-

Posts

252 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by JKC27

-

-

30 minutes ago, Javelin said:

I wouldn't try to connect styrene to wood. Due to the different expansion coefficients it's likely to crack at the seams.

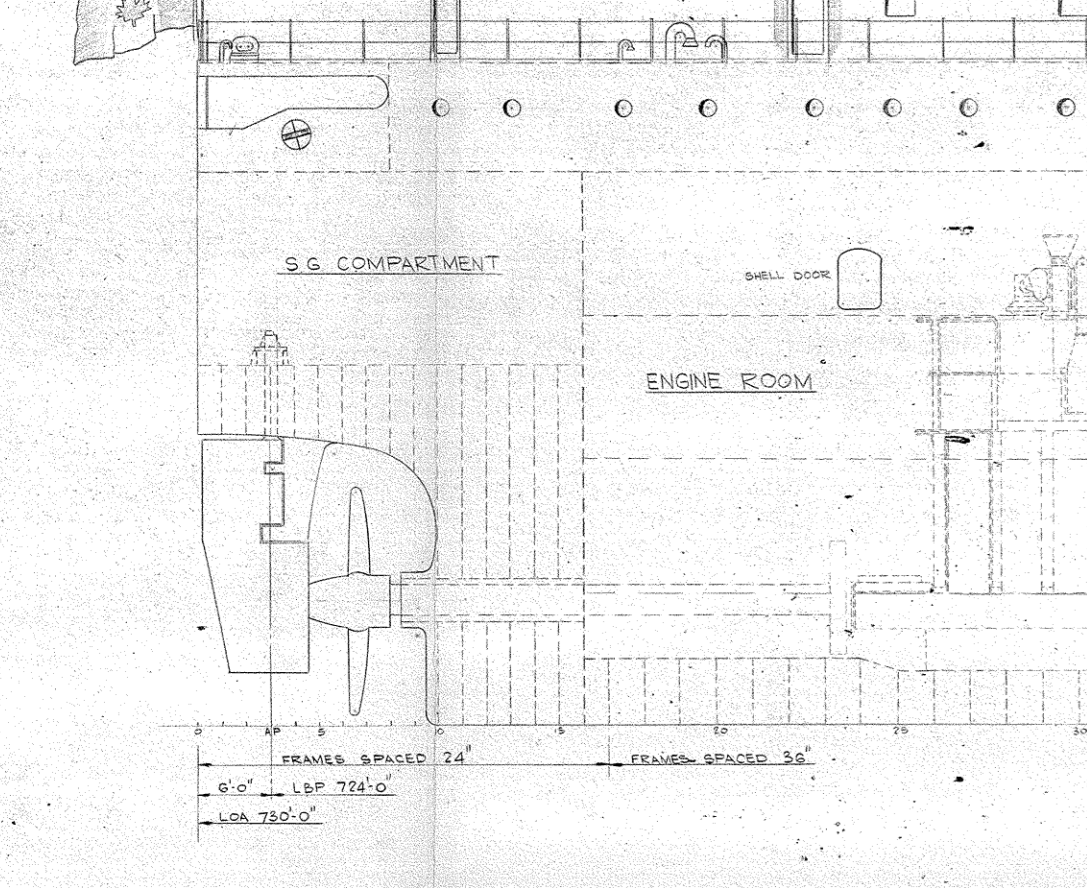

It's not fully clear to me what the shape of this vessel is from the plan, I'm assuming a twin prop -twin rudder configuration?

If you want to go full styrene, I guess making styrene strips (=planks) over styrene frames will be the easiest way in such an area. Afterwards you can fill the gaps with filler and sand smooth.

For the stern itself I'd make a false stern/last frame to end the planks on, then level all planks there and put the full stern plate behind that.

Although I'm mainly a styrene builder, I must admit for such a size model, I'd prefer wood. Styrene becomes very brittle and if you're making such a large detailed model, it might as well last for a while...

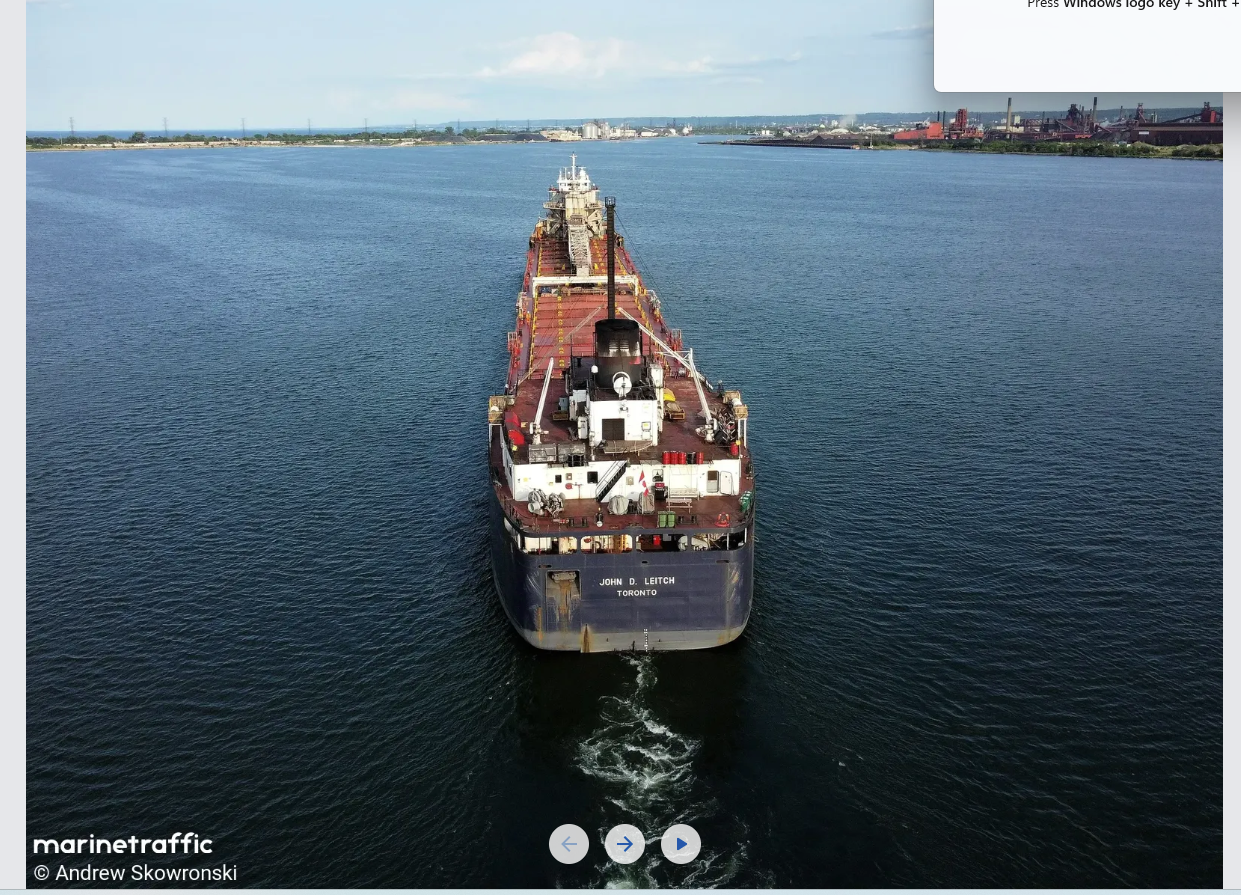

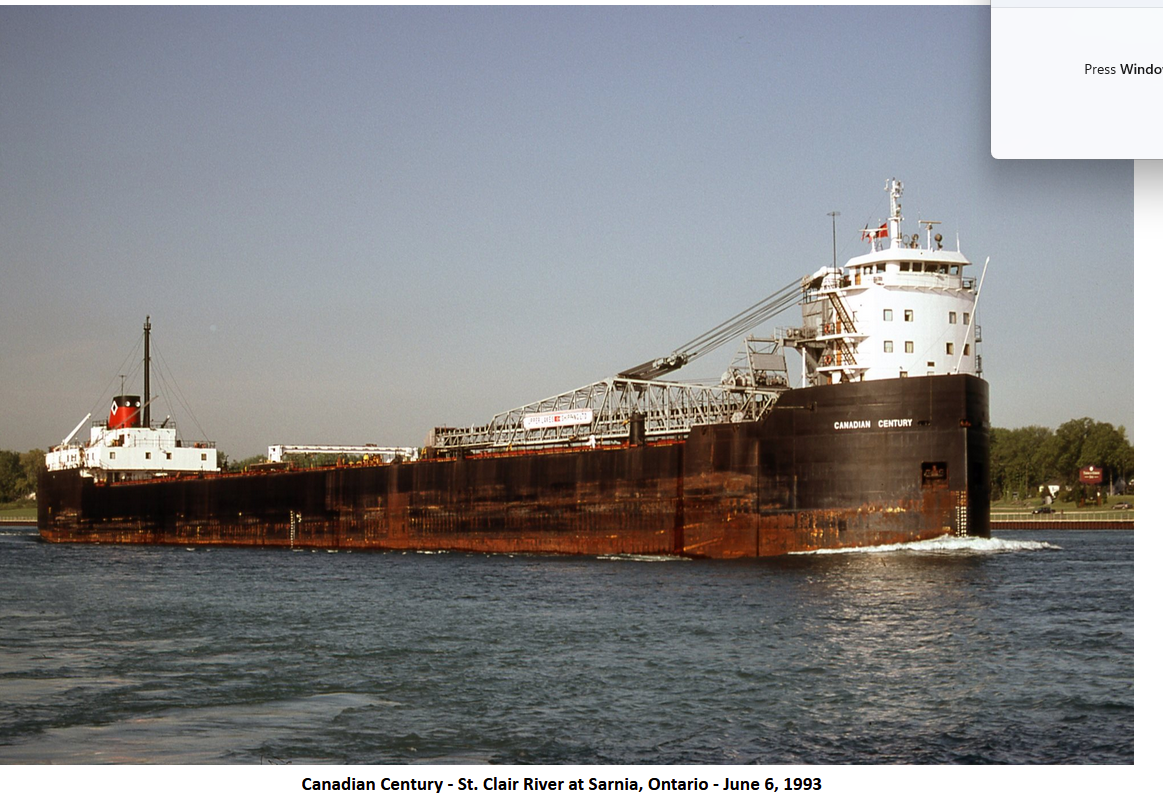

It's a single prop, 2 rudders. here are couple other pics I grabbed from the 'net.... Hard to see, but this is what she looks like. I really can't see a way of making the rudder/prop area with styrene.

-

Sorry that I didn't post my last completed build and it's progress, or my latest that I am working on, but they are also great lakes freighters.

My 2 builds (Algoma Strongfield - which has a build log on here) and it's fleetmate (Tim S Dool - no build log as mentioned above) were built from scratch at 1:200 and 1:192 scale respectively using basswood for their hulls. I like working with it as it's easy to shape and readily available, but a little pricey in my area. These are large ships, thus large models.

As I evolve as a modeller, I am always thinking of different ways to make my builds easier, etc. A model with a solid basswood hull that is almost 48" long is heavy. For my next/current build I have been working on building the pilot house, accomodations, etc..... actually building an unloading boom too which is turning out good (I will post pics for this build and make a log - I promise!). I plan to add led lights on the masts, cabins, and maybe deck if all works out. This has led me to consider doing a hollow hull. Doing so with basswood or balsa (even if for just the sides) is simple enough, and would the stern as a solid block. Leaving the solid block would allow for me to shape area where the propeller would attach, and rudders. However......I thought it be rather simple to do the hull out of styrene sheets, easy to weld together, but......how would I go about that back end area (pic included in this post) with styrene? I am thinking that wouldn't be possible......maybe somehow attach a carved wood back end to hollow styrene hull?????

Thoughts/suggestions???

- Scottish Guy and Paul Le Wol

-

2

2

-

Been a while since I've been on here, but wanted to chime in on this.

When this happened, right away media outlets were talking about this happening in the great lakes/seaway. Here in Windsor we have the Ambassador Bridge that connects Windsor, Ontario to Detroit, Mi - and the way it is designed/constructed (80+ years old now), there is no way a ship strike could happen, and the new bridge downriver that is almost complete, is also strike safe. The entity that oversees the St. Lawrence Seaway (all the locks, canals, etc.) also reassured the public that measures are in place to make sure this cannot happen.

-

Hello and welcome aboard from a fellow Ontarian (?)

- MBerg, mtaylor, Keith Black and 1 other

-

4

4

-

On 10/10/2023 at 2:29 PM, realworkingsailor said:

As a correction/addendum, (and a largely forgotten bit of lore) the cam style clamps are properly called Kestner clamps, and the patent for these clamps dates to 1947:

https://patents.google.com/patent/US2583053A/en

Andy

The other style hatch cover that @Roger Pellett is mentioning that are used on the new US build Mark W Barker, as well as a few here one some Canadian lakers namely Spruceglen and Kaministiqua, are called McGregor hatches I believe? See these commonly on the "salties". Large hatch openings for large size cargoes, as opposed to the hatch farms typically seen on the boats that carry grain or taconite.

- Roger Pellett, FriedClams, Canute and 3 others

-

6

6

-

How I just found this, I don't know, but I will say that this is breathtakingly amazing.........and RC even! Love the fittings, and the windows......top notch!

Your attention to the minute details is just fantastic. This ship almost reminds me of the smaller versions we have on the great lakes, that carry petroleum related products.

This type of ship is very close to my main interest, as well as style of build.

Great job!

-

Woodland Scenics makes nice dry rub lettering/numbering in different sizes/fonts. I used it white lettering on a dark blue background on my 2 builds (one is posted on here, the other I didn't do a log but will post pics when done).

https://woodlandscenics.woodlandscenics.com/show/category/DecalLetters

- mtaylor, paul ron and Geoff Matson

-

3

3

-

Thought this may be of interest to many folks on here. Thanks to my daily perusing of the good ol' www.boatnerd.com

- Canute, Roger Pellett, allanyed and 3 others

-

6

6

-

Thanks Gregory - PM sent

-

Welcome aboard Deyson!

Great resources here, and even greater people! I too took up the hobby when the pandemic first raised it's ugly head.

- ERS Rich, mtaylor, Ryland Craze and 1 other

-

4

4

-

For my current build, which I didn't create a build log for......sorry folks...... I am almost done, but need to print the company logo for each side of the stack as well as at the bow of the ship. I need the interior part mirrored, so it's facing the other way. The bear always faces forward, so the image below would be on the starboard side of the bow and stack. I need to rotate the interior only. I tried it with my previous build, but was unhappy with how it turned out and honestly took more time than it should have. I can't figure how to do it in paint, and I'm not well versed on this type of software. Resizing isn't an issue.

Suggestions on how to best do this?

-

Also.....just curious how the ship is mounted to the base or acrylic?

- thibaultron, Canute and mtaylor

-

3

3

-

Wow...this looks fantastic!

Great job on this. Sure makes me want to explore this as a possibility for my lake freighters.

- mtaylor, thibaultron and Canute

-

3

3

-

-

-

Call me crazy, and I can't find it anywhere, but I am pretty sure I remember someone on here posted a while ago about making deck lights using a certain type of nail or pin, and just bending the head?

Trying to replicate modern deck lights, just won't be illuminated of course.

Anyone remember this????

- Keith Black, thibaultron and mtaylor

-

3

3

-

-

I think I am coming along with this one now. Never started a build log this time though, supposed I could and get caught up on that!

Waiting on my prop and other fittings to arrive to make sure I don't have to make any adjustments before I sealing things. I did end up grabbing a can of the sanding sealer posted above and some find grit paper too. Been working on other parts of the ship and a Spitfire plane kit.

Hoping I can get this ship done for the model show coming up in September!

-

-

Been having some PC issues, and time (not enough of it) issues......

I am working on another great lakes freighter. I am again using basswood for the hull, and it is coming along nicely. I am getting to the filling in any gouges, gaps, etc on the hull stage. Sanding and filling with wood filler. This time around, when I paint, I want my hull to have a much smoother appearance so the grains of the wood are not visible, giving it a look of steel (smooth). My other laker build (Algoma Strongfield) turned out pretty good, but upon close inspection it still looks like painted wood - could be the clear coat I used???

Any suggestions, tips....?

-

Welcome to MSW, from the deep south (Windsor)

- mtaylor and Keith Black

-

2

2

-

Welcome aboard!

Chris said it best above......... I would say point 3 is, in my opinion, the most important. Find something that you are interested, and happy searching! Do you want to do a sailing ship.....a warship....sailboat....cargo ship....etc., then what era?

There are a ton of resources on here, plus online as well.

-

Roger,

Saw this on the daily boatnerd Today in Great Lakes History today:

https://boatnerd.com/today-in-great-lakes-history-april-27-2/

Today is the anniversary of the sinking of the Benjamin Noble in 1914.

- Canute, FriedClams, mtaylor and 1 other

-

4

4

-

31 minutes ago, Paul Le Wol said:

We stopped by to see SS Keewatin just after her arrival at Port McNicoll. She looked so sad and tired. I didn’t realize that they had done so much work on her. This is great news. Thanks for posting this.

I subscribe to the Kingston marine museum's newsletter and heard about it late last year, plus I visit boatnerd.com daily to keep up on the latest freighter news, and they also are very good at updating other related news stories around the lakes. I was hoping the timing would work out to be able to get down to the waterfront after work, and it worked out good - plus the weather was nice too. Seems like my luck usually has something like this happening and the ship goes by at 3AM.

- Canute, realworkingsailor and mtaylor

-

3

3

Exploring different ways of hull construction

in Building, Framing, Planking and plating a ships hull and deck

Posted

I actually picked up a couple bricks of hard styrofoam (XPS expanded polystyrene) from a local Michael's - called CraftFOM https://www.floracraft.com/products/floracraft-foam-xps/

really light weight, looks easy to carve/shape - not sure how you'd adhere styrene or cardstock to it without it melting though. I haven't played around with these yet. The only reason I haven't is the concept of trying to make it a smooth surface to look like a steel hull......adhering styrene sheets to it with the proper glue would melt it (I am pretty sure at least).