SandyBay

Members-

Posts

37 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Cast Off reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

Cast Off reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

J11 reacted to a post in a topic:

Armed Virginia Sloop By captain_hook - FINISHED - Model Shipways - Scale 1:48

J11 reacted to a post in a topic:

Armed Virginia Sloop By captain_hook - FINISHED - Model Shipways - Scale 1:48

-

CDW reacted to a post in a topic:

18th Century Armed Longboat by Arthur Wayne - FINISHED - Model Shipways - Scale 1:24 - Small

CDW reacted to a post in a topic:

18th Century Armed Longboat by Arthur Wayne - FINISHED - Model Shipways - Scale 1:24 - Small

-

SandyBay reacted to a post in a topic:

America by TUEL - FINISHED - Mamoli - Scale 1:66

SandyBay reacted to a post in a topic:

America by TUEL - FINISHED - Mamoli - Scale 1:66

-

Canute reacted to a post in a topic:

Chaperon 1884 by mbp521 - FINISHED - Model Shipways - Scale 1:48 - First Build Log

Canute reacted to a post in a topic:

Chaperon 1884 by mbp521 - FINISHED - Model Shipways - Scale 1:48 - First Build Log

-

SandyBay reacted to a post in a topic:

Red Jacket by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - Scale 1/8" = 1' (1:96)

SandyBay reacted to a post in a topic:

Red Jacket by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - Scale 1/8" = 1' (1:96)

-

SandyBay reacted to a post in a topic:

U-552 by yvesvidal - FINISHED - Trumpeter - 1/48 - PLASTIC - Type VIIC U-boat

SandyBay reacted to a post in a topic:

U-552 by yvesvidal - FINISHED - Trumpeter - 1/48 - PLASTIC - Type VIIC U-boat

-

Very nice, they certainly look the part.

- 133 replies

-

- chaperon

- model shipways

-

(and 2 more)

Tagged with:

-

Tom E reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

Tom E reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

Tigersteve reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

Tigersteve reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

SandyBay reacted to a post in a topic:

HMS Victory by Patrick Haw - Caldercraft - Scale 1/72

SandyBay reacted to a post in a topic:

HMS Victory by Patrick Haw - Caldercraft - Scale 1/72

-

Nikiforos reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

Nikiforos reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

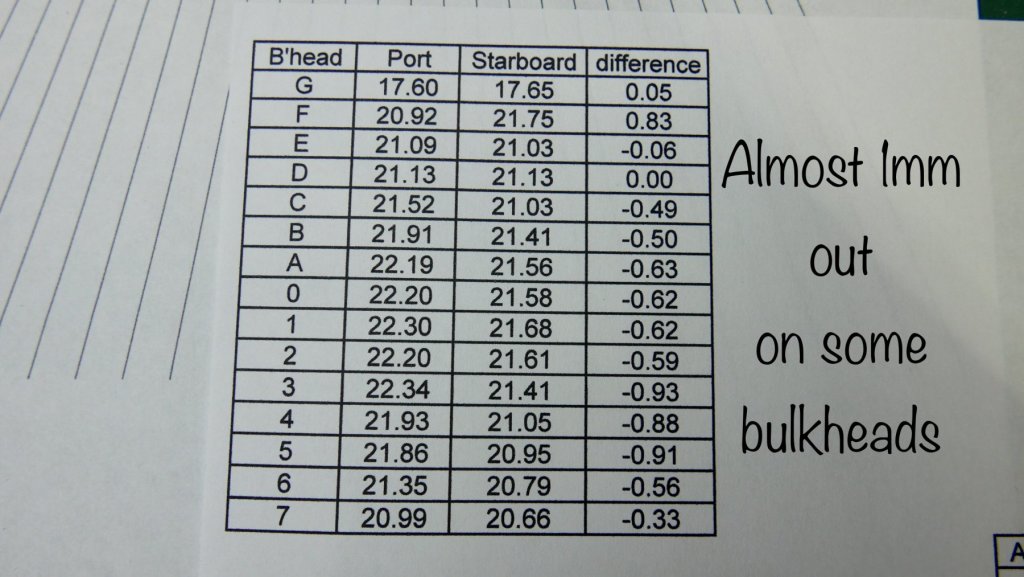

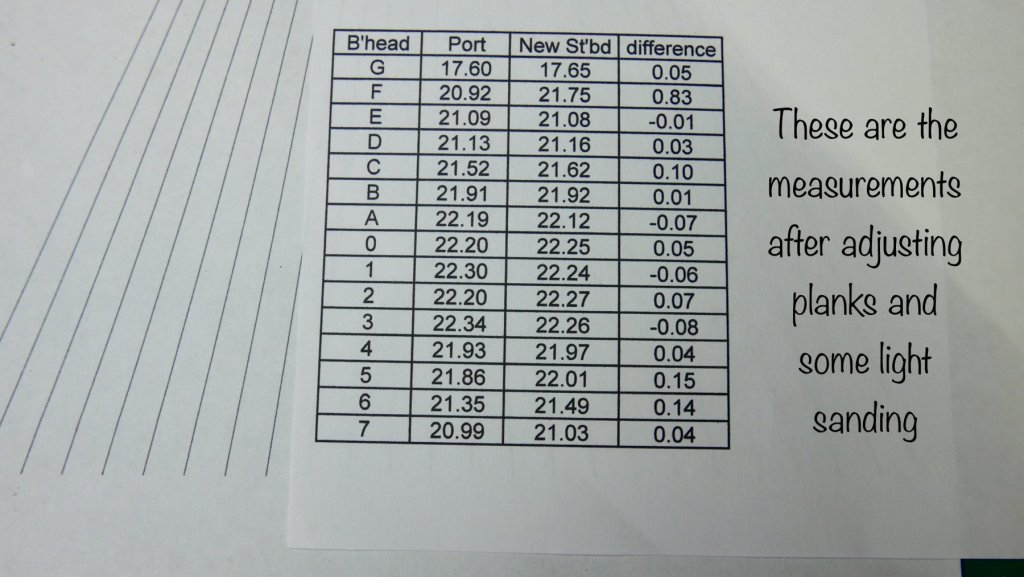

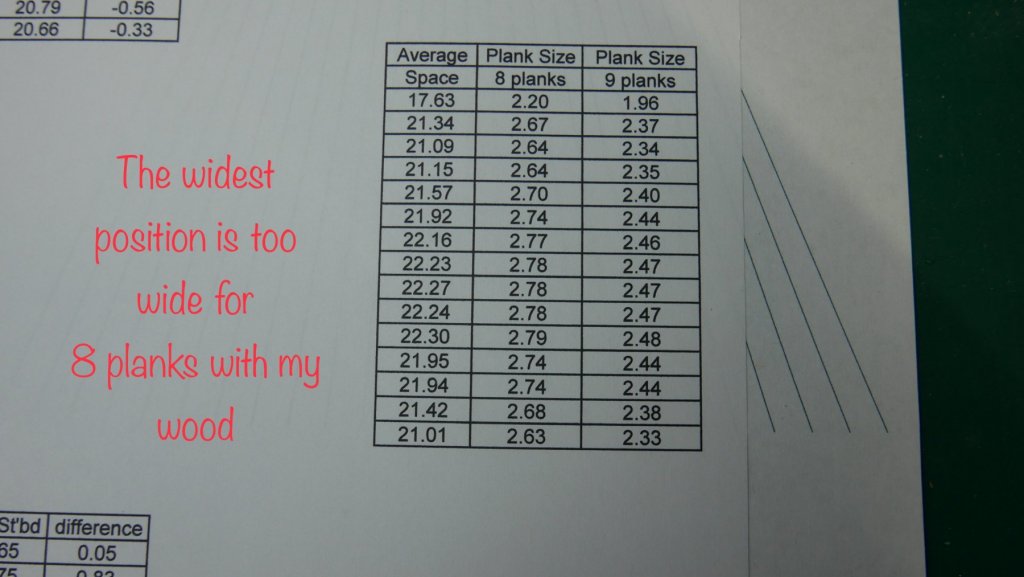

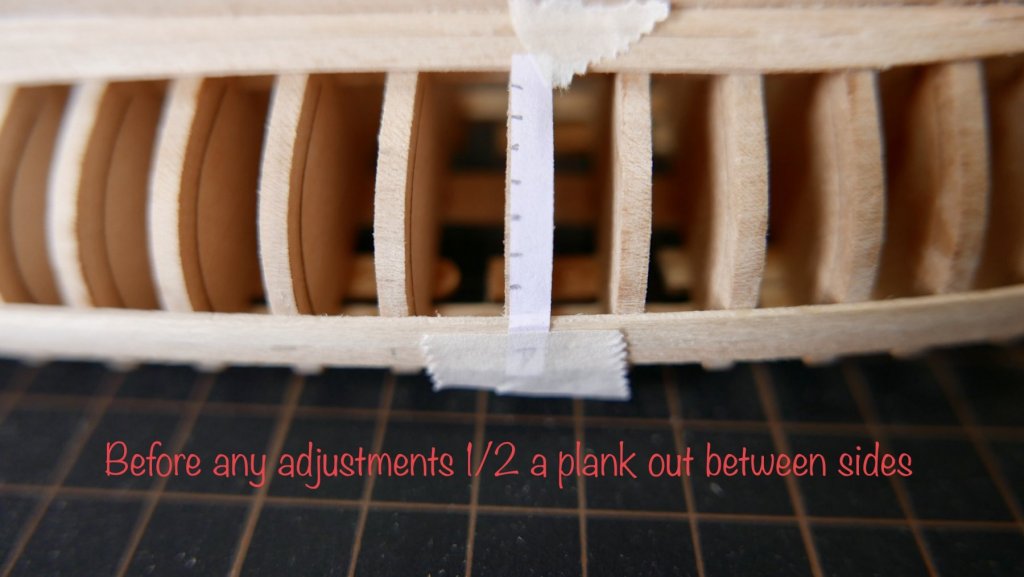

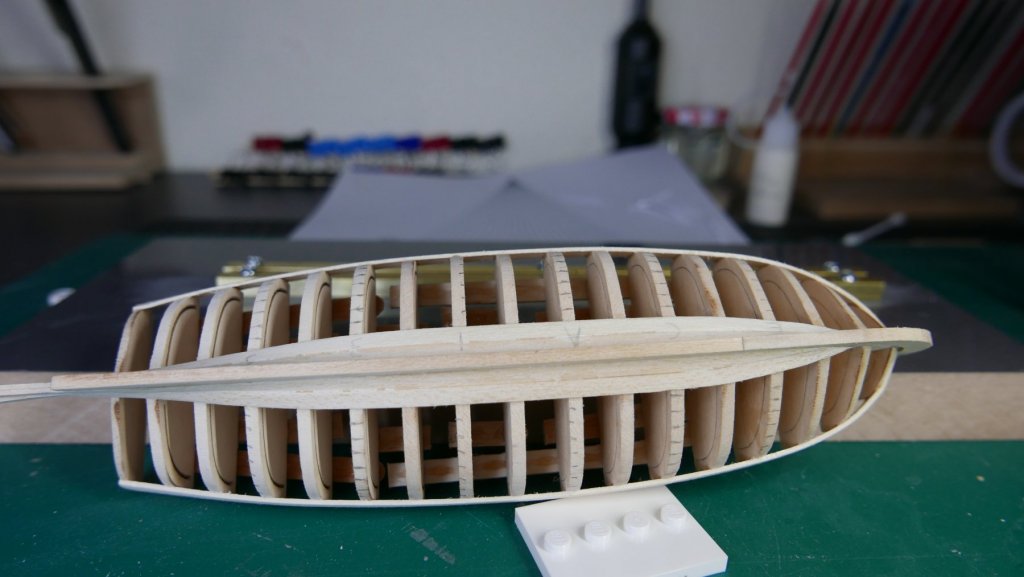

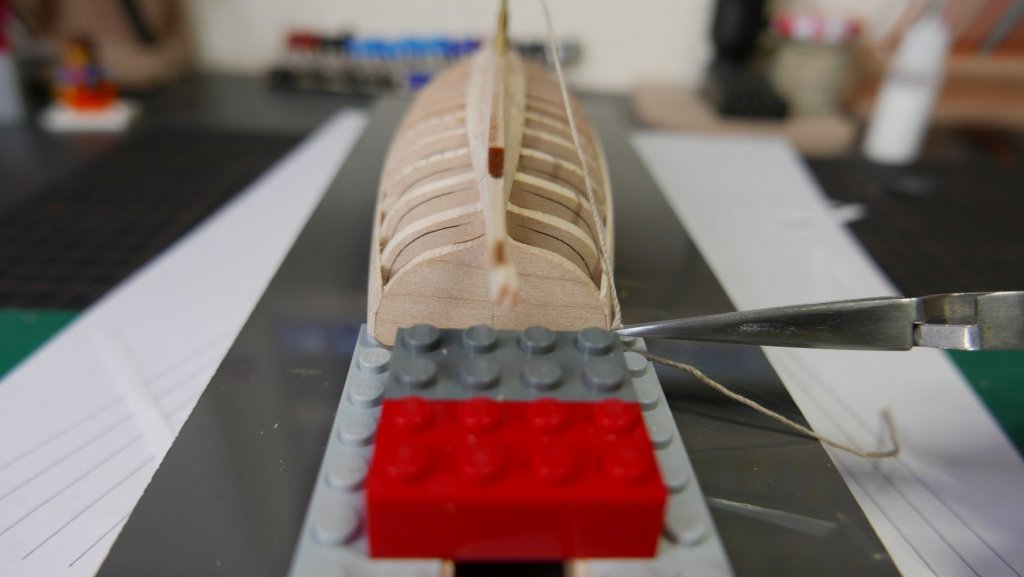

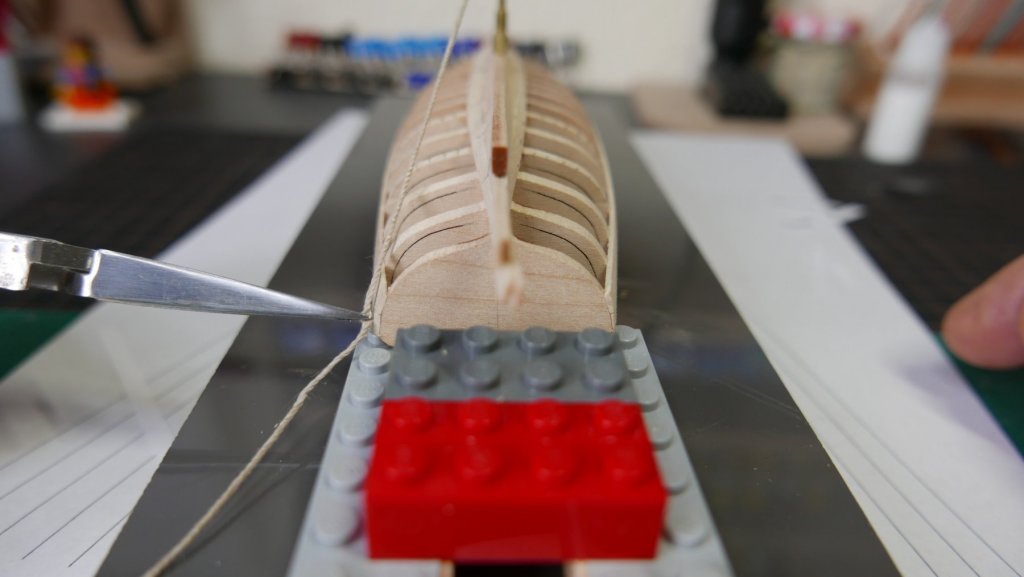

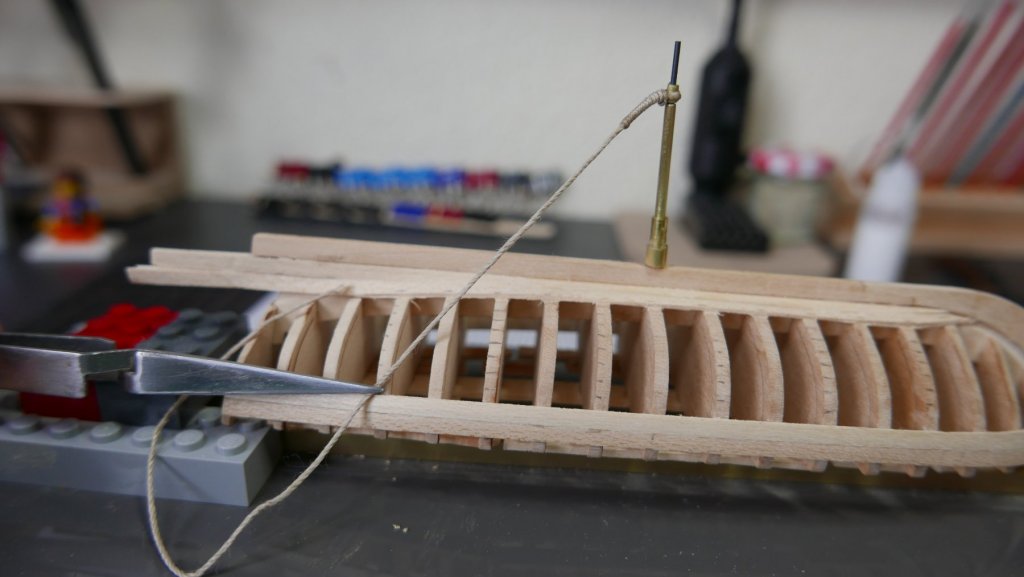

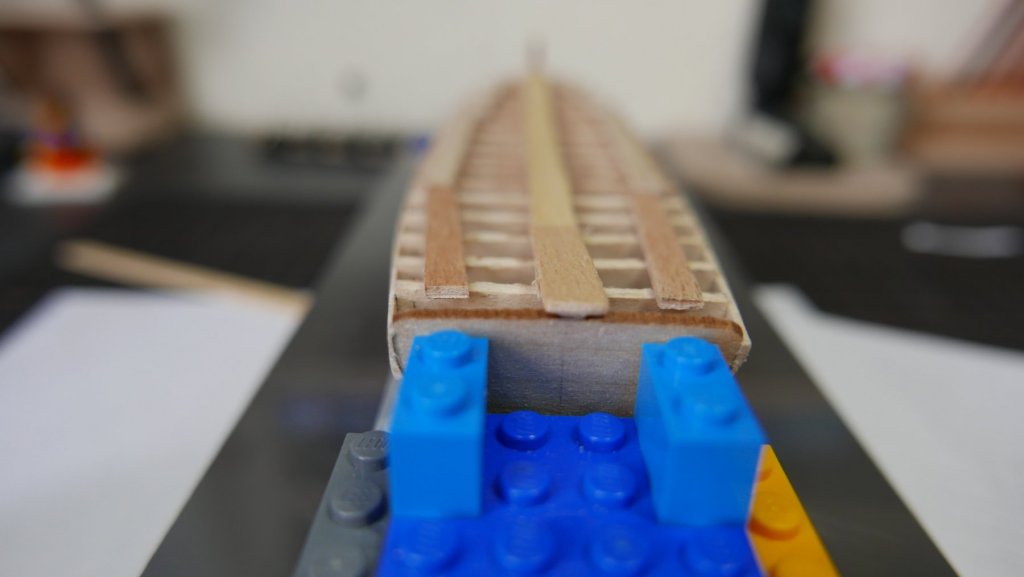

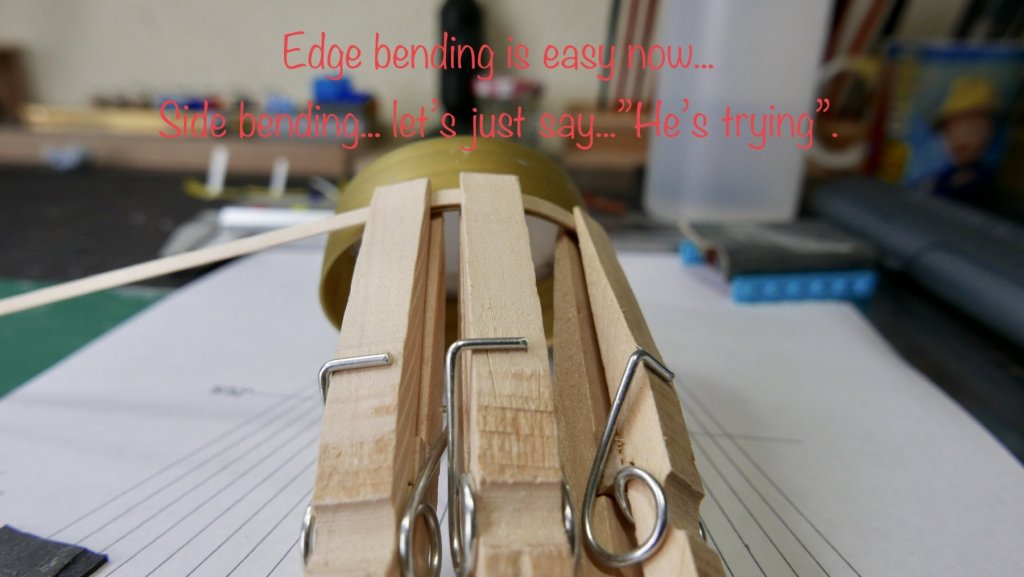

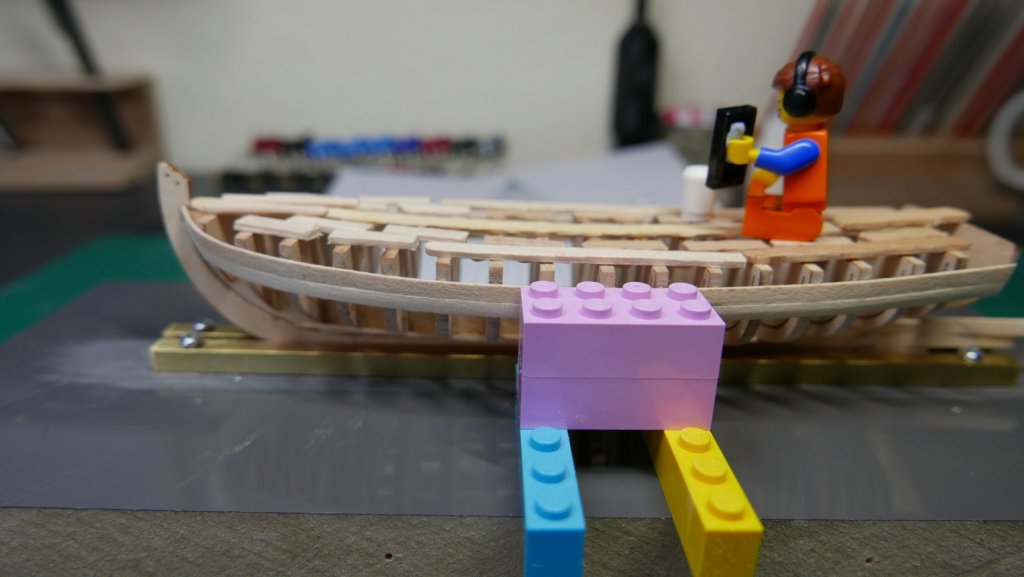

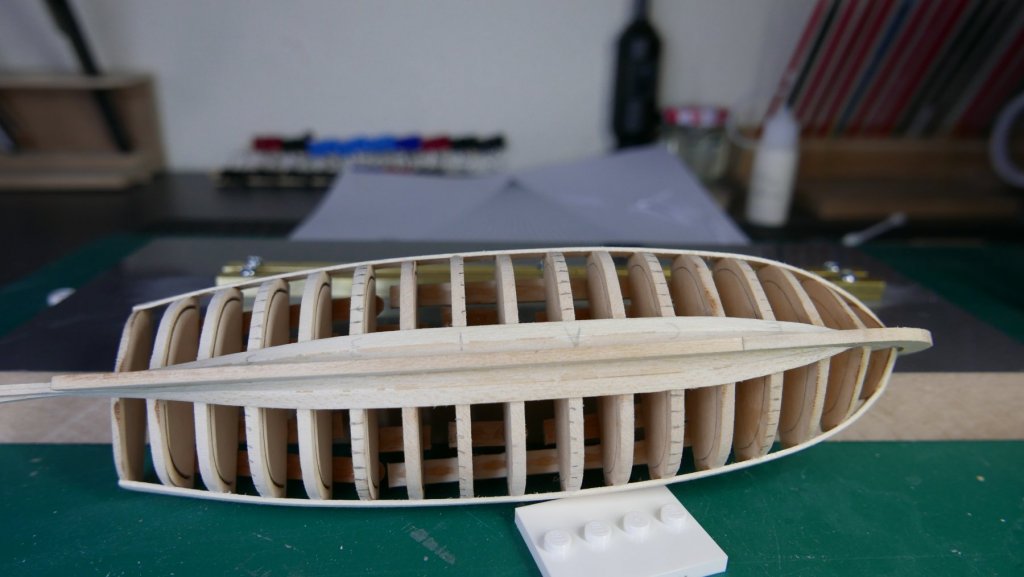

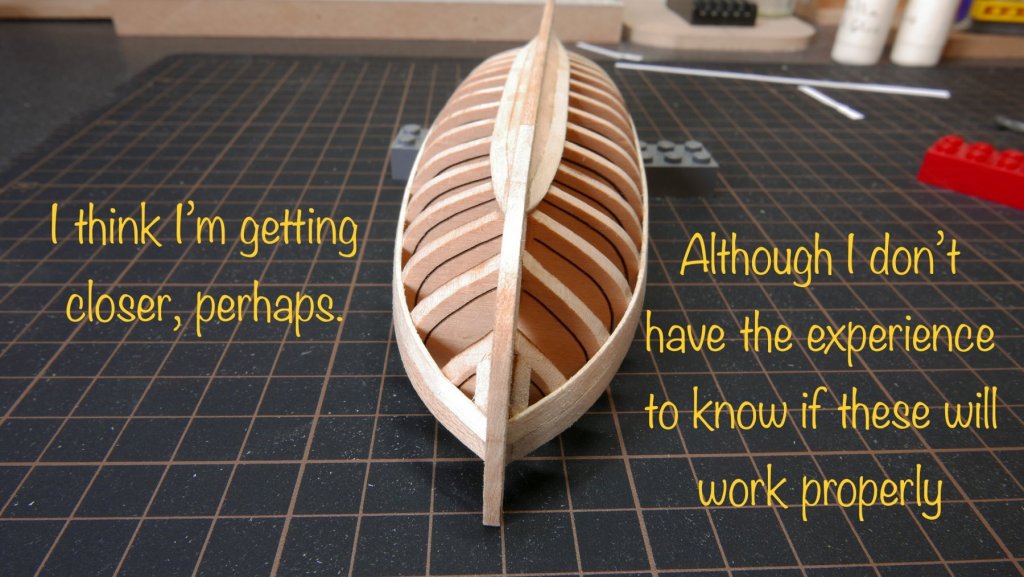

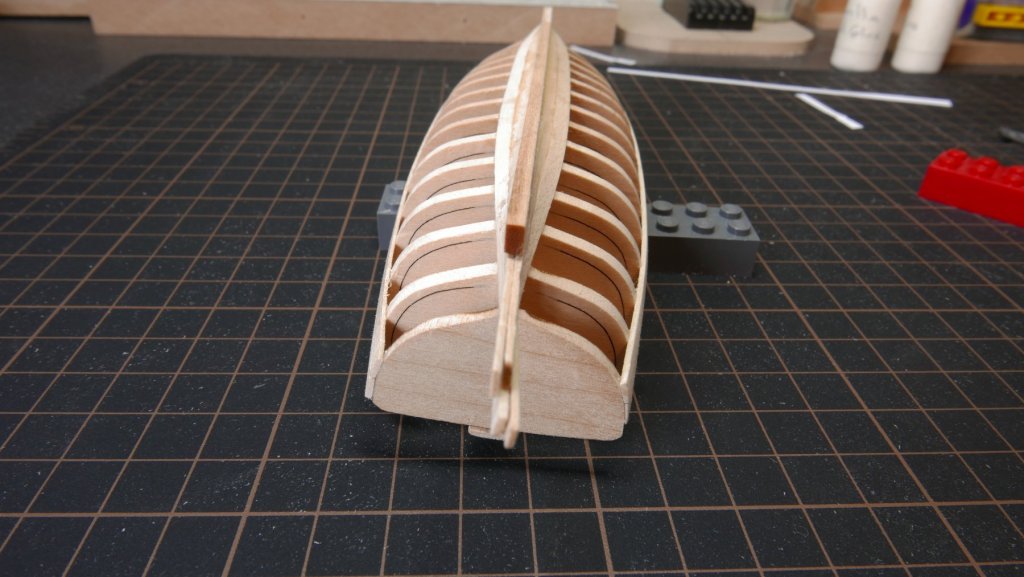

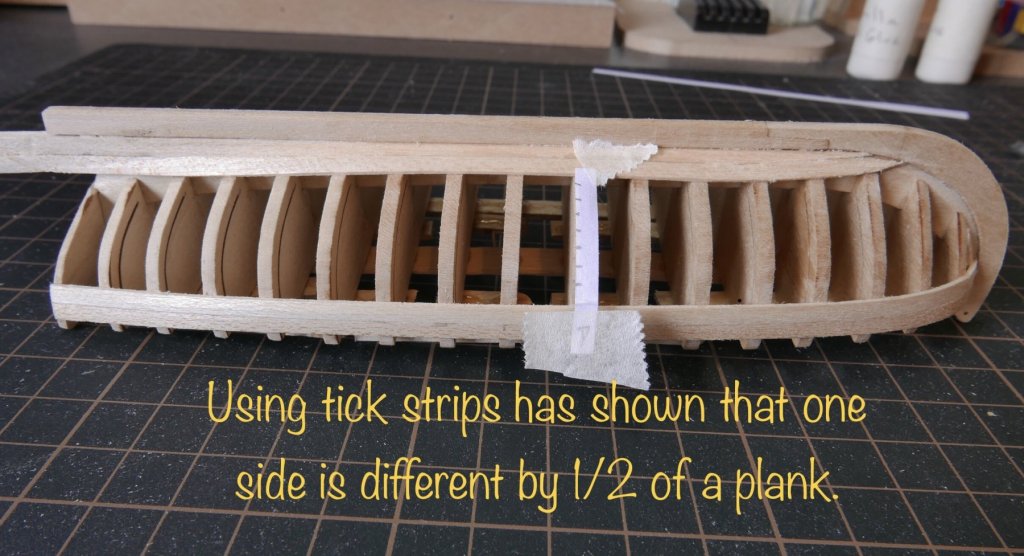

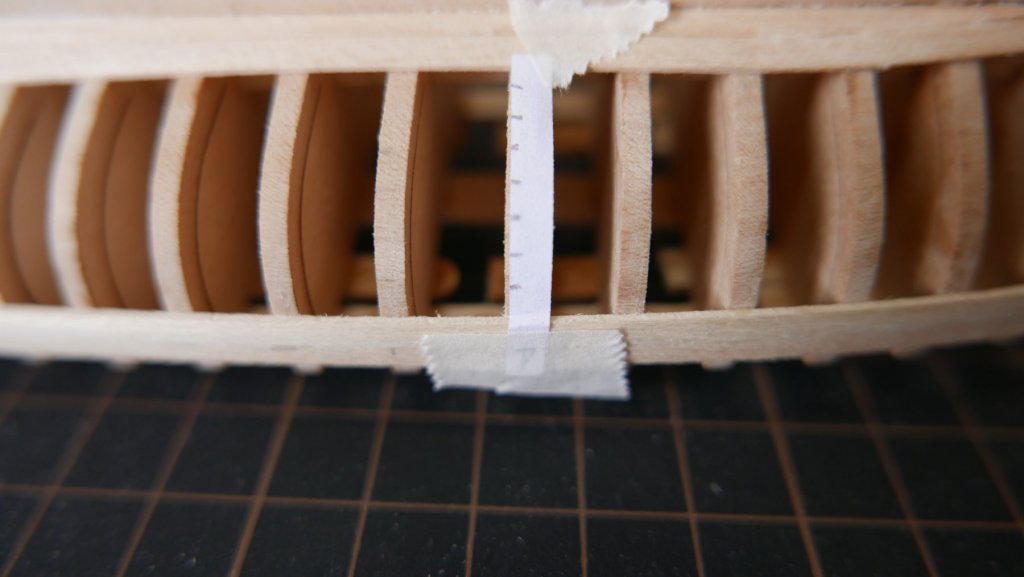

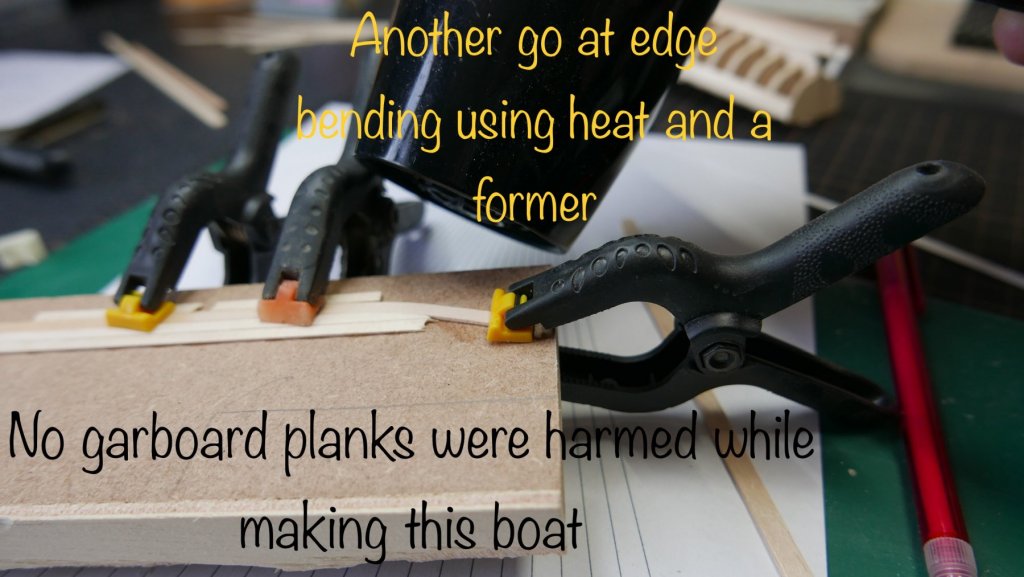

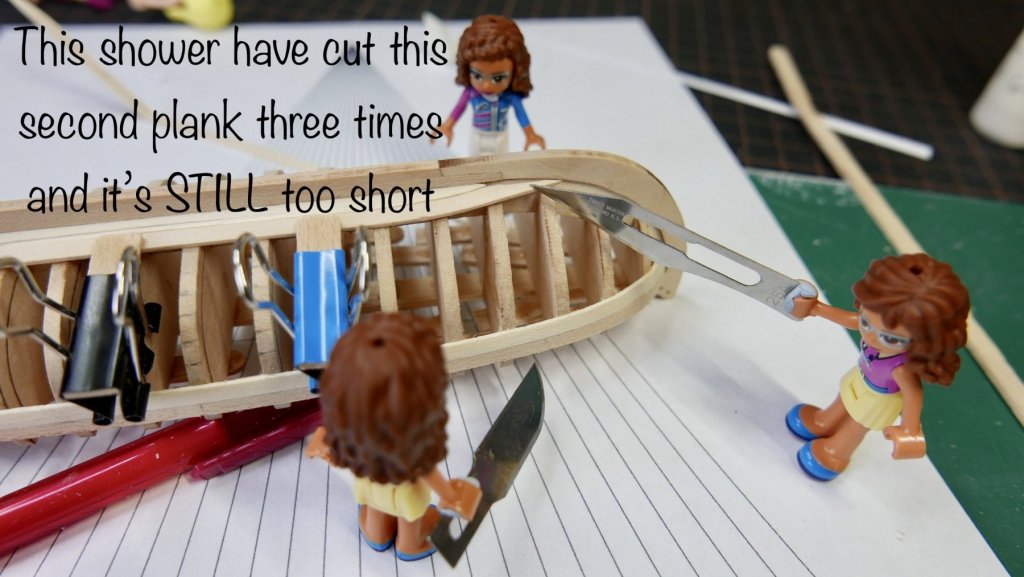

Well I’ve taken on board all the helpful comments I’ve received here and immersed myself in learning about bent wood. Following on from what gsdpic suggested and using Vossiwulf’s stylish method I’ve checked and rechecked my plank positions. Well the top two planks were different heights so I carefully removed one set and reglued them correctly. Then useing a planking fan I tick marked every second bulkhead. It still didn’t pan out so I measured and recorded the gaps on every bulkhead and found that I was considerably out on several positions. I was confident now about the top four planks which meant the inaccuracies had to be in the two keel planks each side. They’d already been fitted and changed twice before and I was dubious about getting them off again and cleaning up the glue without breaking some of the frames free from the keel. I took the decision to simply sand those planks to even up the spaces between port and starboard. I don’t want to run the risk of losing heart and stopping because I’m not getting something as nice as I see on your build logs so I’m cracking on again and it seems to be going ok (ish). I’ll tell you what guys, building boats isn’t like doing a jigsaw is it. Some pictures to follow but my iPad is denying any knowledge of them at the moment so I’ll have a stern word with it.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

EJ_L reacted to a post in a topic:

Medway Longboat 1742 by Chuck - FINISHED - 1/2" scale

EJ_L reacted to a post in a topic:

Medway Longboat 1742 by Chuck - FINISHED - 1/2" scale

-

Ah, perhaps I should have read to the end of the thread BEFORE I emailed you asking if you intend to continue offering the kit. 🙂

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

SandyBay reacted to a post in a topic:

America by gsdpic - FINISHED - BlueJacket Shipcrafters - 1/48 scale

SandyBay reacted to a post in a topic:

America by gsdpic - FINISHED - BlueJacket Shipcrafters - 1/48 scale

-

gsdpic reacted to a post in a topic:

America by gsdpic - FINISHED - BlueJacket Shipcrafters - 1/48 scale

gsdpic reacted to a post in a topic:

America by gsdpic - FINISHED - BlueJacket Shipcrafters - 1/48 scale

-

gsdpic reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

gsdpic reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

I’ve just read your log from beginning to end and I’m just blown away by the sheer amount of work involved to get your model to where it is now. Did you (or your admiral) ever work out how those cherry strips mysteriously ended up in your online shopping basket.

- 162 replies

-

- america

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Ahhh! That’s a brilliant idea Vossiwulf, thanks for the picture and I’ll definitely have a go with that method.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

Thanks Gary, Todays job is to carefully measure the positions of all the planks and then formulate a plan of action. I will probably take the pragmatic view that no one (apart from you lot on here) will ever see and inspect it from underneath so visually the top six or seven planks each side are more important. I always knew this would be a learning experience and I’ve certainly learned that you can’t just stick a model boat together like you can a plastic kit.

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

I was, in retrospect, quite casual about the symmetry on each side as I built it and obviously my chickens are now coming home to roost. I have always been impressed by the wooden ship models I’ve seen but now I have a whole new level of respect for the painstaking attention to detail and skill which is necessary to produce a quality ship model. It is so much more demanding than any plastic aeroplane kit. Would you happen to have a photo of your carbon fibre datum machine in action as I’m having trouble visualising how it would work?

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I could do with some advice if you’d all be so kind. I’ve been working through using tick marks on the bulkheads and as I found on the first bulkhead, the available space is approx half a plank less on the port side. I’ve checked the height of the planks on the gunwhale and they seem the same heights so my inaccuracies must be in the garboard planks. my question is this, is it better to reduce all the planks on the small side or try and sand the garboard area so the space to plank is the same as the starboard side?

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

SandyBay reacted to a post in a topic:

18th Century Longboat by SandyBay - Model Shipways - 1/48 - first build

-

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

- 33 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.