-

Posts

2,472 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dr PR

-

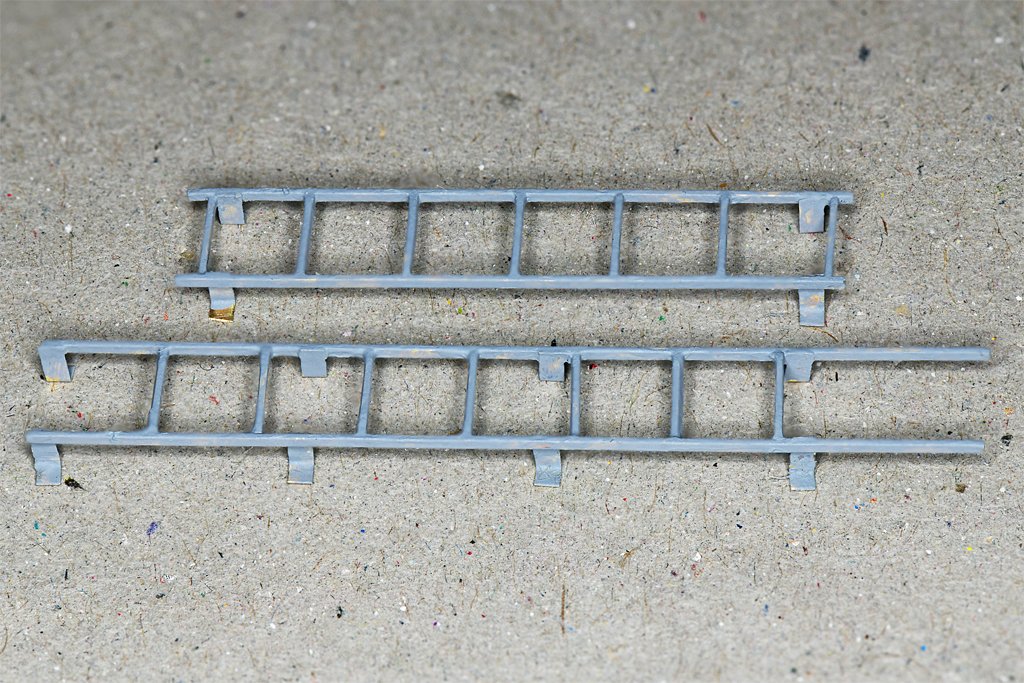

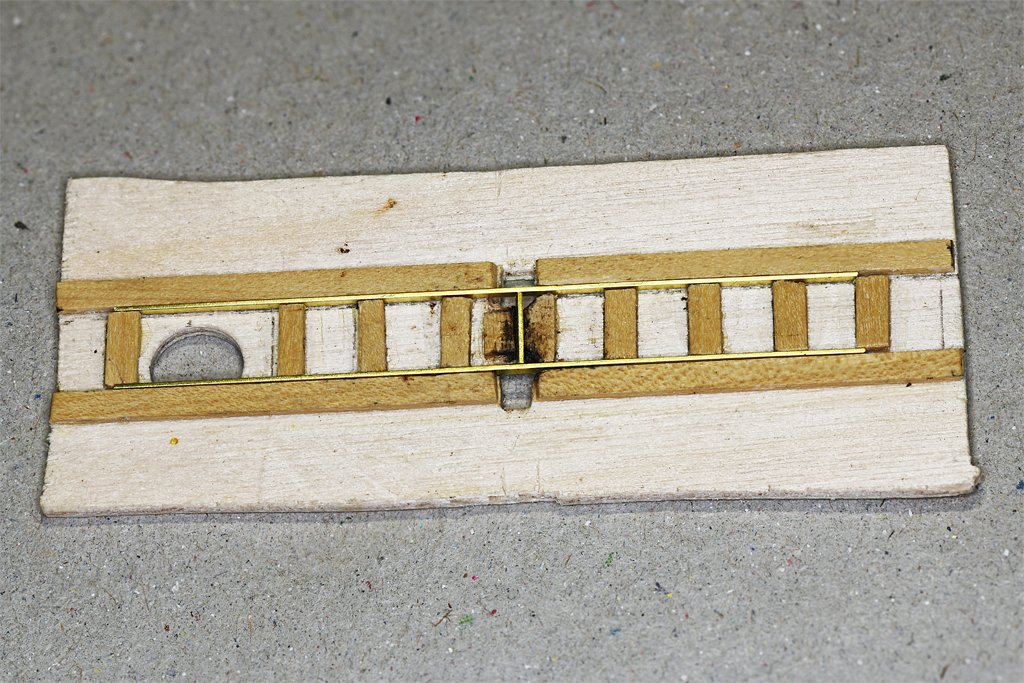

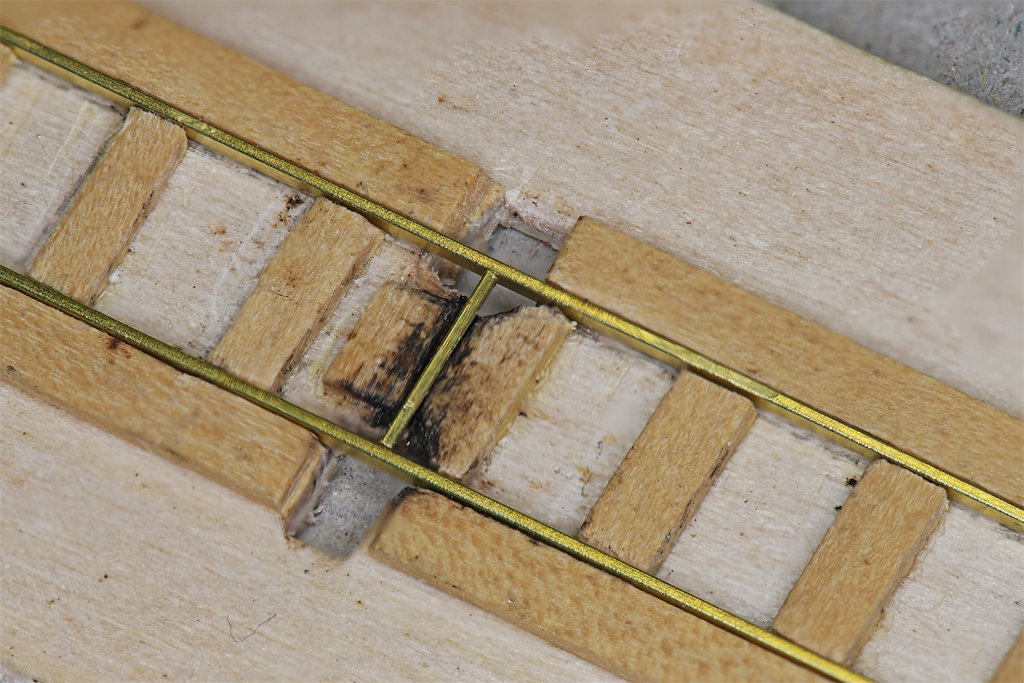

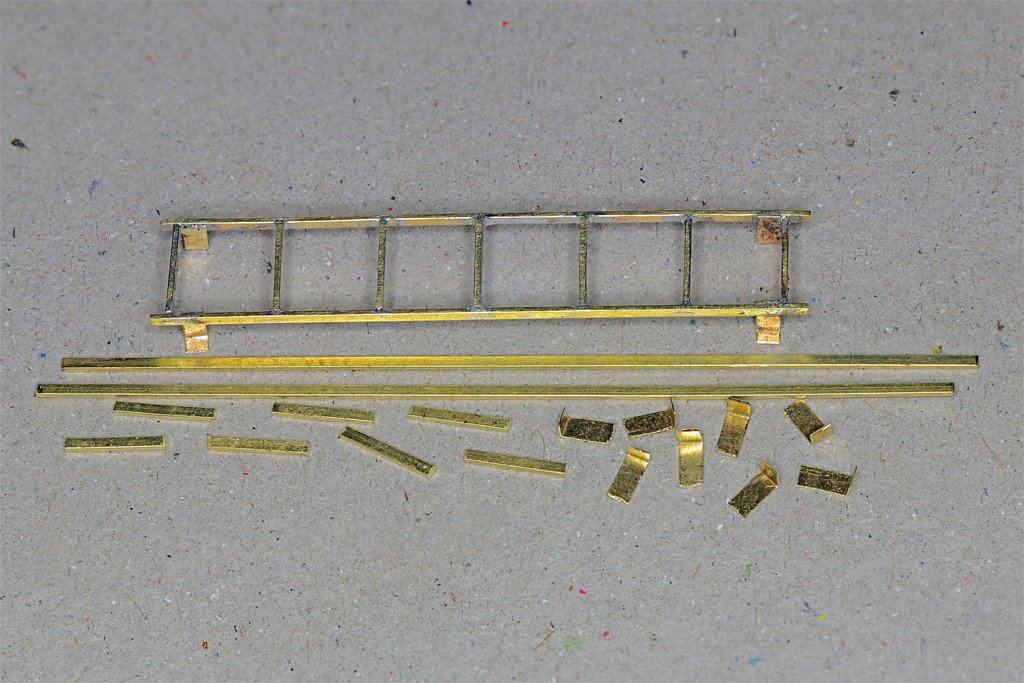

Next up is vertical ladders. I need four for this model. One of the assembled ladders is shown here. It will go on the aft end of the main deckhouse, on the starboard side, from the main deck to the O1 level. Below it are the pieces of a "kit" for a longer ladder that will go on the port side of the O1 level deckhouse from the O1 level to the O2 level on top of the pilot house. The ladder parts were cut from some 0.030 x 0.015 inch (0.76 x 0.38 mm) brass strip made by Special Shapes Company. They made many different small brass shapes, including "U", "H", "L", solid rectangular and round rods. Unfortunately they are no longer in business and I know of no other company that makes these parts. I bought out the stock years ago from a local hardware store that was run out of business by big box hardware stores. I guess there isn't enough profit for the big store paper shufflers to bother stocking these things. The actual cross section dimensions of the side pieces and rungs of vertical ladders in the US Navy were 1 3/4 x 3/4 inch (44 x 19 mm). That would be 0.036 x 0.016 inches (0.9 x 0.4 mm) at 1:48 scale, so the brass strip is just slightly undersize. All of the ladders on the MSIs had rungs spaced 12 inches (305 mm) vertically. This was pretty common in the Navy. However, not all vertical ladders (ladder rungs, steps, etc.) were the spaced the same. When I made the CAD model of CLG-5 the blueprints often showed the spacing of the top rung below the upper deck, and the bottom rung above the lower deck. Then the blueprints said to space N number of rungs equally between the top and bottom rungs. This produced spacings from 11 to 15 inches (279 to 381 mm), although about 13 inches (330 mm) was the most common. The rungs were all 12 inches long (305 mm), although the blueprints show ladders were also built with 18 and 24 inch (457 and 610 mm) widths. I made this jig from scrap wood for assembling the vertical ladders. The 0.094 x 0.030 inch (2.4 x 0.76 mm) side basswood strips are spaced precisely at the outer dimension of the ladder sides 0.28 inches (0.25 + 0.015 + 0.015) or 7.1 mm. At the center are two wooden pieces spaced just over 0.015 inch apart, the narrow width of the ladder rungs. As you can see, the ladder rung is placed in this slot. Holes were cut through the base and wooden side strips to allow a soldering iron tip to contact the brass parts. More basswood pieces were glued to the base spaced exactly 0.25 inch (6.35 mm) from the right hand center piece. Really only three of these spacer pieces are needed to assemble a ladder - the center one and one to either side. But the additional pieces serve to hold the assembly in place and show any spacing errors that might creep in. The gap between these spacer pieces and the outer side pieces is the narrow dimension thickness of the brass strips, 0.015 inch. The brass parts fit tightly between the wooden jig parts. Each ladder rung was soldered on both ends to the side pieces. I placed a small drop of liquid flux in each joint and then touched the tinned tip to the joints briefly. I used a metal tool to hold the rung down until the solder hardened - otherwise it would try to lift out as the soldering iron tip was raised. The photo on the left above shows the correct way to assemble the ladders. First an end rung was soldered between the sides at the proper end position (this varies with each ladder). Then the assembly was lifted and moved so the rung was positioned one step to the right, tightly against the spacer strip. Then the second rung was soldered in place. The assembly was lifted again and moved one place to the right. Another rung was added and so on. It is very important that this sequence is followed to ensure that the spacing of all rungs is equal. Starting at the middle (as shown in the right photo above) or trying to install the end rungs first and fill in the rest later will likely result in uneven spacing. After the ladders were assembled they were cleaned up with files, brushes and sandpaper to remove excess solder. Then the ladder supports were soldered on. These were made from 0.005 inch (0.13 mm) brass strips cut from a large sheet to a scale 3 inch (0.0625 inch or 1.59 mm) width. The faces of the ladders were spaced 6 inches (152 mm) from the bulkhead surfaces. That is 0.125 inch (3.175 mm) at 1:48 scale. The long legs of the supports are 0.125 inch, and the mounting "feet" were 0.0625 inch. Soldering the tiny pieces in place was a test of my patience. A drop of solder was placed on the mounting surface of the supports. I used a resistance soldering "tweezer" tool to pinch the support to the ladder side and then applied a brief current to melt the solder. This worked most of the time but a few of the pieces moved before the solder hardened and I had to remove them and start over. But I finally got them all done. The parts were washed with acetone to remove the solder flux and then painted with acrylic paint. After they are mounted to the deckhouses they will be painted again to touch up thin spots. Before making the two ladders for the ship's mast I will need to replace the two wooden pieces at the center of the jig where the soldering is done. They became charred after repeated soldering. However, most of the black stuff you see in this area is solder flux residue. I had to clean the residue out a few times to be sure the new rung piece fit properly.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Welcome to the hobby! The problems you are encountering are things we have all been through. What is important is you are learning!

- 19 replies

-

- Viking

- Artesania Latina

-

(and 1 more)

Tagged with:

-

Eberhard, Thanks! But with your watchmaker's tools I think you could have done a much neater job.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Gaffrig, Thanks for producing the name. I have been trying to remember "breasthook" and it just kept eluding me.

- 257 replies

-

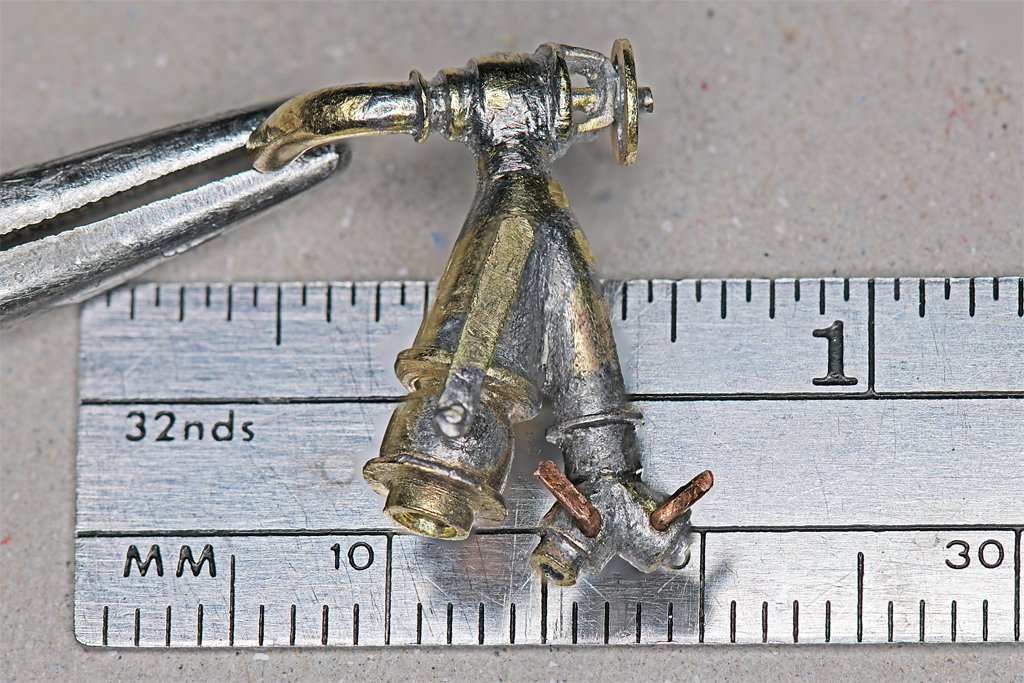

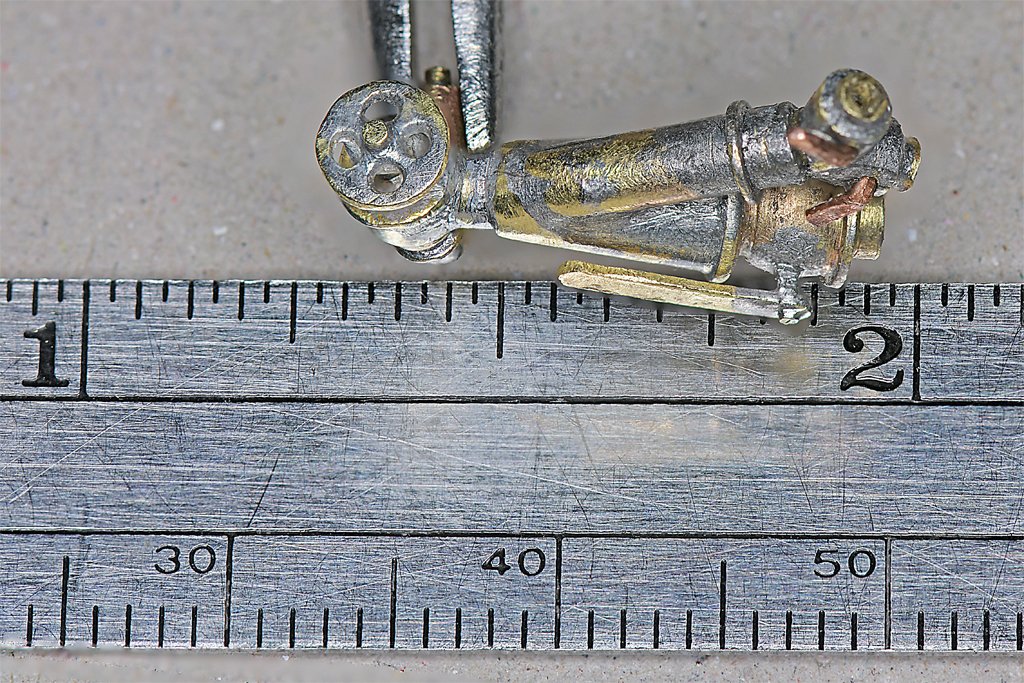

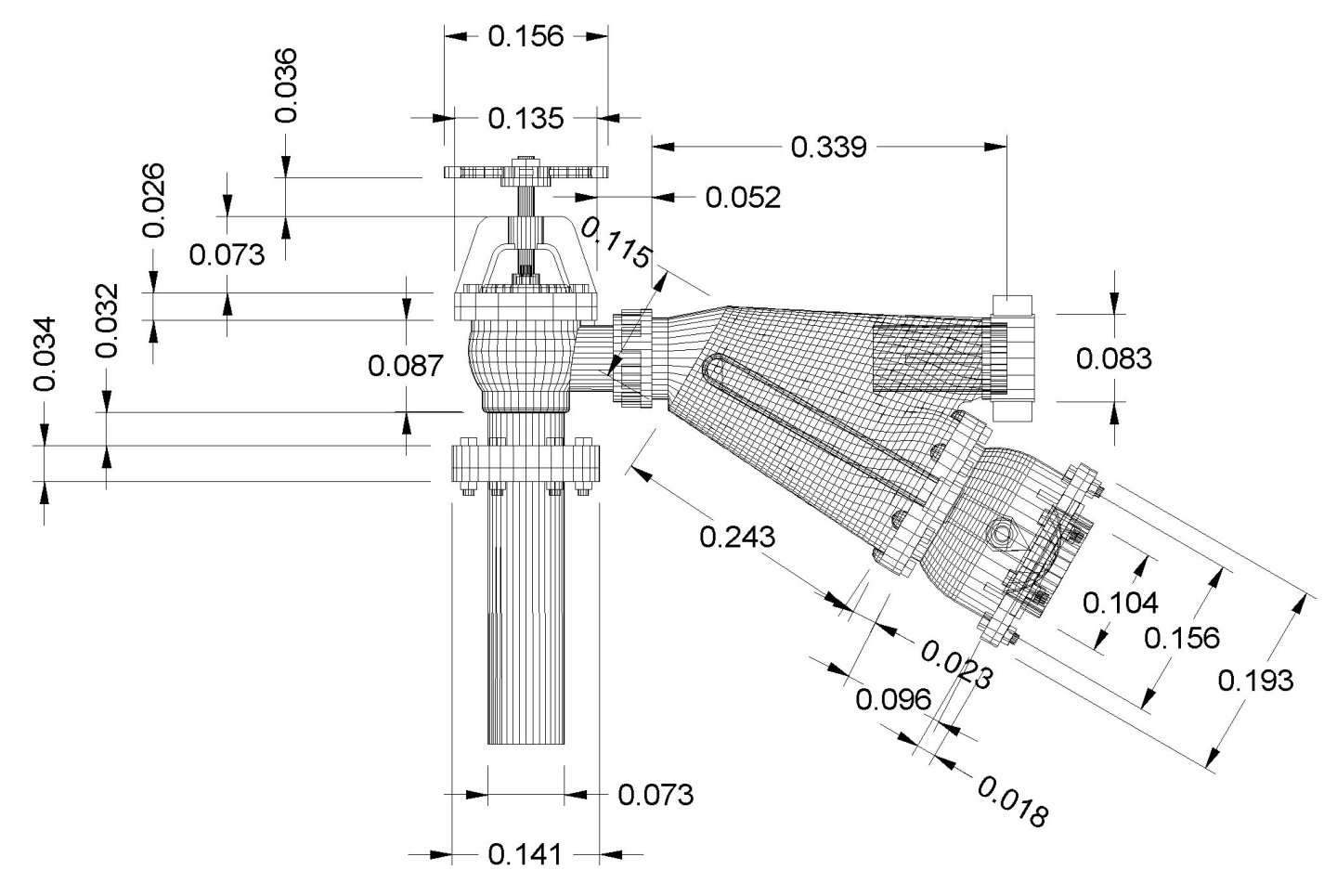

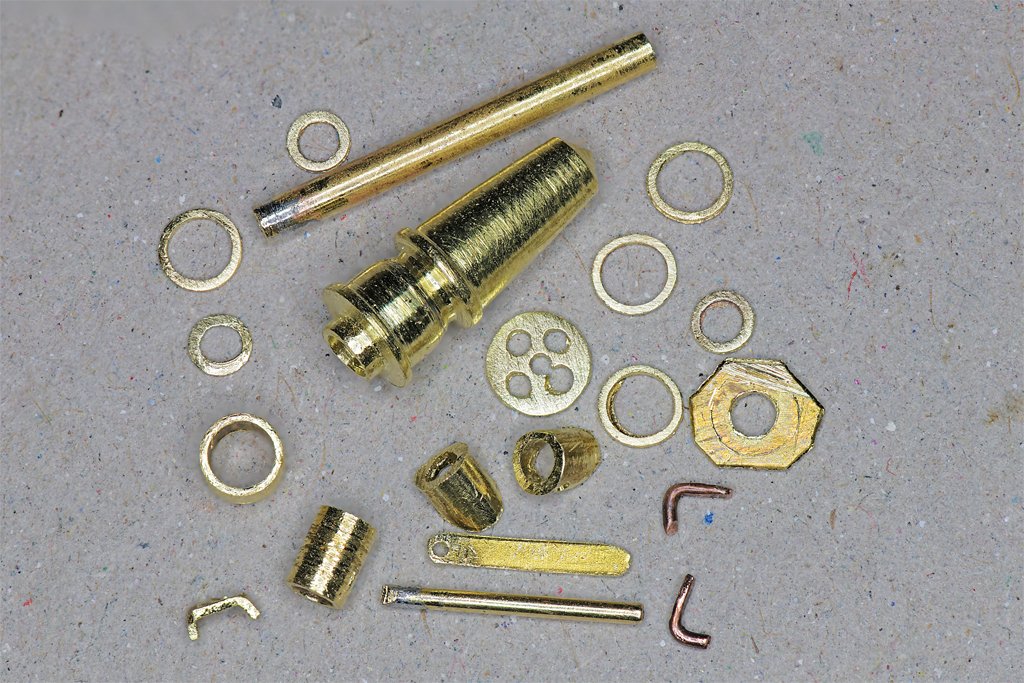

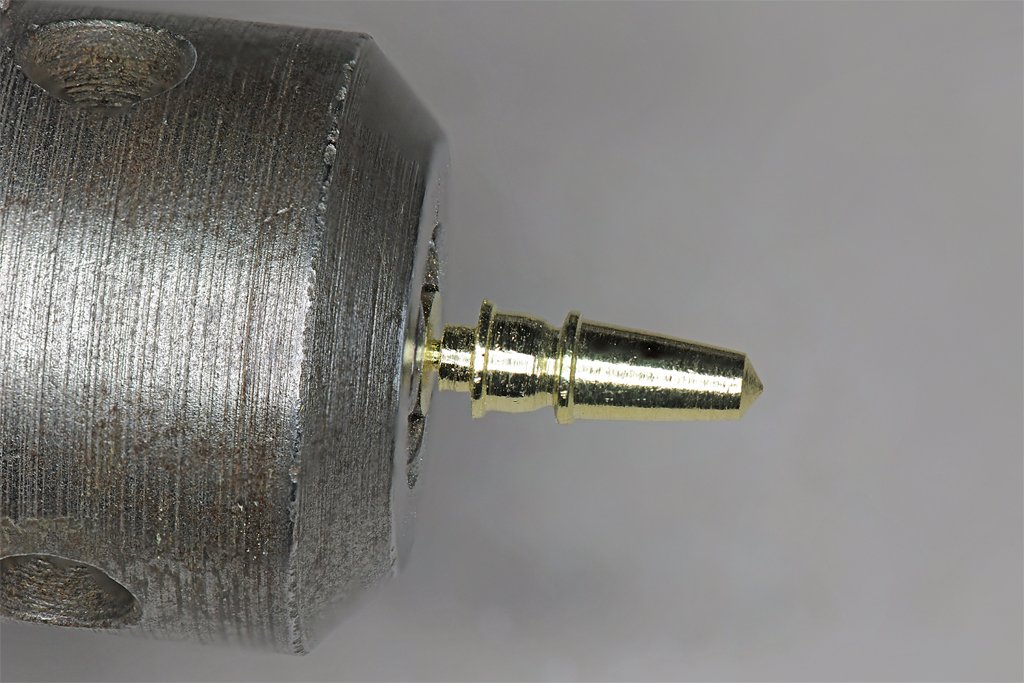

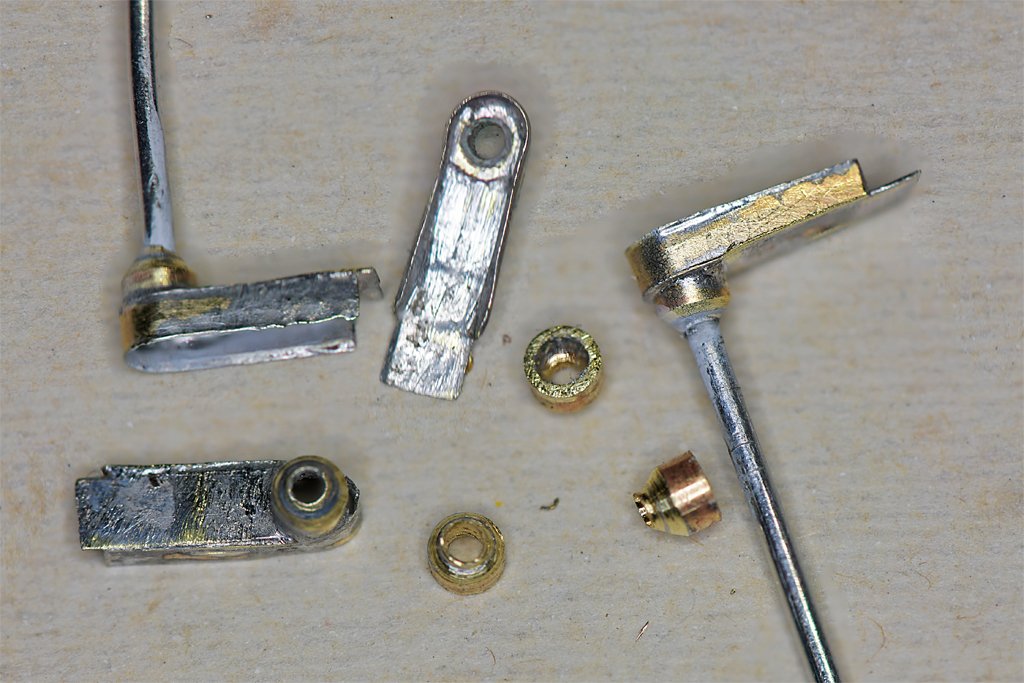

The parts on the left are a "kit" to make one of these things (on the right). This is a 1:48 scale shipboard fire hydrant. I made the 3D model for my USS Oklahoma City 3D CAD model. I rescaled it to 1:48 for the Cape model and added a dual 1-1/2" hose attachment to the outlet as shown on the Cape blueprints. Once again this is pretty small stuff! I made all of the parts out of brass rod, tube and sheet. I count 22 individual pieces in all. At the top is a globe valve to shut off the flow of water. Then there is the larger strainer and collection part at lower right. Ships use sea water to fight fires, and barnacles and other marine growth form in the water intakes. This debris can clog the fire fighting nozzles, so a strainer diverts the garbage to the large collection part. The long handle opens a valve at the end of the strainer to flush out all of the debris onto the deck. The most difficult part was the conical strainer body. I thought about different ways to make it and decided to "machine" it out of a piece of 0.188 inch (4.8 mm) brass rod. While I was at it I decided to carve the globe valve discharge outlet and a couple of flanges from the same piece instead of trying to piece together multiple parts. I used my 3/8 inch (9.5 mm) "hand lathe" to make the part. This is an ancient 3/8 inch electric drill I purchased in 1972 after leaving the Navy. The bushings are shot but it is still useful as a poor man's lathe. This would have been a LOT easier with a real lathe!!!!! I used files and a thin curf saw blade to carve out the piece. You might think I was crazy to attempt to make this complex part using a hand drill instead of a real lathe. I would not disagree with that assessment! OK, I am crazy. But hey, it worked!! The rest of the assembly was made of 0.039 inch (1mm) brass rod, 0.0625 inch (1,6 mm), 0.091 inch (2,3 mm), and 0/125 inch (3,2 mm) brass tubing and 0.005 (0,127 mm), 0.010 (0,25 mm) and 0.015 inch (0,38 mm) brass sheet. I used an ordinary soldering iron and a resistance soldering station to assemble the parts. The resistance soldering tool has the advantage of focusing the heat in the places that the pieces fit together, and not heating the entire piece. Nevertheless, each of the 17 solder joints was reheated up to six times to allow the parts to be repositioned. This is the final assembly. It looks so good at arms length, and then I look at the macro photos and it looks like it was dredged up from the Titanic! This is the first finished assembly. Tomorrow I will make the second piece from the kit of pieces shown in the first photo. It took a day and a half to make this assembly, but that included making the parts for the second assembly. The second part should go faster. The entire thing was made by hand using a collection of drills and files to shape the brass.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

You definitely need to put the hoops on the mast before adding details in the tops. I assembled the mast on my schooner model with the hoops in place and the tops rigged. The boom and gaffs were laced to the sail off the mast, and then attached to the mast. Then I tied the gaff sails to the hoops. That was tight work! I think it would be better to assemble the gaff sails to the boom and gaff, and tie the hoops to the sail. Then you can slip the hoops over the mast and attach the boom and gaff to the mast.

-

Brass stock in small sections....?

Dr PR replied to Mark Pearse's topic in Metal Work, Soldering and Metal Fittings

Years ago I bought out the small brass stock from a hardware store that went out of business. Some of it was K & S, but the really tiny stuff was from Special Shapes company. I guess they went out of business or were bought by another company because the web site no longer exists. They made brass shapes like "L", "H", "T" in dimensions down to 1/32 inch (0.8 mm) plus rods down to 0.010 inch (0.25 mm) diameter. I don't know of anyone making this small brass stock now. -

I have used a acrylic sealer prior to painting wood with acrylic paints. I haven't noticed significant fuzz on basswood or boxwood. Of course, the purpose of the sealer is to fill and tiny cracks or grain, and it is always sanded afterwards to ensure a smooth surface for painting. FolkArt all-purpose sealer, satin finish

-

John, I think I will use thin cardboard for the hoses. It should fold easily and the somewhat fuzzy surface will resemble the hoses. Steve, Most of it will be hidden by the hoses.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

I have been making some of the small detail parts. Some of these were fire hose racks. Drawings for these are in the blueprint set, so I didn't have to guess at the dimensions. Still, as I converted the 1:1 dimensions to 1:48 the actual size of these parts didn't sink in. It was only when I started cutting the tiny pieces out of sheet brass that I realized this would be a bit more challenging than I had anticipated. The plans call for 3/8 inch (9.5 mm) metal plate. That comes out to 0.008 inches (0.2 mm) at 1:48 scale. I decided to use 0.005 inch (0.13 mm) brass for the front "D" shaped pieces. But that stuff is pretty flexible, so I made the rectangular back plates from 0.010 inch (0.25 mm) brass. The part the hoses hang over was made from 0.091 inch (2.3 mm) brass tubing. This is a bit over the true scale 0.083 inch, but the 0.091 inch tubing was what I had to work with. Here are the finished hose racks. The 0.91 inch brass tubing was sawn down the middle to create "C" cross section half tubes. Four of them have 0.146 inch (3.7 mm) long pieces of half tubing. One has a shorter 0.094 inch (2.4 mm) hose support. The longer parts are for fire hoses, and the shorter one is for the fresh water connection hose to a shore supply. These things were a test of my patience! Getting one end piece soldered to the tubing was fairly simple, but I had to reheat each of them several times to reposition the tubing in the correct position on the end plate. But when I tried to solder the other end piece to the tubing the whole thing unsoldered and came apart. The wet solder stuck the parts to the tweezers and everything was a mess! But if first you don't succeed ... and as you can see I finally got them done. The key to success was using an ancient aluminum tweezer-type heat sink dating back to the days (1960s) when we soldered individual long lead TO-5 package transistors onto circuit boards. I had the old Radio Shack part in my tool box. When I clamped it to the tubing close to the already soldered end piece it absorbed the heat and prevented that solder joint from melting. Still, I had to work quickly, and had to repeat the process several times to get the second end piece in the correct position. It was slow tedious work. These things are ridiculously small! I have a partially assembled 1:96 scale model of the USS Oklahoma City CLG-5. Someday I want to resume that build. But it has dozens of small parts like these hose racks - but half the size! I think I will have to use 3D printing for that build, and I will need a much better printer that the one I currently have!

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

George, Good to see you back in the workshop. That is an interesting rig in the photo. I have seen it in books but this is the first model I have seen that has the mainsail with the diagonal spar. Harold Underhill calls it a sprit-sail rig (Sailing Ship Rigs and Rigging, Brown, Son and Ferguson, Ltd., Glasgow, 1969, pages 13 and 72). The diagonal spar is called a sprit. He shows the sail plan of a Thames sailing barge Lady Daphne with this rig. So it wasn't limited to the Mediterranean.

-

For what it is worth, on mid 20th century US Navy ships with wooden decks the planks were laid over steel decks, with short stub bolts welded to the deck (it was really nasty trying to walk on that deck after the planks were removed for replacement). The planks had small diameter holes half way through to fit over the bolts, with a larger diameter hole above that for the nut. Caulking was hammered around the nut and a wooden plug was hammered into the hole over the nut. The blueprints specified that the wooden plugs be cut from the same type wood as the planks, perpendicular to the lengthwise grain of the planks. This left the "side view" of the wood grain exposed on the ends of the plugs, and not the "end view". When the plugs were installed the grain on the top of the plug was to be aligned with the grain in the planks to make the plugs as invisible as possible. So the intent was to hide the plugs. You could see the plugs if you were standing directly over them, but they were invisible from one or two decks above. I suspect this same technique was used in the 19th century to bolt planks to steel ribbed hulls. However, trenails were cut with the grain, so the end grain is visible and distinct from the grain of the planks. Even so, on freshly cleaned (holystoned) decks the trenails would not have been visible from more than a few tens of feet (several meters).

-

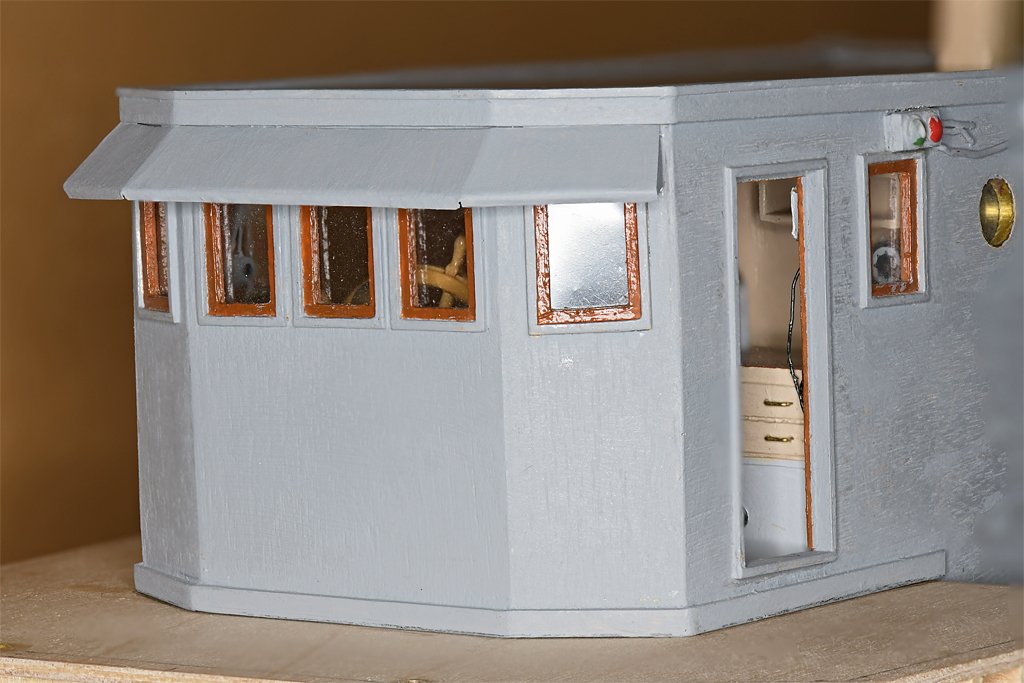

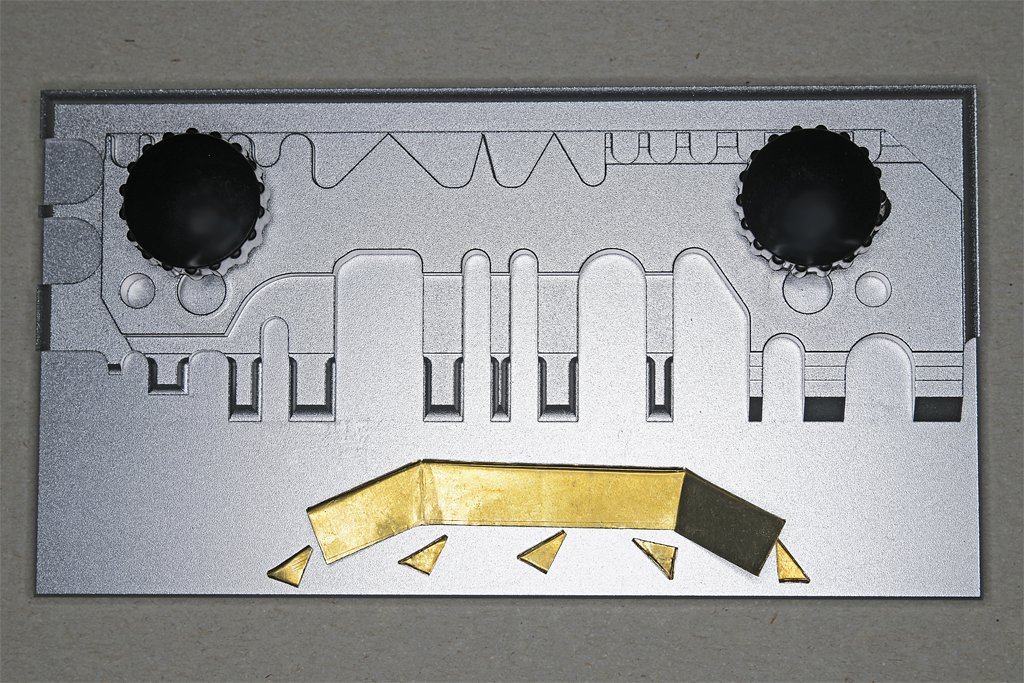

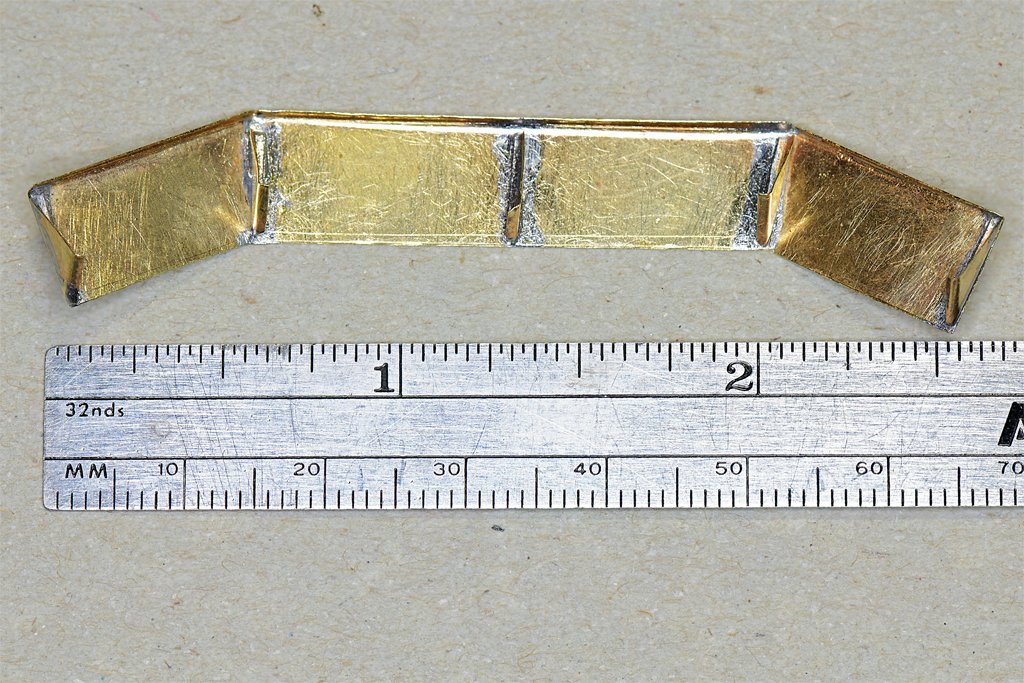

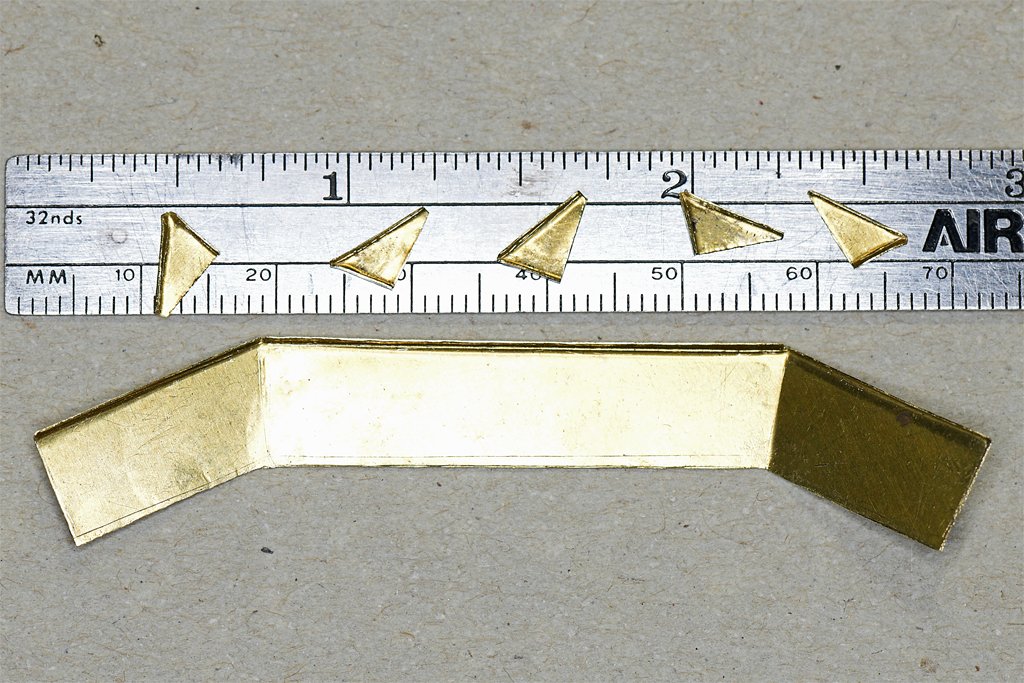

Today I added the "visor" or sun shade over the windows at the front of the O1 deckhouse. The parts were made from thin brass sheet. I used a new Photo Etched Parts Bender AB-4553 from joystarttools.com (China). I saw a smaller version of this tool recommended in another thread on the Forum. I got the larger version because I will need to bend some longer pieces when I get to the equipment on the after deck of the Cape. The tool is 5.52 inches (140 mm) on the long side, and the upper part can be rotated to use the long straight edge to bend parts almost 5.5 inches long. This was my first time using the tool and it worked as advertised. I made bends that were only about 1 mm (0.039 inches) wide. It was easy to use. The small triangular support pieces were made from 0.003 inch (0.09 mm) brass sheet. For the larger surface I wanted something a bit stiffer so I used 0.0065 inch (0.14 mm) brass. This was a bit less than the scale 3/8 inch plywood used on the ship - that would b 0.0078 inch (0.2 mm). The supports were soldered to the bottom side of the visor as shown on the photo right below. The 1 mm (0.039 inch) lip along the front edges of the visor stiffened the piece. On the real ship this was a strip of wood attached to the bottom front edge of the plywood visor. Here are a couple of photos showing the visor in place on the deckhouse. I have been looking forward to making this piece. It was practice using the bending tool. When I get around to making all of the minesweeping gear on the after part of the ship I will be bending a lot more small parts.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Vaddoc, I normally sand between paint coats because I use a brush and that can leave some brush marks. It also helps to make a smoother final finish. However, I used plywood for the deck house sides and tops on the Cape model, and it has some significant visible grain features even after I had sanded it smooth. Each coat of paint fills in a bit more, until the graininess is hidden. I used one or two coats of acrylic sealer, but this wasn't enough. You can see this on the lower deckhouse that hasn't been painted grey. With all the small details that have been added I won't be able to sand it anymore, so the final paint coat will be pretty thin, just to cover the scuff marks from the prior sanding and handling. Then a final coat of satin acrylic varnish will finish the paint job. I have already done this on the hull and main deck. In hindsight I suppose I should have used sheets of basswood for the deckhouses. The basswood I have has a much less grainy surface than the plywood.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

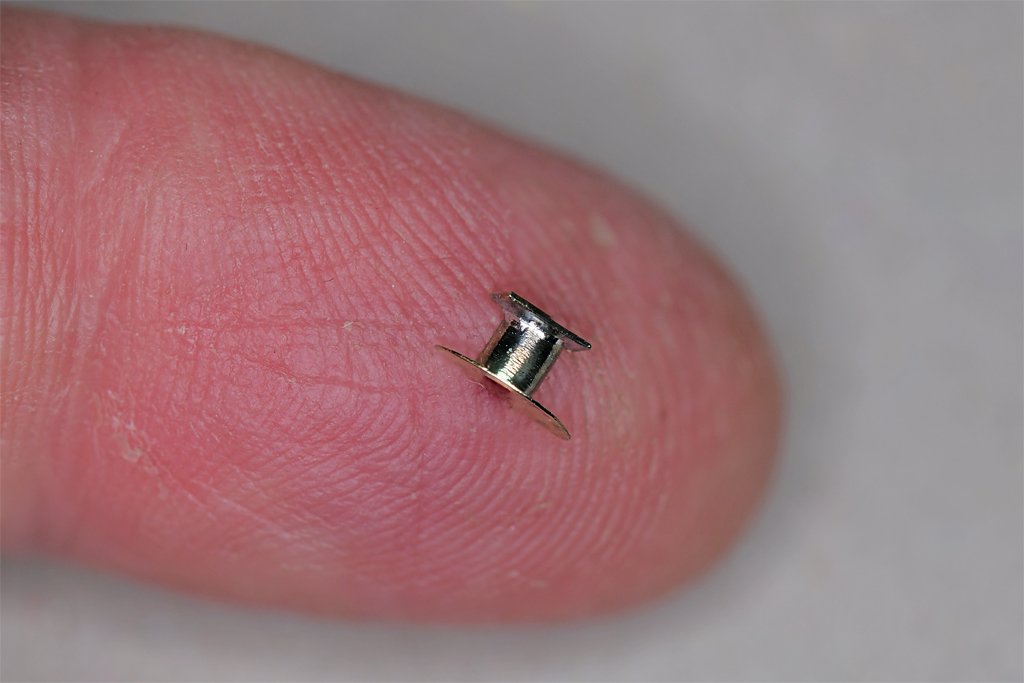

These are deck drains. The flat metal parts are 0.005 inch (0.13 mm) brass sheet. The drain pipes are 0.038 inch (0.097 mm) aluminum. The drain funnels were made from 0.062 inch (1.6 mm) and 0.092 inch (2.3 mm) telescoping brass tubing. The drain channels are 0.1 inch (2.5 mm) wide, to provide a size reference. Assembly was tricky. I soldered the brass tubing first, and then turned the end to create the "funnel" shape. The "U" shaped channels were then soldered together, using a wooden dowel to bend the brass strips and align the sides and bottom while soldering. These two steps weren't much of a problem. Then the "funnels" were soldered into the channel. This had to be done quickly, with a minimum of heat, to avoid unsoldering the parts of the channels and funnels. I had to repeat this a couple of times for each piece to get things aligned properly. The aluminum drain pipes were glued into the funnels with super glue (cyanoacrylate or CA). I made tiny "U" brackets from 0.005 inch (0.13 mm) brass strips to fasten the pipes to the deckhouse bulkheads. Here are some photos of the drains on the aft end of the O1 superstructure. The main deckhouse also has drains on the aft end port and starboard, and the O1 level bridge wing decks have drains port and starboard. I used aluminum wire because 1) i don't have brass rod the correct scale diameter, and 2) it is much easier to form the curves with the soft aluminum than with harder brass. But that meant I had to glue the aluminum and brass pieces instead of soldering. Epoxy would have been better for bonding aluminum to brass, and the brass parts to the wood superstructure. But little mechanical strength is needed in this application so CA should work OK. After the glue sets overnight I will brush the drains to clean them up and then paint them. The entire O1 level superstructure needs another light coat of paint, and then some satin acrylic varnish.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Tapering Masts and Arms the easy way

Dr PR replied to Johnny Mike's topic in Masting, rigging and sails

I have done the same thing, and it does work if you do move the piece back and forth past the center "dead zone." But if the piece is flexible you can end up removing more material on the ends than in the center because the disc sander is more "aggressive" at the higher speed outside edges than in the slower center. I have also placed a spacer on the platform to raise the piece above the center. -

Thanks for the complements fellows! For the vent there are supposed to be eleven "slats." I used 1/64 inch (0.4 mm) plywood for the slats and started out with them at a 45 degree angle. I prepared a spacer to set them at a uniform spacing. "The best laid plans ..." I only got eight to fit, and the upper slats are not at exactly 45 degrees. But the spacing is pretty good so it looks OK. Besides, it will be hidden under a ladder.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

More details on the deck houses. I have put the "lid" on the O1 deckhouse. I still haven't attached the O1 level house to the main deck house. I have been adding some deck edge trim around the sides of the deck houses. While it adds some nice detail it also serves a very good modelling purpose. The house sides and decks are made of 1/16 inch (1.6 mm) plywood, with the decks resting on the top edges of the sides. Finishing the edges of plywood is trickier than the surfaces, with multiple porous layers to fill. The upper horizontal trim is 5/32 x 1/32 inch (4 x 0.8 mm), and the lower vertical piece is 3/32 x 1/32 inch (2.4 mm x 0.8 mm). These dimensions are pretty close to scale. The vertical piece conveniently hides the edges of the plywood deck. The real ship was built with 3/4 inch (19 mm) plywood house sides and deck. The trim served to seal the edges of the plywood from the weather. The main deck house has the same type trim as the O1 level house. There is also another 3/32 x 1/32 trim piece at the bottom of the deck house sides. The houses fit pretty tightly to the decks, but there are some slight gaps. These bottom trim pieces allow me to cover any gaps and seal the houses tightly to the decks. A vent trunk fits to the rear of the main deck house. Inside was a large fan that ventilated the engine room below. The blueprints and early photos of the MSIs show deck edge trim like on the house sides, and a hawser reel on top of the vent trunk. However, when I was aboard in 1969 both of the MSIs had an inclined ladder from the main deck to the top of the vent trunk. Steps had been added up to the O1 level. I will be adding the ladder and steps. Originally, if you were on the O1 level and wanted to get to the main deck you had two choices. There was a vertical ladder on the starboard aft side of the main deckhouse. Or you could go through the pilot house to the radio room, and down an inclined ladder in a companionway. Then you could go through the mess decks and passageway to the door at the port rear of the deckhouse (shown in this picture). I guess they got tired of taking the long way around and added the inclined ladder. The hawser reel was moved to the port rear corner of the O1 level, above the door. There was another addition to both MSIs inside a recess in the main deckhouse port side. There was a scuttle in the deck at the bottom of this recess. It was an escape scuttle from the mine sweeping generator room. Originally there was nothing in the recess. But somewhere along the line a locker was added at the top of the recess. I do not recall what was stowed in the locker. The recess was 3 feet (about 1 meter) wide, and the locker was about the same height. It would have been about 18 inches (about half a meter) deep. I'll be adding more small details to the main deckhouse sides, and planning for the life rails on the O2 level. I have also started on the mast. Conveniently, it was 12 inches (305 mm) square, and that is 1/4 inch (6.4 mm) at 1:48 scale. I used a 1/4 inch square dowel and rounded the edges slightly like the real mast.

- 492 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Tapering Masts and Arms the easy way

Dr PR replied to Johnny Mike's topic in Masting, rigging and sails

Are you using the same taler for the full length of the mast? A long tapered cone? From what I have read the mast is more like a long half oval, tapered more on a curve than a straight line. Widest at the deck (partners) and tapered in quarter lengths in a non-linear fashion. Divide the length of the mast from the deck to the crosstrees into four sections. The relative diameter at each quarter is: deck (partners) 1.0 1/4 0.984 2/4 0.933 3/4 0.857 crosstrees (hounds) 0.75 I used to use a simple taper using sandpaper for the masts when I first started building ship models (50+ years ago). But when I learned real mast weren't built this way I started using the 4/8/16 tapering method in order to get better control of the mast shape. It is a lot easier that it sounds, and produces a more accurate mast shape. YT pointed out a problem with your method. With a disc sander the rate of material removal is proportionate to the speed of the sanding surface. The outer parts of the wheel rotate faster, and the center doesn't rotate at all for practical purposes. You can't use the entire diameter for tapering because the center doesn't do much, if anything. You can modify the process by placing a spacer to raise the work piece above the center, so the sanding surface is moving, but it will still be faster on the outside of the disk than near the center, and will be more aggressive at removing material. It will be very difficult (but not impossible) to get an accurate mast taper this way.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.