-

Posts

205 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wacom

-

Thanks for the kind comments Chuck, the lantern is temporarily mounted at present, I like to make delicate items like this removable so they can be added closer to the finish of the build. Thanks for the advice re the rudder opening, it is my intention to open this up before planking the deck to make it easier to clean the debris out.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Possibly the American cousin to my Kiwi one🤔🤔 Thanks for the comment and thumbs up.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

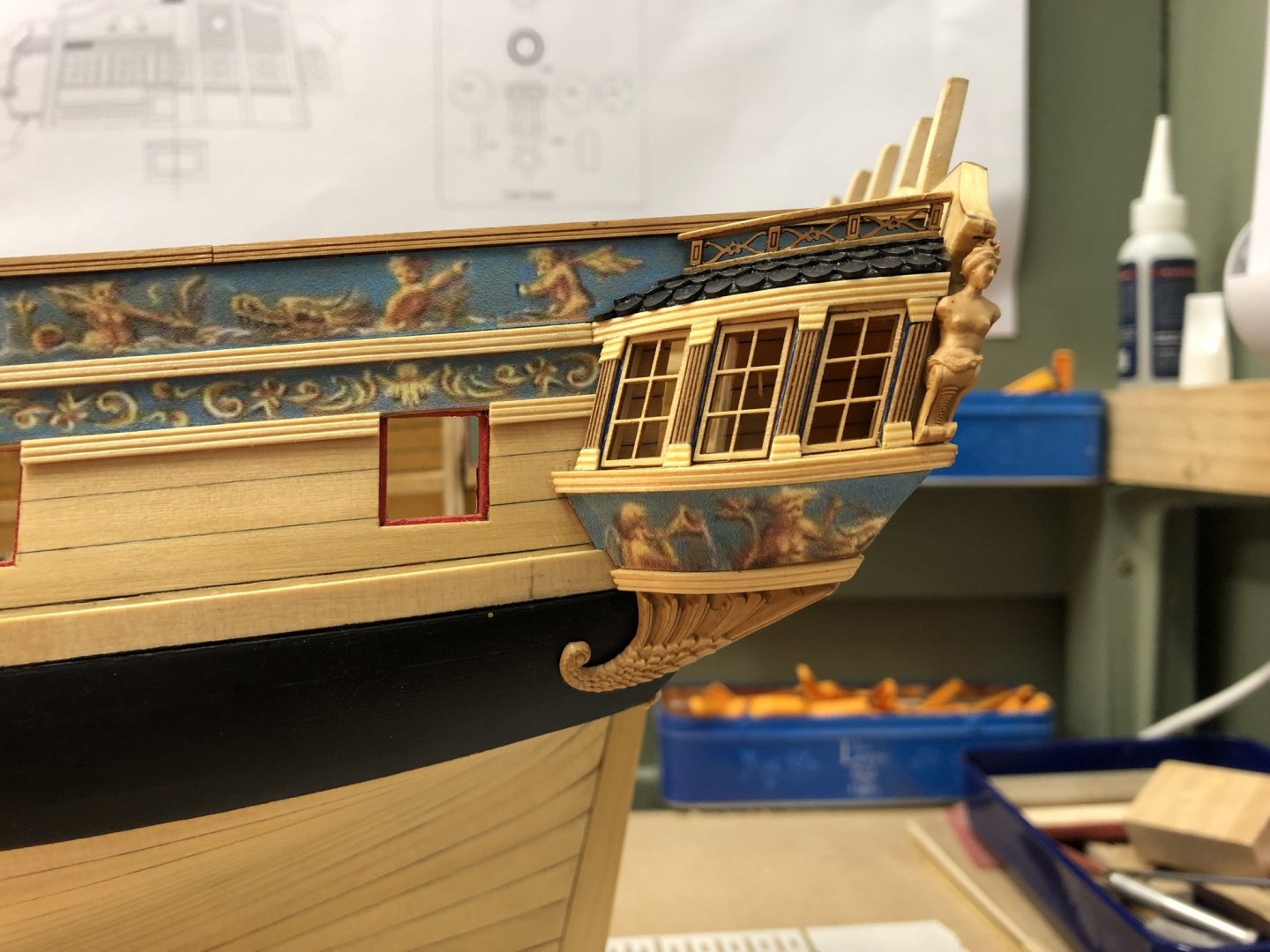

Nearing the finish of chapter three. The eagle eyed will notice the little lady Missing from the left column. In one of my senior moments I broke her while removing the casting from the sprue, as luck would have it the gremlin that lives in my workshop took the opportunity to hide the missing piece, never to be seen again. Thankfully Chuck is generously supplying a replacement, but with shipping the way it is it could be sometime yet. My thanks must also go to Mathias (Beckman) in allowing me to use the design for the frieze on the upper counter, thank you. Taking a leaf from Jim’s Book I spent some time making a stand from bits lying around the workshop. The base was bought by my wife around 25 years ago as a key rack, made from Rimu a native New Zealand timber, it only required polishing with oil to finish. By mounting the ship on the stand its possible to see the sweet lines of the hull to full advantage.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

1/16" Square Brass Stock - Where to find?

Wacom replied to Walker_Wheeler's topic in Metal Work, Soldering and Metal Fittings

https://www.wirejewelry.com/square-yellow-brass-wire-1.html -

Hi Chuck, good to see you back 0n Winnie again. You mention the curve on the forward planking, will this be curved the same way we did the hull planking or will they be laser cut?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well done Jim, looks good.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great job on the moulding, the colour blends well with the hull timber, you will soon be looking for chapter four😎

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi Kim, Thanks for this information, I have tried DMC Babylo and believe it will do the job, the world of thread Is a real minefield. Here in NZ, Babylo is offered in three sizes with many different colours, but speaking to the supplier I am told that DMC havent made the smaller size in a long time, plus many of the colours shown as available arn’t. Go figure🥴

-

The carvings certainly add pizzaz to Winnie. I have a piece of sprue treated with the gel as you Rusty, then coated with WOP. Did this a few weeks ago and it still looks ok to me. Don’t know if its necessary and will wait before deciding to coat the rest. Very interested in what others think.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Any opinions on this Proxxon DS 460

Wacom replied to md1400cs's topic in Modeling tools and Workshop Equipment

I have this saw and find it easy to work with. Only dislike would be the dust blower, not very effective at all. Blade changing is very easy and so far have found the two speeds more than enough. That seems to be a good price too.👍 -

Your usual high standard Rusty😎

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

The planking looks good to me👍, ask yourself, will it be any better if you do it again from the start? If the answer is yes then do it, if the answer is not sure then carry on. I think Longridge wrote along the lines of do the best you can and move on, otherwise you run the danger of never doing anything. You are very right, we are our own worst critics.🥴

-

Thanks for the reactions. Rusty I used this to plank the bottom of the hull and added an extra piece to allow it to be attached to the bench. The hull then just locks into place and is quite solid.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If you ever wondered how someone with a creaky back and even creakier neck gets to work on those difficult bits of Winnie look no further. I find that jigs to hold this large hull are a must, this one was developed to allow me to add all that fine decorative details on the stern.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks guys for the comments and reactions.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

+1, combined with the colour of the wood its turning out to be a magnificent model.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Slow progress to date, the port side quarter gallery and frieze installed. The mouldings are not as per Chuck, the making of the scrapers for them had me beat after many, many attempts so I decided to go with the A.L. scrapers I had As Mr Sinatra said "I did it my way" whilst trying to keep the ship in the spirit of this fine prototype. The roof and lady in the corner are only sitting there as are the windows, I consider them too delicate to permanently attach at this stage. And so onto the starboard side.

- 137 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Unimat or Sherline... your feedback, please...

Wacom replied to Jorge Hedges's topic in Modeling tools and Workshop Equipment

+1 on the Proxxon, until recently I owned and used a Myford super 7 lathe considered by many to be one of the finest lathes made for model engineering. When I began building the Winchelsea I sold the Myford due to space considerations and replaced it with the Proxxon 250. I am very impressed with the capabilities of this small lathe but the number one plus for me is that I can use it sitting down. The machine is a pleasure to use. -

I see your “supervisor” is taking a keen interest.😁

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for that Chuck, now I can stop beating my head against the wall looking for it.🤔

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.