-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by raven62

-

-

Hi there,

today I can make the first real test on a lake with the crane. 90% works well. Just the steering needs an improvement.

After two hours of testing and some fine adjustment I'm very happy with the crane and his behavior.

As a result of that recognition and the great fun I had, I will invest in a professional rudderpropeller steering hardware.

The mechanical indicators are not good enough for my eyes if the crane is too far away.

And some impressions

- mtaylor, GrandpaPhil and dvm27

-

3

3

-

- GrandpaPhil and mtaylor

-

2

2

-

Hi

hope you can see my post in another forum ( and it is allowed to post a link)

Powder coating at home part one

-

Hi there,

it's been a while since the last update.

Actual state is:

It swims, all rudder propellers and the crane are working fine. The hull is paintend , some Scale-Details are added (some are still on the todo-list 🤗 )

and so it's time to put it in the Water.

Ok. A very small lake 😂 , but really important for me. Steering with the rudder propellers is extremly unfamiliar for me.

To get it on a bigger Lake I've build a combined display and transport utility.

Todays work was to build a technical looking load , maybe a large silo

I think, a first testdrive is coming soon, but I'm waiting for lead to made a propper trimming.

- GrandpaPhil, KeithAug, mtaylor and 2 others

-

5

5

-

-

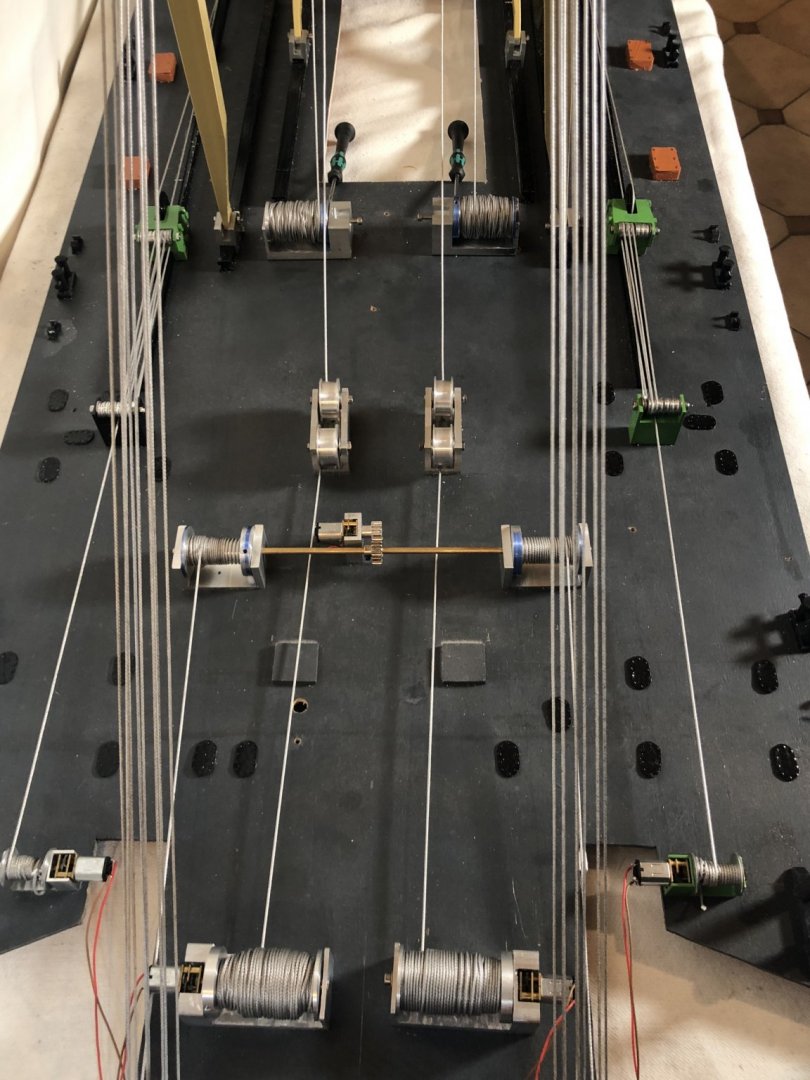

After only three months the mechanical Parts for the crane are finished.

Eight winches ✅

Five booms ✅

Several hundreds of meters ropes ✅

Six self casted lead hooks ✅

About 130 pulleys ✅Some Impressions

The motors for the last winches are on their way, so i've blocked them in an unusually way.

- mtaylor, GrandpaPhil, KeithAug and 2 others

-

5

5

-

-

- KeithAug, mtaylor and GrandpaPhil

-

3

3

-

-

21 hours ago, wefalck said:

Such small chain would be difficult to find ... I found that chain, at least in small scales, can be reasonably well simulated by twisting two wires together, but not too tightly. Two lengths of such wire are then again twisted together against the original direction. This will looks reasonably convincing like a somewhat twisted chain.

Thanks again. 👍

Looking great, easy to make and not so much work to install.

A little setup-test

- BenF89, KeithAug, GrandpaPhil and 1 other

-

4

4

-

-

- mtaylor, KeithAug and GrandpaPhil

-

3

3

-

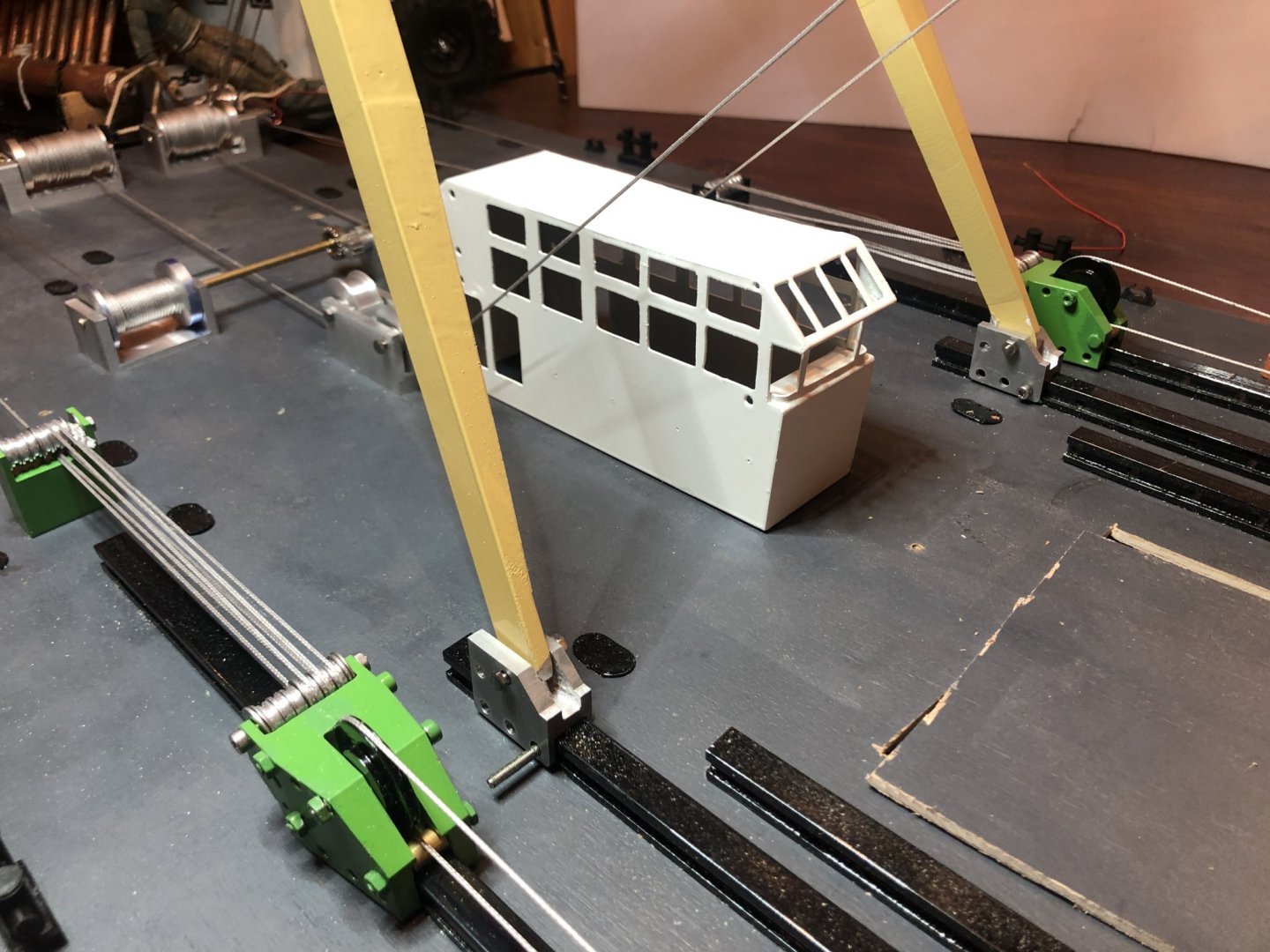

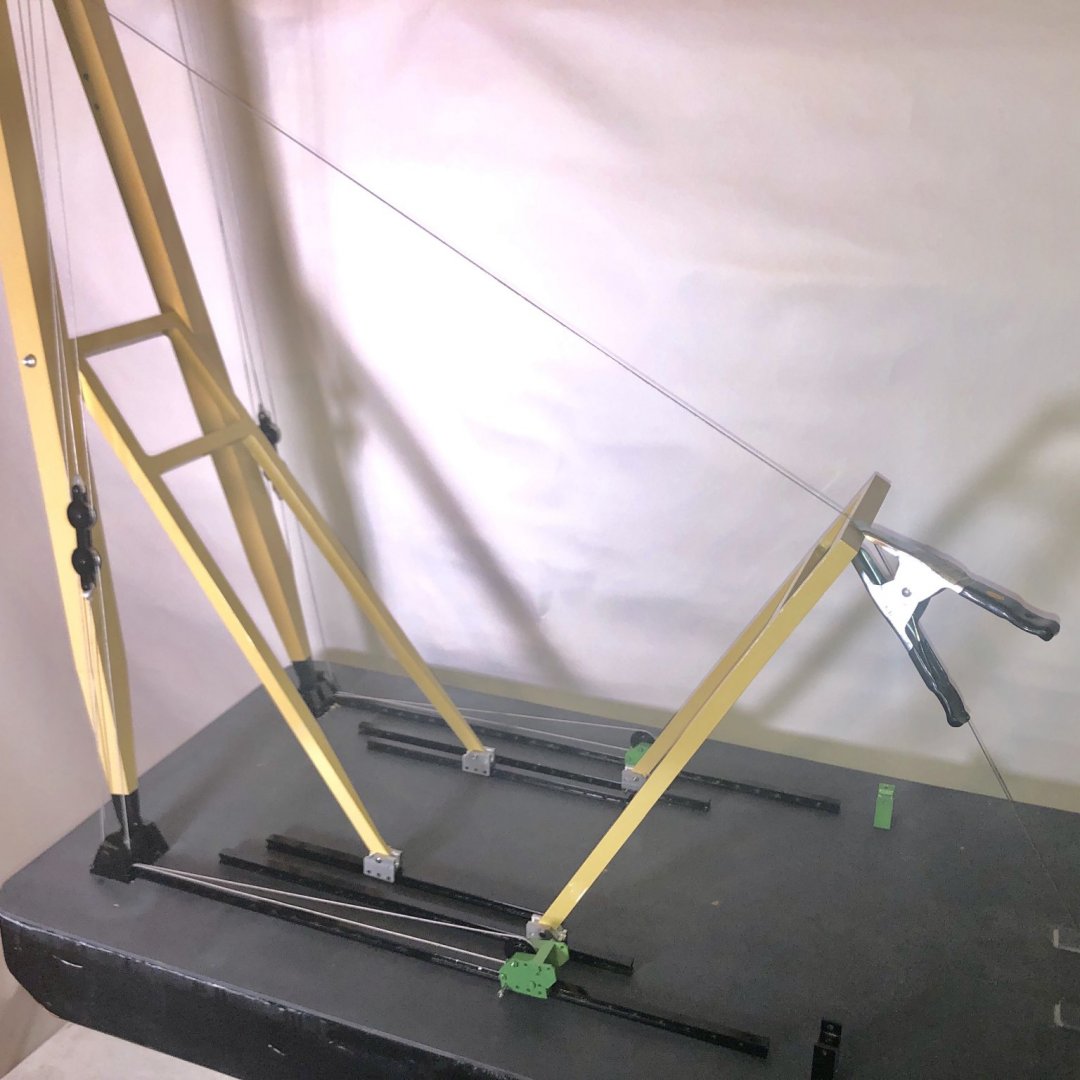

The booms are moving.

Slow but steady. Here you can see a short clip -> Instagram <-

Slow but steady. Here you can see a short clip -> Instagram <-

Thereby I'm now sure that the crane will be work and beside the technical aspects, the optical and scale parts will get more room in my work.

For example, today I've print, paint and mount the 30 manhole-covers.

Additionally I've made the eight Lead castings for the Hooks.

Casting was new for me but works very well and now the eigth Hooks are waiting for they blocks.

Before painting I've tested the strength of the hooks. Same setup as planned.

I think, it's enough.

- KeithAug, Roger Pellett, mtaylor and 1 other

-

4

4

-

- mtaylor, GrandpaPhil, KeithAug and 1 other

-

4

4

-

- GrandpaPhil and mtaylor

-

2

2

-

- mtaylor, GrandpaPhil and KeithAug

-

3

3

-

- mtaylor, GrandpaPhil and KeithAug

-

3

3

-

Meanwhile, I acquire a taste for my resin printer and it seems, that I'm now able to make reproduceable result. Thereby I dare to make some more complex parts like the counter weight of the topboom.

Painted and mounted

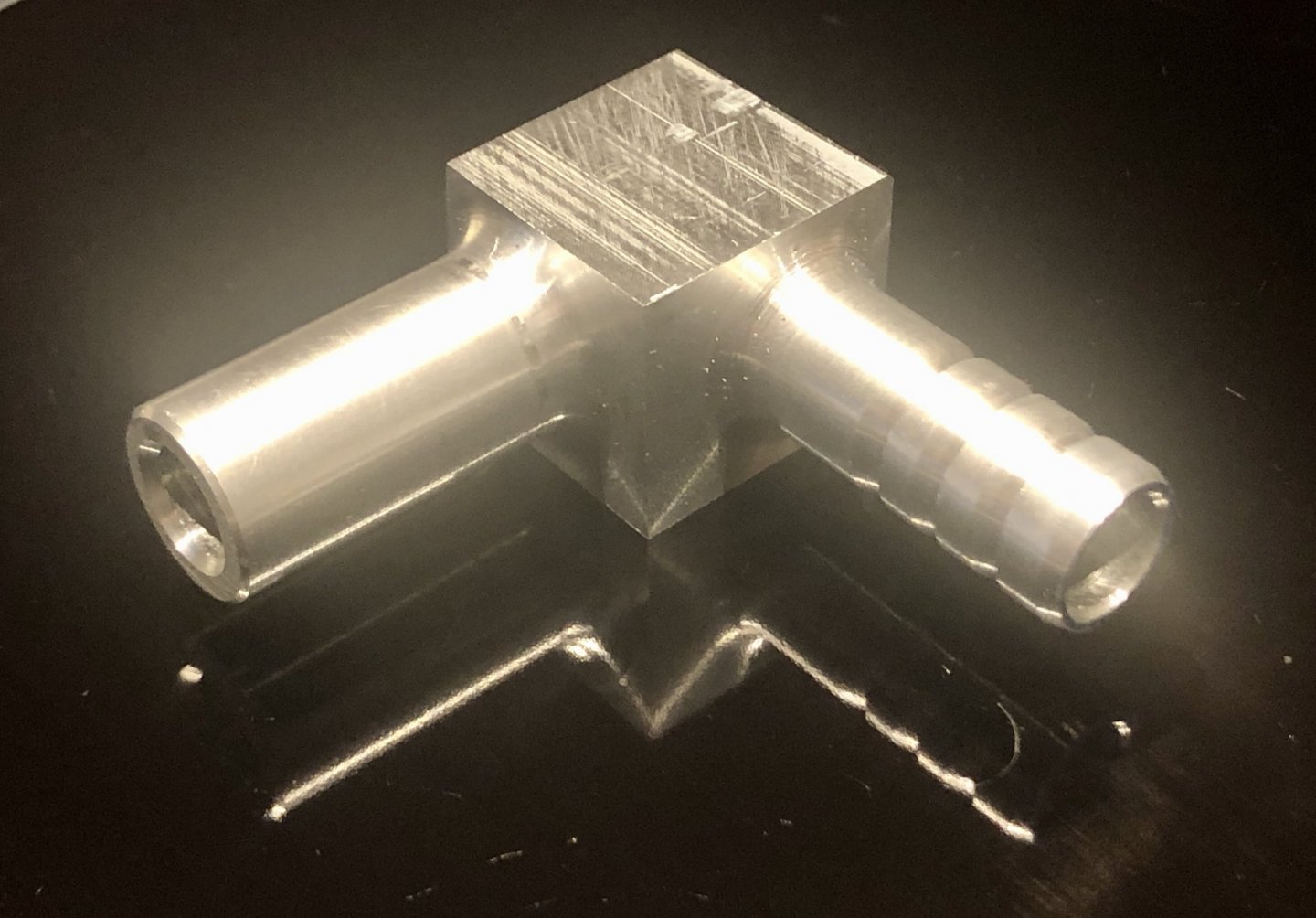

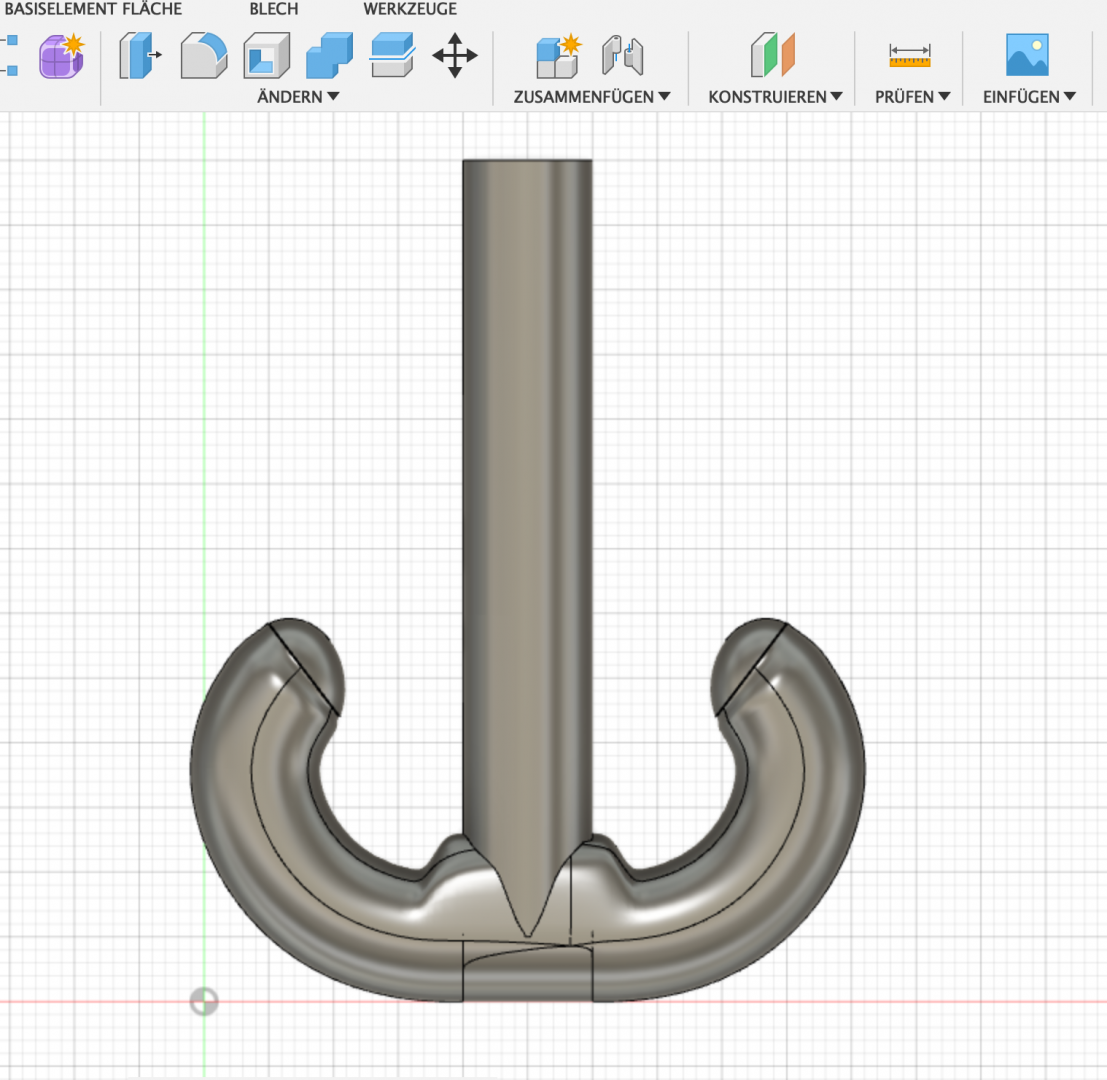

Also,I've made a good progress in handling Fusion 360 and made a first positive form for the hooks.

I'll need heavy hooks on the cables to tighten them. So the hooks will be poured from lead.

- GrandpaPhil, wefalck and mtaylor

-

3

3

-

-

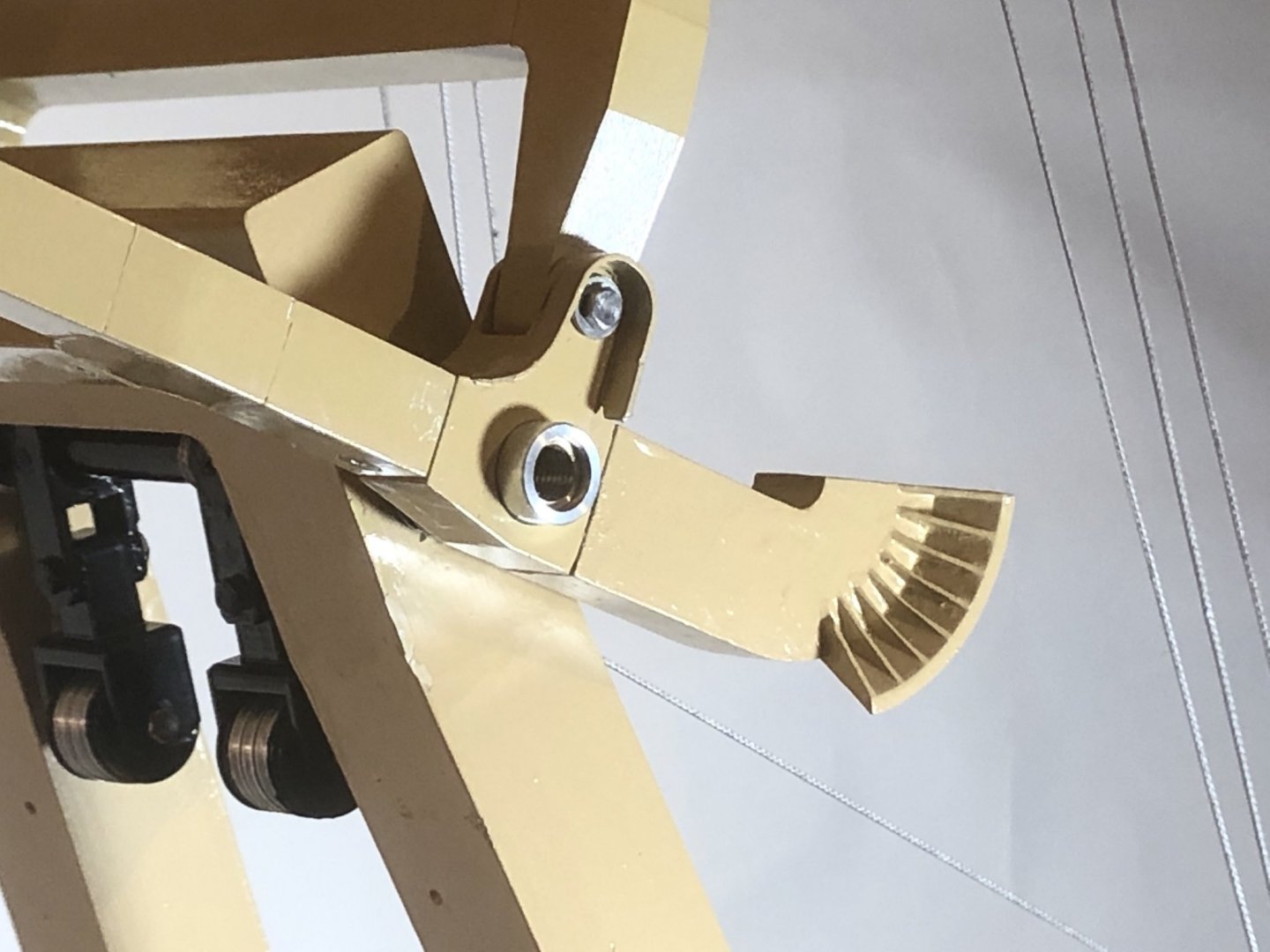

I'm sure that the mechanics will work and the leaky Hull is waterproofed too. So I've started with the embellishment of the parts I've done so far.

I can't lacquer very well so I've learned Powder Coating my metallic parts. It smells very vicious and you have to use a mask, but it's much less work for preparations.

A big limit for the size of the parts is the oven. In this case I must divide the mainboom, but fortunately the topboom fits exact

simultaneously my new resin printer works on the first scale parts....- GrandpaPhil and mtaylor

-

2

2

-

How do fix the motor? It‘s very strong for his size.

-

Today i've reached a major milestone in my project.

This little geared motor ( an euro-cent for comparison) can lift the topboom easily with 7.4V and 2 Kg weigth on the peak

The sizes of the machine are so pretty, that i'm able to put really scale housings on it.

Now I know, that the rest of the mechanics will work too. So I can start with sanding, filling, powder coating and so on.

Electric lifting the topboom on Instagram

- GrandpaPhil, JeffT and mtaylor

-

3

3

-

First part of rigging is done. Half way of ropes and pulleys to move the topboom. I'm glad to see, that i've build the correct geometric and rope guides to fold the crane

A short trip along the ropes with all its pulleys etc.

-

Enak by raven62 - FINISHED - Scale 1:50 - RADIO - floating crane

in - Build logs for subjects built 1901 - Present Day

Posted

Four Weeks later the Deck and his Details and Weathering has finished.

Thanks for watching.

Bye.