-

Posts

257 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by acaron41120

-

Looking for an image/photo/drawing of the 1813 HMS Carron. It was purchased by a British captain and renamed the HMS Duncan. Any info or what the ship looked like would be really appreciated. Thanks.

-

I was just surfing the net and found a company that carries about all wooden ship model kits. To name just a few I saw Mamoli, Ochre, and a lot of others. Many of you know about them but in case you didn't check out Ages of Sail. And no...I'm not promoting them, just providing a site to our members.

-

Interesting question that I've actually never thought of. Each to their own in this case. In all my builds I've used the etched deck as the false deck and planked over that with the planks supplied in the kit for the deck. I use a wider planking strip for the margin planks and a slightly thicker plank for the king plank.

-

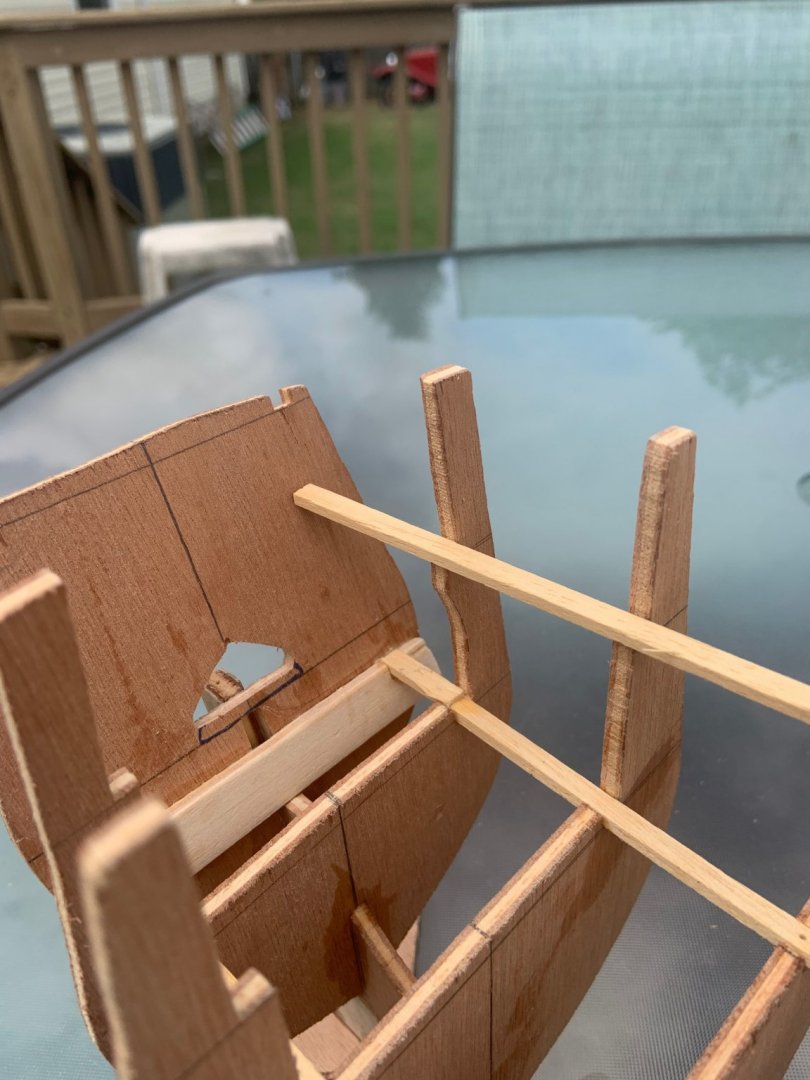

I'm about to fair the bulkheads. I have the main deck (false deck) in position and temporarily secured with push pins. Before I start sanding to fair the bulkheads two questions come to mind. The first is should I secure ALL the decks or just the main deck? Second is the batten that I want to add along the top of the bulkhead to keep them in position.What thickness should that batten be? Would 1/4 inch square be too big?

-

I've heard of and used the pencil method on both my later period ship models. But only on the deck planks. Never heard any mention of simulating caulk on the hull planks before. Interesting idea and I guess on the real ships of those times some sort of caulking method was used. But I've never have read anything about it. I too would like to see a photo of a model ship with hull caulking.

-

Thanks to all who replied. And thanks to this site I found yet another book on planking. Well...more of a pamphlet than a book as its only 16 pages with illustrations. The title is "Planking Model Ships" A step by step procedure for beginning and advanced modelers written by Richard Mansir. Looks to be a series of workbooks by Moonraker as it is workbook number 1. I'll have to check out Moonraker to see if there are more of their books on line.

-

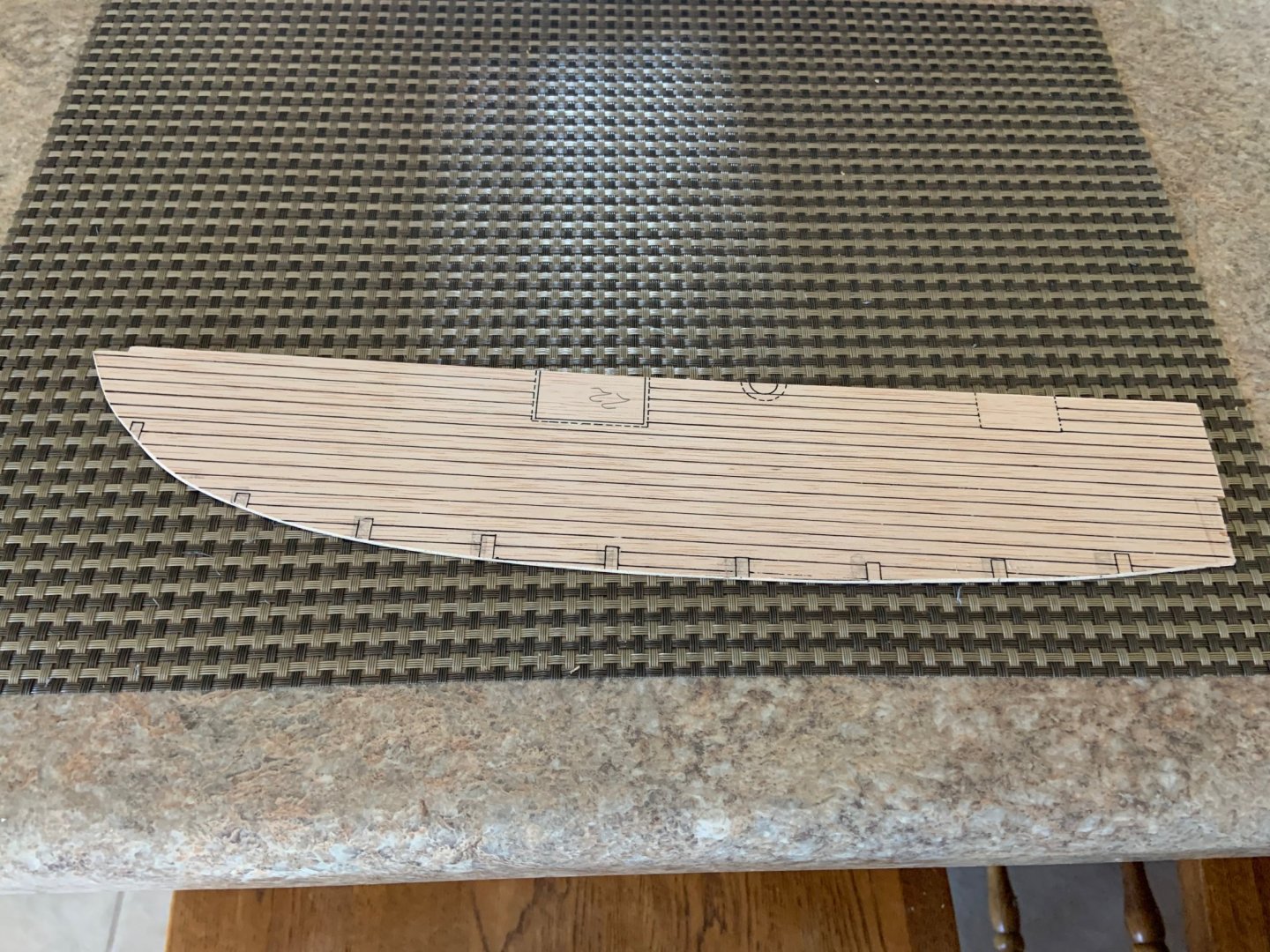

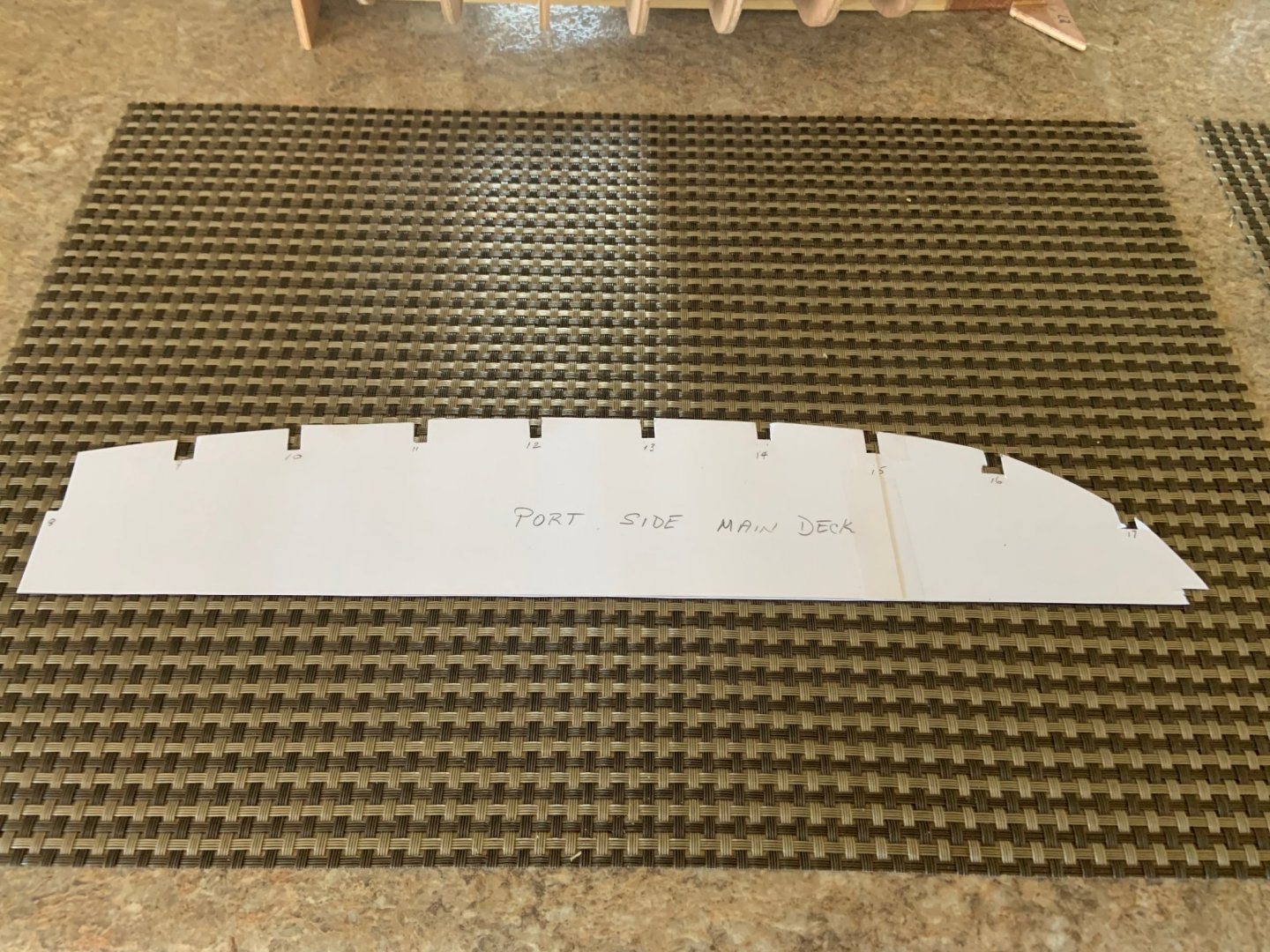

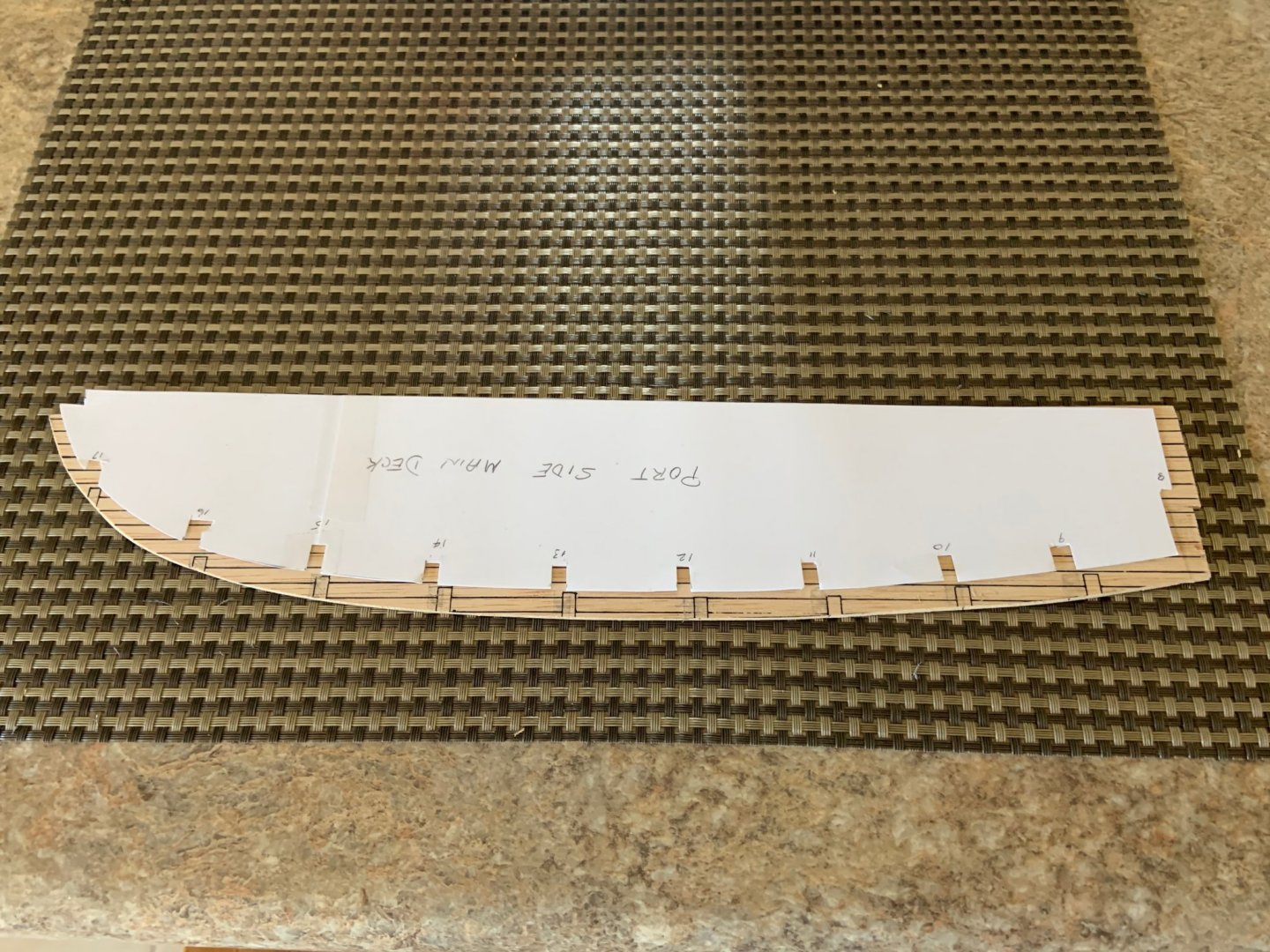

Posting this update for new builders to show how important a template can be when building their ship. These photos show the port side half of the main deck. The first is the deck showing where to mark the cutouts for the bulwarks. The second is my fitted template with the cutouts where they belong. The third shows the deck with the template showing how much the marked deck can be.

-

I've seen this section and really haven't figured this out. It sounds interesting but just what is the purpose and idea behind a group project? It really sin't explained.

-

PJ. Here is the link to my build log.

-

Welcome PJ. Je suis Allen Caron from Warner Robins, GA. You have come to a great site and as said before please do a model blog. I am building the Santa Maria by Billing Boats. It will be great comparing your ship and mine as we do our builds.

-

Welcome! If you need assistance this is the place to get it.

-

Artesania Latina has a 1:50 San Francisco Cross-section on eBay for a little over $100. Most others I've seen come from China and I'm not certain to their accuracy.

-

Not sure if this is the correct title but there are kits out there of, oh say, the HMS Bounty, where the kit is just the section of the ship at midship and when complete it is displayed on a wall shelf etc. I know its a personal preference/liking but I'd like to know what the builder of these thought and were they satisfied with them. Allen

-

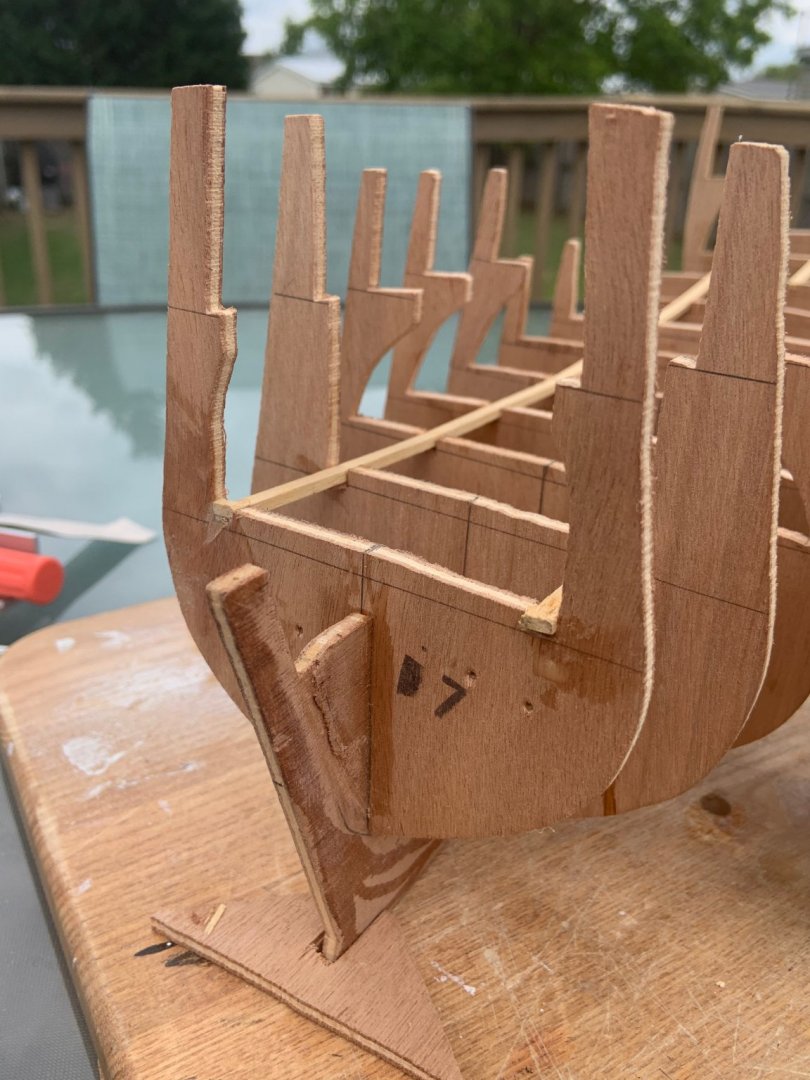

Well had the build going and while checking for everything being square I found that the stern (Bulkhead in this kit) was improperly installed by myself. So today I carefully removed the bulkhead 5 and 6 and made the necessary corrections and dry fit it to recheck. So far so good. What follows is the misalignment and repair photos. I believe that I was paying more attention to the placement of the opening for the tiller than the plans. Lesson learned. This is how the stern lined up. I don't know how to edit the photo but the notches on the top of the bulkhead should line up with the notched second deck. The plank shows where the top of the bulkhead should fit. This meant I had to remove the stern bulkhead and associated lumber. This is how it looked after the stern bulkhead was removed. Still had some cleanup to do but I didn't have to fabricate two new pieces. Everything came off nicely. Just a final cleanup then I'll do my first dry fit. This is the stern post after the bulkhead removal. A little more cleanup and then start reassembly. This is a dry fit to make certain that all lines up as it should. Final dry fit. Now I have to plug the opening for the tiller and move it where it should be.

-

So a ships wale is used to protect the hull from damage caused by the ship hitting the dock/pier?

-

Chris. That must have been cool being tutored by him. You're a lucky guy. Thunder, that's the book I referred to a lot when building my other ship kits. I continue reading it especially now with building a blunt-nosed hull. I'm still having trouble understanding how to determine the number of planks needed on the hull and how to decide how many battens to use. I have never used that approach. I always started planking from the deck down and then from the deck up. But I'll figure it out and ask questions here.

-

I have read and reread an excellent book for model ship builders. Thought I'd pass this on for those who have never read it. The book is entitled "Planking Techniques for Model Ship Builders" and is written by Donald Dressel. This book covers all types of ship model building from Plank-on-Frame, Plank-on-Bulkhead and Scratch builds. Allen

-

Bob. Sorry for the length. I started the Billing Boats kits in 1977. The kits I built were (in order of build): Marie Jeane Bluenose Bluenose II Oseberg Roar Ege Santa Maria (just started) Until I found this site I was okay with Billing Boats. I selected them for two reasons the primary was because my first build was while stationed in England and that was the only boats the store in the city carried. The second reason was their rating system for builders (beginner, advanced beginner, intermediate and expert). I have stayed with them because of familiarity. But somewhere between 1980 and now they have made a number of changes. The biggest was their rating system. The Bluenose is a good example. It went from a 1 star (advanced beginner) to a 2 star (intermediate) and their was no change to the boat that I can see. The quality of their kits was okay to me but that was because they were the only kit builder I knew. Since then I have found that their instructions are lacking in places and the plan views are lacking as well. As for wood quality they use a lot of mahogany strips for planking and now have switched to a less brittle wood. Abichi (I think). Since the internet came I have purchased all my kits from eBay. Same Billing Boats kits but found in estate sales and were less expensive than Billing Boats USA where I would have had to order them from. Over all, I think if you took the best parts from all the kits Billing, Maunta, Artenesia, etc.) you'd end up with a pretty fantastic kit. But even more expensive! Allen

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.