-

Posts

7,417 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

131 year old iron hulled ship Wavertree being restored

Mirabell61 replied to captainbob's topic in Nautical/Naval History

thanks for sharing that information Bob, i do hope that the workers will do a splended job on Wavertree`s restoration on that old iron hulled cargo sail ship. Also I`m very pleased that the Peking will be brought home to Hamburg instead of being scrapped, she also will be restorated and moored at the new planed Hamburg Harbour Museum... Nils -

Thanks Nenad, as Mark said, this sort of thing probably hapened to all of us once... I hope to see the progress on your CS, you always come up with interesting ideas for producing details.... Cheers, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you very much, Mark, John (Neptune), and John (Jim Lad), and all the "likes", Nice words Mark, I`m doing something else, before fixing the shrouds.... John, (Neptune) I saw, that you undertook a real deep dive into the log...., thanks for your interest, I`m pleased you enjoyed it, you`re very welcome to stay tuned... John, (Jim Lad) thanks for the compliment..., I`m also happy to see the feedback from my Australian fellow-builders (other side of globe...) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thank you very much Scott, the deck planking is running along quite smoothly Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hello Johann, thank you very much for your nice compliment...... In the moment I`m still a bit frustrated due to my own fault accident with damaging the foremast lines and shrouds, so I`m doing (planking) the deck, which will take several days to do.... Viele Grüsse Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Don, many thanks for stopping by and for your nice words. I`m very pleased that you like this early heritage "Atlantic Runner" Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

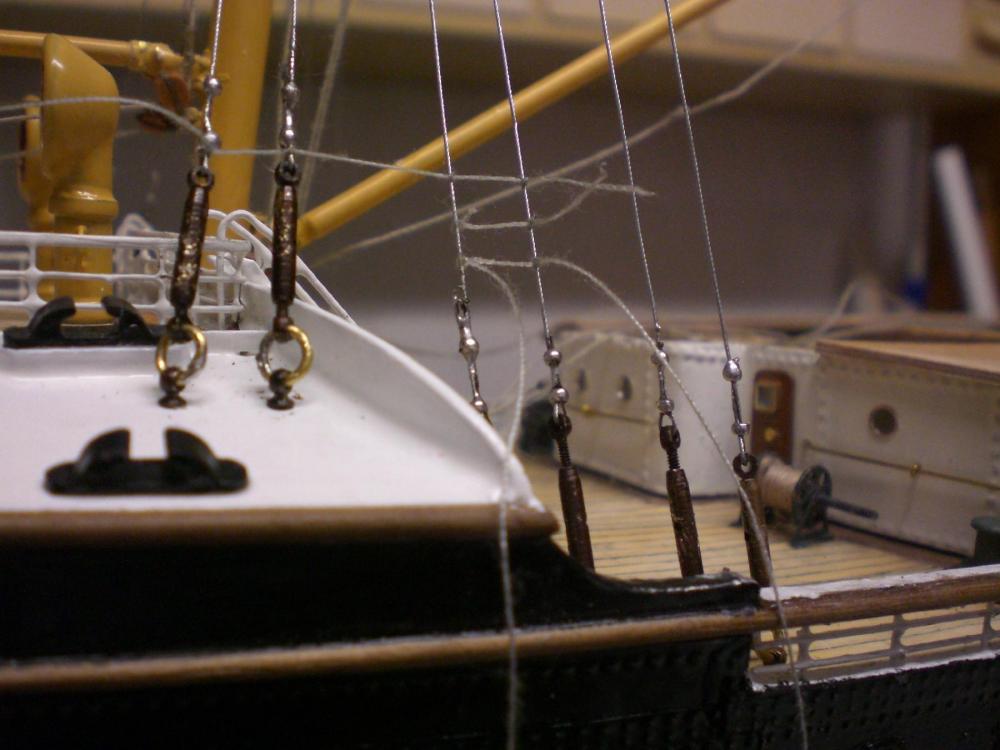

Thanks Patrick, have now leart "by heart" to more more carefully ....... Am now studying fitting out of promenade deckhousing windows, doors, portholes, stairway to upper and lower decks, etc...... Also made a prototype of the boat`s davit with tapered (stepped) ends, from 2mm down to 0,8 mm diam. The upper end is 1,5 mm and anealed and flattend at the end and bored for the davit block (boat-tackle) Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update Started with the coamings for the promenade decks super structure. It`s going to be a "longer" session. After that the railing will be put on. On 26th May this project was under way for the first 12 months. Had a little shock yesterday when I was a bit uncautioius in turning around, standing sidewise of the modeling table, and by mistake knocking my arm against the foremast from half back stb. side. This overstressed the shrouds and backstays so much that I probably shall have to replace these. , the mast stayed straight. Will be some fiddely repair work, but it could have come even worse, was my thought ...., anyway that`s an event that drops one`s attitude to zero for the moment Nils the middle gap in the front of the promenade deck has been closed here the contours of the super structure can be seen (mahagony) here the deck is started with 2 mm wide and 0,8 mm thick pine stripes (pencil caulking of the plank edges) the promenade deck will have the same appeal as the forecastle- and the waist deck

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Siggi, looks like this is going to be a wonderful planking job on your barge..... Nils

- 58 replies

-

- barge

- ships boat

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron by cabrapente - FINISHED

Mirabell61 replied to cabrapente's topic in - Build logs for subjects built 1501 - 1750

Beautiful work Cabrapente, Nils- 332 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

A very good job Dan, boat and rigging look excellent... Nils

- 175 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Bruce, your CWM is a wonderful build of a whaler working ship. Excellent handcraft work and a pleasure to explore the details... Nils

- 245 replies

-

- model shipways

- Finished

-

(and 1 more)

Tagged with:

-

Many thanks to Bob, Mark, Patrick and Michael, much appreciated comments... and all the "likes".... Bob, I think that around 1900 the people were not as tall as todays, so 1:160 scale will be acceptable Mark, the experience with the steel cables is from usage on my tall ships, where there are so many shrouds and backstays to keep under tension (turnbuckle screws) thanks Patrick, pleased you like it... Michael, sometimes I`m not pleased with the first result, but it`s most times worth a second try... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hello John, thanks for your interest and for looking in, hope you enjoyed the log tour...... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

the deckhouse looks beautiful Bob, also love those drainpipes ... Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

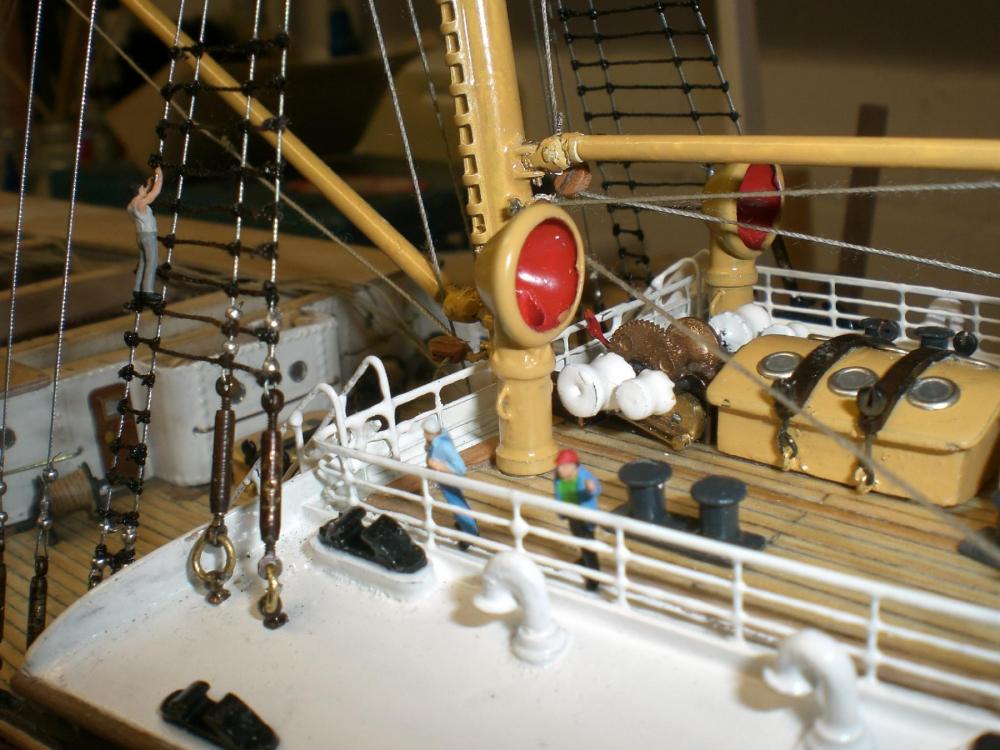

Many thanks Bob and Denis, for your nice compliments and all the "likes".... for the button clicks I`ve changed the ratline color, as the other thread was a bit pale... In lack of crew figurines in scale 1:144 here are some samples in railway "N" scale (1:160), trust they will do as well....although a tiny bit too small in hight Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

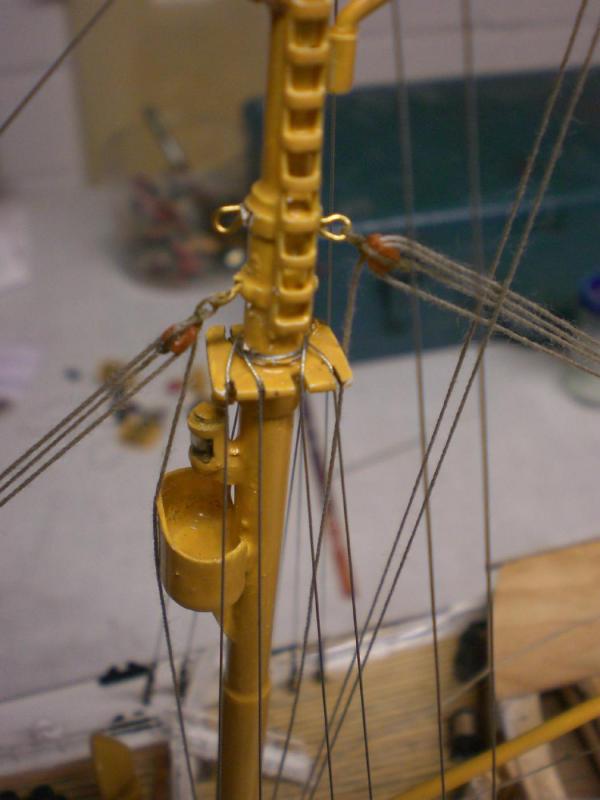

Hi Carl, the shrouds and backstays are from flexibel 7-fold zinc-galvanized steel chord with a total thicknes of 0,3 mm diam. (normaly used for wire controlled model aircraft). After some weeks they get a bit darker when they oxidize. The ratlines are polyester thread Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Keith, that`s the way I like models being built, beautiful lines, excellent handcraft work and clean planking...... very well done ! Nils

-

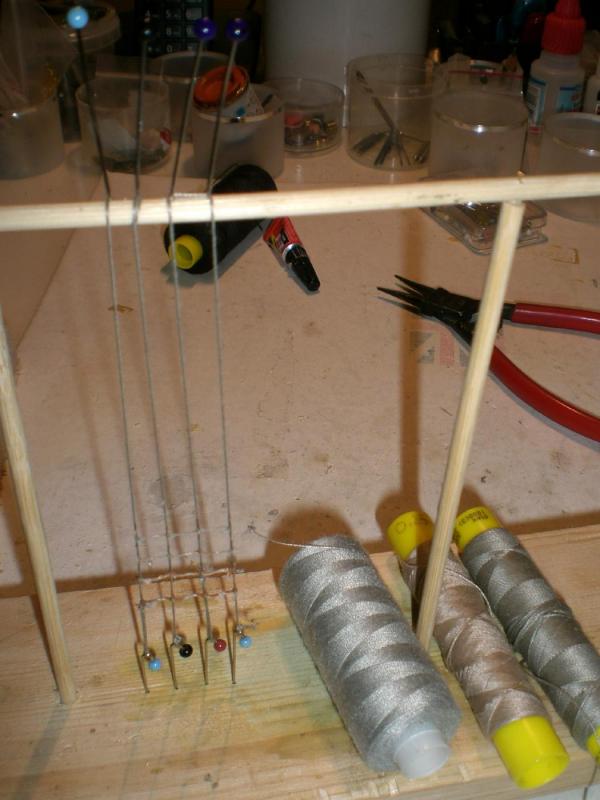

Update starting foremast ratlines, determining the line thicknesses.... Nils this gallows is just a little dummy setup to determine the line thicknesses the shrouds and backstays are from flexibel 7-fold galvanized steel chord with a total thicknes of 0,3 mm diam. (normaly used for wire controlled model aircraft) the turnbuckle srews are the smallest I could find ( M1 left / right thread) the upper shroud distances are given by the 4 slots in the top`s spreader the slotrings for deck fastening are soldered at the joint, in order to prevent opening the ratlines thickness is chosen to 0,2 mm thread in scale (the actual would be ( 144 x 0,2 = 28, 8 mm diam.)

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thank you Carl, you`re right with the fitting out alongside the fitting out quay, but most of that would have been the luxurious fitting out and furnishing of the saloons, which I can skip...... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.