-

Posts

718 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Don9of11

-

Generally I like working with out the dremel. I find when I do detail work I like a tool that is about the size of a pen or pencil and I can control the amount of pressure I use. I guess because I can feel the wood and it's resistance to my pressure. A dremel is a little bigger and much heavier thus making it a little awkward and the feedback of the motor makes it almost impossible to feel the wood. There are some clever jigs that have been created that employ the dremel for a miniature lathe to a router. There is nothing wrong with your dremel, it's always a nice tool to have in your shipyard.

-

How to deal with badly drawn plans?

Don9of11 replied to Redshirt's topic in CAD and 3D Modelling/Drafting Plans with Software

Most likely you are dealing with a copy of a copy of a copy and as such nothing is likely parallel or straight. I found the best thing you can do is establish your perpendiculars, the correct length, breadth and depth of your ship and scale your plans to fit as best you can to those parameters. You'll then need to make some assumptions and educated guesses, create you own water lines and diagonals and make the best of it. In the end your plans will be fair and workable. Warning... with CAD there is a danger of wanting make everything supper accurate and super fair. Little deviations here and there can slow your work down to a crawl and drive you mad...lol. -

Is there any way to unmount the painting to see if any information is contained on the back of the canvas? Sometimes there is information under the backing.

-

THE 74-GUN SHIP by Jeronimo

Don9of11 replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

I just found this build, very impressed with the care and quality of your work Karl.- 194 replies

-

Gary, I've been following your build and wanted to know how much of your lower deck details are still visible?

-

Disappearing lines in drawing

Don9of11 replied to Mark P's topic in CAD and 3D Modelling/Drafting Plans with Software

When I open multiple massive assemblies in Solid works and then open individual components it seems after a fashion SW starts acting weird and strange things happen when working in a sketch or drawing. I've learned with experience the solution is to save my work and reboot. Have you tried rebooting? -

Disappearing lines in drawing

Don9of11 replied to Mark P's topic in CAD and 3D Modelling/Drafting Plans with Software

In my experience the image used for sketching needs to be on a layer that is underneath the sketch layer. I think this is true for most cad programs. If you are trying to sketch on the same layer as the image, your lines, arcs and or points are being hidden because the cad program doesn't know what you want displayed. Try using a different layer for your sketching and a separate layer for your image. -

Just How GOOD is Model Expo's Part Guarantee?

Don9of11 replied to SWOHammer's topic in Wood ship model kits

I've had pretty good luck getting replacement parts from ME. I think if you explain the situation like you did above they'll send a replacement. -

Everything looks good as usual Chuck and I like how you've laid out your monograph. The color photos are nice and clear and the content well thought out. I might have asked you this before, are you doing your own laser cutting these days?

- 269 replies

-

- Queen Anne Barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I think your model is looking great Alan, I'm taking great care to study your work. I do have a question and hopefully it won't detract you to much from your goal. Since Inventor allows you to project 2D curves into 3D, what was the final shape of your upper and lower heights of breadth in the body plan? Do they follow the lines of the Elephant? Druxey commented in one of my post that the designer pretty much had control over this and I'm just curious how they actually projected out. I refer to my post #864

-

Really nice work Alan. Your framing looks nice and smooth with no bumps. That's cool! That would save a lot of time. I'm still reading thru your post to learn how you faired your hull. Have you done a comparison of your centers of floor sweeps, upper and lower breadth sweeps to the Bellerophon's? How closely do they match the original draft. That might be beyond the scope of your work here but I was just curious. What do the zebra line look like now (haha)? ---edited---- SW will let you project 2D curves from different planes to make one 3D curve. Tested it today.

-

I've been learning to work with https://www.onshape.com/ They offer a free plan and a pro plan ($100/mo) At it's core OS is very much like SolidWorks. It is certainly worth checking out. There is no software to download or install, runs in your browser and requires that your system is WebGL compliant.

-

Alan, I was reading through the last few post and paying close attention to how you developed your hull station lines. You sketched out the water lines first and then it seems you matched the curves of the hull station to those points on the water line. Am I correct in that assessment? Have you done a hull surface to see how smooth it is? I hope you doing well and you've just taken an extended brake.

-

Ship Drafting

Don9of11 replied to mholmberg's topic in CAD and 3D Modelling/Drafting Plans with Software

If you're interested in English ship design from say 1780 -1820, I would suggest Steel's "The Shipwrights Vade Mecum" easily found on Google and Ree's "Naval Architecture" which you can find at Abe books or similar rare book stores, also Peter Goodwin's "Construction and Fitting of the English Man of War" and Scantlings of Royal Navy Ships which comprises the Repository and Steel's "Elements of Naval Architecture" by Allan Yedlinsky. Also, Deanes Doctrine of Naval Architecture which has been mentioned already, though Deanes work starts around 1670 if I recall. The Ree's and Steel works mentioned above use a lot of the same language, nearly verbatim in some paragraphs. You could also pop on over and read thru my post "Scantling Questions" http://modelshipworld.com/index.php/topic/4080-scantling-questions/ I'm currently under taking the task of drafting plans for a 74 gun ship from scratch, this is not a tracing or redrawing of existing plans, but real drafting using the sources mentioned above. You'll find references to many of the sources mentioned so far plus a few more. I would recommend that you pick a subject (ship) and a time period because English ship design changed over the years and what was done in one century might not be what was done a century earlier. -

online 3d CAD

Don9of11 replied to Don9of11's topic in CAD and 3D Modelling/Drafting Plans with Software

I thought this might be of interest to all of you following this post https://www.onshape.com/cad-blog/onshape-goes-to-sea -

AUTOCAD 18 DELUXE

Don9of11 replied to yamsterman's topic in CAD and 3D Modelling/Drafting Plans with Software

I would start with very simple shapes, like 2x4's or octagons anything with simple shapes and here's why. Starting with something simple will help you learn the controls and features of AUTOCAD. It will teach you where the icons are (if any) and it will help you learn the basic drawing tasks that you'll need to master to later draw your ship plans. Do a search on youTube, there are numerous videos for beginners. As an extra, go to your local library and check out a high school drafting book and try to draw the simple projects they might have in the book. If you do any scroll work learn to draw your scroll patterns. If you try and tackle something big and difficult, you'll get frustrated and discouraged. Don't be in a hurry and just take your time. It might take you a couple of weeks or maybe a couple of months to master enough of autocad to start your ship plans. -

online 3d CAD

Don9of11 replied to Don9of11's topic in CAD and 3D Modelling/Drafting Plans with Software

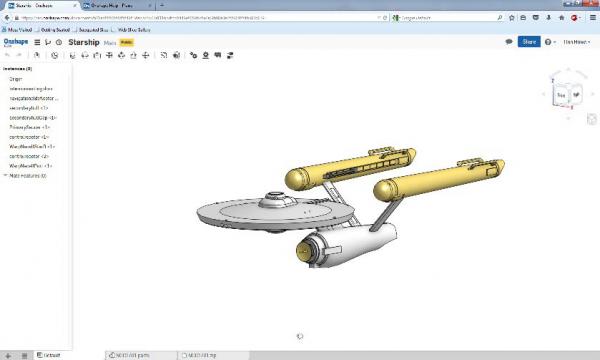

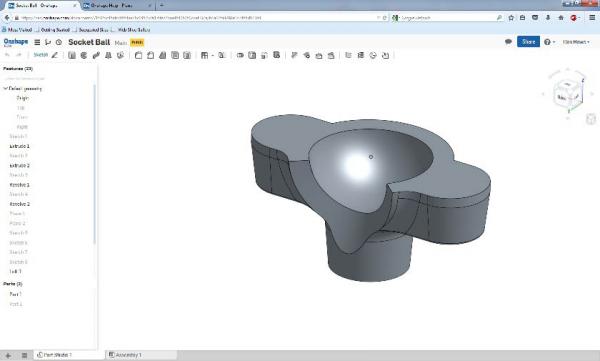

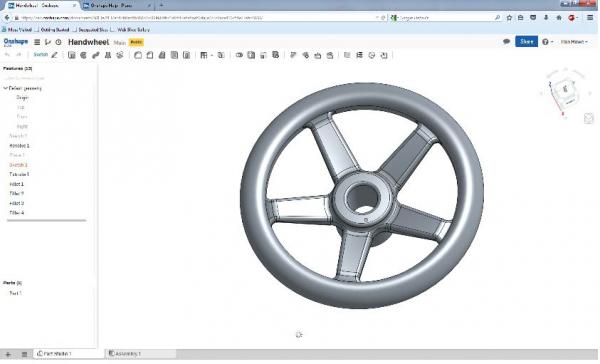

Since my first post a little over a month ago, I have been working with Onshape. I created a Free account and I have been steadily learning how to use the program. Anyone with 3D modeling experience should have no difficulty working with this program. There is absolutely no software to download and none of the programs functionality is withheld. I did have to purchase a new graphics card as my old ATI Radeon card did not support webgl. I spent about $60 on a new card. I can pretty much do any task I want on my PC, stream video or music and the modeling is not in anyway hampered by my multi-tasking. I'm have a dual core pentium processor and it handles things very nicely. I can only imagine what the new i3 and i5 chips can do. Anyway, I have spent the last two weeks remodeling my 74 gun ship in Onshape and I have modeled some other interesting parts. The starship Enterprise was an assembly of a SW model I had created several years ago. This is really exciting technology be cause a doing a group build or in this case a group design is a real possibility. Several people can be working on the same part at the same time and all the changes are saved. That's another nice thing about onShape, you never have to save your work, it saves it for you. You can also go back and review every change you ever made or review your entire modeling process.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.