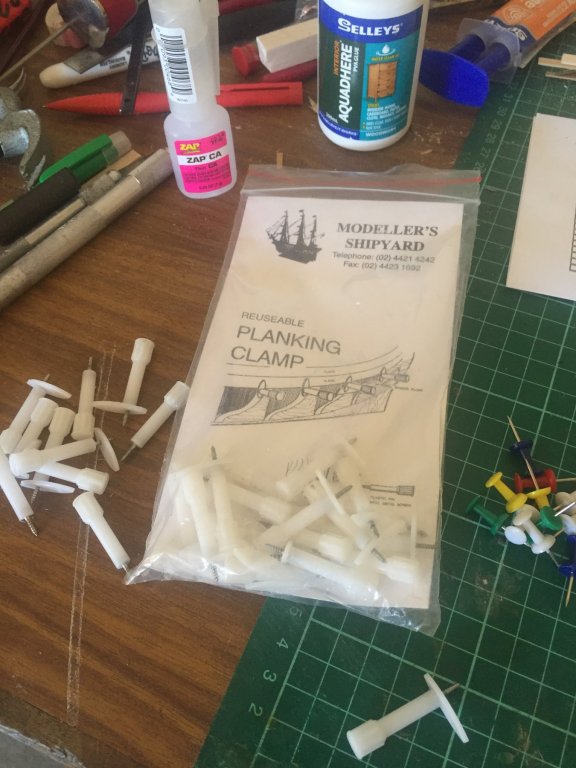

Oh, thanks, Jeff! I really like these planking clamps. I’ve used them on a few builds before. They’re not everyone’s cup of tea, but I like not having to press pins through the plank, if I can avoid it. I feel like I’m stumbling blindly through this build, but I’m also really enjoying it. I’ve been procrastinating about this stern planking and moving very slowly lately. Trying to achieve the quality of other builds on this forum is impossible, but inspiring. I may have found my way forward, but this phase will still take time.

-

Looking really good. I’d be quite chuffed if that were my build.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

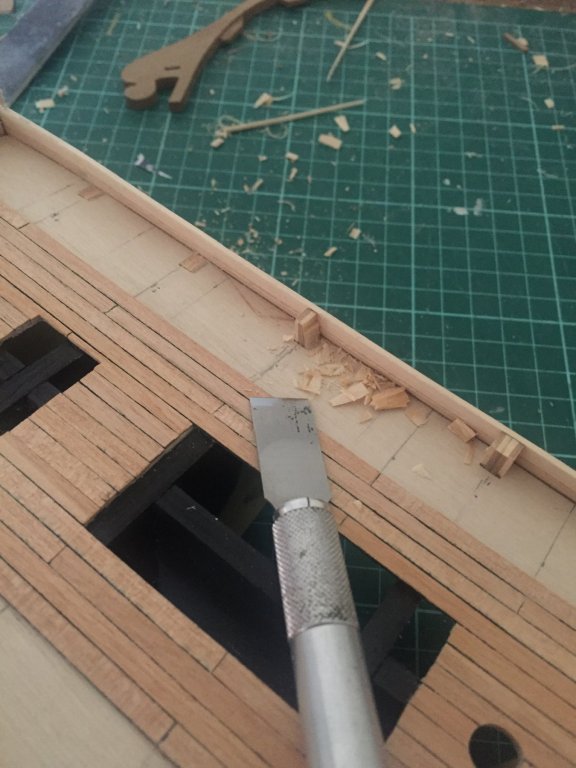

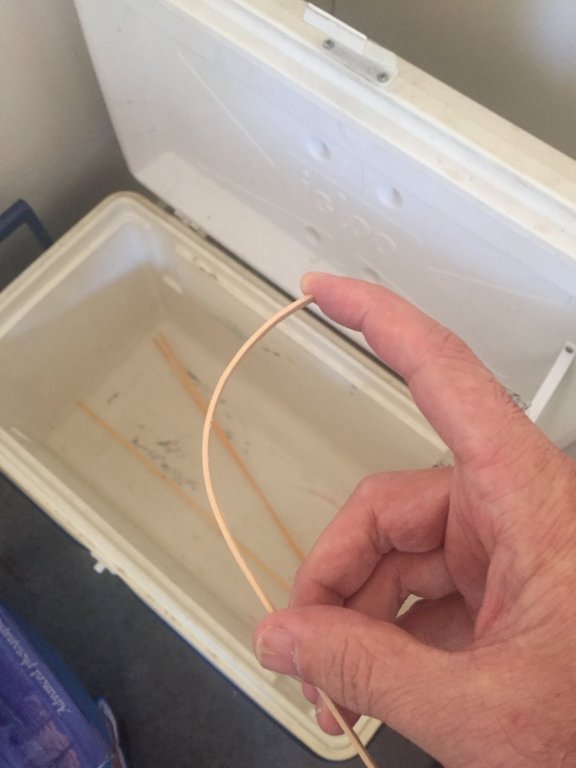

Not much to report. I’m wetting the planks, gradually bending the bow contour, measuring where the new plank starts to naturally overlap the previous one and slice from that point, forward to half width. Not as neat as I’d like, but no real problems so far. She’ll look better after a sanding, but I’m really enjoying myself. Any tips would be most welcome.

-

Very neat. Could you please explain in detail how you tree nailed the deck? Did you use wood filler? Ink? And what size drill? I'd like to learn from a master.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

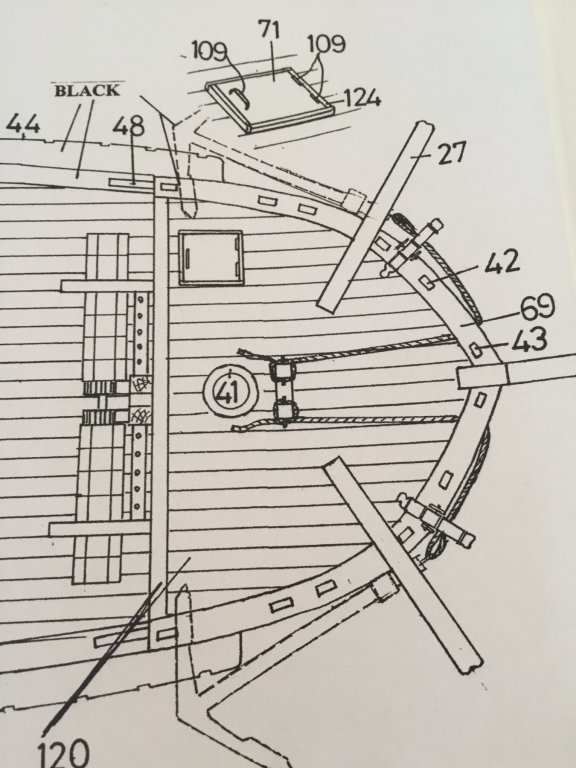

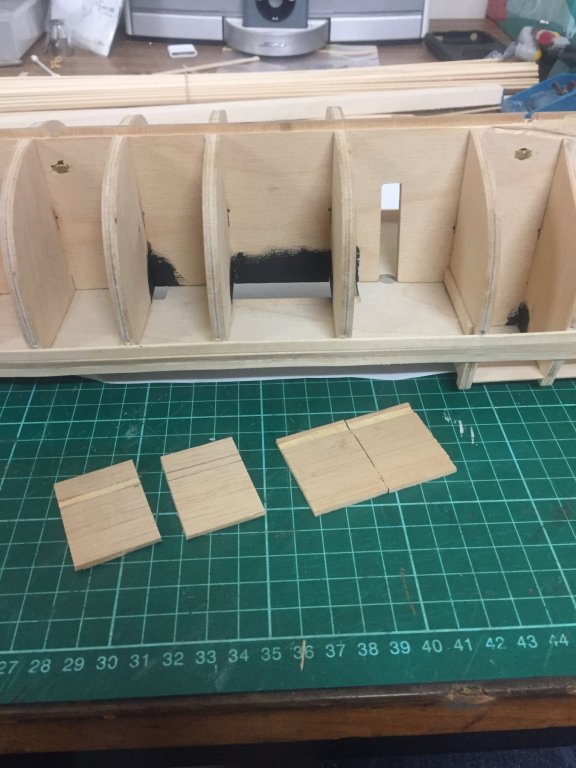

I’m doing everything in this order because I want to place a plank across the ship at the forecastle break and quarterdeck break, and I can’t because the bulwark caps are still in the way. I’ll cut away the caps, line the inside of the bulwarks and paint them ochre red before I finish planking the decks. That way, I’ll avoid getting paint on the deck planking.

-

The quarterdeck hull planks are sanded level with the 8th bulkhead so the aft deck facia (part 57) sits flush. When I fix the facia in place, I’ll sand it’s outer edges to be flush with the width of the 1st layer planking. Eventually, the 2nd layer planking will terminate neatly with the forward wall of the facia.

-

The treenailing was worth the effort. It looks great, I reckon.

- 421 replies

-

- caldercraft

- granado

-

(and 1 more)

Tagged with:

-

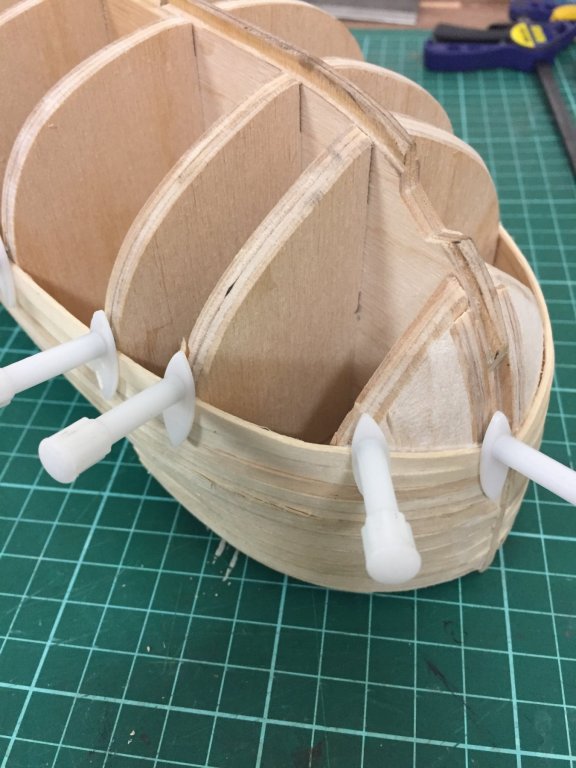

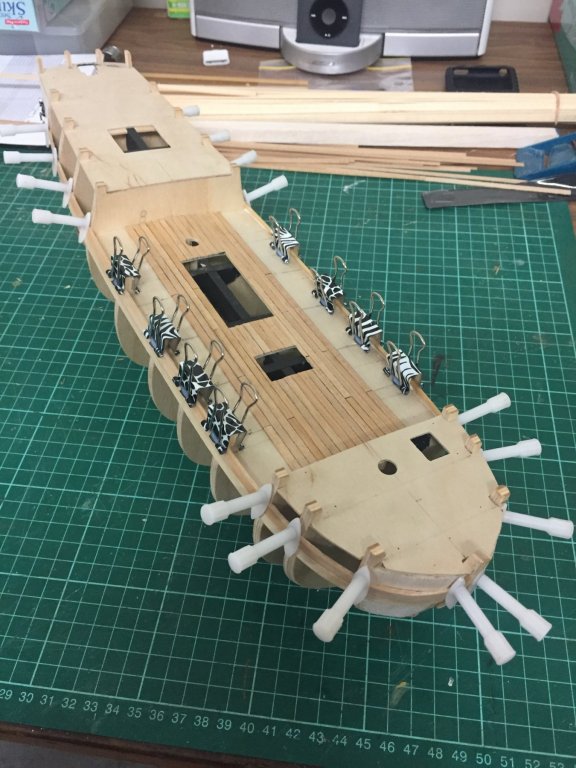

I’ve been agonising about planking the hull, so I realise I had to break the deadlock. The only way I could do that is by charging forward. On my previous ship builds, I used an Artesania Latina plank bender on dry wood. For this one, I’ve been soaking the planks, bending them by hand and fitting them wet. As a result, they’ve shrunk, leaving gaps between strips when drying. This will not do. I’ve measured the distance between the keel and first plank at the widest bulkhead (89mm) and at the first bulkhead (55mm), Working myself into an imaginary frenzy about plank width and distances to the garboard plank....to hell with it.....Crack on! I simply measured half the plank width at the bow and from there, sliced to the fourth bulkhead, where it becomes full width. I pinned the plank in place while damp. I’ll let it dry over night and have a go gluing it in place tomorrow. There’s quite a bend at the transom, but it all seems to be fine at the moment.

-

I’m jumping around a bit, but I’ve been thinking I really should strengthen the mounting nuts. So I grabbed some spare ply, measured the depth of the two nuts and removed the outer ply layer where the nuts would be so they can sit flush. I fitted the 5/32 screws to avoid alignment issues and clamped the doublers in place. Ok. I’m stalling.

-

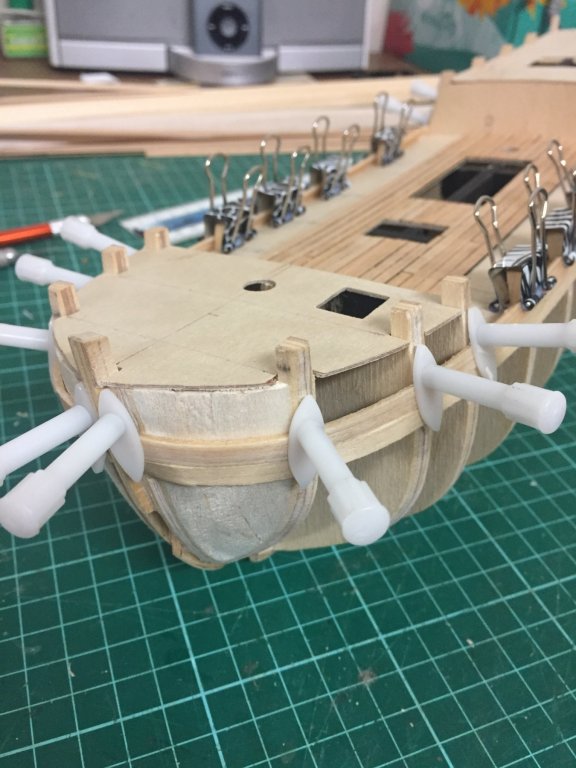

Working upwards, a second untapered plank is placed hard by the first. I’ve used PVA throughout, suplimented by CA on the bow filler. I haven’t applied glue to the main deck bulwark formers, as they will be removed later. Instead, a bead of PVA is applied along the edge of the plank, bonding the two planks to each other. Bulldog clips apply the necessary force to hold the bulwark shape while it dries overnight.

-

The instructions say to place the first plank at deck level. I’ve dropped them down slightly so they’re level with the underside of the false deck. This allows two full width planks to meet neatly with the top of the bulwark bulkheads. I haven’t trimmed the width of this first plank at all. I prefer using these planking clamps where I can. I bought them from Modeller’s Shipyard in South Nowra (New South Wales, Australia) 20 years ago. The business has since been sold, moved to Glenbrook (NSW) and renamed Modeller’s Central. They’re still available. The instructions for Planking Screw-Clamps read “These reusable screw-clamps are invaluable in the construction of plank-on-frame models. In use they simply screw into the edge of the plywood frames and the oval ‘foot’ holds the plank firmly against the frame, without marking, until the glue dries. The need for pins, etc, is eliminated. A loose spacer plank on the lower side or a scrap of planking material glued to the lower part of the foot ensures firm contact of the upper part of the foot with the plank being glued. As planking progresses, the planks cover the holes made by the planking screws. The number of screws required depends on the particular model but since planks are fitted in pairs (one each side) the ideal is two for each frame in the model plus a further two for the stem.” I’m pre-drilling the bulkheads with a #62 mini-drill before screwing in the clamps. I’ve also made a little balsa filler at the stern to assist gluing the plank in place. The lower edge of the plank sits flush with the horizontal former (part 19).

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.