Jeff5115

Members-

Posts

69 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jeff5115

-

I purchased the Amati Endeavor J Class 1:80 scale on E-Bay. I wanted to build this model and since it was discontinued I took a chance and bought it. All the parts are there except the blocks. Could someone please tell me what size blocks I need to purchase? I think all I need at single blocks? Any help would be greatly appreciated.

-

My next build will be the King of the Mississippi. I saw the kit years ago and loved it. With AL out of business I was very happy to find one.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

Hull assembly is now complete. Other than some sanding and trimming some pieces all went together fairly easily. Now on to the masts, rigging and sails. This is the part I am really nervous about. Especially since I will be working from plans instead of instructions. Time to take a deep breath and slow down.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

You may want to include a price range

-

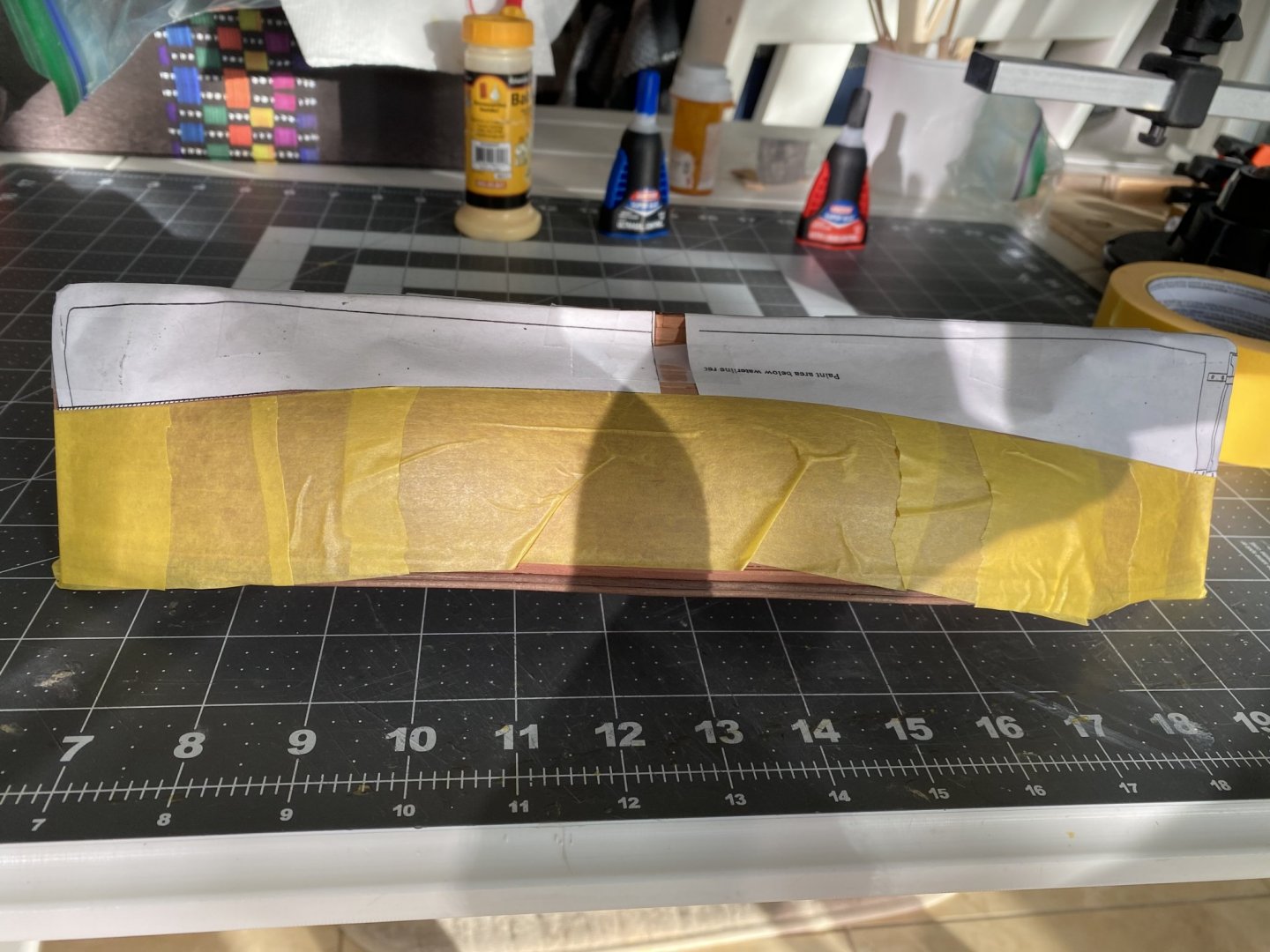

With the waterline re-drawn the hull was painted again and it does look better. Next I will paint the boot top. However, I have to decide what to do with the top of the hull. Since I only have the one lower rubbing strake. I purchased some 1 x 1 wood but it obviously does not match the pear wood rubbing strake. The choice is to use the wood and paint the top portion of the hull black. I would prefer to leave it natural wood but I do not know if these types of vessels would have ever had just one lower rubbing strake. If someone could let me know I would appreciate it.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

Thanks James. I have gone back and used the Amati waterline marker to draw new lines. They now look much closer to your picture. It is actually good to new that I was using the waterline marker correctly. This model has been a great learning experience and loads of fun to build. Hopefully my ship modeling skills are improving and can carry over to future builds. I am absolutely hooked on this hobby.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

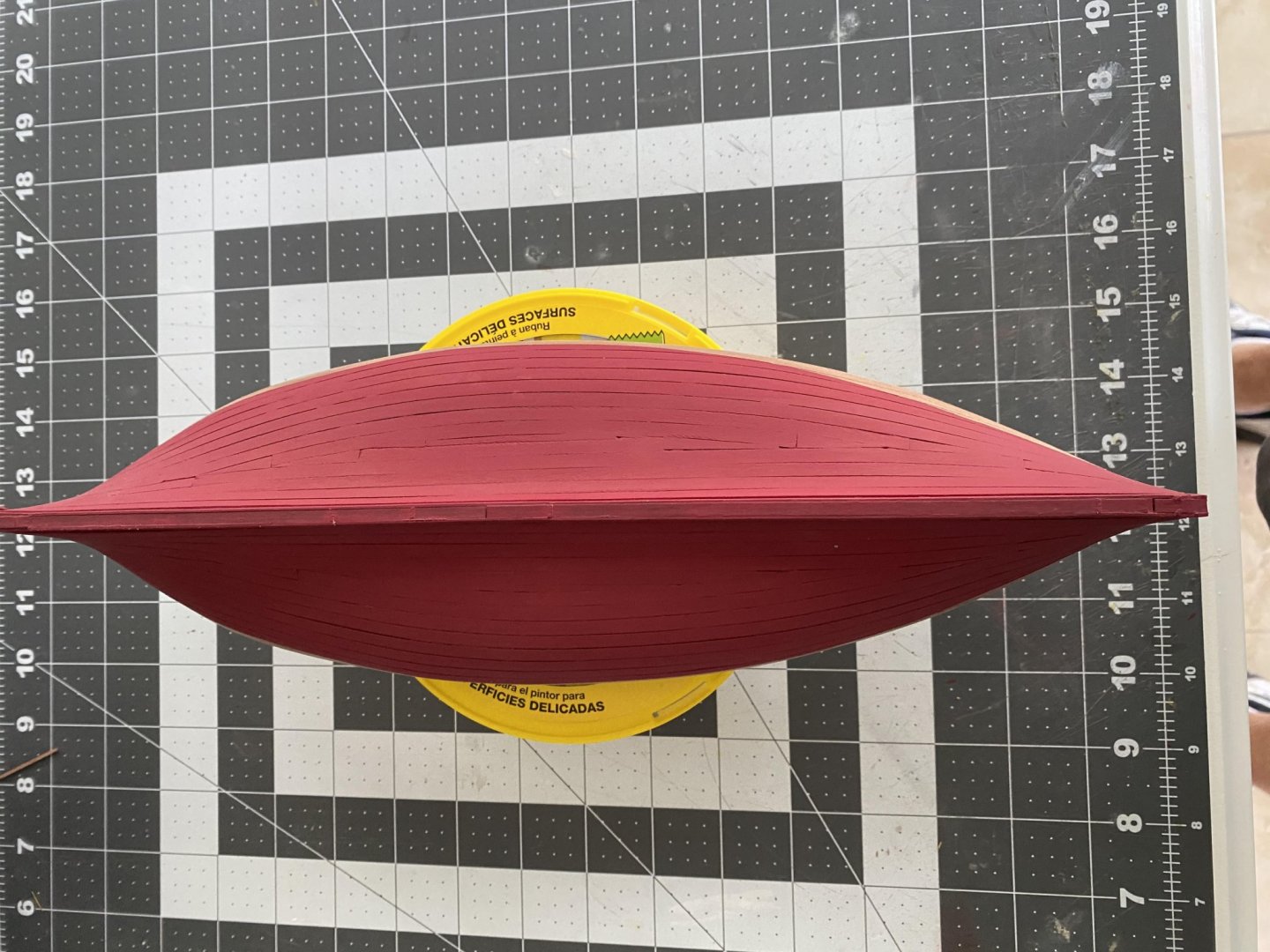

I sanded the hull and then glued on the rubbing strakes. Unfortunately, I snapped one of the strakes in half and beyond repair. Because of the mistake I only have one lower rubbing strake instead of the two. Ordered some 1 x 1 stock and if it is a good match I will use it. The other option is to paint the top of the hull in black. I tried to use the Amati waterline tool but the line went way too high in the center of the hull. I saw that BE had the same problem in his build log. On to plan B. I made a copy of the plans showing the waterline and cut them out to use as a template. The hull was taped off with frog tape and painted with Vallejo red paint.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

The second planking started out quite well. I was able to get 7 planks on without tapering any planks. I was able to complete the planking but did need to add a stealer plank on both the starboard and port sides. I am not sure if this is an acceptable technique to use on the second planking.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

Nice job John. I just added this model to my collection and am following your build with great interest. I am also a newbie builder and hope I can learn a lot from you.

- 45 replies

-

- j-class yacht

- amati

-

(and 2 more)

Tagged with:

-

Next up was the start of the first layer of planking. This was the point as a newbie I was dreading. Just hoping I could muddle thru this step without ruining the model. While the planking may not be great I was able to complete the first layer.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

After fairing the bulkheads the it was on to gluing on the bulwarks. After gluing on the first side of the bulwarks I noticed some small indentations from the clamp pressure. This was resoved on the other side by using some scrap wood under the clamps.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

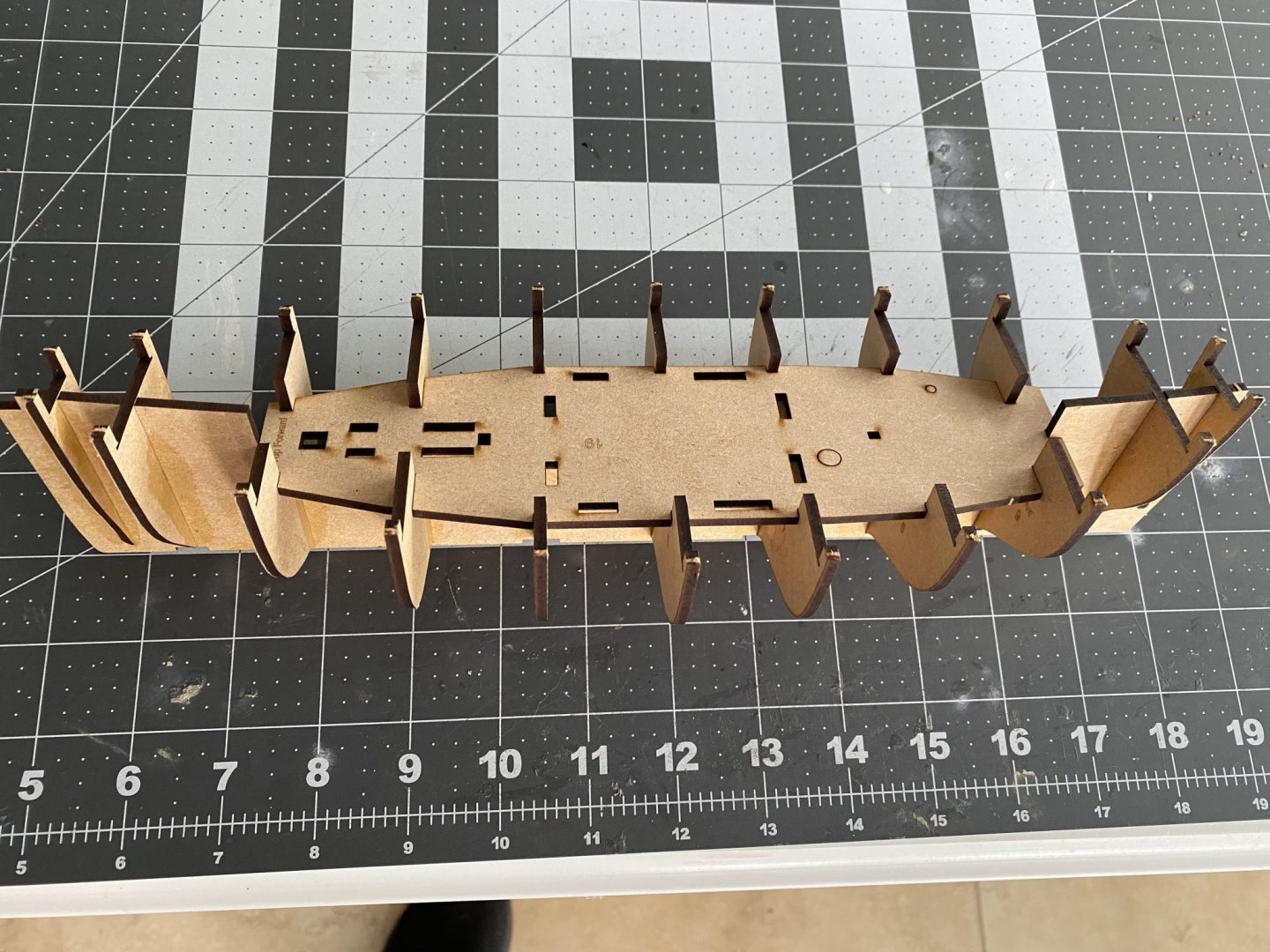

The bulkheads and some of the infill parts had engraved lines on them. These parts were beveled prior to gluing on the hull. You can see in the pictures the beveling helped as a starting point to begin fairing the bulkheads. You can also see the false deck has been glued down at this point. The deck fit into a recess on each of the bulkheads so it was perfectly aligned. This step was a little nerve racking as the deck had to be nudged into position and I was concerned about it cracking. Once I had it in place and dry fitted I was not going to remove the deck as it takes a little work to get into place.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

After deciding to try out this hobby I made my first mistake. I selected a ship that had poor instructions and did not have a single build log on this site. I have put that model on the shelf for now and decided to look for a model more fitting to be built by a newcomer. After seeing and reading the build logs by James H and BE I was very interested in building the Lady Eleanor for my first ship build. The Vanguard model site had the complete manual for this kit available for reading. That convinced me that between the other build logs and the very complete instructions that this was a good kit for a total newbies first build. The model is extremely well built and the directions take a beginner thru the steps assuming you know very little about ship building and terminology. I really appreciate the instruction detail and there are plenty of photos to help visually with the build. The initial building of the bulkheads on to the false keel was very easy. The bulkheads fit snugly into the keel and required no squaring. Here is the ship assembled with the bulkhead and sub structure put together.

- 38 replies

-

- vanguard models

- fifie

-

(and 2 more)

Tagged with:

-

This ship is on my future build list as a possibility. Thanks for the detail in your build log as it is always helpful to learn from others. Have you seen the build tutorial for this ship on the Amati website?

- 34 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

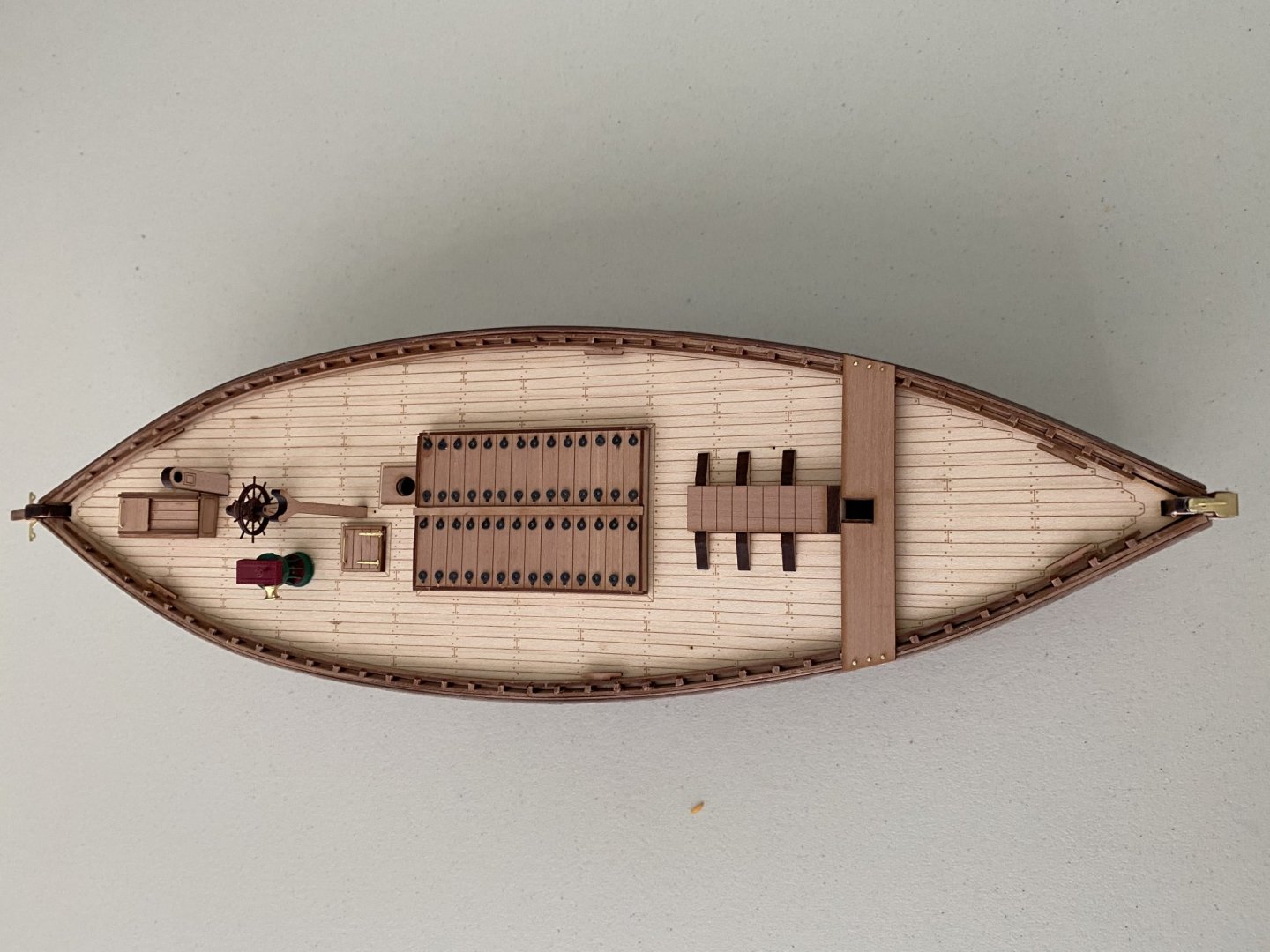

All of the metal fittings and the deck furniture have been placed on the deck. I had to rely mostly on the plans because the instructions did not have much detail. Made me very nervous but in the end I think I got everything placed correctly. Both the companionway and the skylight were scratch built using the plans. They look just OK to me. Since this is a learning experience I am glad I am learning how to use plans and hopefully my build skills are improving.

- 13 replies

-

- model shipways

- katy of norfolk

-

(and 1 more)

Tagged with:

-

My Fifie is arriving today. As a newbie I find myself studying other builds on this site to gain knowledge and see what other build challenges and success others are having. I looked at the build log by James H and thought that this would be a good beginner model for me. After visiting the Vanguard Model website and reading the manual I ordered the ship. I have to compliment Chris Watton on his website design. He includes the manual on the website for his ship offerings. This allowed me to read thru the manual. The level of detail for this ship is just what I need right now as a beginner in this hobby. My current build plans and instructions lack the detail I would have wanted as a newbie and is making things difficult for me. Also there are no build logs of the ship I am working on. So the info you can provide in your build will be very helpful I believe to someone like me.

- 195 replies

-

- lady eleanor

- vanguard models

-

(and 1 more)

Tagged with:

-

I am working on my first ship model which has a solid hull. I have been using an electric drilI and found it difficult to accurately drill holes. The kit required drilling of masts at two different angles and even the precise position of the hawse cheeks were a challenge. What is the method that would produce more accurate drilling? I am not opposed to purchasing a rotary tool drill guide or even a small drill press.

-

Been a while since my last build update. Scuppers have been cut, stanchions, covering boards, cap rails, side sheer molding, wales, and tiller all added and painted.

- 13 replies

-

- model shipways

- katy of norfolk

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.