-

Posts

1,135 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by CPDDET

-

-

Keep at it. You'll be surprised at how your skills develop as you move through the build.

-

Unless, or untill, you reach the point of scratch building your models, the errors in the kit are just a fact of life.

I have already accepted that my Bluenose, which is my first build, is more of a learning tool for future builds. I doubt anyone becomes an accomplished shiprwright untill they work their way through the first build.

Stick with it and make each stage your best effort. You will be surprised at how much you skill improves as you progress through the build.

- popeye the sailor and dragzz

-

2

2

-

Seems like many parts and pieces leave a lot to be desired. My MS Bluenose was the same way. Just have to do the best you can with what you have.

Don't get too discouraged.

-

Check out this build as well. I believe the topic is covered there.

https://suburbanshipmodeler.com/category/bluenose-canadian-schooner/

-

Another option is to carefully cut each extension so they all match. Then when you make the false frame pieces, cut them to match the dimensions of the extensions.

-

You could use the bulkhead extensions as a guide and carefully edge glue the bulwarks to the hull plank. Then use an Excel saw blade bent to a 90 degree angle to cut the extensions flush.

-

I would not remove the extensions until after the bulwarks are in place.

-

-

Unfortunately my skills with the new mill are very limited. It will take time, practice and the help of more experienced builders to reach a fuller potential. But one has to start someplace.

-

Sherline 2000 with multiple options.

Will list if interested.

Got great advice from an experienced modeler, retired guy.

Dave

- Retired guy and Duanelaker

-

2

2

-

-

No hurry, take you time

-

- Retired guy, GrandpaPhil, bhermann and 1 other

-

4

4

-

I have found a light sanding with 800 grit paper does a pretty nice job.

If paint is to be applied I sand as above, paint on a light coating of Delta Ceramcoat (sanding sealer), let dry and sand again. This gives a nice clean, fuzz free surface.

After paint has dried I spray a matt finish of acrylic sealer.

Both the Ceramcoat and acrylic sealer can be found at Hobby Lobby, or probably Michael's Crafts.

-

Looking very nice!

- dragzz and popeye the sailor

-

2

2

-

Looking very nice, Patrick.

-

I have found MSW to be very responsive when I requested replacement items.

-

Next up on the build list was the Jumbo Jib Boom Crutch. The top piece and knees are laser cut pieces but the uprights have to be cut from stock. The instructions call for 1/8 square stock but I found the thickness of the laser cut pieces closer to 3/32nds so that’s what I used for the uprights.

I cut a scrap piece of wood to place between the uprights in order to keep them at a 90 degree angle while clamping. Using PVA glue I set up clamping on my MicroMark magnetic jig. I have found this 10 ¼ inch square metal tray very useful for clamping various items, especially when it comes to building deck furniture. The ends of the metal plate are bent up at a 90 degree angle which is a big help. In order to keep the glue from bonding to the plate I taped a piece of plastic wrap on it. Plastic wrap (Saran Wrap) seems to work well for PVA and wax paper for CA.

After the glue dried I did some sanding and glued on the knees, again with PVA.

Then mounted the assembly on a scrap piece of wood with double stick tape. Staying with my color scheme, I put on 3 coats of Varathane Poly Stain instead of painting it white as the plans call for.

According to the plans and the instructions that came with the model, the hoisting mechanism attached to the crutch as well as the engine box on the port side of the crutch were removed for racing, so I will be skipping those and install the boom crutch without these parts.

As best as I can tell the counter shaft assembly and stand remained on the ship for racing, along with the windlass. So next up will be the countershaft assembly and stand. Some of these parts look usable while others look very rough and will probably have to be remade.

And so it continues……

- Nirvana, bhermann, GrandpaPhil and 2 others

-

5

5

-

19 hours ago, Snug Harbor Johnny said:

I've reviewed your build thus far and am impressed by the care and craftsmanship you exhibit. It is an inspiration for me to better my intermediate (at best) technique, yet in this line we all must chart our own course. Doing the best we can , within practical limits, can be a source of satisfaction one can't put a price on.

Thanks for the kind words!

- Overworked724 and Ron B

-

2

2

-

20 hours ago, CPDDET said:

What's more important at the very start is getting your keel pieces flat and straight. I took a tip from a great book to make mine and I'll pass that along to you ASAP.

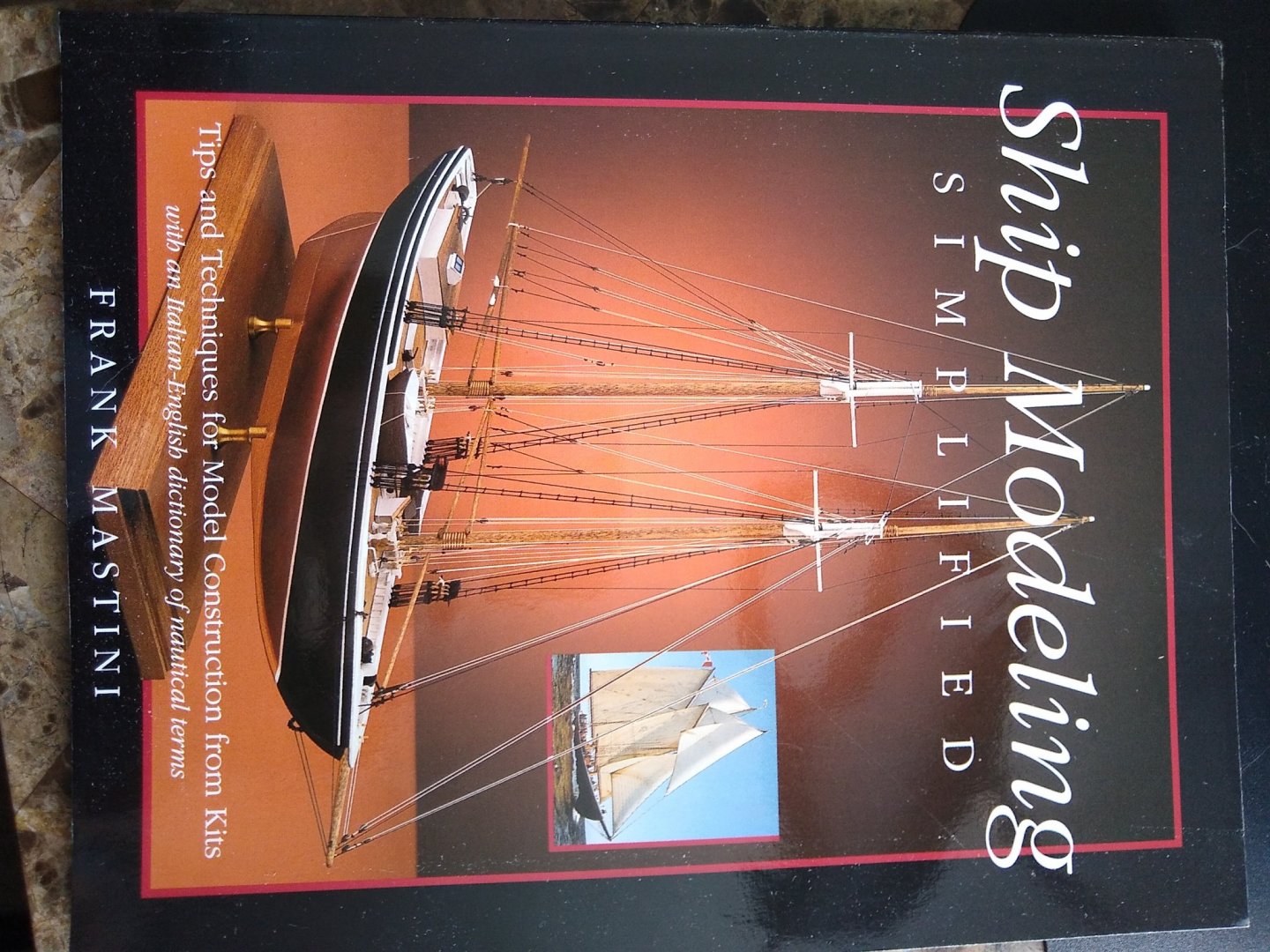

The Book

The layout board for the keel

It's simply a piece of shelving cut to length and a ledge board screwed down even with the bottom edge of the shelve piece.

This allows one to rest the bottom edge of the keel pieces on the shelf and glue them together. Then I placed a second piece of wood on top of the keel and clamped all three layers ( shelf, keel and top board) together. You can use wax paper or index cards over the glued joints.

- GrandpaPhil and Ron B

-

2

2

-

Have you measured on the plans?

-

Well said. Progress in technique is what matters.

-

Please be more detailed if you can. There are many people on this site that will help you.

-

Could very well be. In my opinion the Amati is well worth the price, and the wait.

Bluenose by dragzz - Model Shipways

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Yes, it's great for the brain. Just figuring out how to build each piece really expands our knowledge of tools and how to use them to our advantage.

Bluenose is my first build and I view it as a primer for future builds.

So much to learn.