-

Posts

745 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Danstream

-

That's the look of bleached deck! Very well done. Dan

- 39 replies

-

- Amati

- Victory Models

-

(and 1 more)

Tagged with:

-

Thanks Roger! Please, go on and be my guest, but be aware that it is a deadly boring job 🙂. (I gave up with framing the small apertures).

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Hi all, just a very small update of my build. I prepared and framed the stern fascia and after some bending and tweaking, this part was eventually glued to its place. The result is not bad: The grain of the wood is very obvious and it needs to be addressed before painting it. The quality of the wood used for these type of pieces is quite poor, in my view. On the stern sides, I rebuilt anew the lateral fascia supports trying to match the involved angles and maintain the possibility of decorating them with the kit provided photoetched friezes. Finally, I went back to staining the deck with the aim of reducing the contrast between lighter and darker planks. After three light passes, I think I achieved a reasonable result. Just as a side note, because I didn't have any proper staining powder at hand, I ended up using my strong Italian espresso coffee as a staining agent that left a good coffee aroma to my model. Best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Good result Alan! I use the Vallejo Metallic on top of Tamiya gloss black and they work fine (I find the Tamiya X-1 better than the Vallejo's). As you noted, the preparation of the surfaces is as important as the finish itself. Note that these paints can be happily mixed with each other and you can obtain subtler tonal variations if needed. Following your build, though I am a bit silent in these days. Best regards, Dan

-

That adverb 'soon' sounds a bit optimistic, but thanks for your encouragement. My next objectives are to finish the transom, glue the small wales and the cap rails.

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Hi all, I finished the deck with surrounding strips that should finish off the edges of the deck and resemble a sketchy waterway. I also lightly stained the timbers, but the look of the deck didn't change much. Next, I glued on the main wales as required by the instructions (3x1 mm walnut strips, 2 strips each side). At the stern, this is how I terminated the wales: I am pleased with the way the wales turned out, but I don't like the way the ends of the planks look at the stern. I am considering to cover them with a layer of thin walnut strips to hide the ends and the thickness of their glue line. Another problem, also flagged by other builds and lately also by @flyenrw in his build, is the definition and the placement of the transom band and its side support pieces. I will see how to fit them to their intended locations. That's all for now, best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

The details and the finish are very good! I always liked the brutish and pugnacious look of the Tempest. I have also a metallic Tempest to be built in my stash. Just one comment, are we sure we are talking about natural metal finish and not a 'high speed silver' dope? I am mentioning that because this was the common finish of British planes after WWII when they were not camouflaged. Whatever the real finish was, yours looks great! Best regards, Dan

-

Maybe inserting a brass pin into the joint? Drilling into the leg isn't too difficult, you start with a very fine bit and then progressively large ones. Drilling a socket into the wing is more critical, but it does need to be dead right, a slightly larger socket will allow for some angular adjustments. If you use CA gel, the gel will fill the larger space. Of course, you have to evaluate which thickness of the wing you have there, because the risk is to go through the wing upper surface. You have to keep the leg pieces correctly aligned in place until the gel cures. Please gauge your abilities before committing the parts, I have done similar things with reasonable results. Good luck, Dan

-

🙂 You are right, I will anyway not stain the deck and let it alone for a while. I am busy now with the wales which I am going to glue with CA because I don't want to use pins to keep them in place. Thanks also for the infos about the products for weathering. Best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Thanks Andrew, that's surely an effect to be considered. I am thinking of spraying the deck with a very diluted acrylic grey, say a matt neutral grey, to be sprayed after I sealed the grain as a sort of transparent filter. Do you have any experience on something similar? Thanks Ronald! I appreciate your positive approach. I will see how it looks after the varnish. See also my question in my comment above. Best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

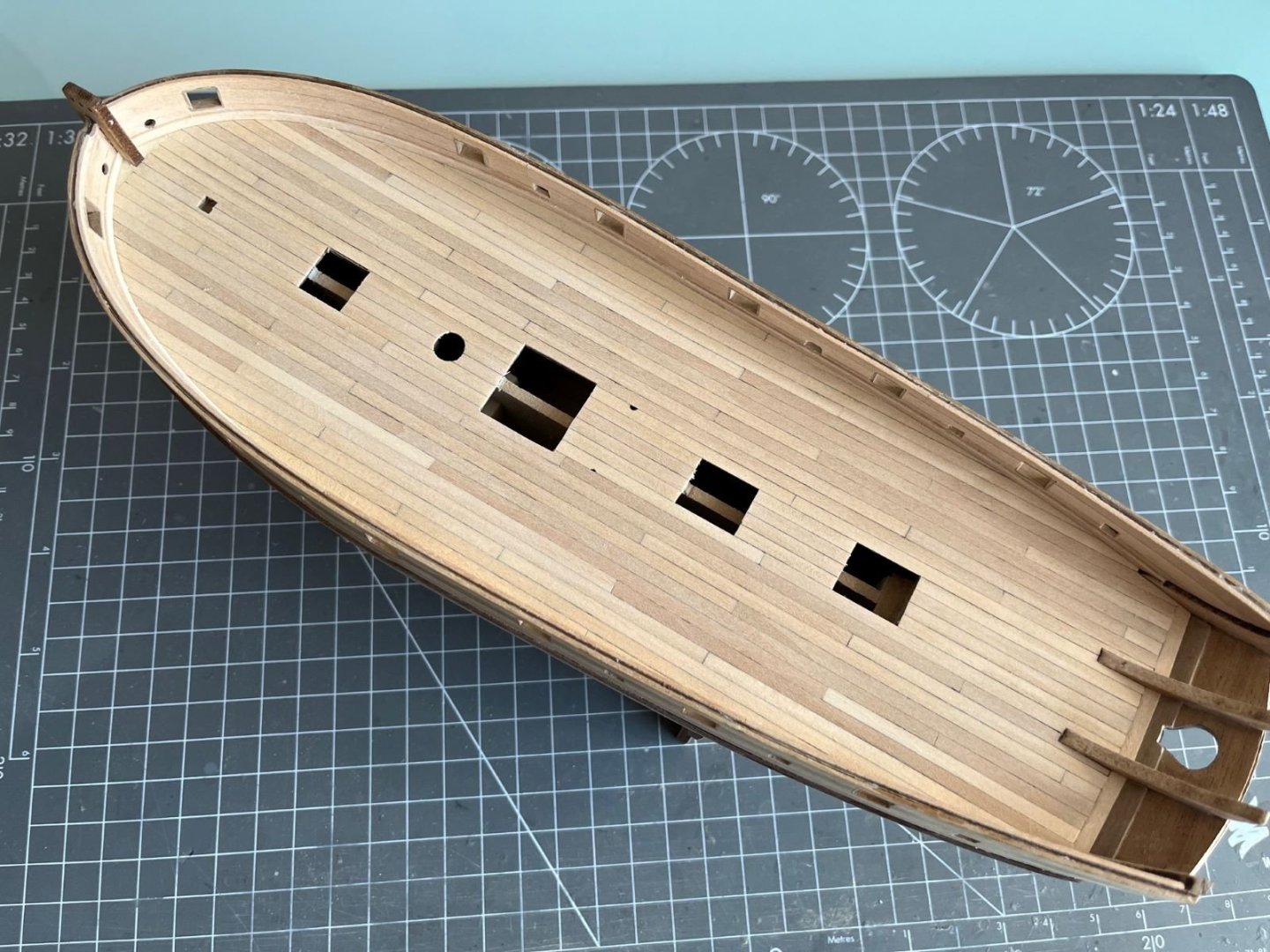

I just finished planking the deck. To be more practical, I took some short cuts and simplified the application along the bulwarks. I will refine them later. I didn't think of sorting the strips by their color, when I realized that they had different colors and the deck looked as a patchwork it was too late to do anything, hence I went on like that. I also sanded the deck with a fine grit. Next, I will seal the wood with a transparent varnish. Best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Yes, it should be vertical, but did you know that it shouldn't be symmetrical? It had a section like that of a wing (flat on one side and curved on the other) to generate a lateral force and assist the pilot at take-off to use less rudder pedal. Of course in a model it is hardly visible and I am mentioning it just for fun. Keep up the good work with this icon. Cheers, Dan

-

Good progress on the Aluminum (paint and bare). Do not forget the darker panel where the exhaust shrouds are located. They were made of steel and had a darker, shiny finish. They were so distinctive and you can see them in any picture of a Mustang. I also think that the version D is the most graceful and handsome one. Dan

-

@Canute, thanks for your first hand piece of experience! In my note, I was focused on drag reduction, but of course the most significant improvement achieved by of B.L. control by blowing is to keep the flow attached at very high angle of attack making possible flying at low speed, lower than those possible without it, as you reported. But I am blown off at knowing that the slat system costed as much as 1,500 pounds!! Cheers, Dan

-

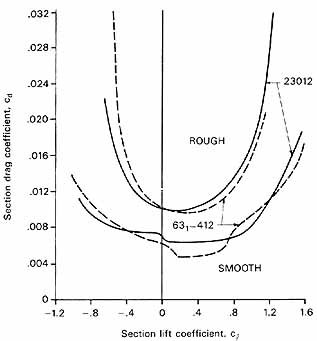

I am following with interest, I am probably the kind soul that enjoyed a discussion with @Egilman about this subject 🙂. I am sorry, but, with all respect, I need to comment few details about the description above, for the sake of precision. Definitely, aircraft from 1940 did not have the blowing systems described above. In addition, the blowing, sometimes referred as 'supercirculation' is not intended to reduce skin friction drag, but its purpose is to delay flow separation (hence to reduce the so called form or pressure drag) and not to maintain laminar boundary layer. Few example that I can easily remember that had this system (at the leading edge of the flaps) were the F-104 and the British Buccaneer, both having extremely high wing loading and the need to fly at high angle of attack at low speed. At very high speed, or at cruise, the angle of attack is very small and the blowing is not needed. Coming back to the Mustang, it had wings equipped with so-called 'laminar wing sections' that are sections studied by NACA displaying a shape that produced a favorable pressure profile which, in turn, delayed the natural transition from laminar to turbulent boundary layer. These were the 6-digits designation profiles like, for example, the NACA 654-415. North American did not implement strictly a NACA section but rather an in-house developed profile obtained by the same mathematical theory that NACA used for their 6-digits. The results and the mathematical theory were published by NACA and industries were made aware of them. The reduction of surface drag was completely passive and it was intended to increase the range or the top speed (which are closely interlinked). A bit of theory now. When air (or any fluid) flows over a smooth aerodynamic surface, it always starts as laminar. For high speed, after a very short distance, the boundary layer switches from laminar to turbulent, but this doesn't imply that the flow is detached. Flow is still attached, it follows the surface, but within the boundary layer, very close to the surface (for high speed we are talking of several mm) the flow doesn't follow parallel, ordered streamlines. With laminar sections, the region were the flow is laminar is stretched further back towards the trailing edge. The larger proportion of laminar over turbulent results, everything else being the same, in a smaller skin friction drag. (from: NACA Quest for Performance: The Evolution of Modern Aircraft, very interesting document, with little math that can be found on line) However, laminar boundary layers have also their negative points and one of the most important is that the flow is more prone to detach from the surface. Turbulent boundary layers are instead more robust and follow better the surface (see the paradox of the golf balls that with dimpled surface fly further than smooth balls). When the flow detaches from the surface, the form drag greatly increases. Sometimes, the laminar B.L. detaches and shortly after reattaches to the surface with a turbulent B.L. Often, it is desirable to have a turbulent B.L. because it follows better the curved surface of fairings (as in a golf ball) and rear portion of wings, especially in the areas where ailerons are located (I am sure you can remember aircraft having vortex vanes along the leading edge in front of the ailerons). The matter is governed by the numerous trade-offs and compromises that are at the base of the system design. In conclusion: Mustang had laminar sections to increase range and/or top speed. They worked with low angle of attack (or low lift coefficient which is the same thing). To work well, the surface of the wing needed to be smooth (see also included plot) and this was the reason for puttying rivets and gaps. However, it is also reported that small imperfections (like smashed insects or paint chipping) were responsible for having areas where the laminar B.L. switched to turbulent B.L. partly vanifying the purpose of these profiles. I am sorry for this long explanation, but the subject is not completely trivial and it is difficult to explain it in a succinct way, but a lot of sources are available on the web. I am particularly passionate about this subject that was part of my studies. I could provide reference textbooks to anyone interested to go deeper and I will be glad to discuss any comment or clarifications you might have. Best regards, Dan

-

Hi Roger, your description of what is going to happen in Florida is really scary. I read similar notes from other members of the forum that live in the affected areas. I hope it will be less violent than expected. Keep me updated and I wish you best of luck for this though moment. On a less serious topic, what you did on the hull of the model sounds good. I am going to apply a similar approach. Take great care, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

I am sorry to hear about your accident. But, hey, when it will be covered by paint I am sure it will be good. I am also counting on the paint to hide my mistakes. The planking of the deck that I am doing now is a much more pleasing and relaxing job. best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

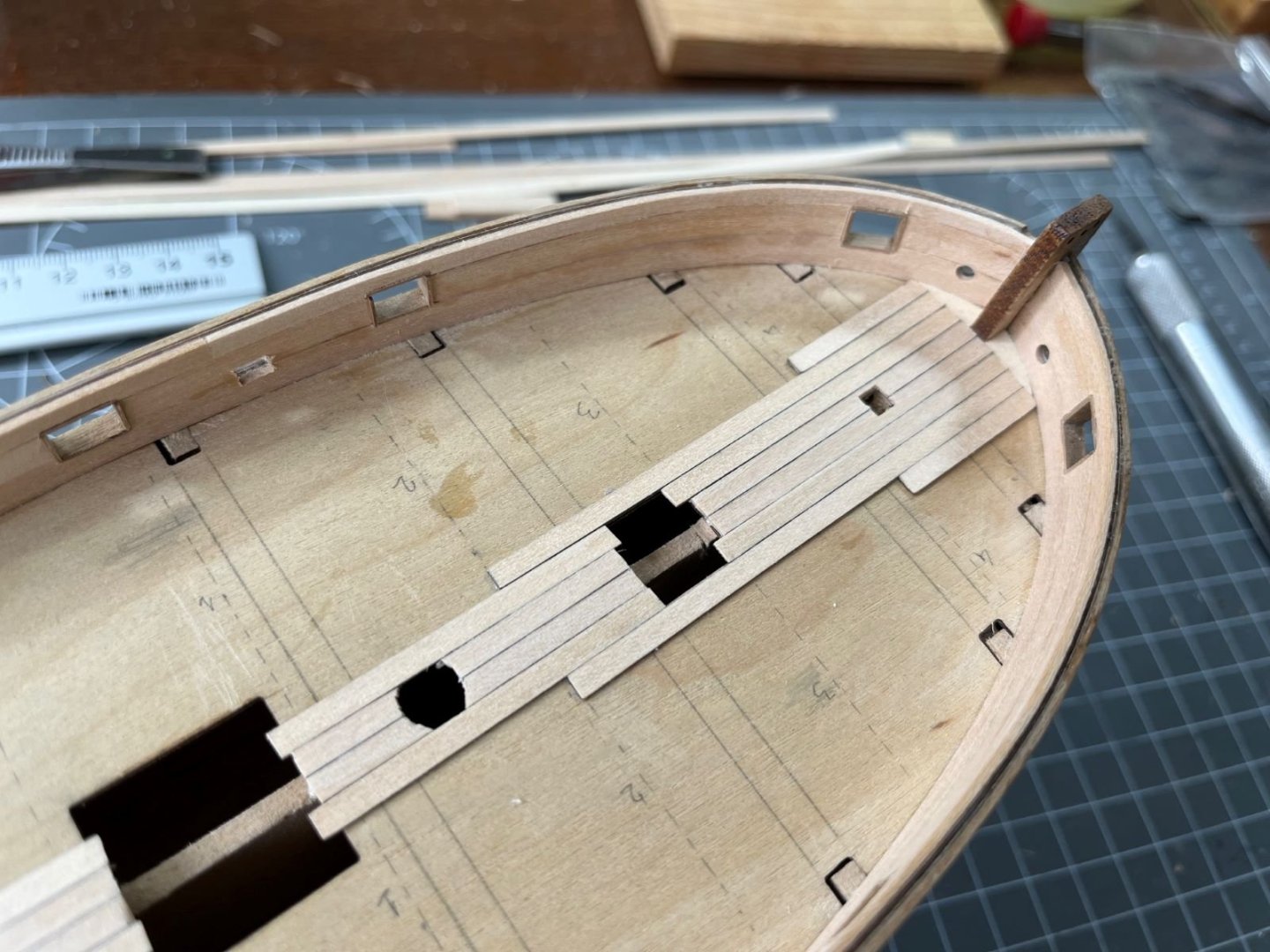

Hi, as anticipated, I started to frame the bulwark cutouts with walnut wood thin strips. I have mixed feelings about the results, I am till working on that: Meanwhile, I received the limewood strips the I ordered by mail, and started the planking of the deck. That's all for now, best regards, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

Beautiful model, with a lot of details to look at, neat workmanship, great representation of sails. Congratulations, Dan

-

I see your point. I don't know yet how I will solve it. Putting the model on its stand with a tilted waterline might look odd. I saw many models of cutters painted up to the wales, but I would like to avoid this a leave a bit of planking exposed. The other possibility, would be cheating and painting the waterline parallel to the keel. 🙃 Regards, Dan

- 39 replies

-

- Amati

- Victory Models

-

(and 1 more)

Tagged with:

-

Thanks Andrew! I ordered limewood strips 3x0.5 mm plus other various sizes. I like its color and little grain texture better to represent a discolored deck. Cheers, Dan

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.c459ce4140b54c12eddb8eedfd446df3.jpg)