-

Posts

1,567 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

good morning folks no 7. after many mistakes I have to live with, /you saw a bit compromised stern ending, ...installing steel bulwark. This operation scared me by lot, as metal sheet must be rounded to fit and must follow first plank gap to ensure its straight and I went for quite solid sheet almost 1 mm to ensure stability of construction . . otherwise it wont be straight. good news is, if maintained so, outcome will be OK. fitted with nails and fastened with 1 plank afterwards. meanwile i broke nose if ship, ouch , so work again,,,,,there is little unwanted dip in bulward right at the nose - for this reason i was not able to turn sheet counterwise any more.... it will be more wisible with topgalant rail installed but will see....first nose making. I used violin iron bending, as it went so so, as its quite thick. 6 mm to be rounded both direction. I did break one , but finally managed it. Intended to make it as original so, ornamentation is to be easily removed if future come up with " another art " stern was obviously most difficult as I had to cut "sheet scarf" I first made wooden guide, kind of mould, and for the stern bulwark I used 2 layers of thin plywoods and metal sheet between them to make a shape. challenge it was I almost cried.. at the end I did straightened it with help of modern device :)) grinder. hooray. sorry for my english. its 10 years without practice. thank you for previous comments etc...

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Hello everyone. chapter 6. planking. sanding etc..fillup of stern _ skip in time to finished stern let me please know what you think. many thanks V. from now on i will sneak peak every time one some small familiar detail without whole frame as not to spoil it, - from very opposite side of build :)) heeey she is born, showing her sexy curves, hooray !

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

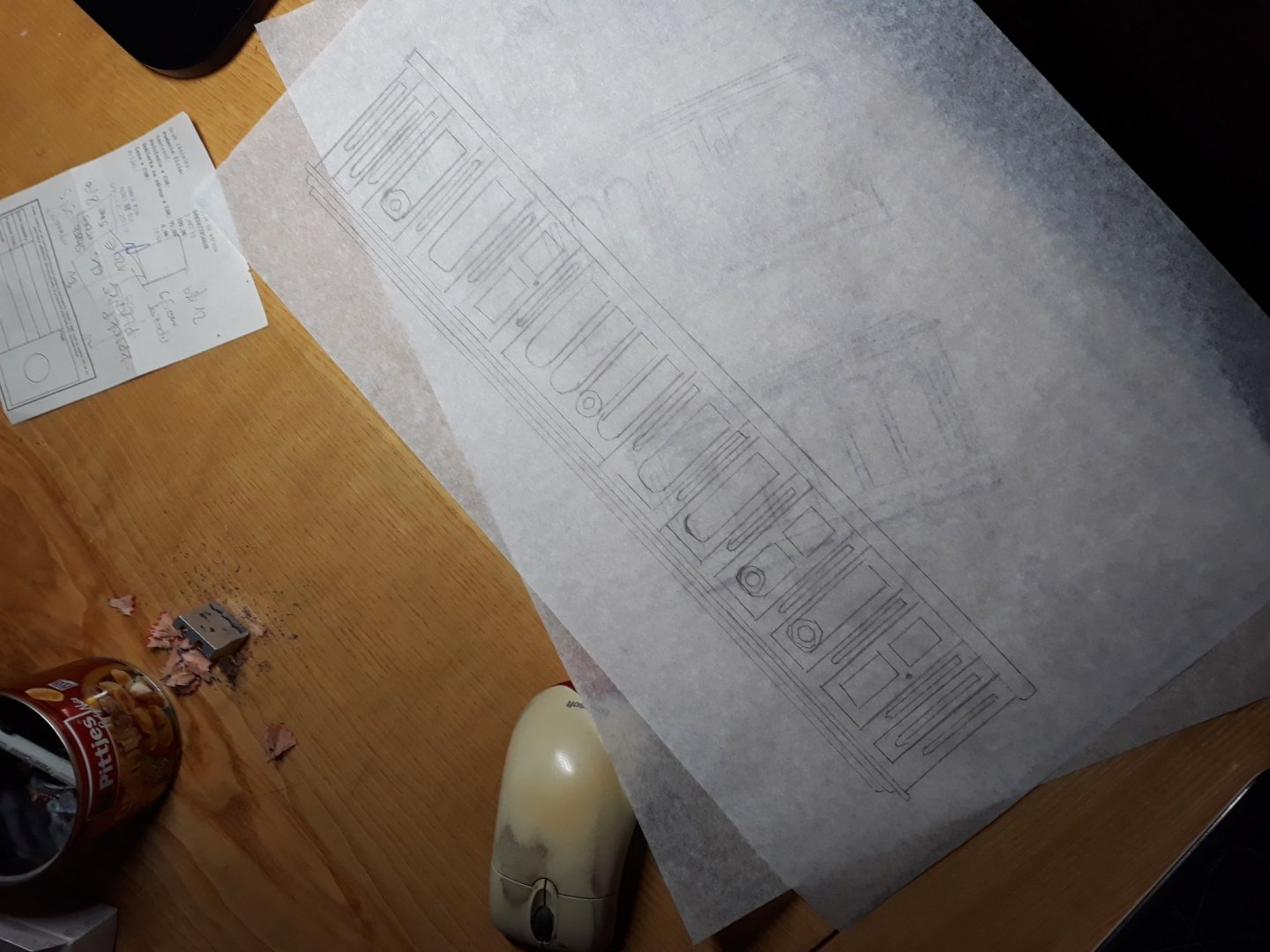

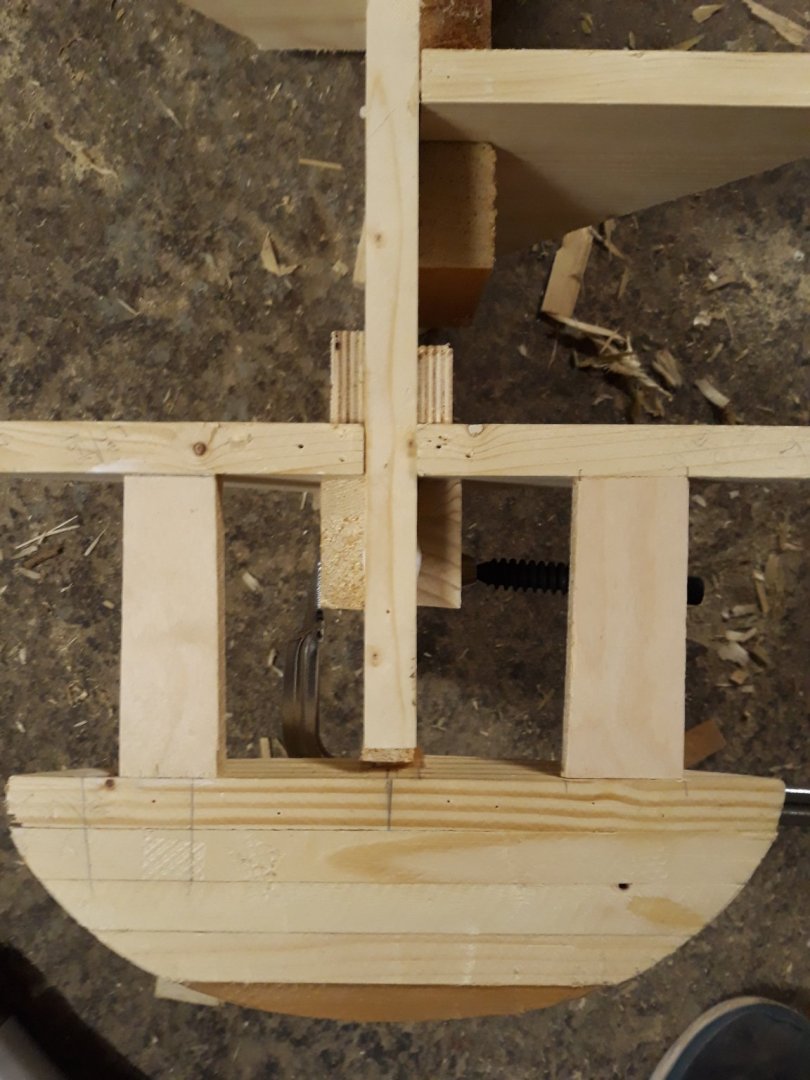

Dear fellow builders, thank you a lot for encouraging words. chapter 5. deck instalment. I used nails, did center deck evevation, masting holes, bowsprit hole, zero plank is installed. ouch. and her sexy bottom from some old wood glued together. I put it together with screws, it strenghtened stern part by good margin before planking. she starts to show off her curves doesnt she as a distraction before planking I started deck houses out of junk cardboards,, last pic from the windows, its christmas time. last peaceful breath of air before planking. next part will be full of painfull irreparable errors from future look I regret enormously that I did not fill up space between last bulkhead and stern to make olanking easier but will see next ... all best Vlad,

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

Very very nice work Peter, im watching it on. good luck

- 207 replies

-

- billing boats

- cutty sark

-

(and 1 more)

Tagged with:

-

Thank you Martin! Yes scale scares me a lot, and decorations etc.... fingers crossed. But it is her timeless charm that haunted me to go on with her

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

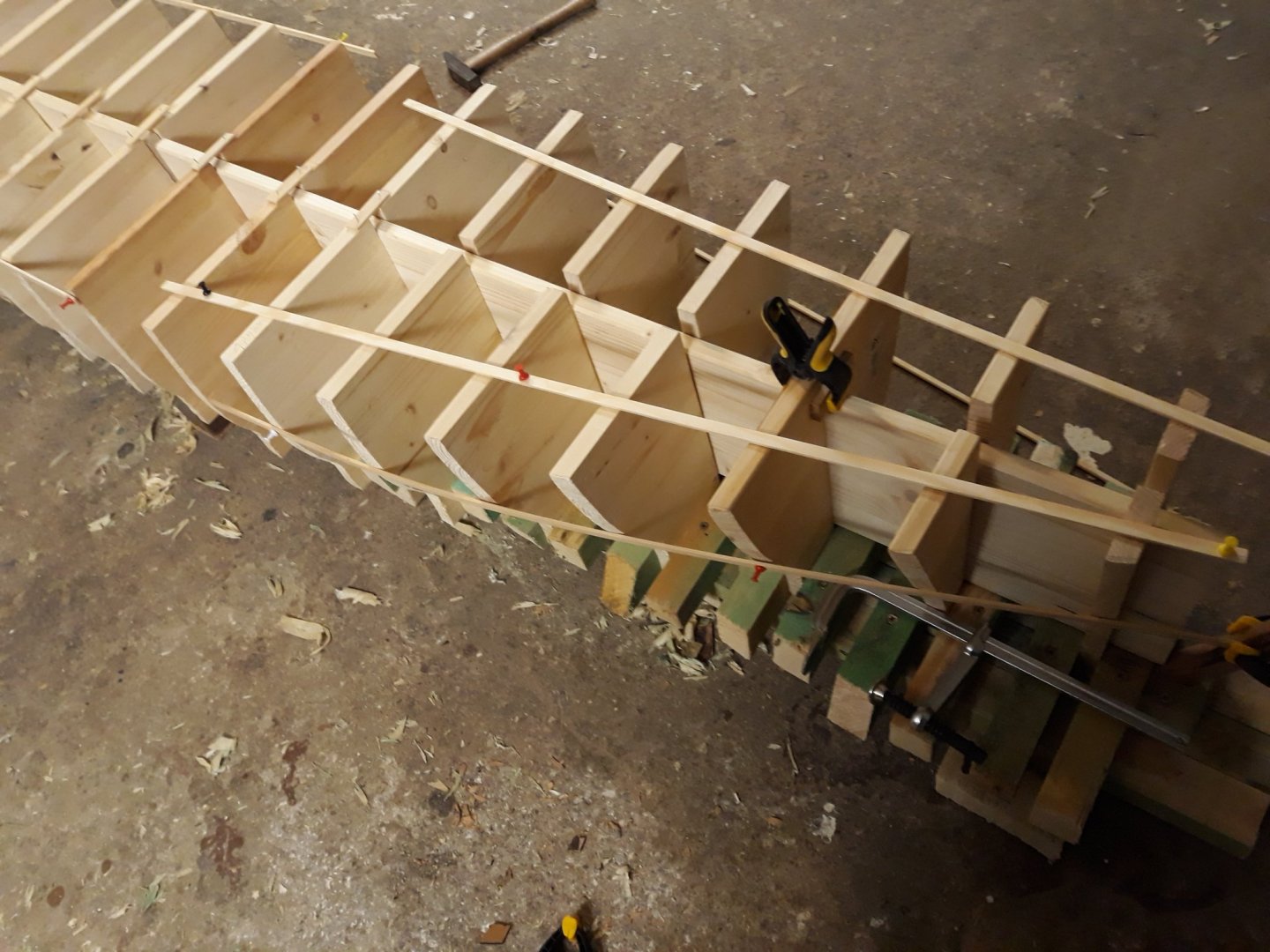

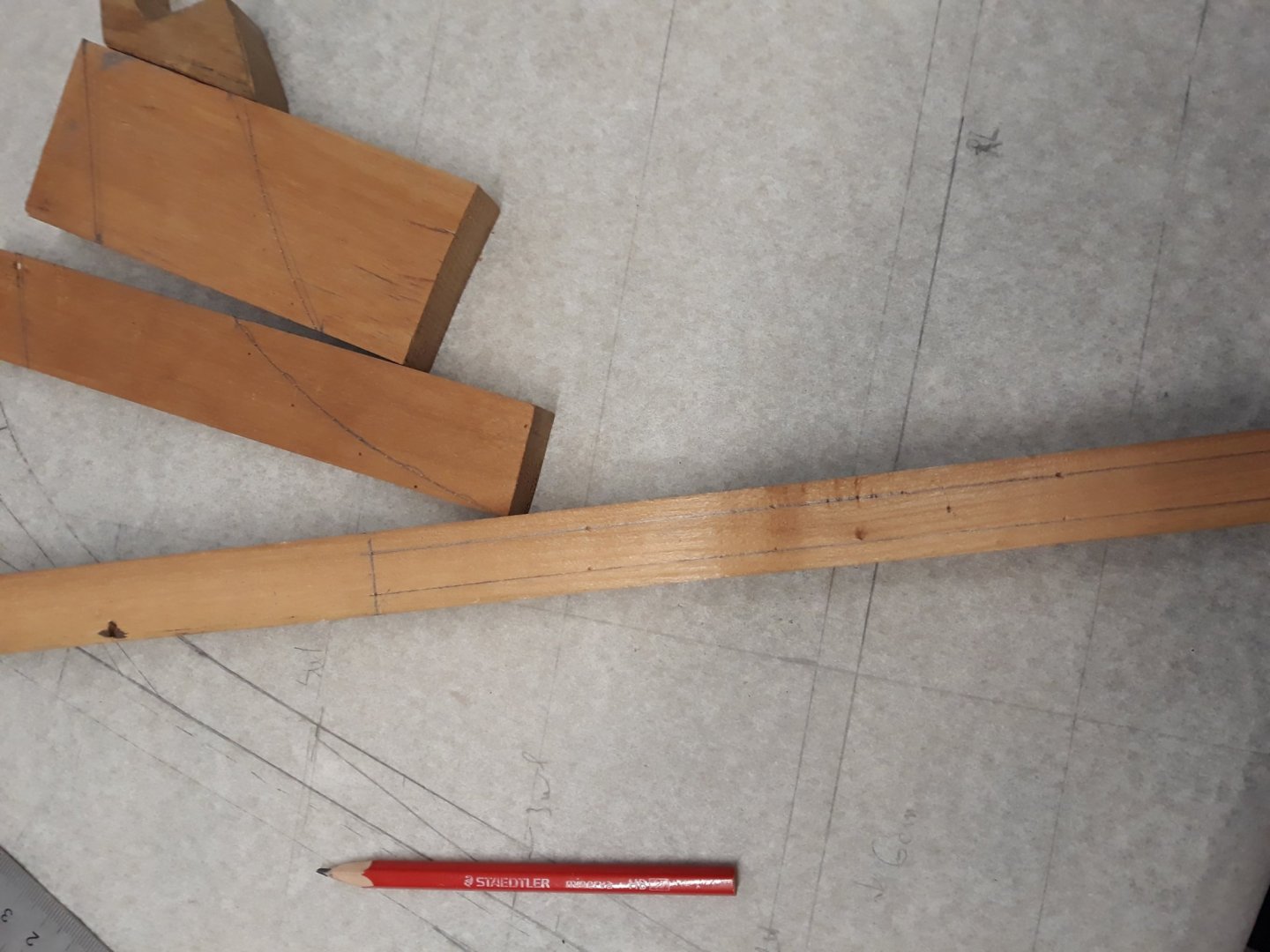

Good morning guys, part 4. many rainy days included. bulkheads out of cheap pine wood. cut manually and planned manually. jeez. Instalment bulkheads is most funny, but tricky part as well. constant checking of measurements etc... hope you enjoy. I fastened stem, quite satisfactorily for me at the moment, but stern part is very fragile at this point, not sure how to go further. will see. all remain fragile at this point bulkheads only glued to central line but secured at the bottom enough to be firm. thinking of stabilizing and securing sfter planking from bottom part, not sure how at the moment, to keep it reasonably light. its heavy anyway. its is straight enough for me at the moment, after checking horiyontal vertica lines, i could have cut off work from the basement. ...most fearsome part , doing it manually. finall correction of bulkheads and planking fo follow enjoy.

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

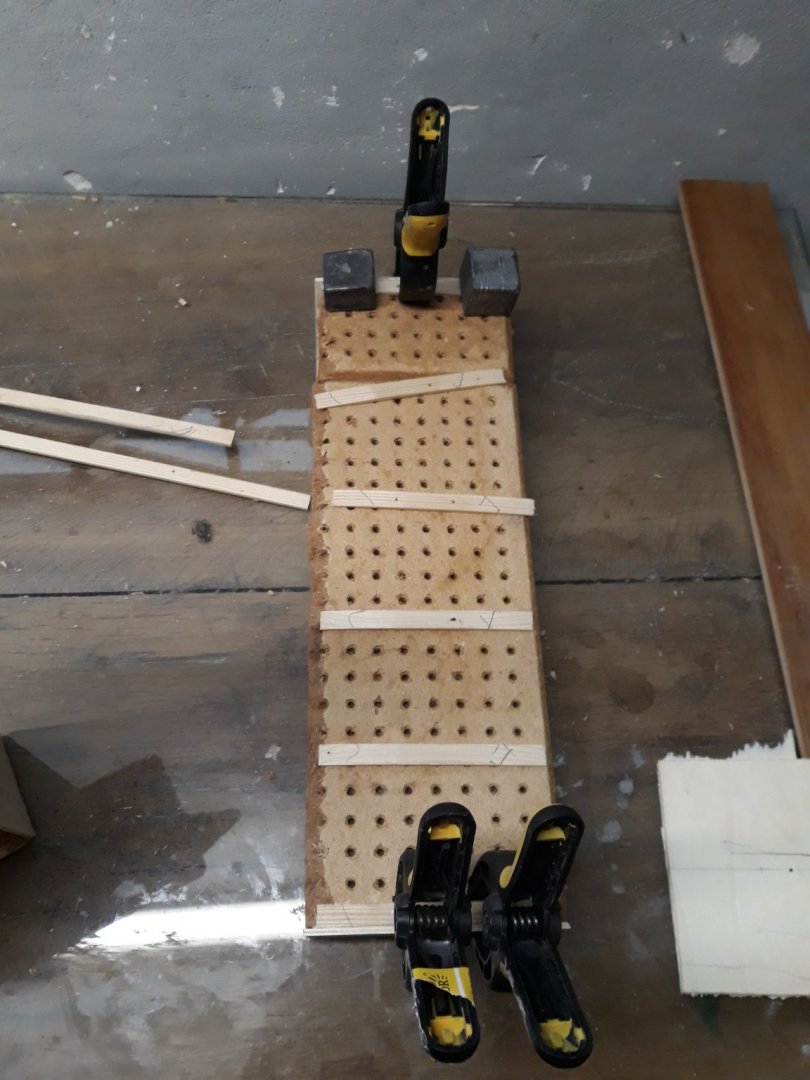

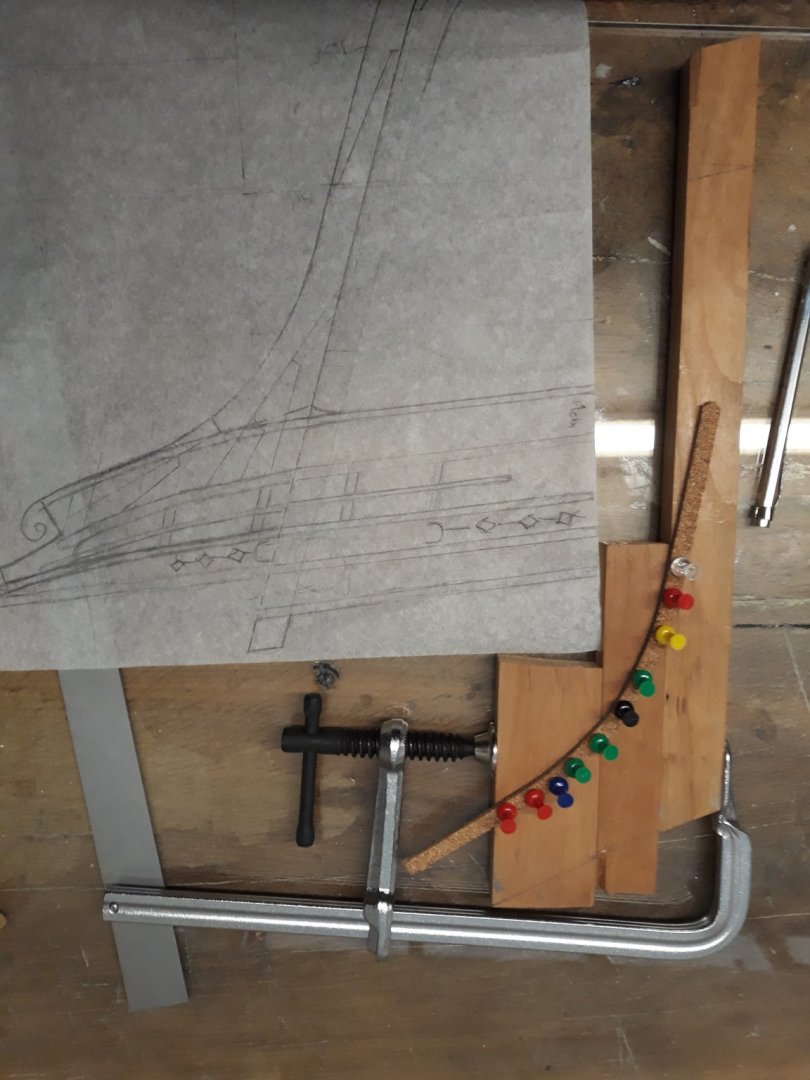

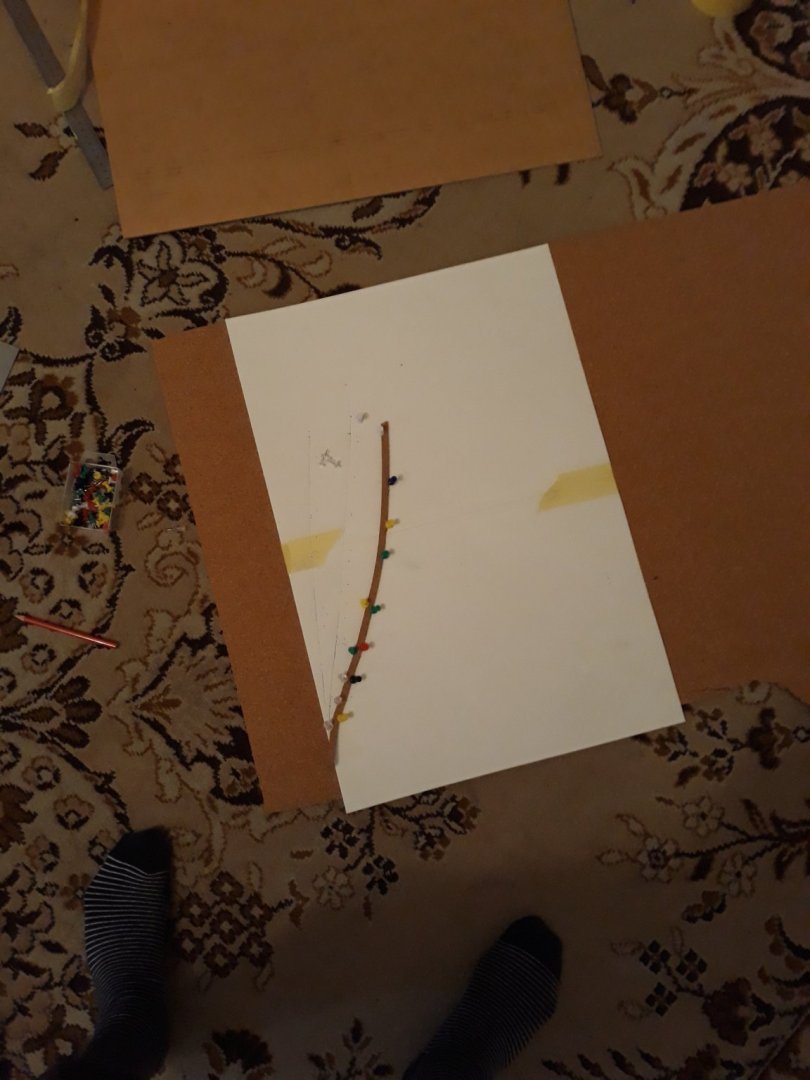

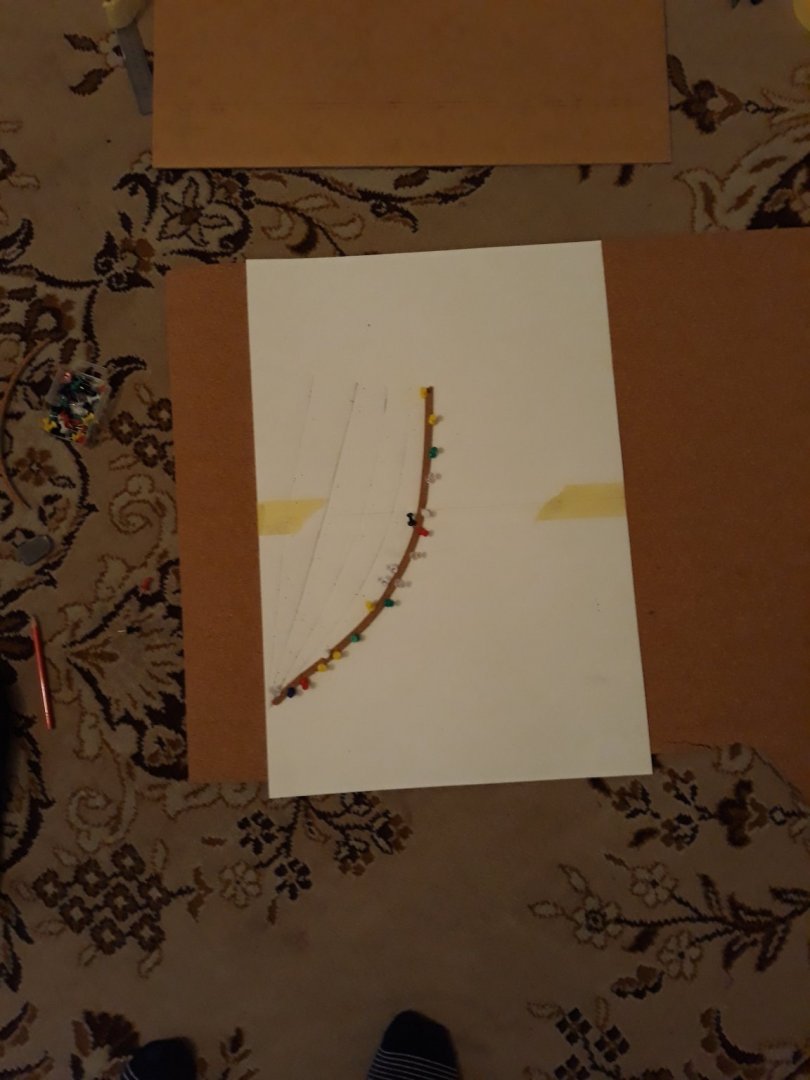

Good morning folks. 3. shipyard construction. My workshop turned to shipyard. photos look a bit scary, but in this case precision is ruler of all, I spent a lot of time hand planning and measuring bottom of surface to ensure straight platform and even distance from every section. fastened with screws and glued first. spruce leftovers from roof construction of house. when I saw magnitude of the platform, I almost fainted. ff sake what did I step into.... kingsheads almost ready. Rabbet line turned out to be too shallow after checking, so I had to widen it for 3 mm planks. second pic- this is like what half of platform look like - second half to be joined. next - bulkheads. enjoy.

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

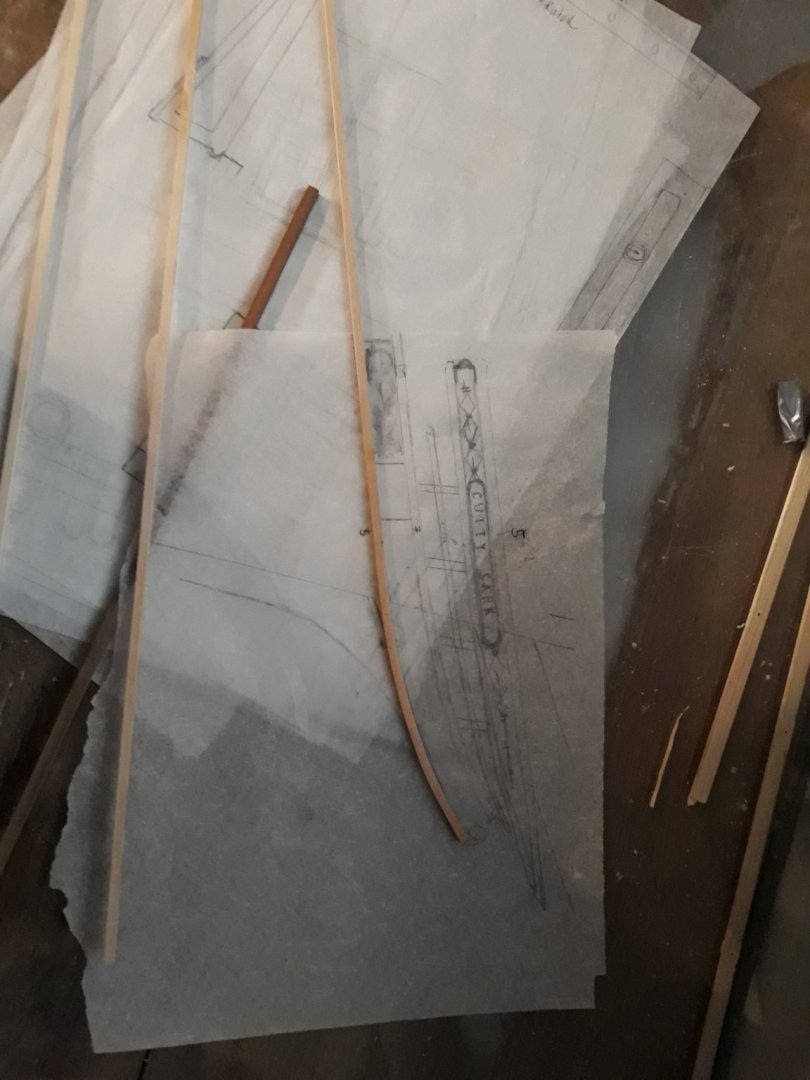

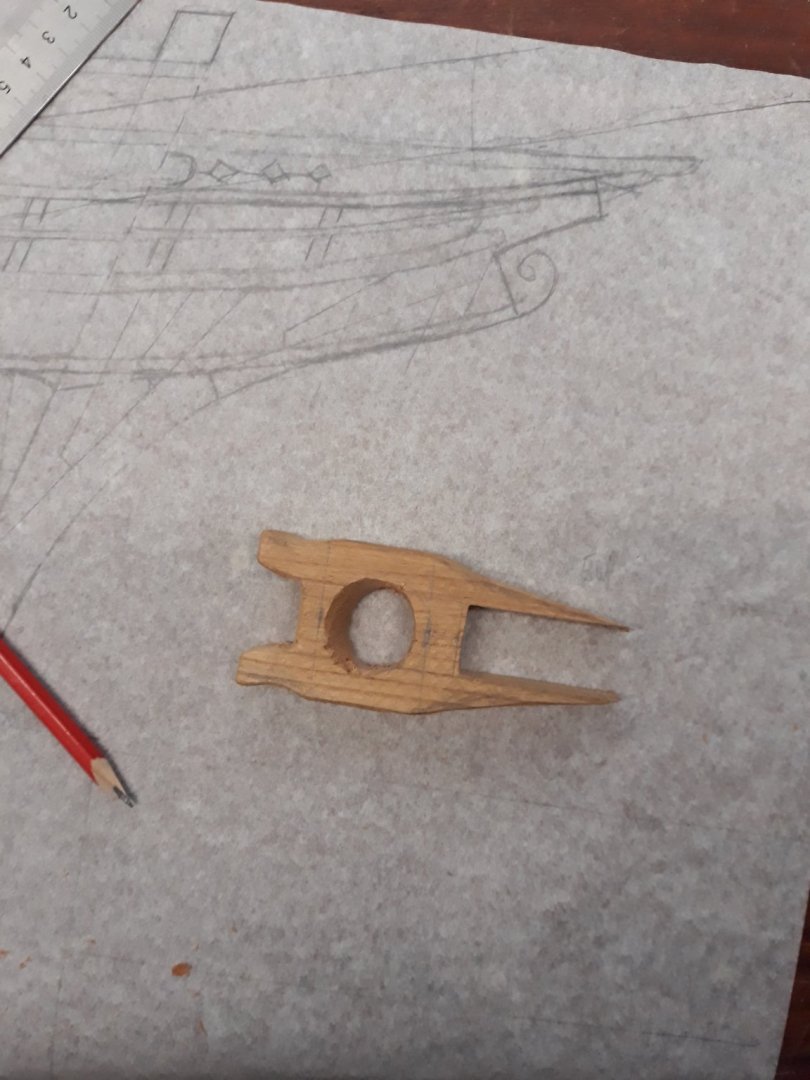

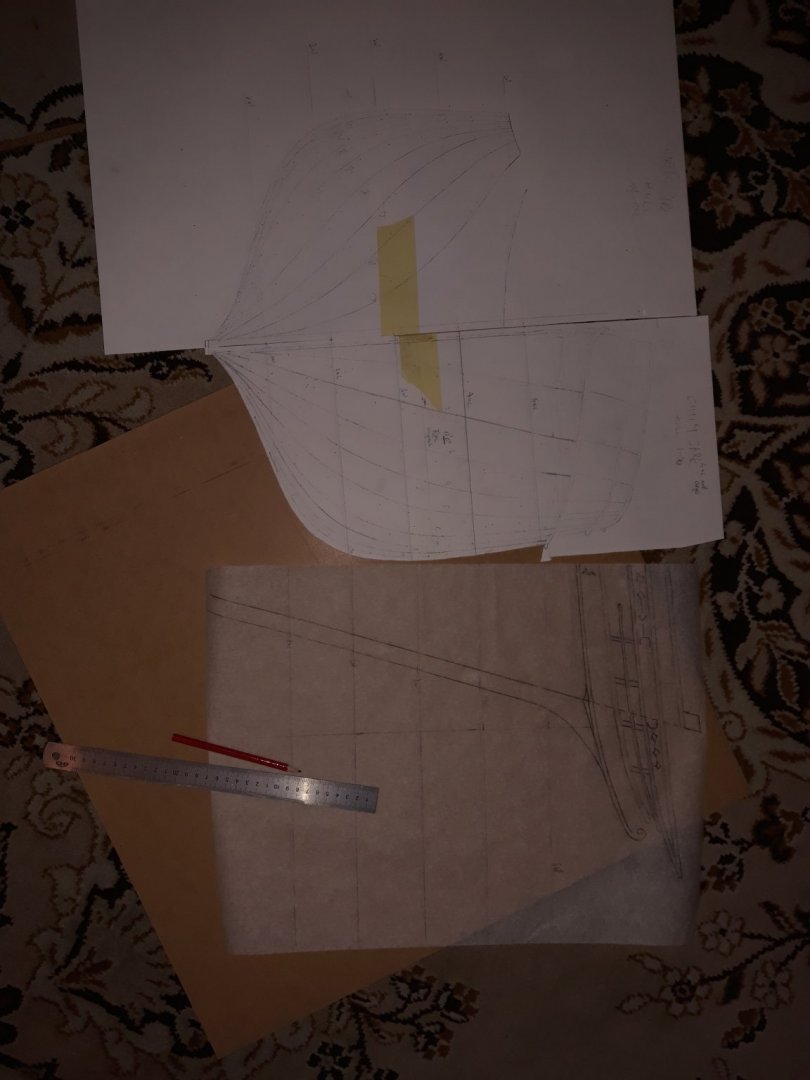

Hello, fascinating precise and important geometry work with needle and pencil is over, gave me headache for couple of days finally excitement starts. making stem out of cherry wood. rabbet line to follow. cheers. Hello. 2.

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

-

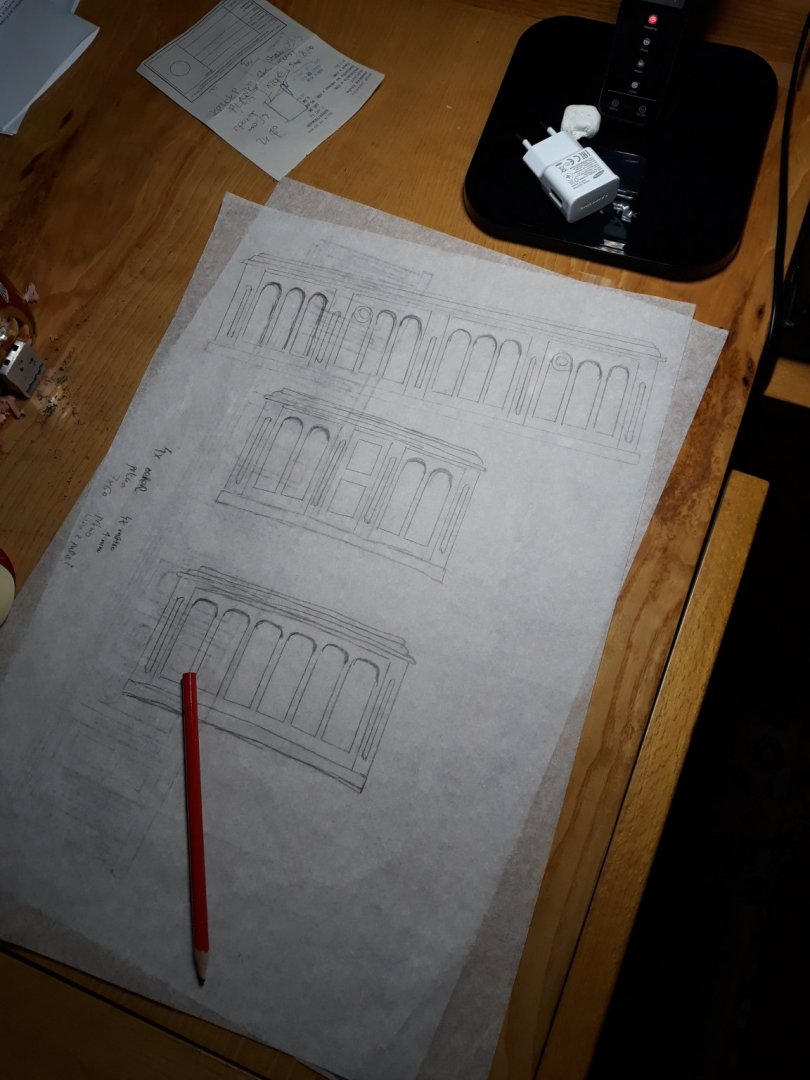

Hello guys, I took the plunge to build cutty sark beauty in this massive scale, but... i am about to finish it now, hovewer I thought I could still get some help or share my limited experiences and technique ...,most likely thinking if I had known amount of work, i would not have started probably. but very glad i did. I am ships "afficionado" since kid time, and being from country wihout sea, obviously. :)) I hope its ok to post backwards, but i will go from beginning, knowing what went smoothly and what i regret ...this was a longest journey of my life, probably knowing about that ship more that I want by now :)) I followed logs of some so I am obliged to share and hopefully provide fun. Original idea was to use as less bought parts as possible, to make most of ship myself, and i decided to go without rigging and masting at this point. it is huuge. 3 meters long ! , beam about 450 mm. I settled at builing it from 2 water level up, as I always liked sea level ships more, being able to install water later on and for practical reasons to compensate a massivness so it is not that big to move. I do respect deeply small scale builders and I confess I am not able to put eyes and fingers to that torture or passion´, whatever you call it, FInally, I will mention a troubles of big builds, that have their own quirks as their advantages for detailing making atc....but bending those big lumbers is challenge.... following Campbell plan , thank you 1. not really engineering approach transferring plan, all 19 bulkheads will be approx 15cm from each other that will I hope provide very solid skeleton for 3 mm think single planking....

- 200 replies

-

- cutty sark

- clipper

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.