-

Posts

976 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by iMustBeCrazy

-

The problem is a lack of standards. There were no drafting text books so it was a case of doing as you were taught. Some drawings such as the one above may, for example, depict a half hull model while others the whole boat. When depicting the whole boat, sometimes objects the far side of the centreline are drawn dashed, sometimes solid. Sometimes extra details are depicted on the half breadth, sometimes not. Ultimately these drawings are not the engineering drawings of today, they are general guides backed up by scantling details and contracts which we rarely see. Or the might be right, but I don't think so.

-

Alfredo, it has little to do with the number of planks, it is about the shape. (although narrower planks are easier to bend sideways). The kit planks are rectangular, mine are shaped (a bit like a ski, see the photo) to fit against the previous plank. This process is called 'spiling'. Spiling can be simulated by 'edge bending', forcing a plank to bend sideways with the use of heat, but wood doesn't like doing that. I find cutting the plank out of a wider piece of wood easier.

- 19 replies

-

- Bounty Boat

- OcCre

-

(and 2 more)

Tagged with:

-

G'day Alfredo, I think that, given you were trying to do 'correct' planking with the wood supplied, you've done quite a good job. First, a reminder that your planking is quite thin (I think 0.5mm) so it can't stand much sanding, go easy. For any very low areas try gluing another layer of planking over the top of the low area (matching colour and grain as best you can) then sanding it down to blend it in. This is so you don't sand too much off adjacent planks trying to match the low area. A little glue applied with a pin in the holes and gaps then a light sanding to get sawdust into them will help, do one at a time and repeat if you have to. Only after you are happy with your fixes, lightly sand the whole hull.

- 19 replies

-

- Bounty Boat

- OcCre

-

(and 2 more)

Tagged with:

-

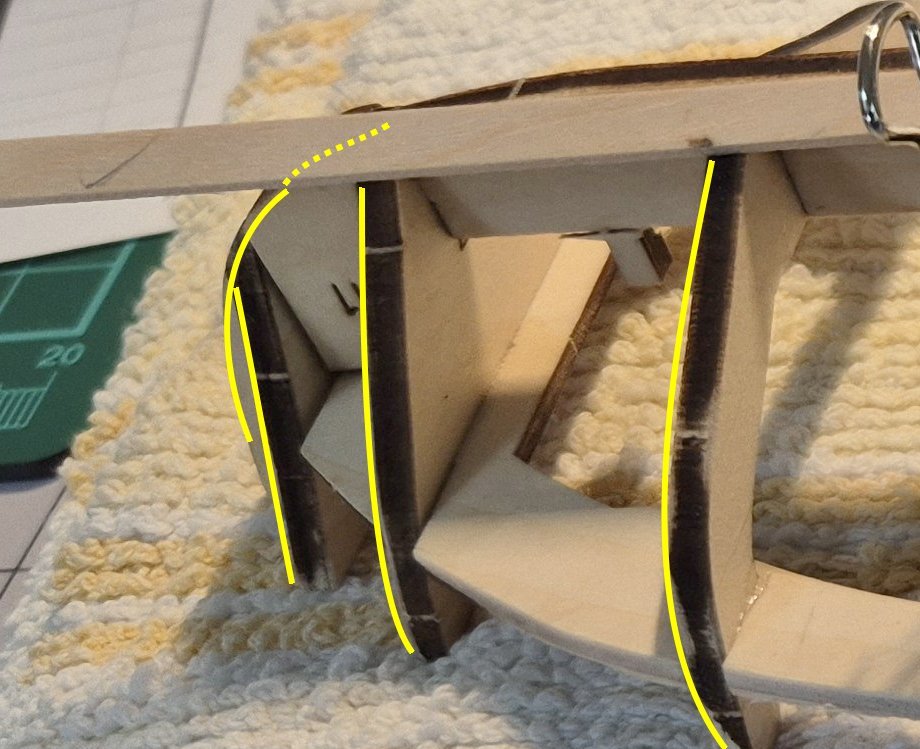

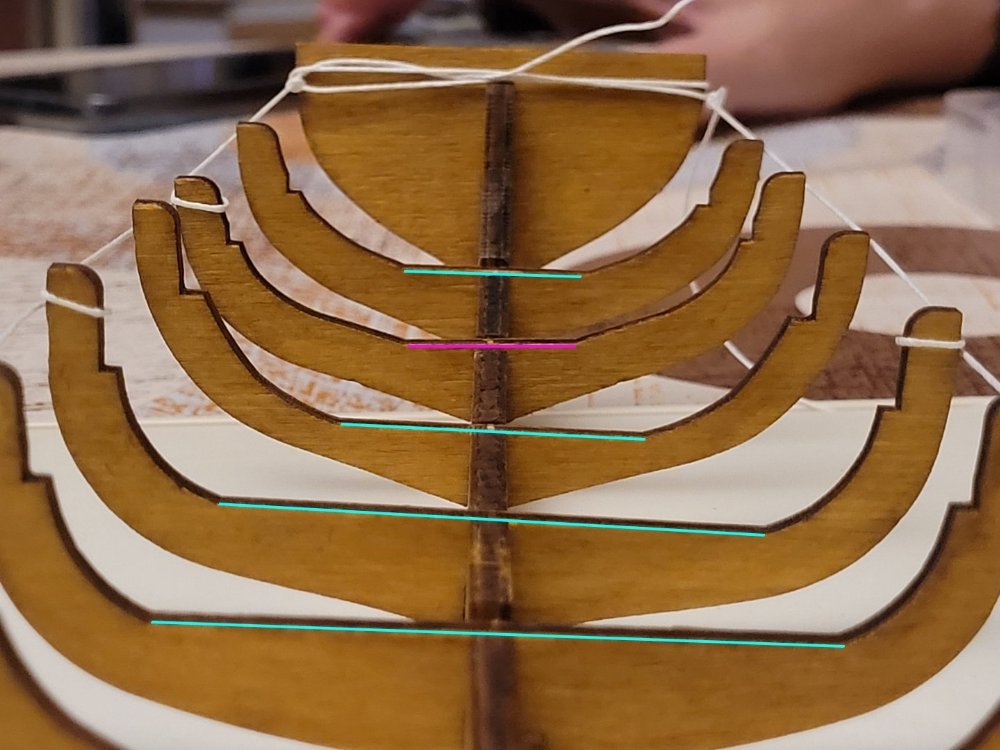

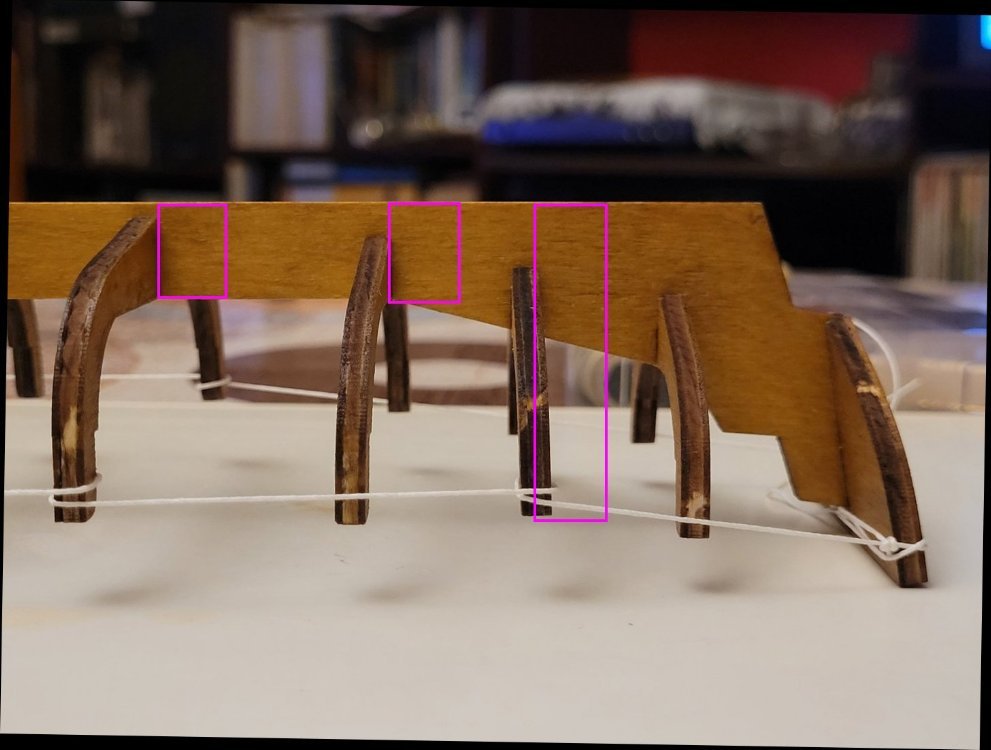

G'day Peter, I found this description on another site, The goal of hull fairing is to bevel the edges of the bulkheads so that the hull planks lay flat. If we didn’t do this, the planks would only hit the corners of the bulkheads. The problem is it only tells a part of the story. The aim of fairing is to have a finished hull with nice flowing lines, without lumps bumps hollows or kinks. Simply bevelling the frames without considering this only allows a greater gluing area, which although important, is only part of the story as I said. Your plank (or batten) should sit naturally against the intermediate frames if held down a few frames apart. Looking at your second pic you would probably have needed to sand the areas indicated below. But only enough to allow the plank to fit.

- 51 replies

-

- bounty jolly boat

- Artesania Latina

-

(and 2 more)

Tagged with:

-

Yeah, that's a one man boat, two at a pinch. Below is Lapwing/Speedy, close enough to Cheerful. The blue outlines are 16' cutters the green 18', the orange a 20' Gig and the pink a 22' Gig, more or less. At a pinch (and in utter desperation) I think a 16' cutter could carry 10 passengers and 2 oarsmen, in a dead calm for a short distance, or more realistically 6 passengers and 2 oarsmen (or 4 and 4) and is I think the biggest I'd put on stern davits. For an 18'er, maybe 4 more (10) but you'd need 4 oarsmen (so 10 minus 2) so only a slight gain, a 20' Gig another 4 more (14) and still 4 oars, a 22' Gig another 4 more (18) but 6 oarsmen (so 18 minus 2). All this assumes a minimum of oarsmen to allow more space for passengers and is just a guess.

- 11 replies

-

- cutter

- ships boats

-

(and 1 more)

Tagged with:

-

Thankyou both, that looks like it's going to be an interesting read. In just the first paragraph of chapter 1 we have for the stem "determine the shape of the stem; and find the centre (E), that shall sweep the lower part, at pleasure". So no rule there. And "And draw the line CF for the aft part of the stern-post, to what rake you please" So no rule there either. I believe this is plate 1.

-

Paviljoensjacht 1733 | Blender

iMustBeCrazy replied to Robska's topic in CAD and 3D Modelling/Drafting Plans with Software

-

And in one of those quirks, in 1938 HMS Bramble (Vigilant class 1822) (by then serving as a lightship) lets say an Aunt of Speedy was modified into a replica of HMAT Supply. Wiki.

- 9 replies

-

- Artesania Latina

- First Fleet

-

(and 1 more)

Tagged with:

-

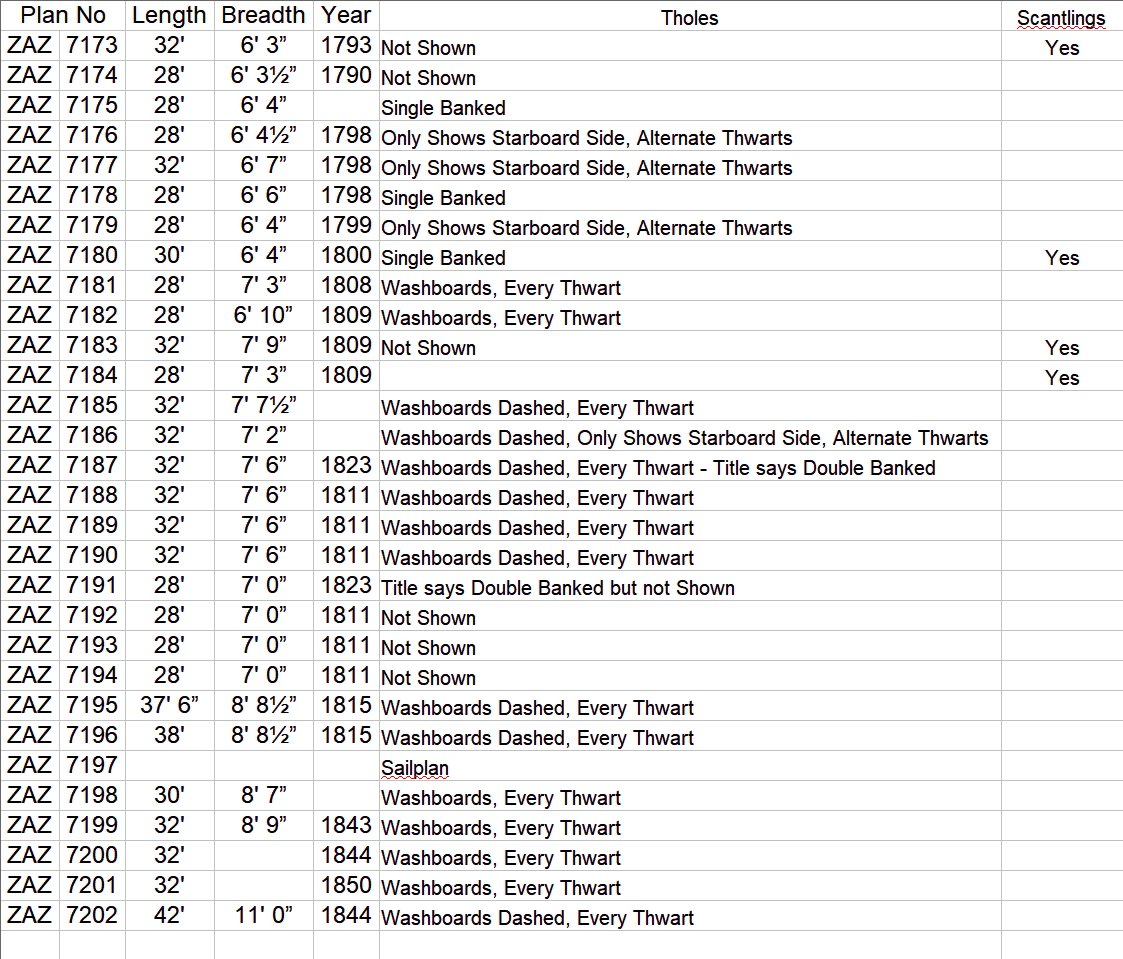

No I can't. ZAZ7239 is certainly not typical but some variation is common. On ZAZ7349 (yours) I wouldn't be surprised if the station spacing was 1' 2 1/4" around the midship area and 1' 2 1/2" at the bow and stern, but total apparent randomness 😲 But with ZAZ7239 as none of the lines is where the numbers say they should be, I suspect the draftsman put the numbers on a rough sketch as a less confusing reference prior to doing the real drawing. That might suggest that the table of offsets was calculated first but might have been 'corrected' as the drawing proceeded. At this stage I'm just guessing.

-

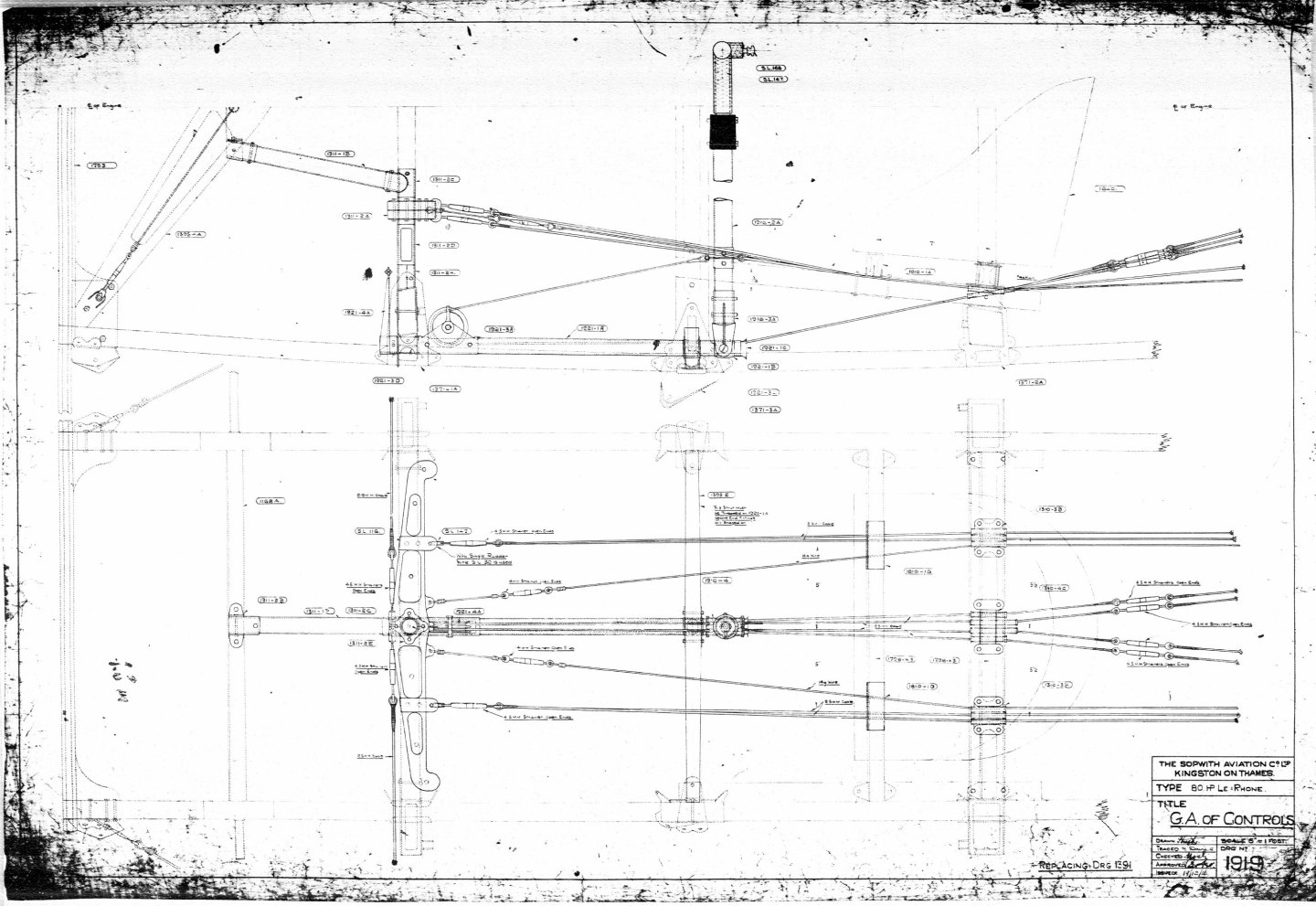

Yes, the drawing is just a pretty picture ( the shipwright would have built from the table of offsets which I haven't seen for a boat). On the drawing inaccurate setting of a compass would be very easy leading to incorrect arcs, a ruler not quite square, a pencil not sharp enough, heck, a cheap ruler v an expensive ruler. All these and more would lead to errors in the drawing. Yes, there must have been rules (or perhaps more like guidelines ). For masts we have formulae such as "Main-mast twice and a 1/4 the breadth of the boat" etc, there must have been others for, say, the thickness of timbers or the breadth of thwarts or .....

-

No problem. The model shipways kit was my first build, it was a good introduction but isn't quite the bounty launch. Cornwall's Maritime Museum replica is also close but not quite (there are more photos on their facebook page, there's a link in the Bounty Boats Facts (below)). All kits (hell, all builds) have compromises be they base on cost or skill level. Anyway, have a read of the Launch, 16' cutter and facts threads linked below.

- 19 replies

-

- Bounty Boat

- OcCre

-

(and 2 more)

Tagged with:

-

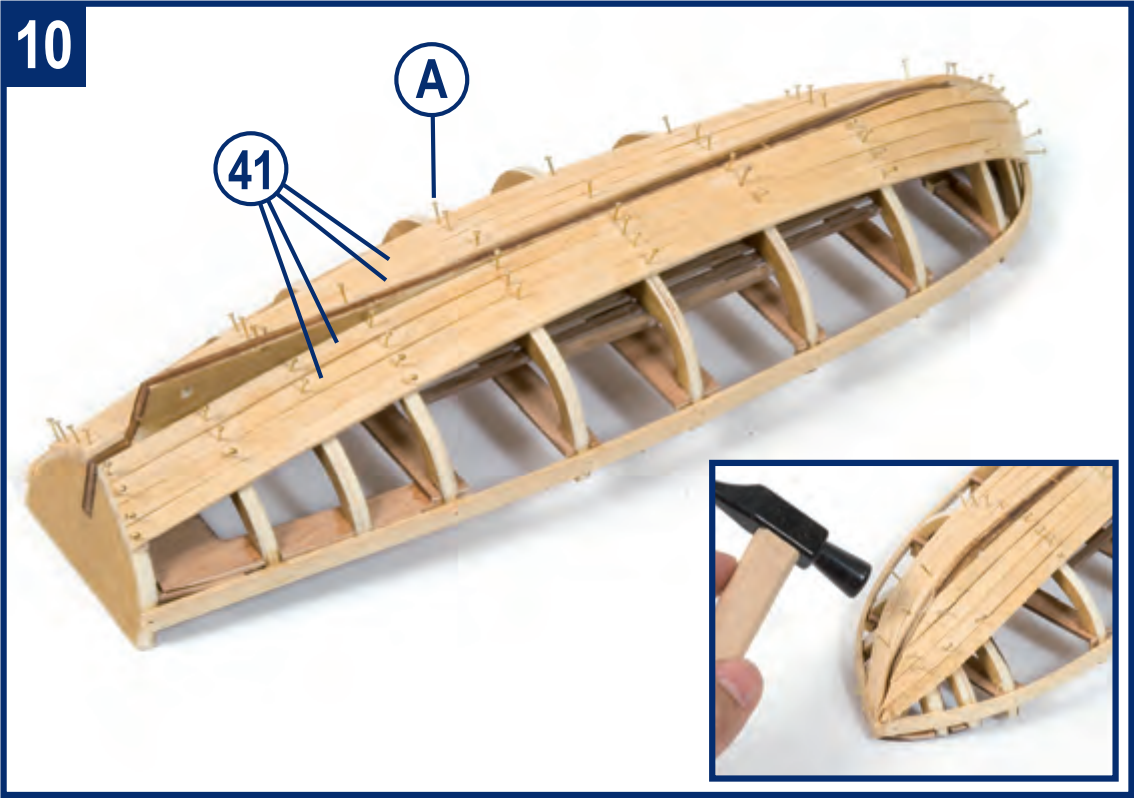

Alfredo, I'm sorry I missed your previous post, I might have saved you some trouble. On a Launch the garboard plank does not follow the keel at the stern, it goes down to the transom instead. Occre does show this in step 10. Occre later cover the 'deadwood' in planking.

- 19 replies

-

- Bounty Boat

- OcCre

-

(and 2 more)

Tagged with:

-

No clear answer here either. Where they may have been carried is a little easier, on deck along the rail (either side) or over the main hatch or dangling from stern davits or dangling over the side or towed astern. ZAZ6347 shows vague outlines of two boats on Vigilant (1821). THIS painting shows at least one boat on Vigilants deck. And THIS painting shows Vigilant with a boat dangling over the side. Missed one, 1783: Cutters employed against smugglers to have 20ft boat instead of 18ft boat for the duration of the peace. Given 200 Ton cutters should have a 22ft gig on a 75ft deck I would expect that Cheerful with a 63ft deck may have had an 18ft boat if they were lucky. Todd, I suggest you cut out some paper boat outlines and see what fits.

- 11 replies

-

- cutter

- ships boats

-

(and 1 more)

Tagged with:

-

Sorry, it's just a simple way of showing if the frames are square to the keel. Using this method, because of the distortion caused by the camera lens, 8 and 9 can only be checked where they meet the keel whereas 10 is close enough to being square to the camera to be checked for it's full height. The second photo is more obvious, the green lines all slope down from left to right but the purple line slopes down from right to left, clearly different. The distortion is why we can't be certain what is and isn't square from your photos, we can give opinions but you will have to check yourself. If you don't have a carpenters square to check with (or yours is too big), these days lots of paper has very square corners. Photocopy paper, business cards, appointment reminders from your doctor or dentist etc. Probably even birthday or greeting cards.

-

From the photos it looks like part Nos 2 and 10 are not square fore and aft and 10 is also not square port/starboard. The rest I can't tell from the photos, you will have to check them. The keel needs to be fixed, 10 needs to be fixed, 2 should be fixed. All frames appear to be in the right positions. Fairing should fix any minor out of square issues.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.