-

Posts

922 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by robert952

-

Make room. I am jumping on board the log. Good luck on your build and do not be afraid to ask questions. And, yes, adding to the build logs, even it there's a bunch out there, on the same ship/boat, you will bring a fresh perspective as you proceed.

- 32 replies

-

- Lowell Grand Banks Dory

- Model Shipways

-

(and 1 more)

Tagged with:

-

Welcome aboard.

-

There was also a suggestion to add SMALL to the title if it was a model of a small vessel (not a small model). Example Dinghy by Robert952 - Midwest Model - 1:12 - SMALL Not critical, and not my idea. However, I do like looking at the small boats. Besides being great models for beginners, they give an opportunity for a lot of extra details.

-

Mainly the weathering you have done on everything. The buildings are weathered very nicely. I tend to 'overweather' items. You show a light touch to make a nice effect. Seeing the Inman building progress was interesting. Similarly, the landscaping texturing is very nice on the tunnel and rock faces. For a small boat (dinghy) project on my planning board, I want to make it a diorama. Though the scale will effect my approach (it's 1:12 - doll house scale?), the way you layer shows me a techinique to use.

-

My humble opinion (and limited experience): I think cutting the filler planks for larger areas like you did in the top photo of the topic #11 is the better way to go. That is because I get too carried away with applying filler in gaps and end up with a mess. Your results may vary. I just think it's worth the time. The bottom photo in topic #12 where you see the filler 'plank' looks very nice to me and will probably need minimal sanding to smooth it out.

- 22 replies

-

- Chesapeake Bay Box Stern Workboat

- Wye River Models

-

(and 1 more)

Tagged with:

-

Nice looking project to work on. Following along with the log.

- 22 replies

-

- Chesapeake Bay Box Stern Workboat

- Wye River Models

-

(and 1 more)

Tagged with:

-

Nicely done. Great looking model. Congrats on finishing it.

- 167 replies

-

- Picket Boat

- Model Shipways

-

(and 1 more)

Tagged with:

-

I realized how often I look at your posts on this build as I peruse recent posts. I am jumping on board to watch the rest of the build. As with most projects there's problems we have to solve (like the deteriorated decal) that need unique solutions. Part of the challenge and rewards when assembling model.s The model looks good. I look forward to the rest of the build.

- 75 replies

-

- Steam Cutter

- Harriet Lane

-

(and 2 more)

Tagged with:

-

I go back to the basic concept of what is of interest to me. I temper that with a bit of what will I learn or get better at skill set-wise. I won't be surprised if I pick out a non-ship model plastic model (or even metal) in the future as variety is the spice of life. I know I need to relearn and improve my plastic assembly, detailing and painting skills. So, that may be in my future, too.

-

Getting Started: From Dollhouses to the USS Constitution

robert952 replied to Jasennord's topic in New member Introductions

Welcome to the madness of MSW. Your tale is similar to mine. I still have a skelton hull about half-way planked of the Golden Hinde from Mamoli. I enjoyed what I did and what I learned from that work, but realize I had to get some of the basics under my belt. Start a log on your build. You'll find a lot of people who like to learn from others and share their experiences and expertise. (From me, you get more of the former than the latter.) Have fun. And remember: -

This is looking good. Yep...learning process continues with every build. Yep...every kit has some 'anomaly' that doesn't show up until you assemble it. And you probably will notice the errors more than a lot of other people when the project is complete. We tend to be harder on our own critique of our work. However, you are doing (IMHO) the correct procedure: Keep Calm and Carry On. And as a QA manager told me what they did on the factory floor: File to fit. Hammer to adjust. Paint to Hide.

-

Great looking model. I'm looking forward to the rest of your build log and your next build.

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I read through your log again and I may have overlooked whether you beveled each plank as you added them. Like you, I soaked the plank and clamped it in place overnight. I left them a bit long so I could cut to size. Keep in mind that my method here is based on upside down hull. So top and bottom is relative to that position. The top of the previously installed plank is left untouched. After next plank dried I put a slight bevel on the bottom edge of the next plank. It was just enough to allow the plank to fit flush on the lower plank and to the frame. I think that helps avoid the clinker effect. I also beveled the planks on each end a bit to fit to stem posts. I was careful to mark stern and bow on each plank since they were 'custom fit.' Finally, I beveled the backside (closest to the bulkheads) of each plank (as you did) to fit to the posts. Entry #6 of my build has some pictures that may help. As for gluing the bilge area, I did like you and used a lot of rubber bands. I also put a piece of wood under the building base to keep the rubber bands tight to the form. It is a tedious job to shape those planks to size. My results weren't pretty. I had to cut some filler pieces. From the beginning as I put the planks on I knew I'd be doing a lot of filling and sanding. (No matter how new the blade on my knife, I couldn't keep the cuts neat.) Entry 15 of my build log shows the ugly details. (However, filler and sanding made it look better.) I think the kit is rated at the proper skill level of 2. Over the years I have seen similar definitions as those that appear on this kit defining the skill level requiring cutting and shaping of wood. When I began working in wood, I started on a model of The Golden Hinde. Like a lot of beginners, I (finally) figured out I needed to learn some basics. A lot of modelers quit at this point. I (luckily) found MSW and read through a LOT of posts. That encouraged me to keep on trying. So, I got a Level 1 kit and built it in a weekend. I figured Level 2 would be the next step. But I found, as you did, it's still a challenge. (And I added more challenge by modifying my build with a keel and sail.) Now whether this should be the second or fourth model someone builds is a personal call. I feel each model we build should offer some kind of challenge. When I look at a model, it's hard (for me at least) to deterimine if my skills are up to snuff. However, I know it's going to be a learning experience. With all that said, I am impressed with how your build is going. You have overcome the challenges very well. So, don't be too hard on yourself. In some areas I wish my build looked as good as yours at the same point. As to 'plunging in for hours,' you'll probably get there. My wife was working a late shift and usually got off about 1AM. Sometimes she'd get off early. I was working on a plastic model one night. I started about 7:30ish. The model was fitting togther well. I was moving along in the process. I heard the door open. I yelled out, "Things slow at work tonight?" figuring she got off early. She said, "Are you alright?" I relied, "Yeah, why?" "Do you know it's almost 2 AM?" Uhhhh...nope. I guess I had made the plunge.

- 24 replies

-

- maine peapod

- midwest products

-

(and 1 more)

Tagged with:

-

Thanks for the link and caveat.

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

I like the vise/clamp you use. Where can I buy one (or two)?

- 90 replies

-

- Friendship Sloop

- bluejacket shipcrafters

-

(and 1 more)

Tagged with:

-

This seems to be a great model to start on for a first build. Don't be afraid to ask questions. Ships are a bit different that Gundam. 😁 Good Luck.

- 46 replies

-

- Dory

- Lowell Grand Banks Dory

-

(and 3 more)

Tagged with:

-

Sitting on the dock of the bay, watching this build on the way. I like watching the smaller builds.

- 18 replies

-

- muscongus bay lobster smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

@JacquesCousteau Thanks. Lots of photos and art works and various modeling sites too. The choices and inspiration won''t be the problem. Deciding how to go will be the challenge. @Bryan Woods Except that Ihave too much invested in this new house and yard, I probably would. However, lawnwork and gardening run in my genes. My Dad (in his 90s) works daily and has an beautiful lawn. @Desertanimal Thanks for the well wishes. I feel I am still feeling my way around to find my true interest. I do like the small boats and may gravitate towards those. However, I have some large models/ships in my stash. They still pique my interest.

- 44 replies

-

- maine peapod

- peapod

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

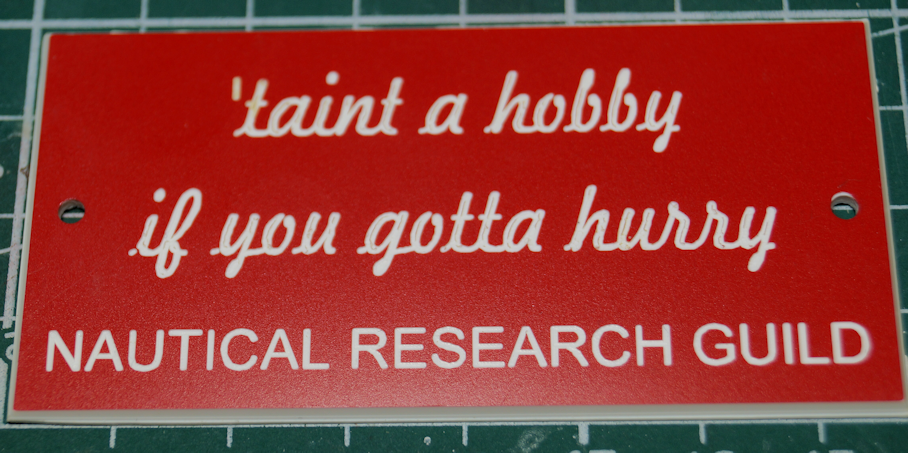

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.