-

Posts

220 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jobbie

-

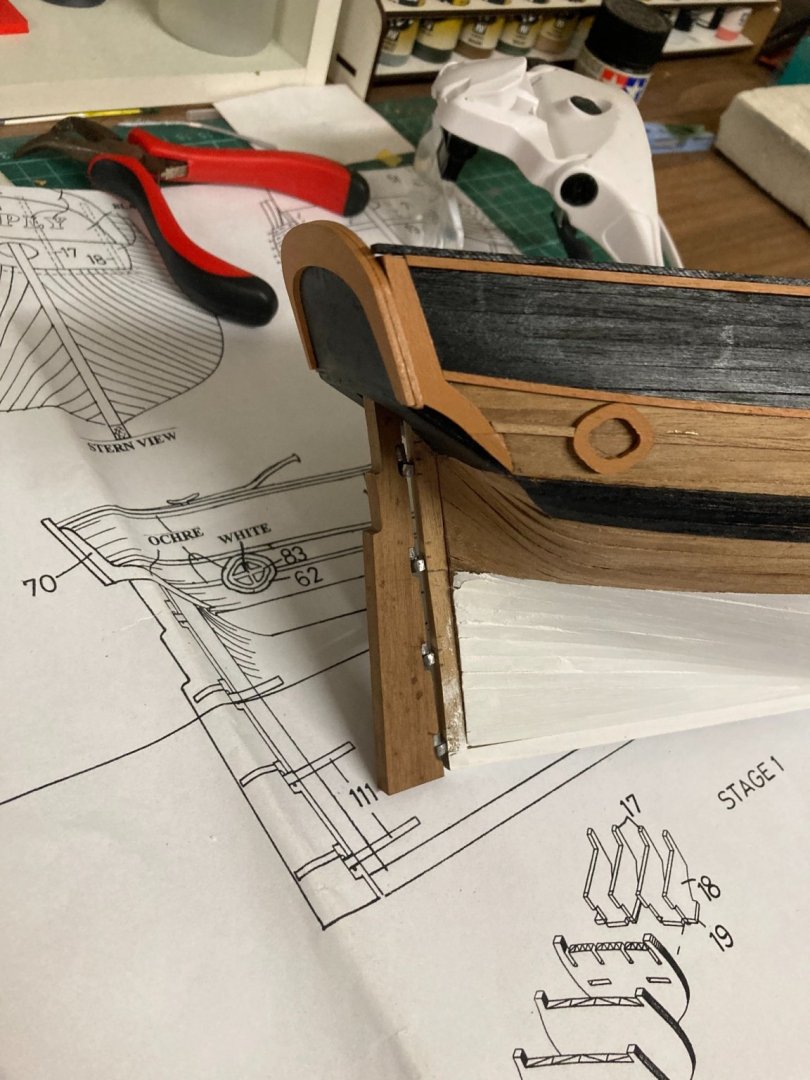

The brass lettering ‘SUPPLY’ and four window frames are primed with a Tamiya rattle-can and airbrushed white Vallejo Air. They’ll require a little touch-up after cutting from the sprue. They’re attached with a two-part epoxy, Araldite. The prow’s painted Admiralty paints’ dull black, helping to cover up the unsightly Cabot’s ‘antique walnut’ putty. (Bad colour choice by me.) It’s amazing how little additions make a lot of difference.

-

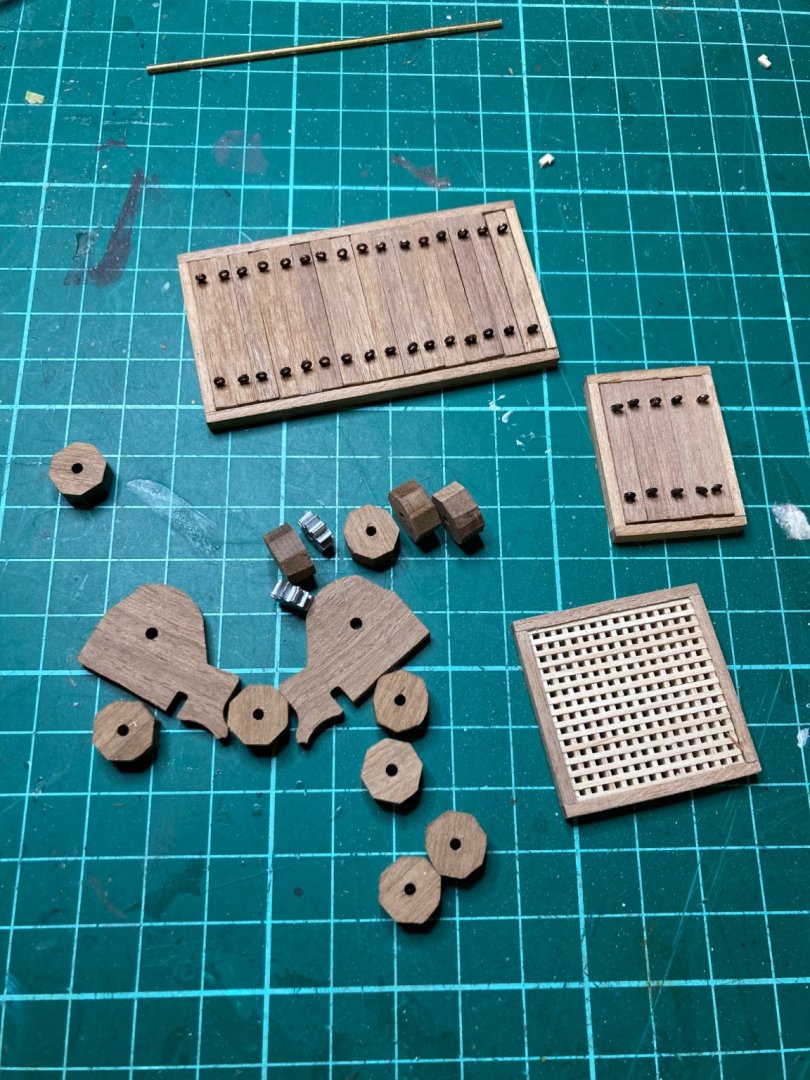

Hatches made following the plans, but I’ve reduced the width of the main hatch from 42mm to 37mm. This is in order to make more room for the train-tackle behind the canon along-side. I imagine the forward hatch on the main deck covers a ladder, so I left it’s dimensions as is. Copper eyelets on the hatch-planks are painted black to represent iron. I didn’t attach a brass ring to them, because in my mind, they’re removed by two blokes, one each side, holding iron rods with a T-handle at one end and a hook at the other. Second ring would get on the way and not be useful. That’s my excuse, anyway. Grating is glued to the quarter-deck, making sure the fully visible strips run fore and aft.

-

Well, I knocked the rudder off already. Oh well, I’ll put it back later. I’ve been drilling hundreds of holes on the decks, and filling them again to simulate wooden plugs over nail-heads. Maybe next time, I’ll actually take five minutes to look up reference photos first…I drilled about double the amount I should have. I wanted to complete the deck properly before I attach the hatch covers and grating.

-

Amazing progress! I’m taking years to build mine. You’re miles ahead! Looking awesome, Richard.

- 53 replies

-

- Supply

- Caldercraft

-

(and 1 more)

Tagged with:

-

I’ve literally been avoiding hanging the rudder on it’s hinges for months, because they were not cast too well. I’ve been working on plastic aircraft kits for a while instead…and really enjoying that. We’re in COVID-lockdown in Newcastle, Australia, so I’m waiting for stuff to arrive in the mail. (Adhesive silk/PE seat-belts for a 1:48 Bf109E & bare metal foil for a ‘58 Edsel.) So, broke out the ship again while they ground to a halt. The rudder was hung in less than an hour, and I loved doing it. The mojo’s high at the moment. We may see more progress tomorrow.

-

Sanded. Filled. Cabin facia fitted. Stem fitted. Stern facia fitted. Rudder post fitted. Canon ports cut (Not shown.) She’s starting to have a little colour applied. I’ve spent some time thinking about whether or not to make some stern windows. I’ve decided not to- I quite like the way the kit looks without them.

-

I reckon I’ll pull up a pew for this one. She looks wonderful, Mike. I loved the reference to the good doctor, too.

- 109 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

A great build. Thoroughly enjoyed reading and following it. Thanks.

- 110 replies

-

- le renard

- artesania latina

-

(and 1 more)

Tagged with:

-

She looks fantastic, Vane. It would be a shame not to finish her. Although, have you considered completing her in the “Admiralty” style? Stubs of the lower masts with no rigging? It’s just that it looks to me that you’d rather crack on with the three Caldercraft kits instead. You could always return to the Corel kit later?

-

Drop-planks are a method of careful trimming plank edges into arrow-heads no less than half their full width, so they can be interlocked with adjacent, similarly trimmed planks in order to decrease their total width at the bow. By this method, I’ve been able to trim five planks down together to terminate at one plank-width. It’s the first time I’ve tried it on a kit. It takes a while to do, but I’m pleased with the results so far.

-

After raising the level of the poop’s bulwarks two planks, I was able to fit eight planks down before I felt the need to begin to taper them. After I’ve cut three further planks at the bow down to half their width, I found the next plank would need to be cut down more than it’s full width allows. The solution? Drop-planks.

-

I’ve realised I hadn’t built up the height of the quarterdeck planking far enough to meet the front facia or the rear transom’s frames (painted red). So I’m building up a measured half-width plank on either side. Beechwood centre with cyanoacrylate at the lower edge, then walnut inner and outer linings.

-

Sziggy8, my understanding is that on the actual British Admiralty built ships, the external planks were about 25 feet long. 25 feet is 7620 millimeters. On my kit at 1:64 scale, that equates to 119mm (4.68”). Quite a usable length, really. For second planking, that should look great, I’d imagine. I’m not choosing to do that because: a : I’m by no means an expert and my method is clearly riddled with errors. b : I’m very much loving the kit but it, too, is clearly riddled with errors. c : It’s too late, I’m committed now! The ship models I’ve built so far have all been shorter in length than the wood strips supplied with them, so...yeah...full length planks. My next kit isn’t, so I’ll probably try sectional plank cuts for the hull’s second planking. The first planking’s hull planks have to align with the ribs, of course.

-

This is how I’m planning to complete the troublesome stern- I’ve planked the sides down to a point shown, and sanded them flush with the sternplate. I’m going to attempt to plank up to where the beechwood ends (yellow arrows), then cut/sand their ends in a line, and plank horizontally above that. (red lines).

-

Wow. It’s been a year-and-a-half since I’d lay a plank on this ship! No real reason- I’ve simply enjoyed building plastic aircraft for a while instead. I’ve had health problems, too: One spinal disc replacement surgery later... I cleaned up the garage and had to move the hull in the process, and I’ve suddenly found new motivation for this....which is odd, because I’ve been given aircraft kits for Christmas that really motivated me, also. I glued four planks today and really enjoyed it. I’m back!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.