-

Posts

1,086 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GGibson

-

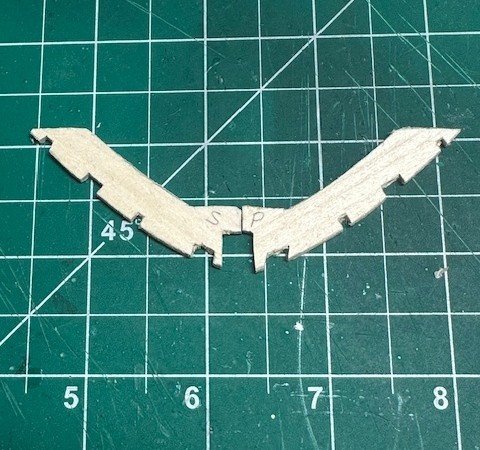

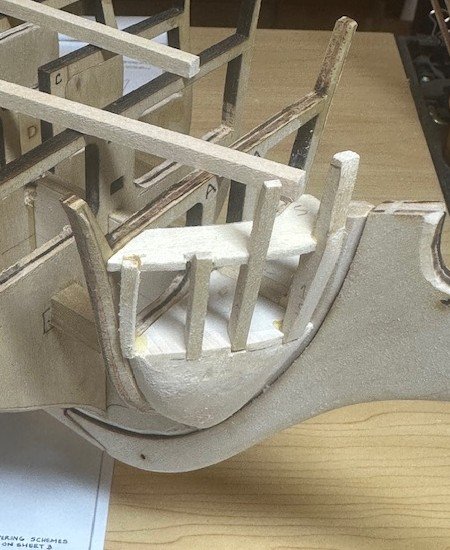

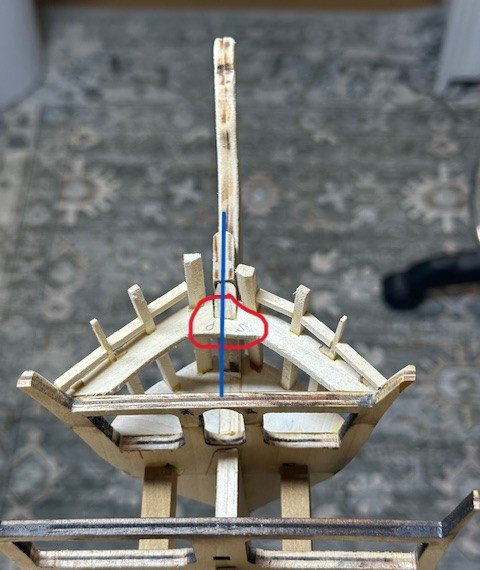

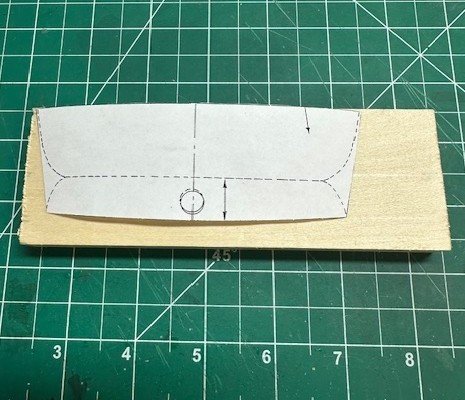

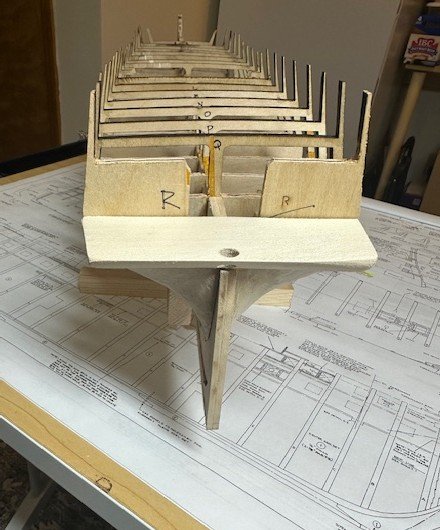

Another “mini-project” done (well, mostly done), so another short update. Bow Knightheads and Timberheads Using the plan copies that I had made to cut up and use as templates, I cut out the spar deck framing piece and outlined it on a 3/32” section of provided basswood sheet. I also flipped it and re-outlined it for the port side framing. Using my scroll saw, I then cut the framing for both sides and sanded to shape. Using the same outline the template” process, I also cut out the knightheads and timberheads for both sides. Several of the build logs I have used for research and guidance mentioned that the lengths of the plan’s pieces might have been a little short, so I added 1-2mm to each of the framing pieces as I cut them, so I could adjust as needed when I fit them on top of the filler blocks. I worked on the starboard side first and used the knighthead #1 piece and the timberhead #5 piece (the one closest to Bulkhead A) to have the spar deck frame to sit on for fitting and adjustment. A bit of sanding was needed for the spar deck frame to sit well in its “slot” between the center keel and Bulkhead A, and the notches both in the filler block and the spar deck frame needed some small widening in spots for the frames to fit well. I also tested the height of the spar deck frame, as well, against the existing tops of Bulkheads A, B, etc., to make sure the spar deck planking will be level. I then repeated all of this process on the port side of the ship. The plans also show the addition of planksheer supports, stiffeners and bridle port header and sill. Using some suggested 3/32” square strips, I added the planksheer supports just above the spar deck level. I’d like to hold off on any stiffener additions until I get a better idea of how the bow area will be completed,, and I’m holding off on the bridle port frames until I get to the gun deck gunport framing, as that will all be done at the same level and I want it to be as accurate as I can. Whether these are good decisions or not… we shall see. It will be easy, though, to add (I think) when needed. I also need to do some additional sanding, both inside and out, to smooth things out. Also, I do recall Jon Gerson mentioning an issue he discovered at this point in his build regarding the bowsprit placement and, in looking further at his build log and at some other logs, I reminded myself that, at some point before it all gets closed up and hard to get to, I will need to widen the area where the two spar deck frames come together to allow for the bowsprit to fit properly. Thanks, Jon! I am also cognizant of the issue Peter reminded me of in his post above regarding the planking placement on these spar deck frames. It is great to have such awesome build logs and followers to rely on through this Constitution build! Y’all are fantastic! Thanks! For now, though, I think I am moving to the back of the ship to begin the stern and transom framing. This, of course, is where everyone’s building methods have changed depending on which Constitution era we are shooting for. Exciting times ahead! Appreciate the likes, follows, comments and criticisms.

-

Thanks for this reminder, Peter! Yeah, I just finished cutting and shaping the spar deck framing pieces before I read your reminder post... ...and am wondering if I shouldn't redo this framing with a slightly wider girth, as you suggested in your Post #14, just for grins. OK, off to make these knightheads and timberheads. 🤷♂️🤞

-

The Syren wheel, albeit the assembly looks to be a bit tedious (excellent lathe work, BTW), does look pretty sharp with some stain, Peter! OK, I am too lazy to pull applicable plans out and do the measurements and conversions, but I am curious (and trying to take meticulous notes). The Syren wheel looks to be in scale with your kit-provided wheel. Is that Syren's 24mm or 31.75mm wheel? Thanks, Peter! Great work, sir!

-

Thanks, Peter. As simple as it is, it really did help me get the blocks to the more accurate shape that they need to be prior to gluing. But not for the brass wire measurements, I probably would have quit shaping the blocks multiple times before hitting the mark. But, in measuring, I would be as much as 2-3mm off in sanding/shaping. So, I kept at it. Hopefully, that will save a lot of additional sanding needed once I actually get to the hull planking. Appreciate the follow and the comments.

-

Excellent question, Jon! And I guess my best response is to use the 🤷♂️emoji and say "I dunno...". Didn't really think about doing it that way and using the scroll saw for the notches. Perhaps it was because my scroll saw is out in the garage and the Proxxon mill is in the shipyard and more convenient to use. I think I am more accurate with the mill, too, than with the scroll saw blade. Was planning on using the mill again for the upper bow framing notches, too. Hmmm.... Appreciate your feedback, Jon. Thank you!

-

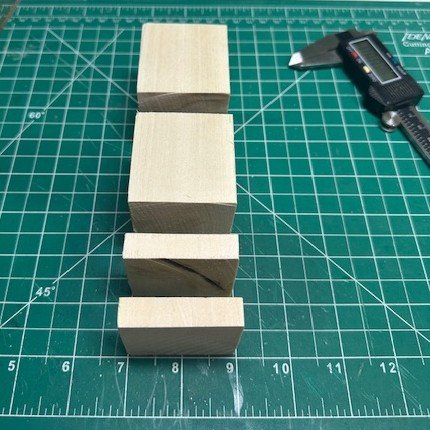

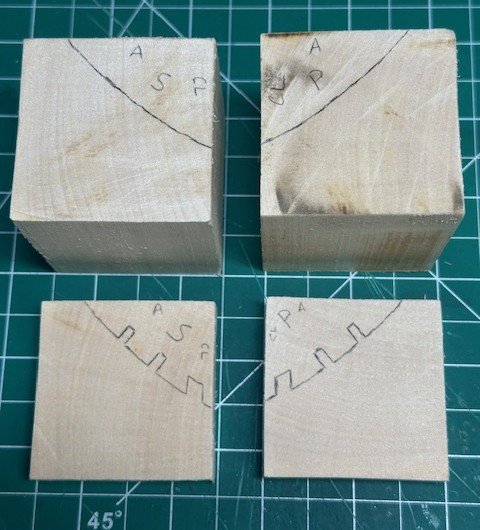

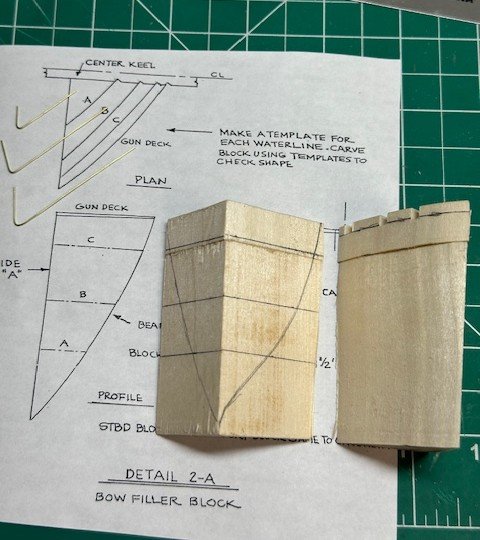

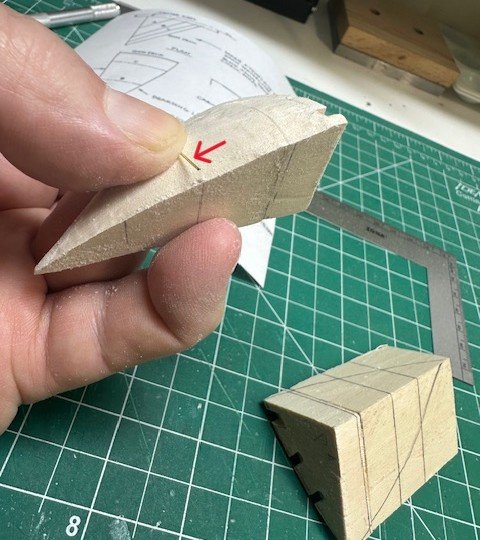

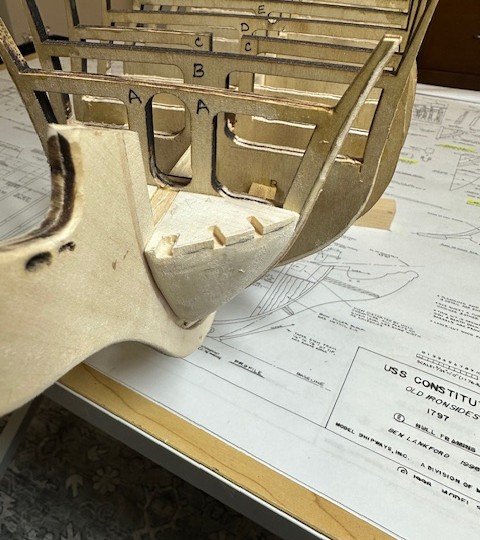

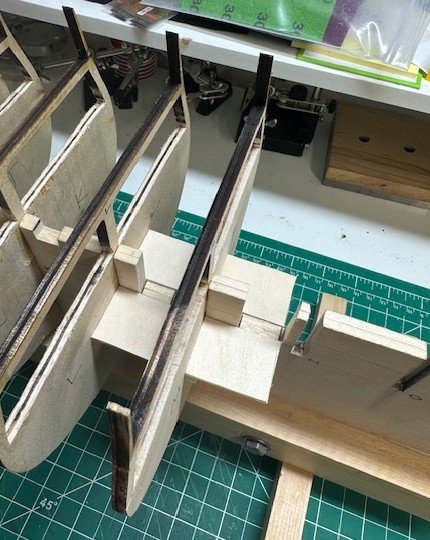

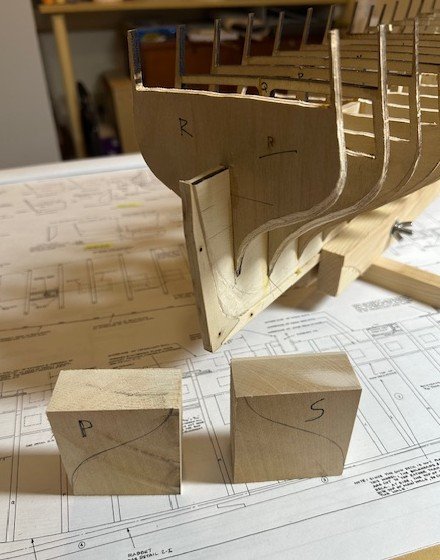

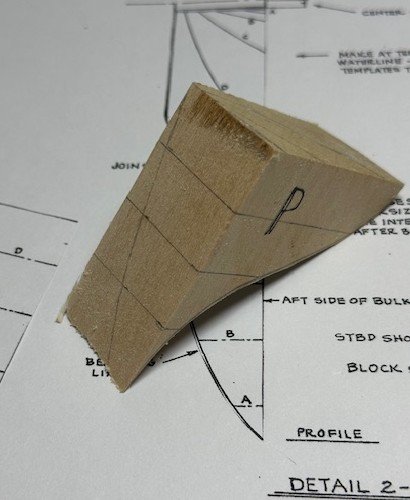

BOW FILLER BLOCKS Yes, another update, I have moved forward on the ship and began working on the bow filler blocks. All in all, I think the completion of the bow filler blocks went smoother than the stern filler blocks. Mostly, of course, because much of the work was essentially a rehash of the process used at the stern. The kit provides us with a 2” x 2” x 6” long block. The plans suggest that you cut that larger block into two 2-1/2 x 1-1/4 x 1-1/2” blocks for each side. Rather than full 2-1/2” lengths, I cut two 2-1/8” length blocks and two shorter ½” length blocks. Employing a technique from Tom (@usedtosail), I will mill the required notches for the knightheads, gunports and head access frames into the ½” pieces, as it will be easier to do it this way on the mill. I will then glue the ½” pieces onto the larger pieces for final shaping. Trace the Gun Deck top view onto each block to ascertain cuts to be made. Note that I have written port and starboard designations, as well as the Bulkhead A and Hull Center Lines, on each block to help keep them organized in my head. Then, using the scroll saw, I cut out the bow filler block shapes. I then moved the top part of the blocks to the mill and cut out the notches. I scribed and then drew a line for the 1/8” depth notches, as suggested on the plans. I then glued the halves together and let them cure overnight. I then drew the A, B & C markings and bearding line shapes to determine how the blocks would be cut and shaped. I also used the same technique I did for the stern filler block shaping, using small 0.51mm brass wires cut to the A, B & C lengths shown on the plan view, which helped me determine amount of sanding to check the shape. Although I know the bow filler blocks will need additional shaping when we get to placing the hull planks, I think we’ve got the blocks shaped well. So, I glued the bow filler blocks in place. Everything seems to look good. I am now working on the knighthead framing and the other bow framing above the bow filler blocks. I appreciate the likes, comments, advice and criticisms.

-

Great finishing work, Matt! Your Pram looks magnificent! 🏆

- 86 replies

-

- Model Shipways

- Norwegian Sailing Pram

- (and 3 more)

-

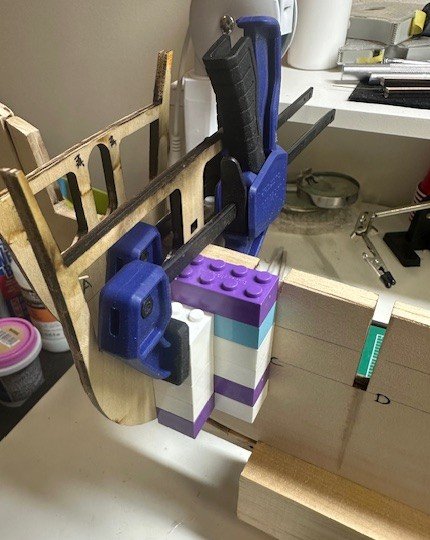

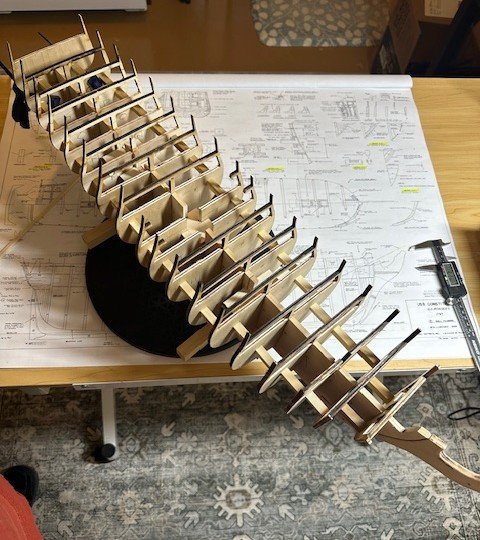

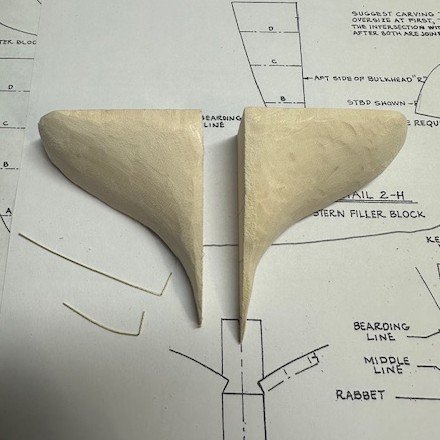

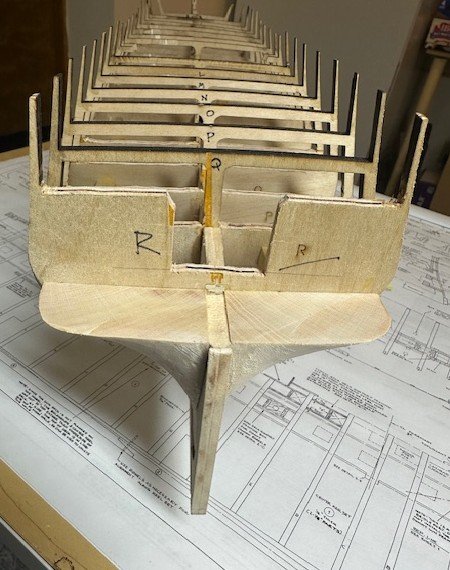

Well, we’ve had a spell of extremely hot weather in the Kansas City area, with recent “feels like” temps over 100o, so it’s good to spend some time in my cool shipyard. Therefore, another small update… BULKHEAD PLACEMENT After doing what I can to the bulkheads and the bulkhead former to prepare for the bulkhead placement, it was time to get them secured in their spots. So, I got the obligatory Legos back out and, beginning with Bulkhead A, went through the slow process of painting a thin strip of Titebond glue on the contact points and then sliding each bulkhead firmly in its slot, matching the reference lines and securing the Lego blocks for the 90o placement while the glue dries. Then moving on to the next bulkhead. At the locations where I will be installing the ladders going from the gun deck to the berth deck, I wanted to have small “landing areas” for the ladders to rest on, so using some thin scraps of strip wood, I glued some support strips and small sheets at those ladder locations as I was permanently securing the applicable bulkheads. Also, in order to provide additional support and strength to the bulkheads, I measured and cut (using my small bench top cut-off saw) some scrap 3/8” square dowel to use as struts between each bulkhead. This gave me the opportunity to make sure the distances between bulkheads on the port and starboard sides were equal (or as close to equal as possible when measuring in hundredths of millimeters). A view of the full ship at this early stage and it’s shaping up nicely… COUNTER & STERN FILLER BLOCK The Model Shipways kit provides a couple of large basswood blocks to use for these pieces. First, let’s work on the counter. The plans suggest a block size of 5” x 1¾“ x ½“, but I started with a 6” x 2” x ½“ block. I used a thicker block so that, in order to drill the hole for rudder stock at a slight angle, I would have room to place a ¼“ dowel underneath the block as I was drilling the 5/16” hole. That worked out well. Once I had the rudder hole placed and drilled, I then repositioned the cut-out counter drawing on the block to trace the outline. I could then, using my scroll saw, cut down the shape of the counter to a more manageable size (less cutting and sanding required). The only recommendation to do differently is to reduce the thickness cut from ½“ to somewhere between 7/16”-11/32”. More on that in a bit. But the initial cuts and sandings had the counter thickness at just about 7/16”, it looked “ok”, and a quick test-fit of the counter and the rudder was successful. I then moved to working on the two stern filler blocks. As suggested in the plans, I cut the blocks to 2-3/4“ x 2-3/8“ x 1-1/8“ sized pieces. I fit the blocks against Bulkhead R and traced the rear profile for the required cuts. I then used the scroll saw again for the initial curved cuts. Then, using the plan and profile lines on the Stern Filler Block Detail 2-H plans, I drew the shape lines on each block piece to help me with the sanding and shaping and… made a whole bunch of sawdust! Using just my Dremel with the sanding disks (went through several of the disks in this process) and my hand-held sanding block, I was able to shape the two stern filler blocks to their required shape. What helped me in gauging the shapes needed were two thin and flexible 0.51mm brass rods that I cut to the lengths shown on the Detail 2-H “plan view” for the C & D waterlines. The A & B waterline marks were so small I could gauge those by eyeballing them to shape as needed. But on the larger curves, the brass rods definitely helped me get to the curvature and shapes needed. As a side note, I really do like the hook & loop “velcro-like” sandpaper sheets and sanding block I have been using. I bought the assorted sandpaper grits that come in rolls in a box and you can cut off what is needed to place on the sanding block. Works really well, and much more convenient than the sanding block I was using previously that I had to measure and cut strips from full sheets. So, as I was once again test-fitting the stern filler blocks and the counter and seeing how everything looked placed against Bulkhead R and the counter sitting on top of the sternpost, I noticed a height level difference between the top of the counter (which will serve as the floor of the Commodore’s cabin) and the rest of the gun deck level on all of the bulwarks. The Commodore’s cabin floor is going to be higher than the rest of the gun deck. Well, crap, shouldn’t these obviously be at the same level?!? When I made the decision to have a detailed gun deck, I followed the lead of others who have done this previously with the Model Shipways kit, and I trimmed 3/32” from the bulkhead former and bulkheads, but I did not trim the section of the bulkhead former directly behind Bulkhead R, where the sternpost attaches. I don’t recall any of the other builders commenting on that piece specifically, but maybe it was just assumed that when you trimmed, you trimmed everything. So, I trimmed that section off, as well. Even with that piece now trimmed, though, the counter was sitting a bit too high. That’s when I gave a shoutout to one of my fellow Constitution builders, Jon @JSGerson, to ask his advice, since it looked like in his pictures, his transom counter sat flush with the gun deck. Jon, confirmed for me that, nope, there actually is a height difference and his photo made it appear to be an optical illusion. Magic…..! Once the front wall (including the buildout for the sofa area) is fully constructed, you can’t see the difference. Very interesting, Jon! Thank you!! He did, though, remind me that Bob Hunt’s practicum does emphasize the importance of getting the transom counter thickness down to that 11/32” point. So, I continued to sand that block until I got to that measurement (with a little more on each side to account for the deck curvature) and, ya know what? I think once we add the gun deck base sheet and the deck planking, the cabin floor should be right at the same level as the rest of the gun deck. Sweet! Sorry for the long explanation but thought it might be worthy of documenting my perils. My concern now is what I might have done to the sternpost in bringing that down the additional 3/32” and will that cause problems with aligning the hull planking, the stern frames, the quarter galleries, etc. The rudder still fits in its eventual place just fine. I guess “we’ll cross that bridge…”. When I was making the cuts into some of the bulkheads and the bulkhead former to allow for the ladders going down to the berth deck from the gun deck, I failed to also make a cut into Bulkhead R prior to placement for the sofa area buildout. According to the US Navy plans, if I am measuring the small scale plans accurately, that buildout area looks to be 8’ wide, which at our 1:76.8 scale, converts to 1.25”. So, I cut that area out of Bulkhead R. I did make a couple of notched cuts at the top of that extraction so that, when necessary, a new support beam can more easily be placed at the top of that cabin wall. With that opening completed, I think I was ready to permanently secure (glue) the two stern filler blocks. Of course, additional sanding and shaping will be necessary once the planking is placed, but I think we’ve got the stern area about where it needs to be for now, While I placed the counter on top of the stern filler blocks for looks, I have not glued the counter in place yet. In looking ahead at the work I am going to be doing with the transom frames and their locations, it may be wise to keep the counter loose for now, so that it will be easier to cut the slots in the counter where the frames will be seated. For now, though, I think I will move to the bow filler blocks, the knightheads and the timberheads. I hope I am doing things well. I certainly have a treasure trove of available insights and information from prior build logs. Thank you! And thanks to all for reading, following, commenting, advising and criticizing! You are all appreciated!

-

You are finishing up quite nicely, Matt! Congratulations! And, yes, after my first build, I became a Ropes of Scale customer and fan, as well. All my subsequent ships have their rigging. Congrats again on a great looking Pram! 👍🏆

- 86 replies

-

- Model Shipways

- Norwegian Sailing Pram

- (and 3 more)

-

Caldercraft Red Ochre

GGibson replied to scrubbyj427's topic in Painting, finishing and weathering products and techniques

How close are the Winsor & Newton red ochre variations? -

Great work, Rod. The winch assembly was probably one of my favorite parts of the Bluenose build.

-

Never really thought about any coverage on brass, Peter. But, referring to an expert, especially when it comes to brass work in ship modeling, I looked at my copy of Ken Foran's (@xken) book Modeling Building with Brass - 2nd Edition. When discussing cleaning parts, on page 113, he states that "parts that are to remain a natural brass finish can be clear coated, using lacquer or urethane spray can finishes intended for this purpose."

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.