-

Posts

1,566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

BTW… the base is not heavy. It would need to be screwed down if you want to tug on it.

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

I’m not either, but I’m getting better at it. Takes practice this model will definitely give you the opportunity to practice. Took me several attempts and hours to get what you see here. You need the right tools. 👍

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

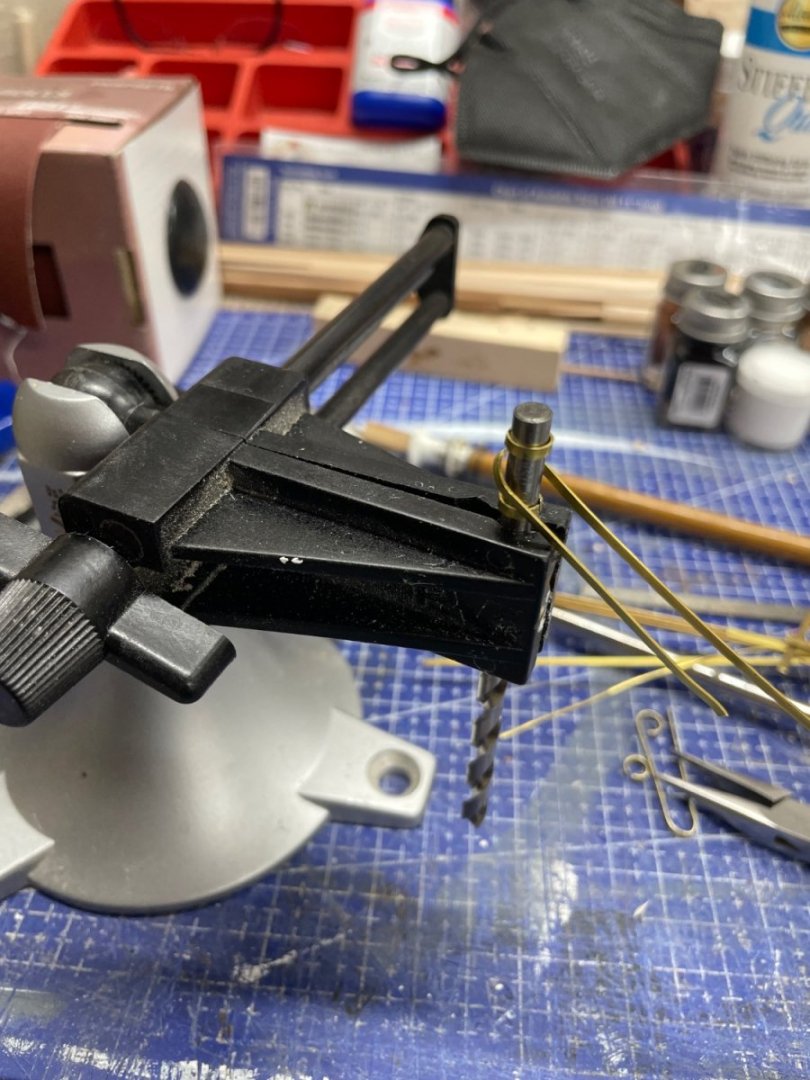

I like it too, I’ve had it a very long time. I don’t remember where I got it, but I found one at your favorite delivery service. PANAVISE Model 201 "Junior" Miniature Vise,Silver / Black https://a.co/d/f4guiqj

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

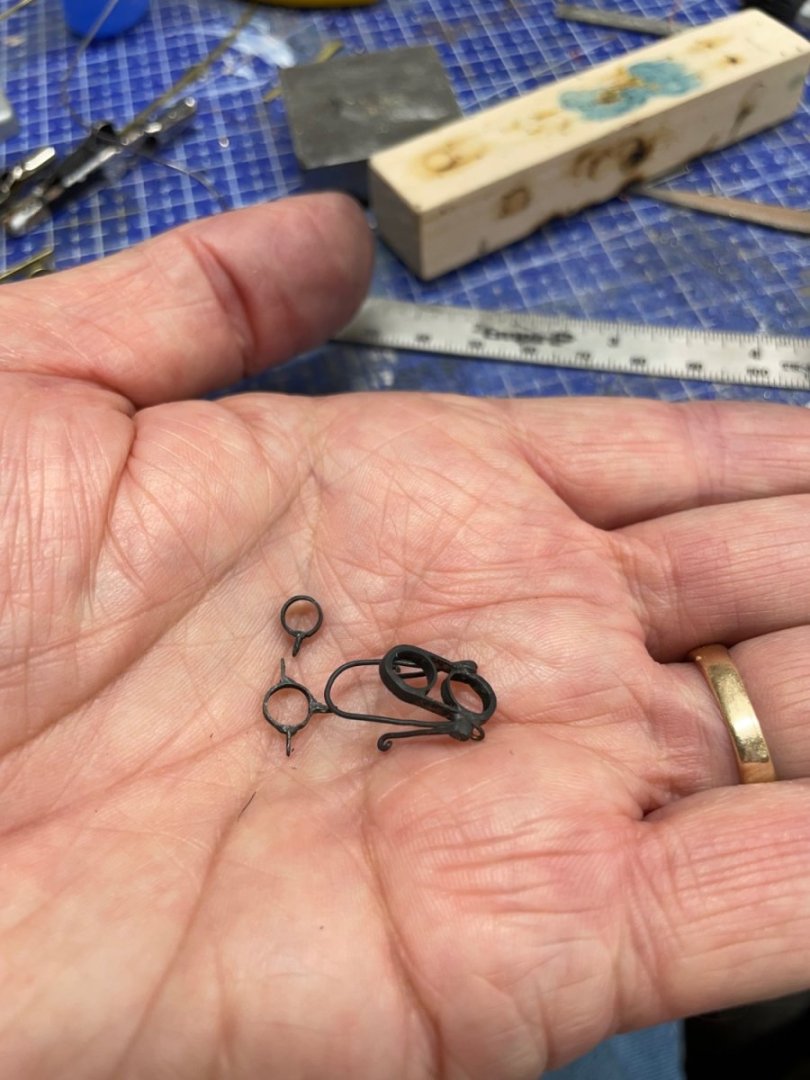

Opening up my Micro Foundry… Fore Mast Cap… 3/16” Drill bit… Soldering .9 mm drill bit complete assembly additional soldering Still working on my soldering skill set. Lots of micro filing needed to clean this up. Cleaning with Acetone Blackening Brush off excess crud to polish it up. 3 of 99 parts to go. Steady as she goes. Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

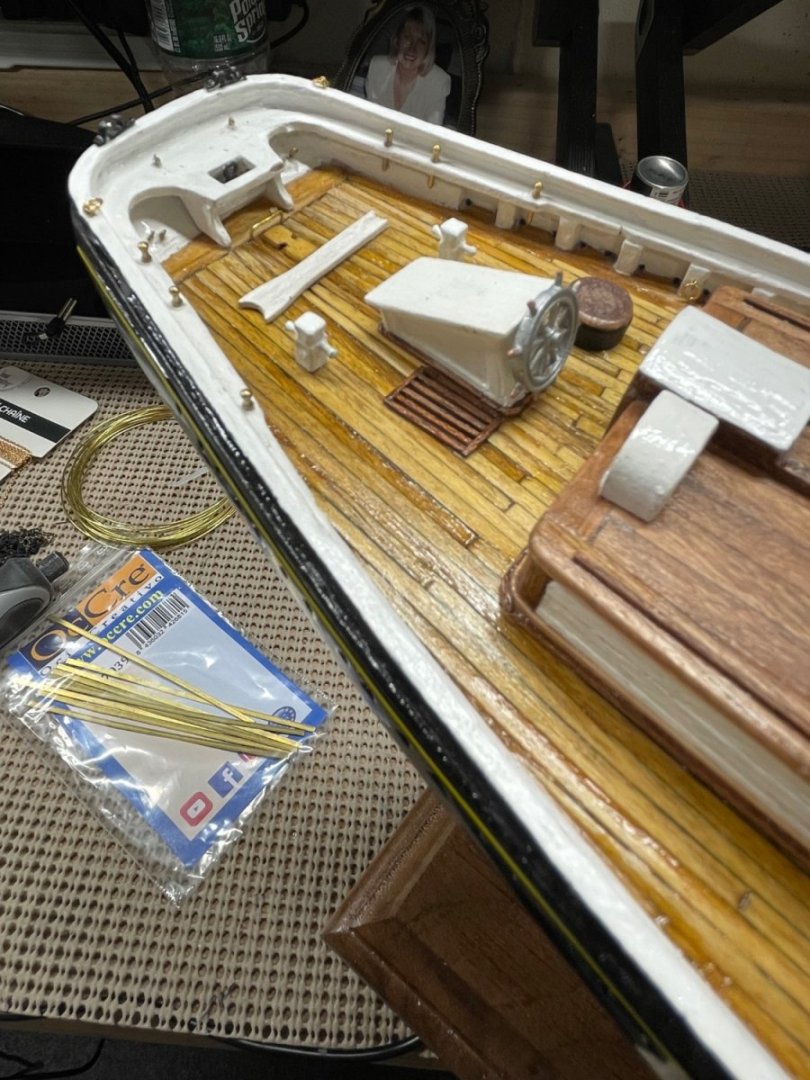

Beautiful work! Looks like you are making great progress. You did it again, thought I was done with the deck but forgot the Jumbo Job Sheet Traveler Horse. I thought I triple check those drawings. 😜 Lots of details to capture. I’m going to fix that right now. Thanks

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Deck Furnishings complete… Although my goal was realism in the storage of 16 oars and 20 Thwarts in the top Dory, which I believe I achieved, I don’t like the look. So, I have opted to place 8 oars neatly laid out in the top Dory on each side. I think it’s a much better presentation. The Deck is complete, just over a year since I started this project. It was July 18 2022 when I opened the box. I estimate 600 hours a year based on my first build where I actually tracked my hours. 😆 We are ready to go aloft! Thank you all for your comments, likes and encouragement a long the way. Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

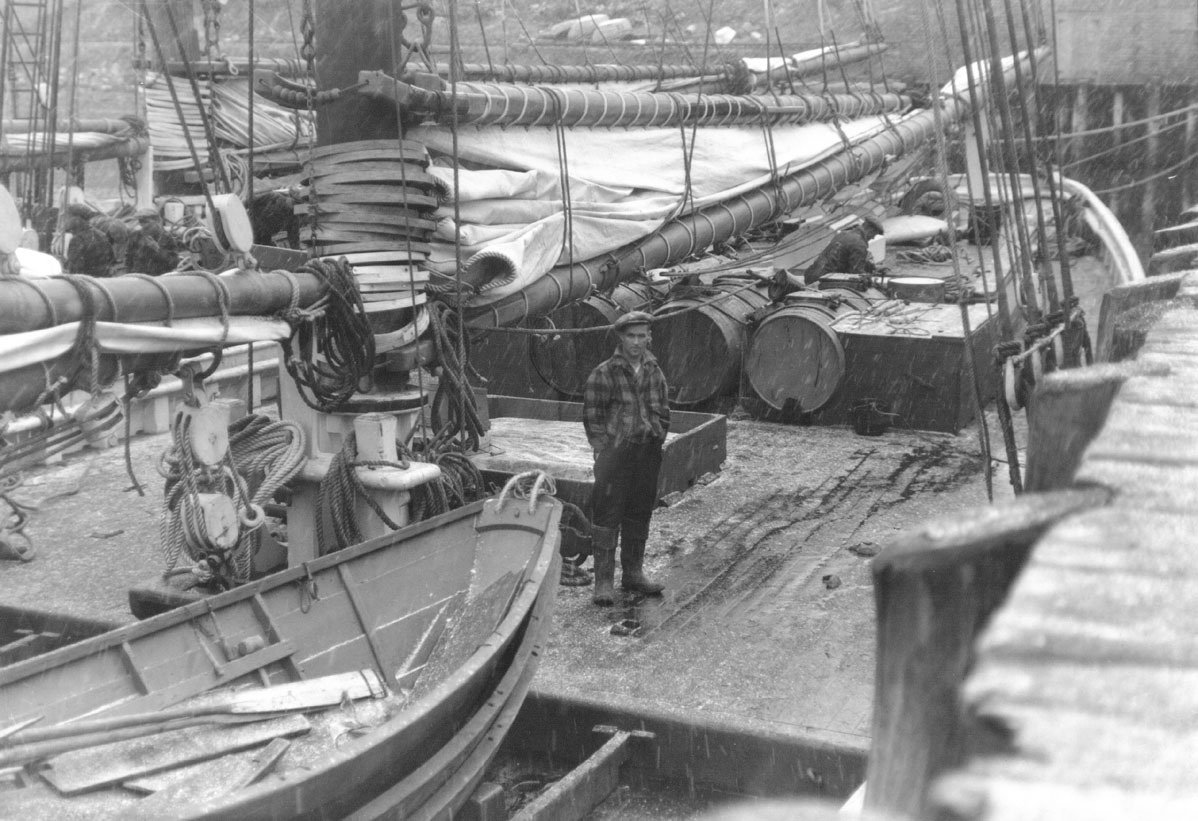

On second thought… I will probably go for all the glory of my inspiration photo. I have looking at this photo on my bench for three years now. Steady as she goes… 🍻

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

We got a ways to go before we can set those sails. Cheers 🍻

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

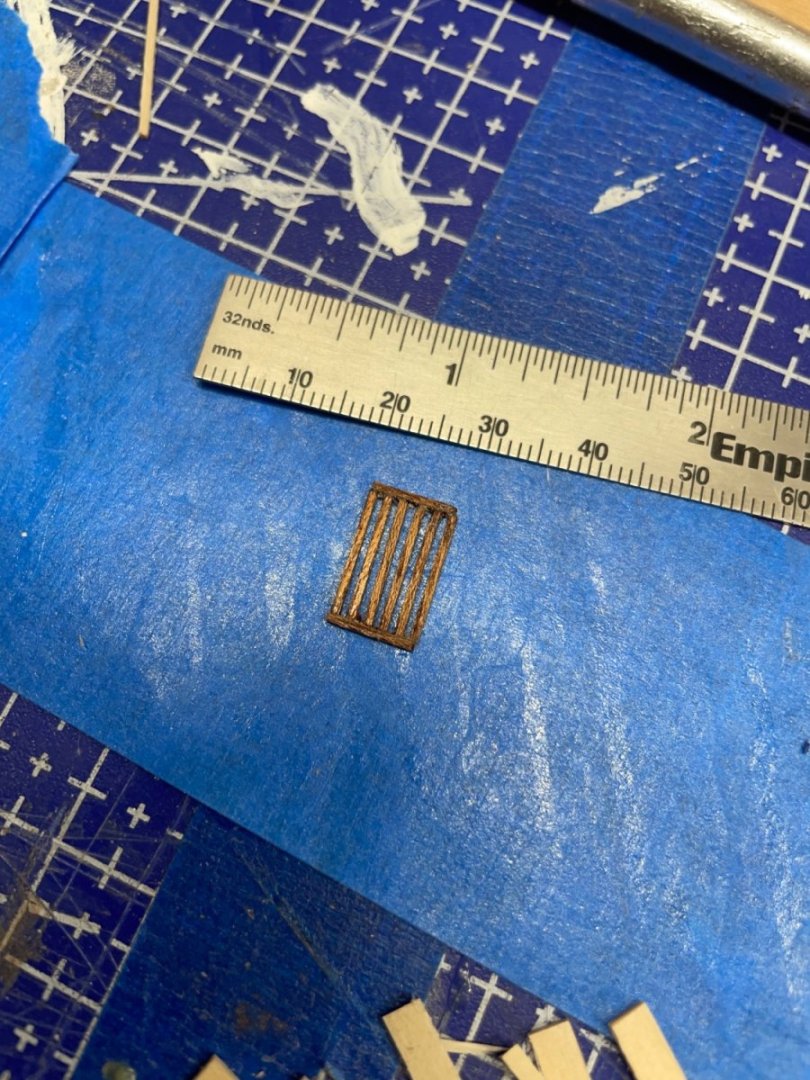

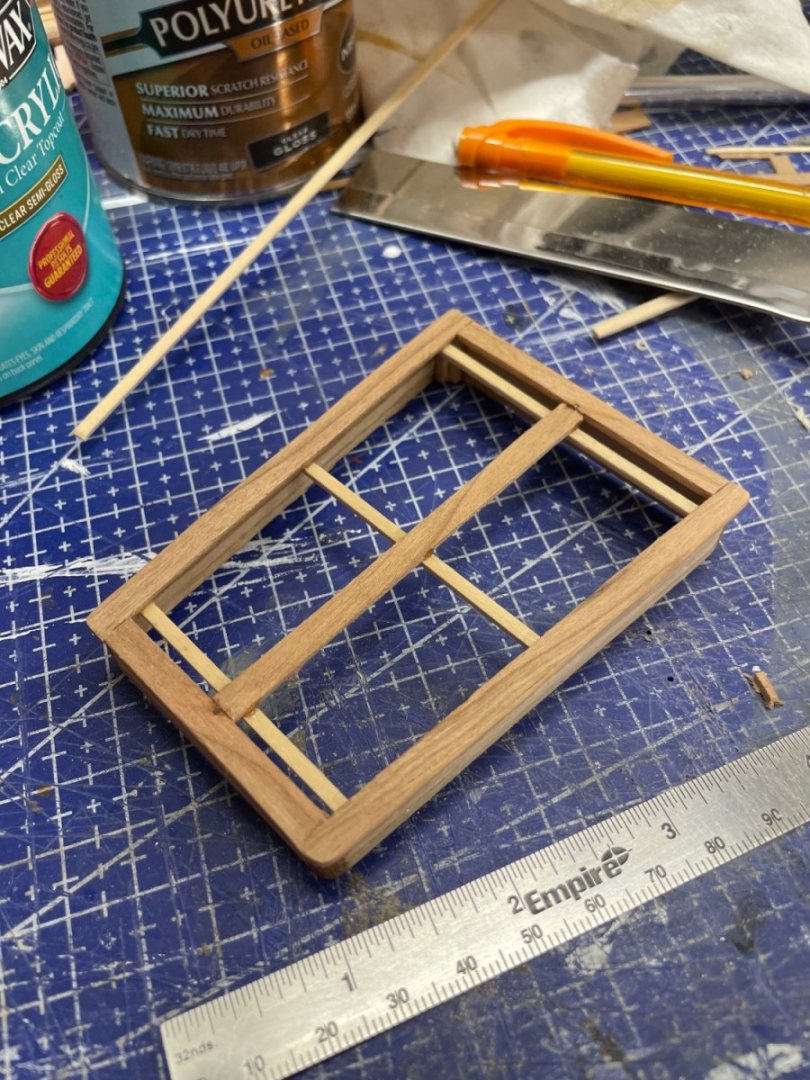

Batten Platform… @GGibson Thanks for the reminder, I nearly forgot to place this small but important detail. I used 1/32” Mahogany, only because I didn’t have the 1/64” material in a hardwood. I think we can overlook the over scale on this one, just this once. 😆

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Yes, I have considered silk span. Definitely an option for a smaller scale. I like to use muslin materials, however the material in kits is usually too heavy. This photo shows two kit supplied “sail cloth” and a third locally sourced (JoAnn Fabrics) muslin fabric. Muslin fabrics are not all created equal. The bottom one is the locally purchased muslin. My goal is to create the full sail and fold it down as in the photos below, with all of the stitched and rope detail. 😎 If the sails won’t cooperate, then I’ll set sails up full with fair winds. I believe I can do this at this scale. Wish me luck. 🍻

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

You are correct, schooners needed to be slid down the ways before they weighed too much. If you look closely at the launching photos in the archives, nothing was done regarding rigging until launch. As for folding the sails down on the booms the sail material has to be very thin to represent the furled or folded sails properly. Most kit sail materials are not fine enough. I have some thinner material that I’ll have to experiment with, once I get the sails sewn up, to decided if I leave them up or bring them down on the booms and fore deck. Decisions and Research 🧐 to be done for sure.

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

I know it’s a little detail, but for me it’s all about the detail. 🧐 BTW… A launching way sounds like a nice display. I haven’t done one of those yet. I’m considering sails hauled down and stowed, myself. Steady as she goes. Cheers 🍻

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Looking good 👍 Glad I’m checking in, you just reminded me of the battens beside the wheel box. I’ll have to get back to that after I finish the Oars. John

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

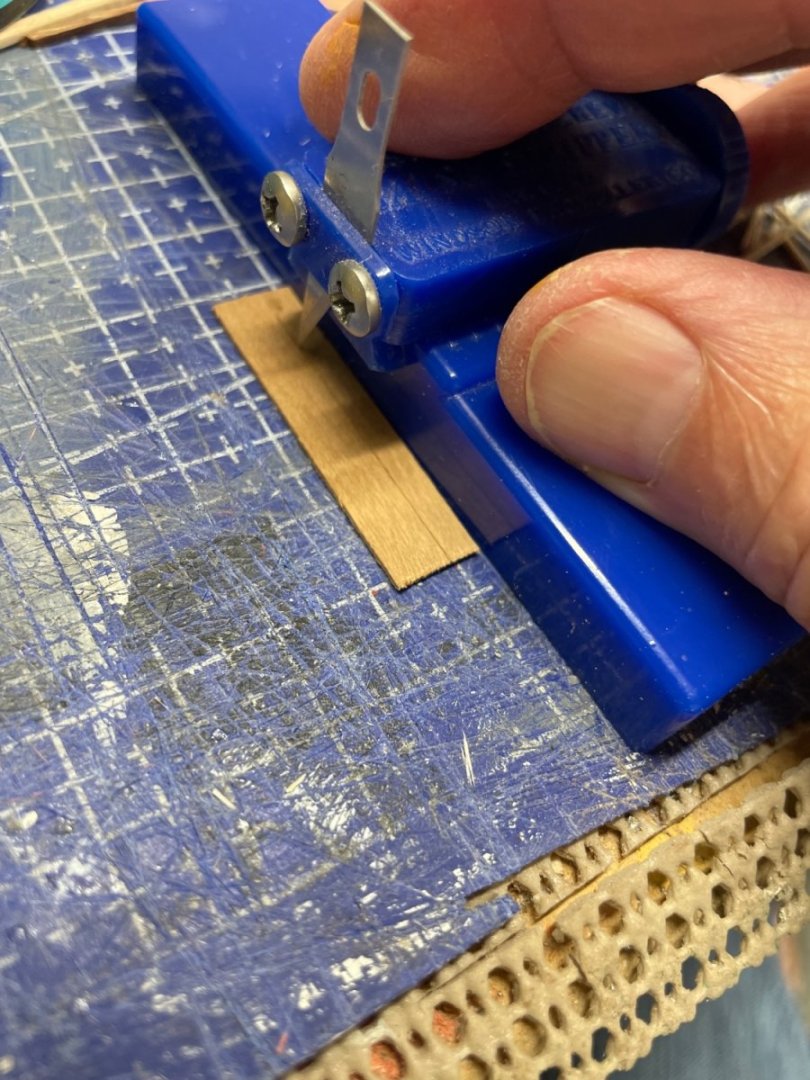

Yes, I got it from Micromark.com. Works well on thin stock.

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks I’m noticing the hardwood sheets (Cherrywood) make for more consistent staining, than basswood. You are welcome to incorporate any ideas, they may or may not have been my ideas to begin with. 😆

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks… Love the crewman with his hands in his pockets. LOL 😆

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks… The 1/64 scale Barrels came from a modeling web site Frenchman River Model Works. https://frenchmanriver.com/Wooden-Barrels-_p_96.html Good stuff 😎

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

I debated building a working deck with the barrels and bait stations all the way thru the construction of them. 😬 I’m still not quite happy with the finish on the storage bins, I may redo the tops. Darn OCD. I’m considering a few bait line buckets, But I don’t want to turn it into a diorama. LOL 😆 Thanks to all, for your comments and 👍… John

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Additional Deck Furnishings… Deck Furnishings are now complete and ready for fishing. Next up oars and thwarts stowed in the top Dories as seen in the fore ground of this photo. Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

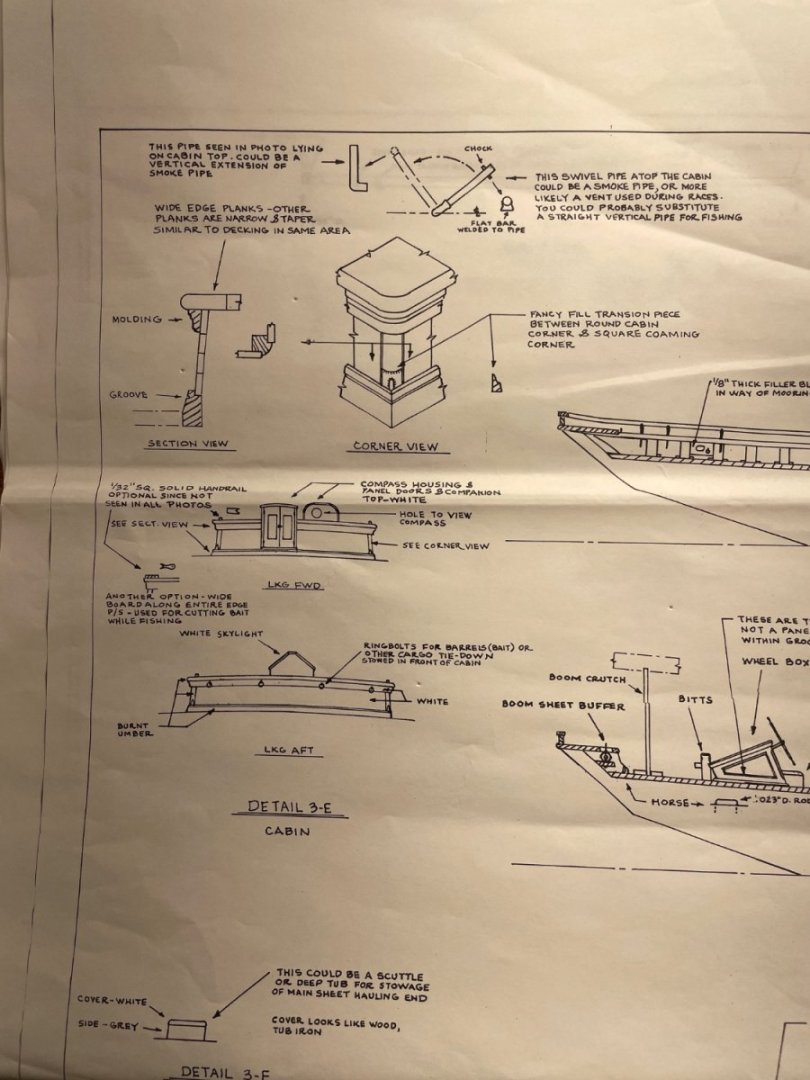

Wheel box etc… Deck furnishings complete. Woo Hoo! Next up… I have decided to add a little something to the deck. I am going to add fishing gear. I asked the question, Are we going to fish or cut bait? The answer is of course, YES! More research 🧐

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Nice build so far… Looks like we are at about the same stage on our Bluenose builds. I’ll pull up a chair, we can keep tabs on each other. I’ll PM you some photos, that should help… John

- 184 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks for your comments, are you building the Bluenose II or the original? Here is a vintage photo of the original Bluenose just before it was sold. I’m trying to strike a balance, using the Bluenose II photos as a guide to my finishes but build her as the original. Do you have a build log posted? Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Pumps and another Hatch… Up next, The Cabin… Details… Here are a couple of photos I took on board the Bluenose II. Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.