DaveBaxt

Members-

Posts

1,324 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DaveBaxt

-

Thank you Allan and to everyone for their kind likes and replies. I am trying, but do find a lot of the upgrades difficult and don,t turn out as well as I hoped but hopefully some improvment on each previous build I have done. Fasioned a spectacle plate out of copper plate and then lightly blackened.

-

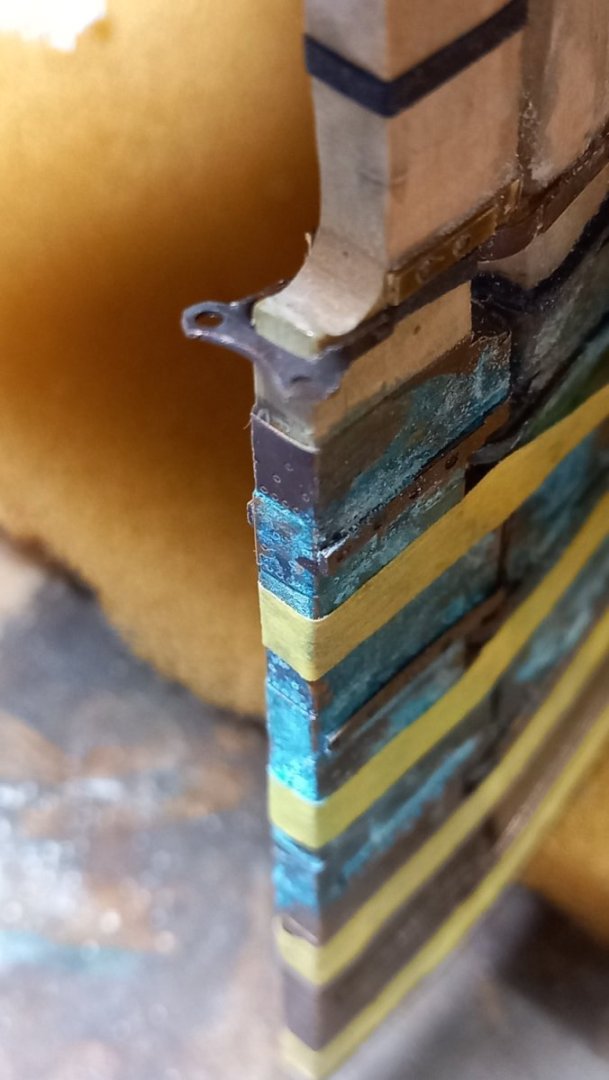

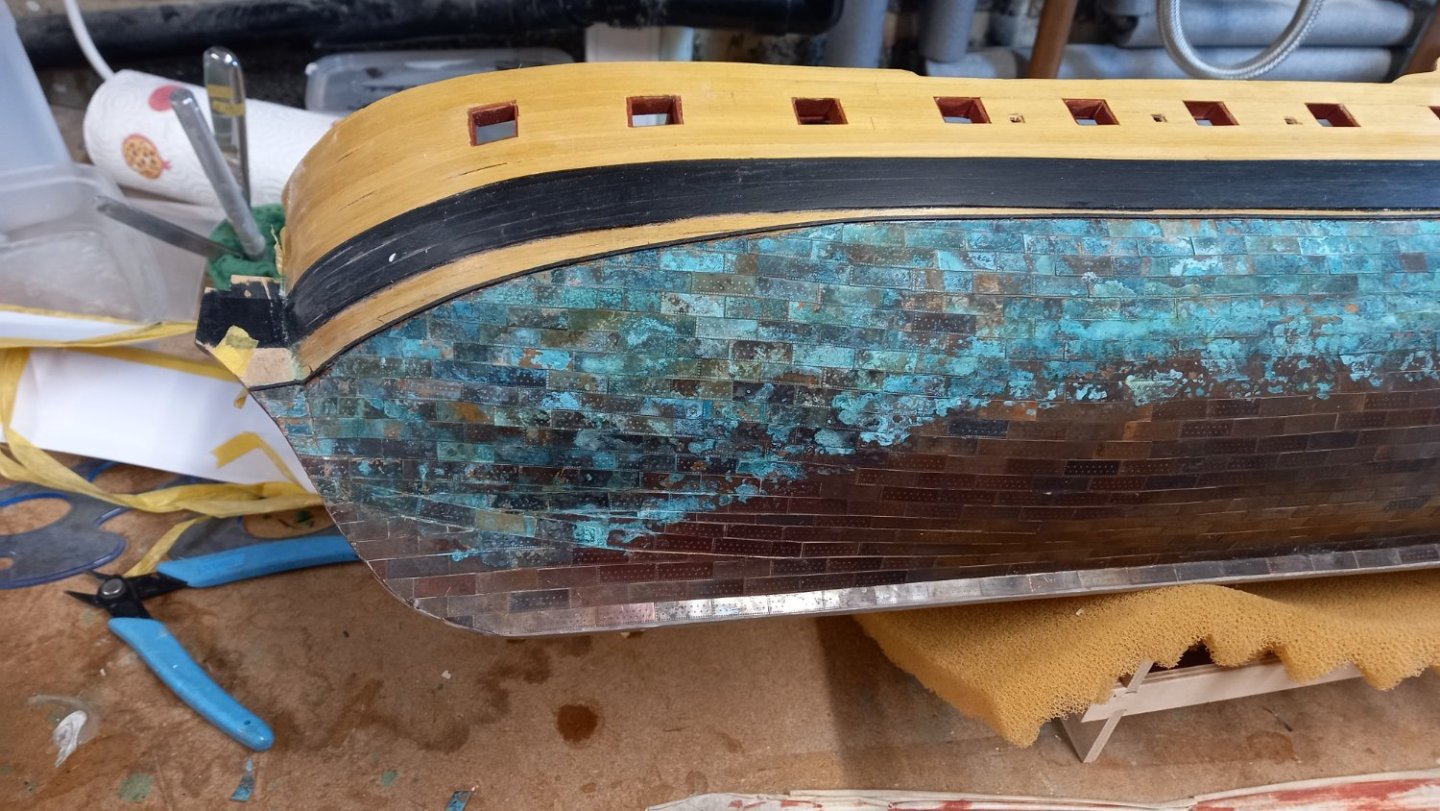

Rudder, Pintles and rudder brackets..I made a new rudder from 5 mm boxwood as the top of the rudder above the copper plates would be visible rather than the supplied rudder made from walnut . I also tapered the rudder as per the stern post .I also made my own pintles from boxwood rather than use the castings supplied by Caldercraft as I had a lot of problems with these when I used them on my Endeavour build. A big improvement but still far from perfect . Even though I fitted the pintles individually I still had some issues with the copper plates stopping the rudder from moving so ended up removing the tiles from the inner edge of the rudder to allow free movement. I then painted the rudder edge with Dark Star, aged copper acrylic paint . I also painted the rudder brackets the same colour to simulate a bronze alloy rather than blackened brass. See my question posted regarding the effect of electrolysis on Iron brackets when copper plates are fitted to the hull. I found this part of the build quite difficult and time consuming but eventually got there. I still need to refit a number of tiles which became loose in the process. I also need to touch up a few areas of weathering the copper tiles. I still need to fashion a spectacle plate but as yet have not come up with anything satisfactory wiithout resorting to soldering so looking for some ideas. Anyone?

-

I had assumed these were made from iron and hence the brass etched pintle straps are blacked using various blacking solution (Brass black being my preference) I then started wondering as to the effect of electroloisis between copper plates and iron pintlle staps, especially in salt water.perhaps there is something placed between the straps and the copper plates to reduceelectrolisis, or perhaps the pintle straps are made of copper too. I am asking this question due to finding a model wiith the brass etched pintle straps being painted with copper paint or perhaps the straps could be made from copper imstead of brass and allowed to weather naturally. Personally I rather prefer to have the pintle starps to be Iron as I like the contrast between the copper and iron but wonder what others think of copper pintle starps, when copper plates are fitted to the hull and how accurate this is in reality ?Thank you.

-

Small progress due to another leave of absence ( holliday). Cut out the sections for the scuttles and oars so that the doors would lie flush with the hull and also the 4" scuppers . I only fitted the 3 forward ones as I thought I would ensure the main mast chainplates were fitted to try and miss these if possible. Regards the hinges for the doors, the ones supplied are far to flimsy but managed to find some extra ones left over from my Endeavour kit which is the same 1:64 scale so a bit of improvement I think. I am also in the process of gluing the upper focastle drift rail but still need to make the decorative scroll out of boxwood as per the quarter deck drift rail. Some cleaning and touching up of paintwork is required.

-

Great books an resource for masts and rigging.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

It's starting to take shape now and after a couple of early minor hiccups you must now be pleased with your progress so far. Are you just following the instructions or are you using any other resources? Looking forward to seeing your progress as I think your workmanship is on a very high level.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

I found the drawing of my first build very frustrating but still do to some extent however there are some better ones out there. There is a poll on here which gives you an idea of which kits have the better instructions. I have found Caldercraft very good, especially for rigging. I also understand that Vanguard are up there with the best and have become very popular. Something I am definately consodering for my next build. Anyway for now I agree starting of with a build log is definately the way to go .

-

I have sepent the last couple of weeks replacing the different walnut rails supplied by Caldercaft with 2.7mm square boxwwod and made the the scrolls out of 1.5mm thick boxwood veneer. This has been my first attempt at carving using both 1.5mm Vee chisel and a 1.5 mm gouge. Not too bad but I still could do with a bit more practice. I also used Amatis shapers to get what I thought looked a pretty good profile of the rails but not as accurate as depicked in the AOTS book. I did try and make my own shapers out of safety razors but they did not turn out as good as the Amati shapers or by some fellow modellers on MSW.I also made up the fenders from 2mm boxwood sheet, which I already had in stock. I have followed the Caldercraft instructions as per fitting of the upper sheer rails but have fiited the rails at the channels and left out sections of this rails to allow for the positions of the fore and main channels. I have two more rails to do to fit on to the hull which is the smallest of the rails which are the quarter deck and focastle drift rails. I have tried using 1mm square boxwood for these but think this is too small. So I have ordered some 1.5mm and 1.8mm square boxwood to see which looks the better and whilst I wait for this to arrive, I can move onto a number of jobs which I have put on the back burner for one reason or another and I need to return to these to finish off the work on the hull. This work is mainly the sweep ports, ventilation holes and scuppers. Once again I will be following with the Caldercraft instructions and moving onto the head rails and what I also think will be another daunting task.

-

Welcome and good luck with your first model ships. Don,t forget to ask any questions as there is a wealth of knowledge on MSW.

-

Thank you Theodosius for your coment .Yes I think I went a bit overboard with the weathering and tried to be a bit too reralistic. If I am honest I am not sure if I would use copper plates again as I still believe the nails on the Amati plates are still too big for the scale. I have heard a number of modellers using paper plates dipped in shellac. I have also been doing some experimenting airbrushing acrylic ( aged copper and verdigris) and thought I might try this instead. I think the verdigris look is a bit like marmite tou either love or hate it.

-

A big thanks to DavidEn, Dunnock , Beef Wellington and Ray for all the help with their fantastic Diana Build logs and their approach to the stern and quarter galleries. I have still not managed to get it exactly right and ended up with every thing being a little too high I think .After several attempts using the parts supplied I ended up making a lot of the parts myself but thinking back I probably could have used the parts supplied but think the cast rails and some of the brass parts could have been better defined. I also used the blue paint recommended by Dunnock rather than the dark blue supplied by caldercraft. I also added an extra layer of 1mm wood to the transom and I made the tefferail using 3 mm boxwood to get the concave effect on the lower curve. I also used the brass windows and painted them white after pickling and priming all the brass parts.. Making tafferail out of 3 mm boxwood and shaping to take brass parts and to give a concave effect Gluing tafferail into position Placing decorative rails in position to line up with the position of window quarter galleries . This was rather difficult so ended up making new window frames to hopefully look right . Below Temporary lining up of quarter galleries with stern fascia. In After several different checks and double checking that everything was lining up correctly .In the above photo you can see that the frame for the quarter galleries is sitting too high, so removed and replaced so that the lower edge of the quarter gallery frame lined up with the upper edge of the counter. This ensured that the windows of the stern gallery lined up with quarter gallery windows. There is however some compromise with the lining up of the bottom of the lower gun ports with the bottom of the quarter gallery windows and think this maybe due to positioning of the gun ports to fit the bloomfield cannon so that the gun barrels would lie central in within the gun ports. First I glued the 0.8mm plywood back plate into position followed by the 3mm plywood top and bottom and finally the 0.8mm window fascia, also made from plywood. All these parts were eventually made rather than the supplied parts to get what I felt was a better shape.and position. Starting to take shape. There is some more decorative rail to fit to the underneath of the quarter galleries and the upper and lower stern counter but hoping it will look presentable. Also one or two decoratie parts to fit and some touching up of paintwork, then fitting of the Tafferail to the stern. Gluing the stern fascia onto the the transom has been solved by a number of ingenious ideas from previous Diana builders and due to the inceased thickness of the tafferrail (3mm) I was expecting some difficulty with bending the stern facia into position and I thought the use of heavy gauge rubber bands would be sufficient to bend the stern fascia into position. I ended up with a bit of overkill using a combination of clamps and rubber bands. I also thought of using appoxy resin but only had 5 minute setting time at hand so ended up using ordinary PVA glue so hopefully this will be strong enough.The upper deck supports definately came in hand as did the very large rubber bands. Unfortunately I have made several mistakes and have become quite frustated with this section of the build, fortunately I think the mistakes are hopefully cosmetic and nothing too major. Although my Diana is nowhere near the standard of the previous Diana builds as my skill levels are somwhat under the very high standards of the many experts on this forums. Hopefully the result is still quite presentable because, as of this moment ,after what I feel has been a long time.I do not feel inclined to change anything on this section of the build for the time being. Perhaps I could return to this at a later date and replace the decorative strips using something more appropriate than the ready made walnut strip I had in stock. I do have some boxwood which would be better suited and using shapers for the required profiles. This is what I intend to do with the rails running along the hull . I have decided against adding the ships name to the upper stern counter as I understand this was not the pracice for this period but could be wrong.

-

Another thought due to so few 5 mm planks on smaller model, perhaps 4mm wide planks would be easier but of this would mean starting again and tepering them a bit more. Good luck. Dave.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

Sorry to hear you are having issues with the first planking. That edge bending looks tha same as mine so not sure if I am doing the same as you. Perhaps filler blocks would have helped but perhaps not needed with the number of bulkheads on smaller model. It will be interesting to see what Chris thinks. Good luck and hope you get sorted. Dave.

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

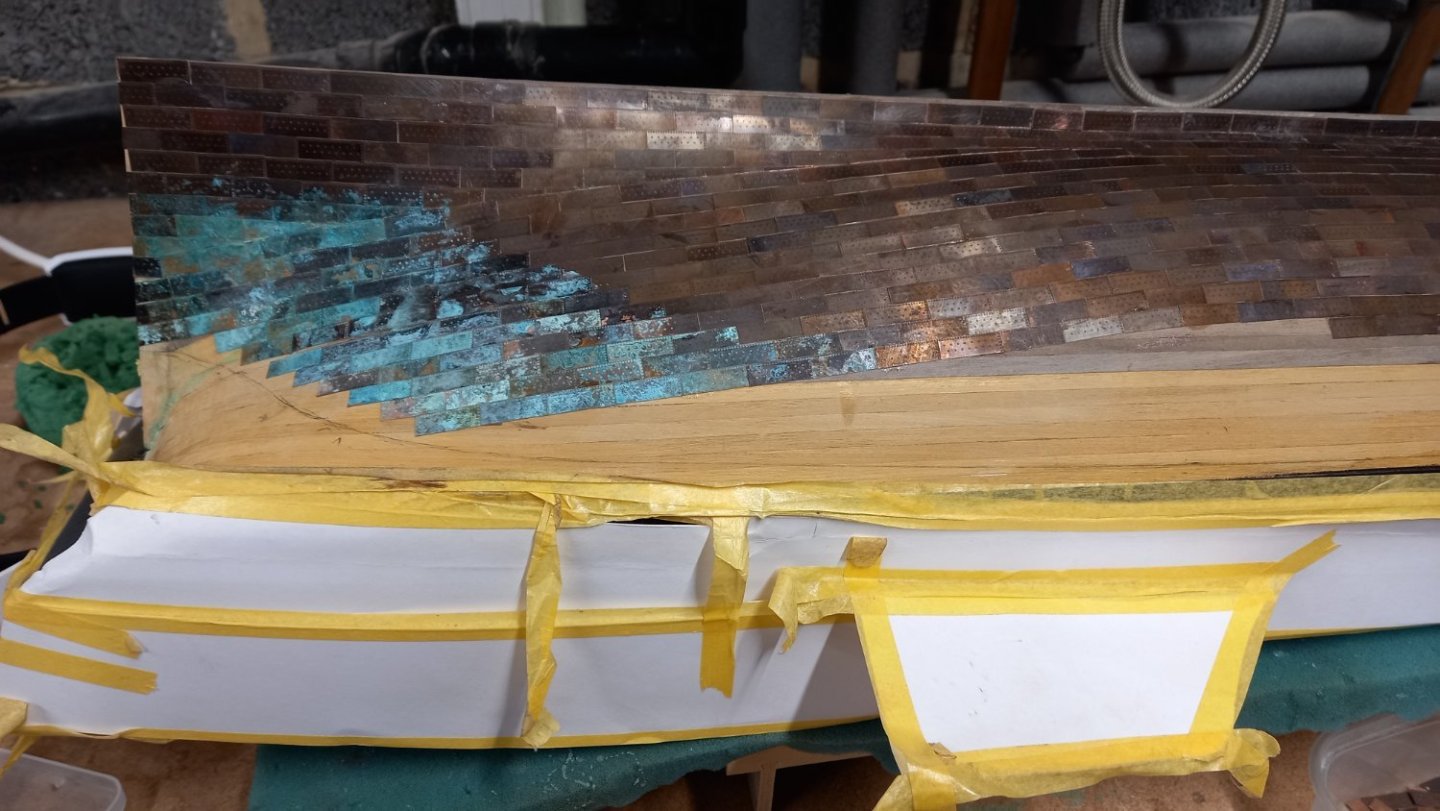

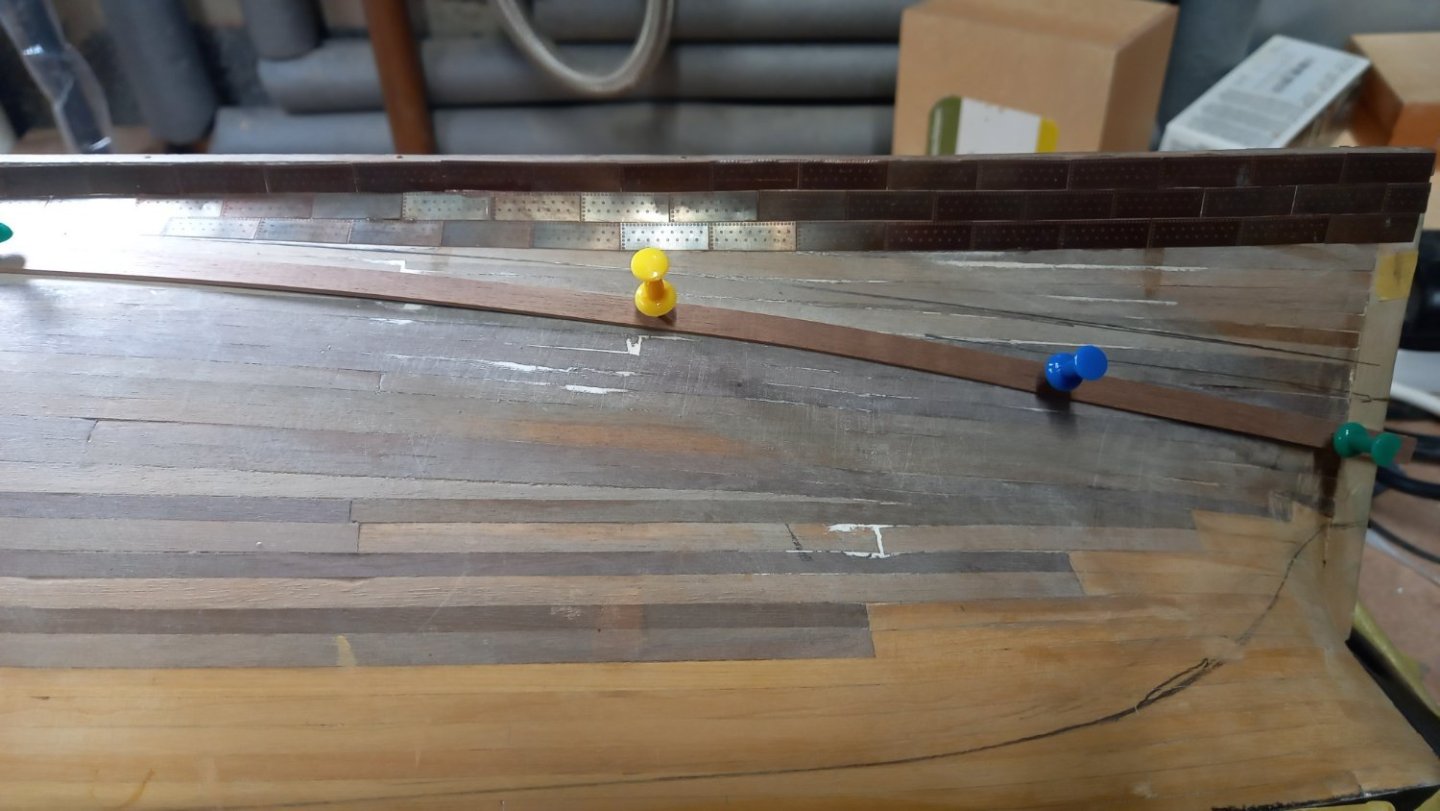

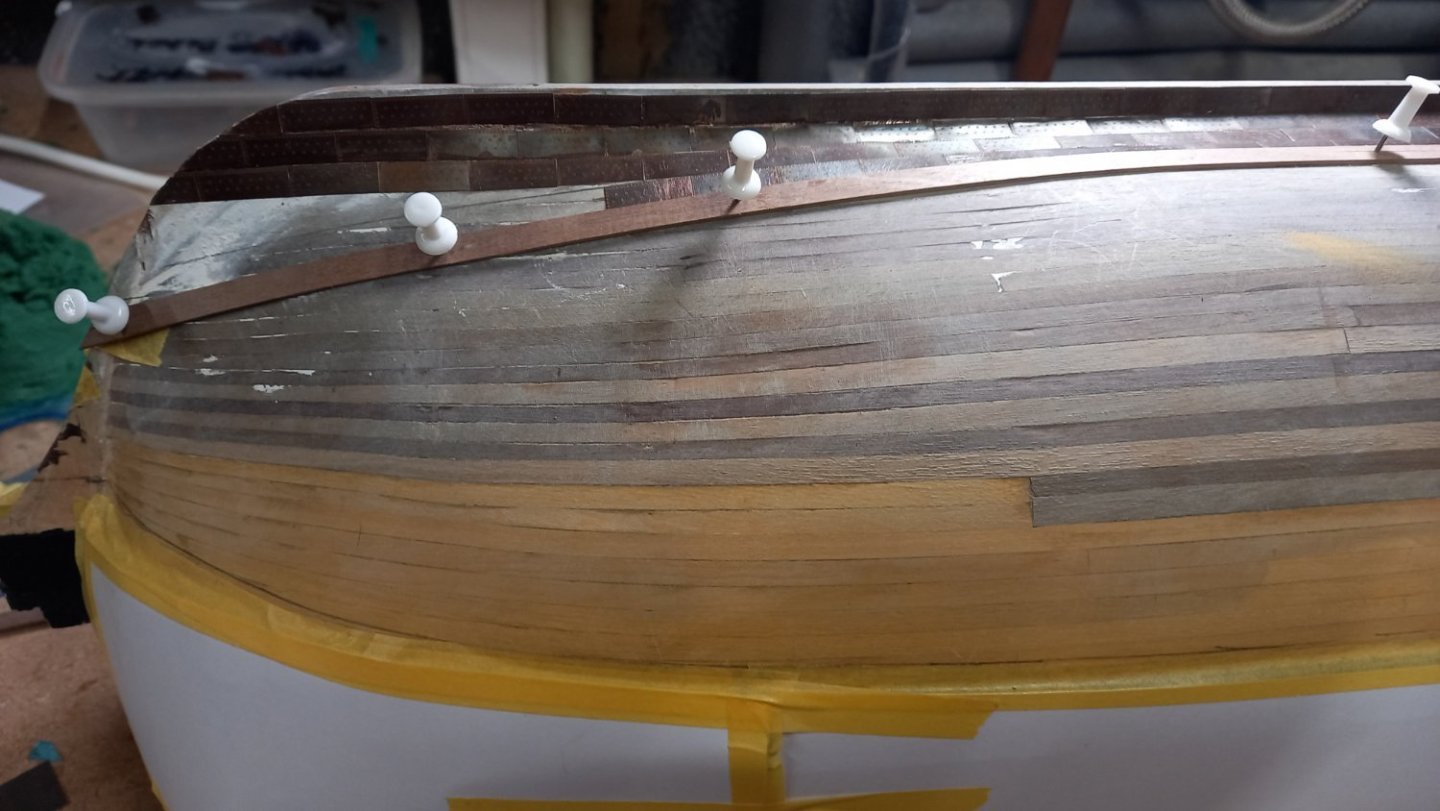

Slow progress with fitting copper tiles due to holiday in Switzerland and returning with Covid so have not felt like doing much other than completing the coppering of the hull and then attaching a 1mm x 1 mm black strip for the water line then making a start on the other side. I wasn,t entirely happy with the port side gore line as such , so using a different approach I used a 6mm wide walnut strip rather than tape to ensure the correct way the tiles would lie and butted the plates up to this strip. This appeared to work best for me but understand there are much better coppering jobs than mine out there but apart from working with hazardous chemicals and smelling super glue I am unsure of aging the plates to this extent is something I would consider doing again.There are still a few areas such as along the stem and stern posts that require attention and still the rudder post to do but in the main that is the copper plates complete. Few! O Once again I now draw my attention to the Stern and Quarter galleries and still wondering to how far I need to go with replacing the parts supplied with kit. I have notices a few modellers replacing several parts including the supplied brass etched windows together with some of the walnut parts with boxwood. I do have some boxwood in stock spo perhaps I will change to this but as far as the brass etched windows , as yet I have not decided which way to go. I used the ones supplied with the kit for my Endeavour and these looked fairly presentable.

-

You definately have your work cut out there.Being a newby myself and currently building the Diana but not as far on as yourself I have found the model dificult enough without correcting someone elses mistakes but can understand the attraction.However it would definately be of interest how you approach this and to see how much is actually repairable but I wish you luck. Dave.

-

I look forward to following this build David and hope you enjoy working with Mdf rather than ply. I am sure you will find your build is as successful as the Diana. Best of luck

- 152 replies

-

- Vanguard Models

- Cutter

-

(and 2 more)

Tagged with:

-

I have decided to change tack slightly as I have decided now after looking at the more recent builds of Diana I thought now would be a good time to start coppering the bottom. As previously stated I will be using Amati plates rather than CC plates as these are thinner and more refined. So that the marked indents look like nails rather than rivets. I would like to make special thanks to DavidEN, dunnock and Ray for helping me with the following process as it was due to their help with regards Weathering , jigs and placing of gore lines etc, all of which have been of great help. After changing my mind several times I have decided to weather the plates first and using the same method as DavidEn using 1 part Miracle grow and 3 parts red wine vinegar. However before this process I pickled the plates and aged them using brass black which darkened them to a similar colour to aged copper. Here using the Amati etched plates was much easier as they could be treated with large numbers and then the backs cleaned off using fine sanding paper. It is my intention to only lightly patina the plates but gradually increase the patina towards the surface to simulate what might be the case in reality but not sure if this is correct. I found after rubbing the surface of the etched plates plates with 000 wire wool and soaking in acetone for a few miniutes then both the aging and patina would work so much quicker to get the desired effect. Below Plates weathered using Brass black for a few miniutes then rinsed in distilled water. Imediately soaked in 1 part Miracle grow and 3 parts red wine vinegar for varying lengths of time between a few miniutes and a few hours then allowed to dry. The backs of the plates cleaned using fine sand paper A few photographes of the progress. YA Just starting to show when vessel the riight way up. Perhaps not to everyones taste however I am fairly pleased in the way it has worked out for my first attempt at fitting copper plates. Fortunately with starting at the keel most of my mistakes are out of sight and by the time the hull is visable I was starting to get the hang of it. Hopefully I wil also be able to remove some of the super glue where the glue was squeezed out between some small gaps. I am still hoping to blend the areas a bit better by adding a bit more patina to various places before finally sealing it all once I am happy with the result. Knowing when to stop might be key here..

-

A question if I may. Is the weight of perhaps the cheaper option of glass too heavy?

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Sorry I missed this build Andrew, however she looks a Beauty. What's next then Vanguard?

- 45 replies

-

- Earnslaw

- Paper Shipwright

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.d909acfd16daa0bdfbc3067b490bbbfd.jpg)

.thumb.jpg.d6f8e62ad7f65c023a6f3fd3b94a8346.jpg)