-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by raven62

-

-

On 10/30/2019 at 8:39 PM, lmagna said:

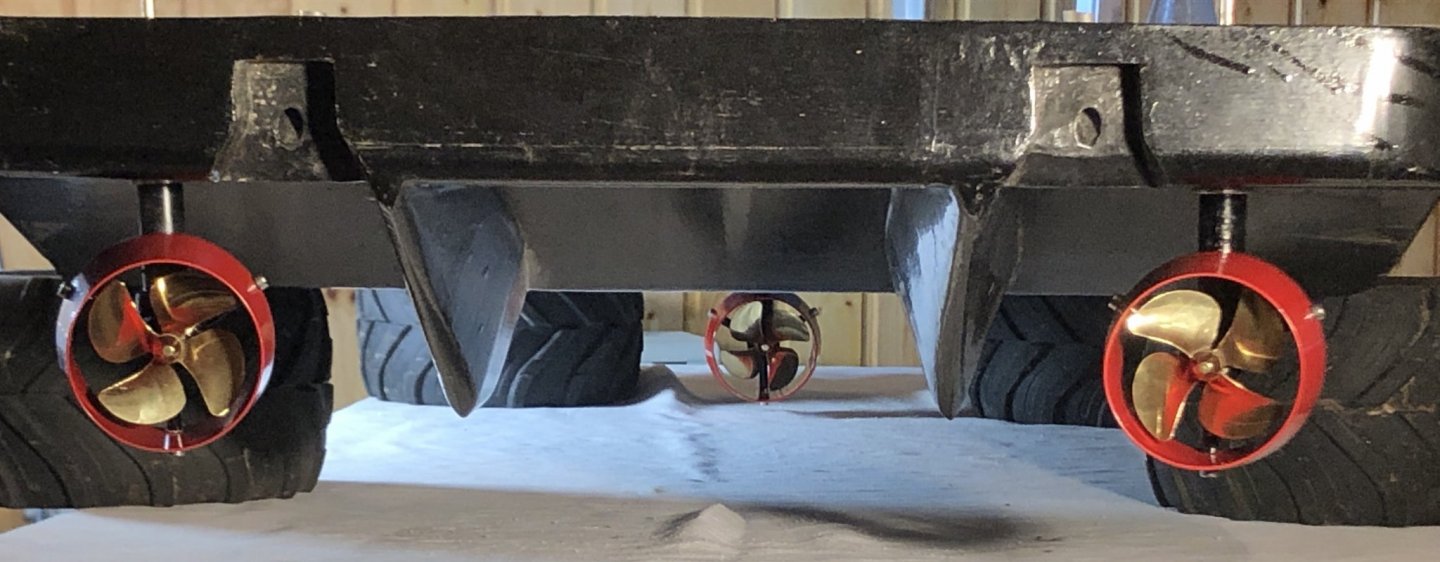

I find it interesting that your crane has three Kort nozzle props that while obviously set up to allow for station keeping, look plenty large enough and powerful enough to provide transit power without the need of a tug. Yet the barge is clearly under tow in the picture.

Great work so far of a very unusual subject.

Hi Lou,

thank you.

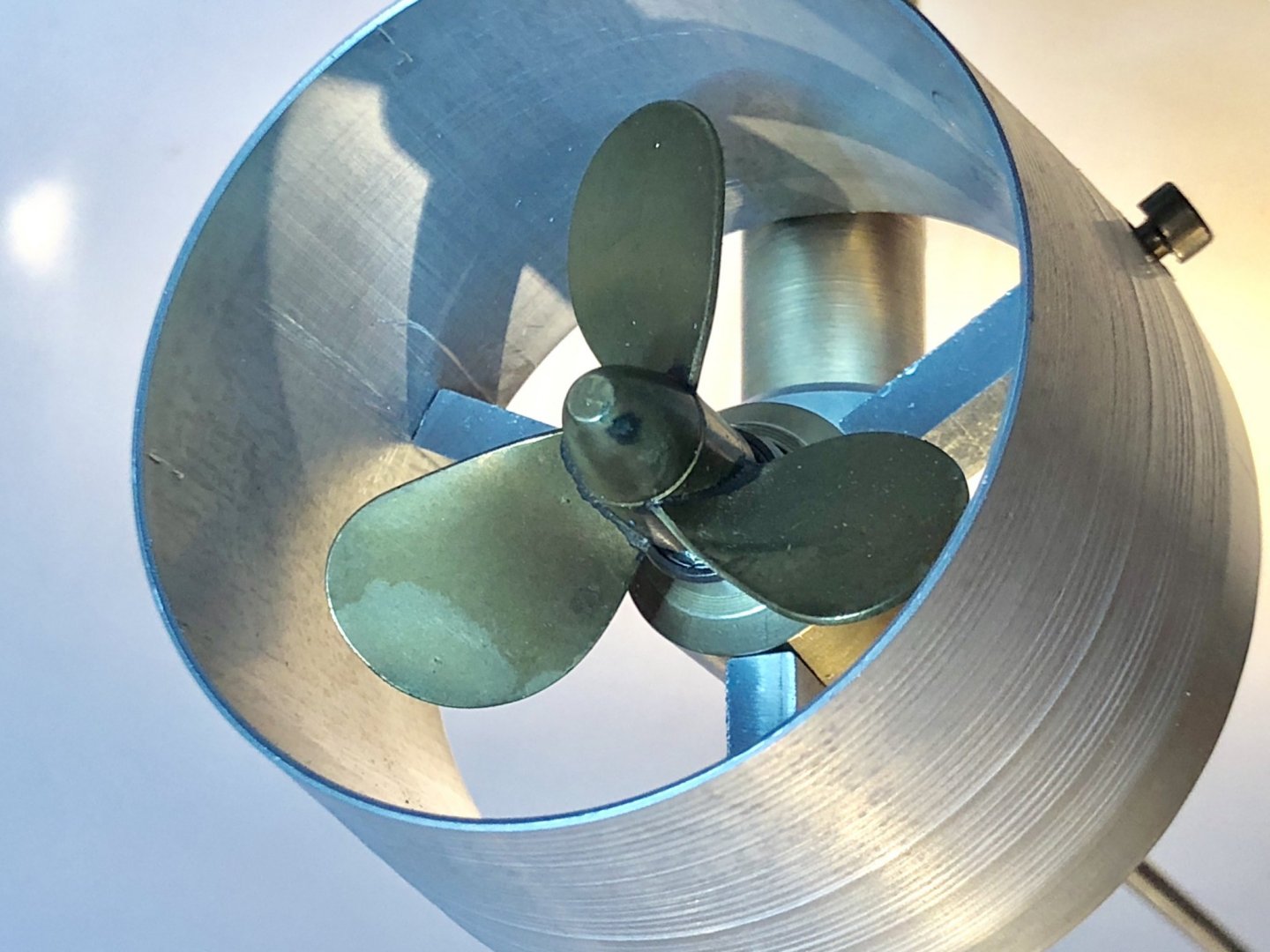

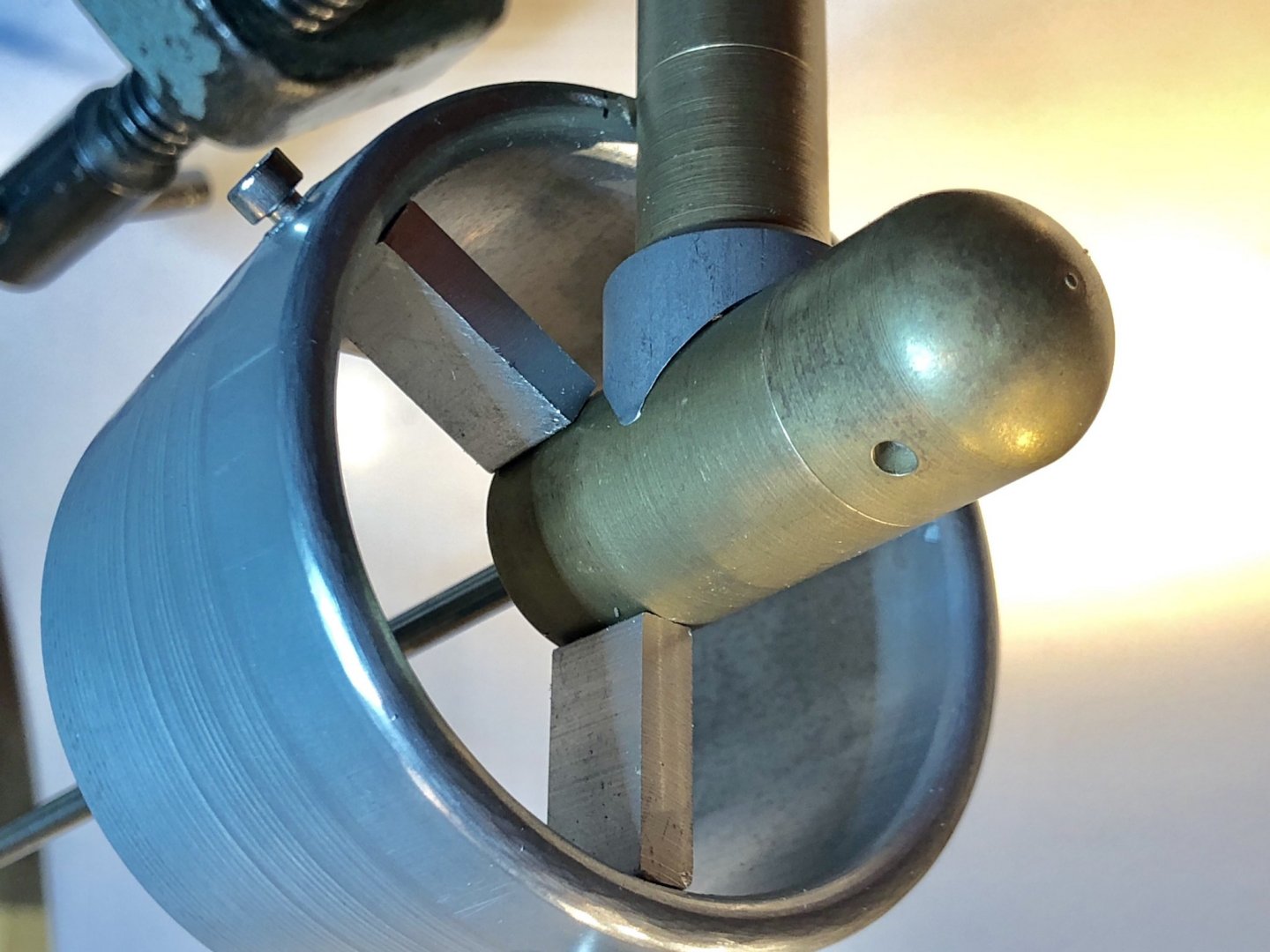

My old Plan from the 90's shows just two nozzles. But the actual technical sheet from the shipping company tells three. So I decide to make three. It will be easier to drive for me.

-

Thanks,

no. The emphasis is on functionality only at the first stage of the build. Because I need fix points for all the scale things on deck. For example: the six rails on deck depend on the exakt sizes of the booms. The positions of the winches depends to the rails. And so on. I'm not really perfect in matching all scale size, so they will varying a bit their location on deck. So the little Details, wich bring life to a modelship, will come when the crane is mechanical working.

I can't wait to solder all the ladders for the booms ( roundabout three meters with platforms etc) 😎

I see, i've forgot to post a link to the original. Here it is: The original Enak

-

-

- mtaylor, wefalck and GrandpaPhil

-

3

3

-

- paulsutcliffe, hexnut, GrandpaPhil and 1 other

-

4

4

-

- lmagna, GrandpaPhil, hexnut and 1 other

-

4

4

-

- hexnut, GrandpaPhil and mtaylor

-

3

3

-

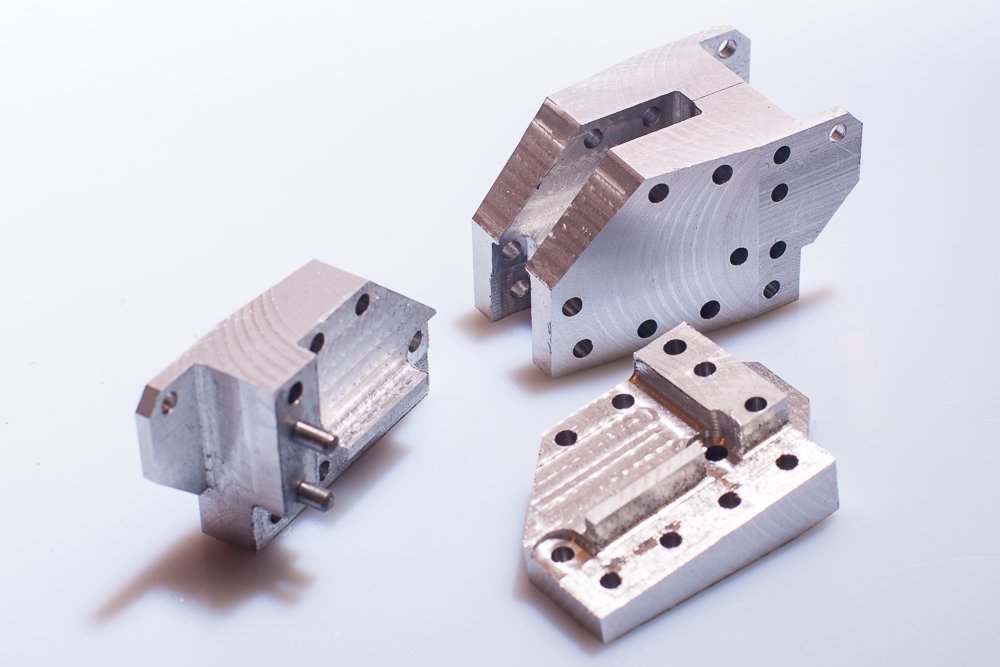

All Parts done, first Parts are powder coated, just waiting on ordered shaft seals before assembling.

An Overview.

(bigger four blade brass propellers are ordered too)

- GrandpaPhil, el cid, mtaylor and 1 other

-

4

4

-

-

- GrandpaPhil, hexnut, Canute and 1 other

-

4

4

-

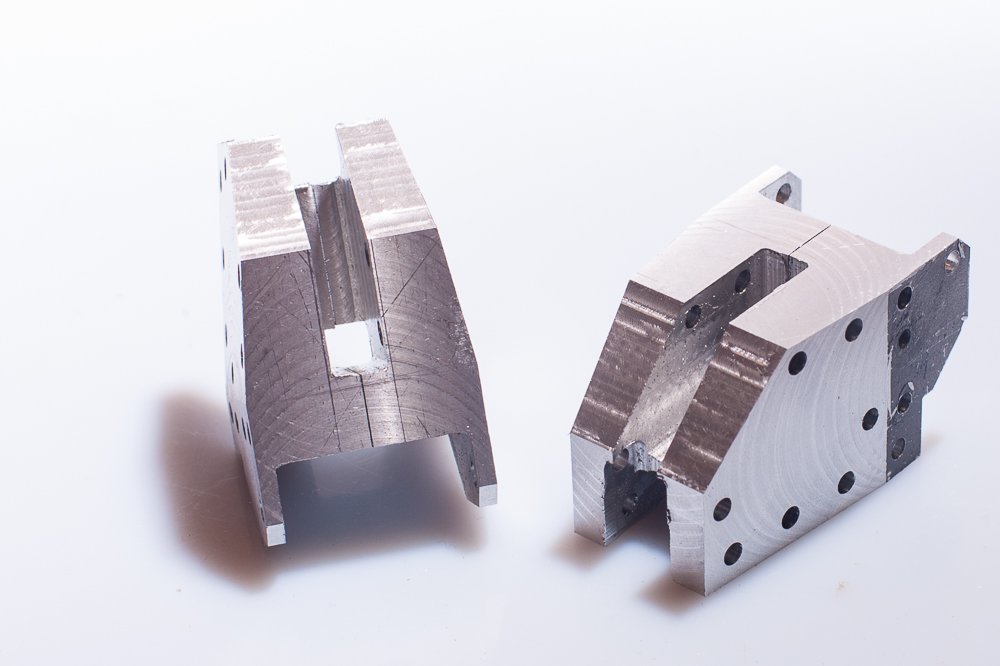

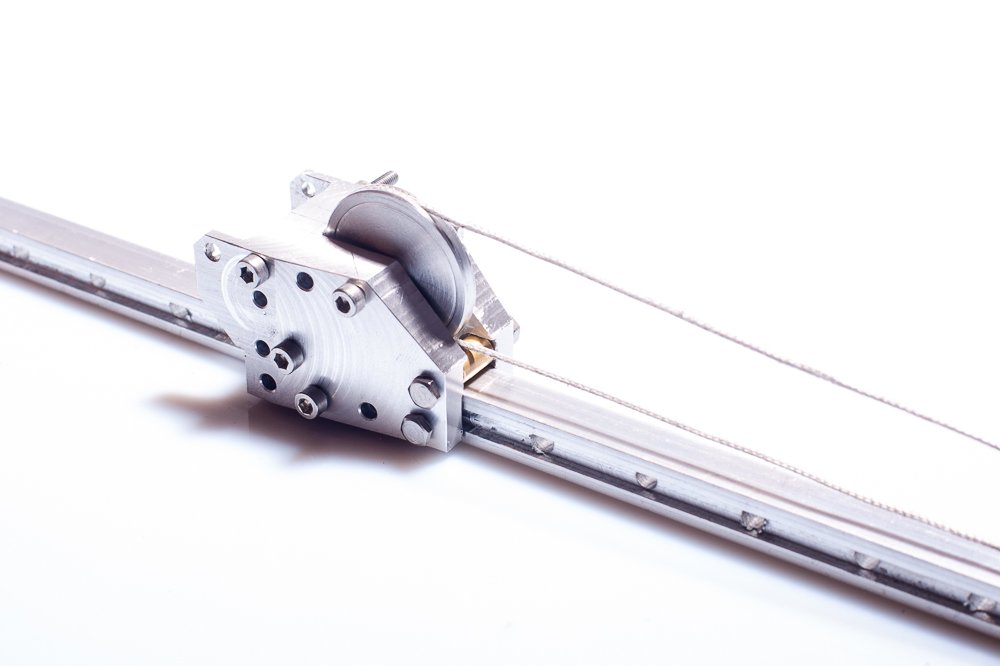

Hi,

today a big Step for the rudder propeller is done. The mechanic ist on his way, but still some todos. The kort-nozzles are roughed up and actually in a tumbler to get a proper surface finish. (My lathe is to weak to get a proper surface on a slope

)

)

You can see a short making of the kort-nozzles here Instagram

Some impressions:

- GrandpaPhil, hexnut, mtaylor and 1 other

-

4

4

-

On 10/6/2019 at 5:03 AM, Roger Pellett said:

Metal working unfortunately takes a backseat to woodworking here. Please expand on your techniques, and thank you!!

Roger

I will. But unfortunately I must recognize that the plans are not really accurate. Same Item have on three sheets three different sizes 😪. Thereby I'm forced to redraw all important things in Fusion 360 to get proper sizes and angles.

-

- Canute, paulsutcliffe, GrandpaPhil and 3 others

-

6

6

-

Hi there,

planning, thinking, planning...... Actually I had enough form planning and decide to begin the work with important thing wich will needed, however the plan ends.

The crane need over 100 pulleys, often 3mm width with different diameters. So it is woth to invest in a selfmade formtool for the lathe.

From a piece of Silversteel I get with the Mill, several Files and at the end with a hand-lapper the folloing Shape.

Simply hardened

It makes now these nice pulleys

Not really perfect on the right side, but I'll have plenty of pieces to do and learn the right adjustments.

Probably the last pulley will be perfect 🙂

- Canute, GrandpaPhil, mtaylor and 2 others

-

5

5

-

- BLACK VIKING, mtaylor, coxswain and 2 others

-

5

5

-

Hi there,

after a short break of 26 years I've restart the build of the floating crane Enak. Based on plans I've bought in 1993 the Build begans with the hull.

The beginning with plywood and balsa wood was easy and the hull became quickly swimable.

But after this first success I have to realise that I'm not able to build the mechanics for the crane. No skills and no tools are on board.

But actually I've get the needed skills in machining metal (I'm an autodidactic amateur, not a pro) I give it another try.

The actual state is

the hull is still water proof

three graupner rudder propellers mounted. I'm very excited if the will work or must replace them.

Electronics are not uptodate and will replaced.

Motors eventually too. May be with slow outrunners to save space.

Next steps will be saturate the wood with liquid epoxy to avoid swelling and build a slip.

The hull will be the single peace of wood. The deck and the cranes structure will be complete in metal.

regards

Ralf

-

Hi there,

since 2011 I'm in my second life as a modeler, mostly building rc offroad cars in 1/10 scale. But my first life was ship-based. And after a 26 years long rest, I'm on the water again.

So I'm here, improve my English and will start a build log about a rc floating crane soon.

Enak by raven62 - FINISHED - Scale 1:50 - RADIO - floating crane

in - Build logs for subjects built 1901 - Present Day

Posted

Topboom is mechanical done. Overall heigth is 175 cm (69 inches) and my cellar isn't high enough. So this unusual perspective

Ths is the position if the crane ist towed long distances or bad weather conditions

I'll try to make the model tough enough to fold and unfold him with his own winches like the 1/1