-

Posts

3,270 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by realworkingsailor

-

Getting near the end. Final assembly consisted of adding the canopy and propellor. The fit for the latter is quite snug and shouldn't require glueing. All the better to ensure the propellor spins freely. The canopy was posed in the open position, but prior to glueing I dry brushed some silver/aluminium along the top edges of the cockpit, to represent chipped/worn paint in the area where the canopy (and clothing, and hands) would rub. It's hard to see at this scale, but at the right angle, there's a satisfying glint of shiny "metal". I've also lightly dry brushed some silver on the leading edge of the prop, I may have to add a touch more. I have since begun weathering using a variety of pastels from Pan Pastel. They're easy enough to use, and if you have a clean applicator, you can "erase" any mistakes. So far I've added soot and other streaks around various likely areas such as the exhaust and radiator outlets, as well as around the gun bays and ejector ports (although one port is hidden in a black stripe). I have a little bit left to do, I'm planning to add a decent bit of "fade" on the wings' leading edges to simulate the effects of dust and grit (and greasy hands and boots). My goal is to make this plane look like it's been working hard, but not too crazy grimy, (like the plane in the photo I posted yesterday). This is, after all, the Wing Commander's personal plane. One does have to keep up some kind of an appearance. Andy

-

This propaganda photo was taken in Holland later in the war. Things didn’t get any better: Looks like the seals on the landing gear door hydraulics are leaking. I’d swear that is rust on the wing lower leading edge, but it could just be the mud on the upper surface dripping down. There appears to be brake shoe residue on the inside of the starboard wheel bay door, and the lettering on the fuselage side looks yellowed, and thoroughly grime covered. Paint chipping and wearing off all over… Andy

-

As promised, a more thorough update. The replacement landing gear legs arrived unbroken and properly moulded (no short shots), and very well packaged (Thanks Airfix!). I quickly had them cleaned up and painted. Following which all of the underbody components could be added The landing gear is a little spindlier than on other models as there are no bracing struts, and, coupled with those massive wheels and tires, care must be taken not to inadvertently snap anything. I would have liked if the landing gear doors actually glued to the underside of the wing (it would have added a modicum of support), but by design there's a tiny sliver of a gap, so unfortunately not. All that remains to be done is to add a sealer coat of Dullcote and add the propellor and canopy (open, this time, to see the cockpit). The end is drawing near on this build, but I am planning to add a decent amount of weathering. Even though this is the Wing Commander's airplane, I'm sure in the hot and hectic summer of 1944, cleanliness took somewhat of a backseat to the operational requirements of the moment. Some photo's I've seen of regular squadron assigned airplanes look like they've been royally run through the wringer. Andy

-

Thanks, everyone, for all your patience! I received a small package in the mail today, and I’m pleased to report that my replacement parts have arrived safely!! I can now resume my build and see it to completion! Overall I am pleased with Airfix’s response. I would suggest that anyone else with kit issues shouldn’t hesitate to contact them, just be patient. On with the build!! 😁 Andy

-

English fleets and small vessels in the early 1700s

realworkingsailor replied to Dan DSilva's topic in Nautical/Naval History

If you can find a copy, “Sloop of War, 1650-1763” by Ian McLaughlan is a great resource. Andy -

If you’re looking for random opinions, (and mine can get very random if needed 🤪), I’d say leave it open, bombs or not. You could display them beside the model on a bomb trolley or something, if you felt. For my Wellington, I’m very happy I left the bomb bay open and would have done so even if I didn’t get the aftermarket PE. Appropriate or not, showing off some of the “guts” can make for a nice interesting model. Andy

-

As an alternative to rubber, have you considered using something else? Have a look through Michael Mott’s pilot cutter build. He made some nice scale seating using pigskin: Even some kind of appropriate coloured simulated leather might work, stretched over a wooden mould of your motorcycle seat. Andy

-

Thanks for all the likes and kind comments! One small update for today, I have finished painting the landing gear doors. Once again, I strayed away from using the supplied decals on the main doors and painted them on as I did for the fuselage stripes. Apparently the ground crew of the kit supplied scheme made a small error when they applied the invasion stripes (see if you can guess what it is 🤔): I've also installed the engine exhaust pipes. They were painted with Humbrol gunmetal followed by a wash of Floquil rust to give a nice burnt metal look. This gets me just about as far as I can go. My usual next step is to paint and attach the landing gear, followed by the last little parts like the arial, pitot tube, etc (any items that would be at risk of damage should an accidental belly landing occur). Until my replacement parts arrive (which I'm really not expecting until the end of this week at the very earliest), I will have to be content to sit and wait. Oh Well.... Andy

-

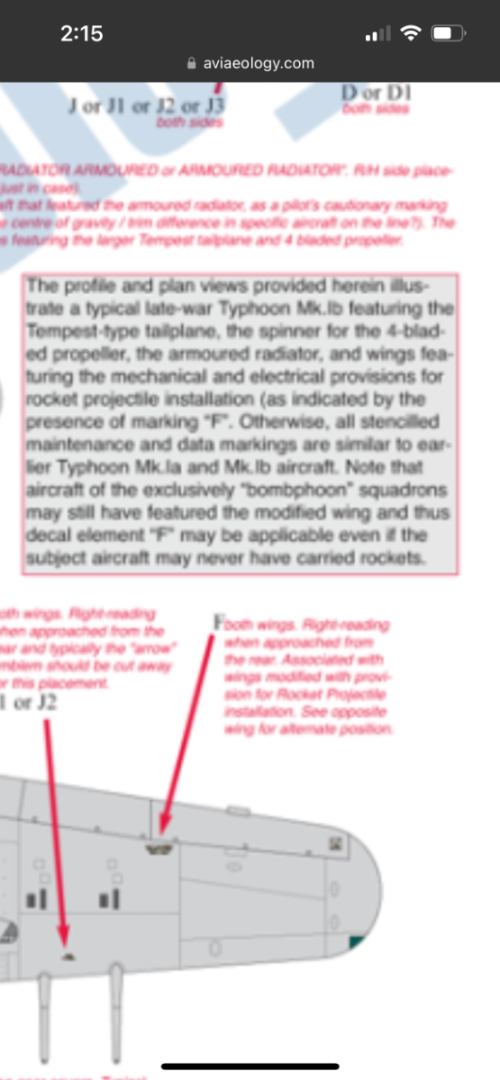

I’ve been doing as much digging on my own as I can, the only real reference that I can find is from a decal company called aviaeology. In their aircraft stencil set for the Typhoon, they are ambivalent on the status of that particular stencil. From what they say, definitely present in rocket Typhoons, maybe/maybe not for bombphoons… In all honesty it’s enough ambiguity for me to leave things as they are, but my curiosity is still piqued… Andy

-

Yes and no. Designed at the outset as a pure fighter (the prototype Typhoon was equipped with 12 .303 brownings), there were performance issues that ultimately made it lacklustre in that role. In the fighter-bomber role, while the Typhoon could carry either bombs or rockets (and were initially designed to be interchangeable), the skills needed to effectively deliver each type of munition were different. The British found it was more efficient and effective for each squadron or wing to specialize in one or the other. All of 143 wing (RCAF) airplanes were bomb carriers from the outset of their transfer to Britain. So I think my question still stands, would that stencil have still been applied to an airplane that, while capable, would not, foreseeably, have been equipped with rockets? I doubt the factories would have applied anything. I think any fitting out would have been done at the various maintenance units, in preparation for whatever frontline unit the aircraft was destined for. Andy

-

Thanks again everyone! The lettering is tentatively finished. As I did with my Hurricane, I laser printed the registration number on blank decal paper. As long as I keep choosing to model airplanes with black painted numbers, I can do this as many times as I like. The font is about as close as I could get and the "1" in 518 is actually a lower case "L", but overall I'm happy. The only spot where I have questions is the stencil located inboard of the underside roundels. It reads "Check Firing Contacts Before Connecting Leads". After I had applied them and figured out what they said, it got me wondering if these stencils are specific to rocket firing Typhoons or were they applied to all Typhoons, regardless. If anyone has information, please let me know. I haven't sealed the decals yet, so removal is still easy. Andy

-

Possibly painted while in the dock. Surprisingly, with the right amount of labour a large ship can be fully sandblasted and painted in a remarkably short period of time (about a week). If the ship was in any way waterborne at the time, it shouldn’t have toppled like that, unless something serious was done to alter the CG of the ship. Most, if not all, commercial dry docks don’t use the old methods where there’s only a single row of blocks under the keel and shoring beams to hold the ship up. Although there are still more blocks down the centreline, there are typically one or more rows of blocks on each side, depending on how wide the ship is. Submarines are, of course, the exception as they usually don’t have flat bottoms…. 😁 Andy

-

I doubt the ship was dry docked for that amount of time. That would cost a fortune, and cost the commercial shipyard a lot of lost business having a dock occupied for that amount of time. Tied up at a lay-by berth is what they’re referring to. Modern dock supports are steel with wood bolsters bolted in place on top. I did read that there were high winds at the time the ship was knocked off the blocks so it’s possible that either the blocks were not in the right place, or the ship shifted during the pump out and didn’t land correctly on the blocks. I wouldn’t speculate any further until the MAIB or whichever investigation authority is overseeing this incident, publishes its report. Andy

-

Thanks! I’ll have a look at his work. I’m sure I’ve already stumbled across a video or two of his (YouTube rabbit holes), I’ll pay closer attention. I think there’s also a factor of scale to consider as well, when it comes to painting or decalling markings. I think if I was working in 1:48 or larger, I’d definitely give it a shot. Although there’s still no guarantee that the paint I might be using is the correct colour either! 😜 Andy

-

A minor setback, and a lesson learned. Yesterday afternoon I was all ready to begin applying the decals and lettering. My intention was to first start with the sky coloured band at the tail. Well, I was not at all happy with the kit supplied decal, firstly because it had to be cut free from the invasion stripes portion, and secondly, because it simply refused to wrap neatly around the tail. It was like playing wrinkle whack-a-mole. There was no amount of setting solution that would ever make that decal comply with the instructions is was being given. So rather than get overly frustrated I decided to go with plan "B": mask off the area and paint it. Properly. And boy, am I glad I went that route. Lesson learned, don't waste time with large stripe decals if you have the option to paint instead. This also reinforced my earlier decision to paint the invasion stripes. One thing I've found with Cartograf decals, while their printing is nice, the decal film can vary in thickness considerably. On my Wellington build, the decal film was thicker, so the decals were fairly robust, and didn't distort when applied. The film for the decals supplied with my Typhoon kit is considerably thinner. This isn't normal a problem for smaller decals, but for larger ones this can be a problem, as the decals will be easier to tear or distort or some miserable combination of the two. The supplied decals for my Hurricane build also had very thin film (hence the issue with the registration number balling up into a mess). For my Defiant build, the film thickness was somewhere in the middle, not as thick as the Wellington decals, but slightly thicker than for the Hurricane, or Typhoon. I should add that since my little detour, I've resumed applying the lettering and have not run into any further issues or, at least, I'm ready for any issues that my crop up and I can plan ahead for dealing with them. Andy

-

If I may, one of my other hobbies is collecting brass model locomotives, so I may be able to provide some insight. Pretty much all brass model trains available are hand assembled, even commercially made ones. Generally the production runs are very small (a few hundred units of a given type), so the industry does not lend itself to expensive tooling and mechanization. The only fundamental difference between a brass locomotive kit (or scratch build), and a "factory" assembled model is the box it comes in. Pretty much all of the solder joints are located in areas that are largely invisible, so that a causal observer wouldn't see them. (There is a little tarnish and staining on this model as its previous owner suffered a house fire and the model was subject to the liberal application of water that fire departments are rightfully well known for), it's otherwise in good mechanical condition. The model was built by Samhongsa in Korea and imported by Van Hobbies (who had a working relationship with Pacific Fast Mail). After removing the three screws that hold the shell to the frame, you can see the underside, and interior is quite mottled with solder joints. Adding to an earlier post about soldering multiple details, in most brass train models, multiple different solders are used with different melt temperatures. Starting with the highest temperature solder and working down to the lowest (although it's worth noting that in the above model, none of the solder will melt with your typical OTC hardware store soldering iron. To perform any repairs, generally a resistance soldering iron is needed, at the very least. Andy

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.