-

Posts

3,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Dan Vadas

-

Thanks Ab, and I agree with your opinion of the kit. I've made a couple of other Halinskis and this one is by far the most detailed . Both the canopies fitted. I'll fit the doors near the end of the build as they can be easily knocked off in the open position (the hinges are "non-working") : The next section of skin fitted. These skins are REALLY tight - you have to be spot-on with the framing fairing as the piece wraps around from from top-left to top-right in one piece : I did a bit of plumbing in the transmission bay using brass wire painted (mostly) in-situ with artist's acrylics : Danny

-

I thought it would be a good idea to fit the two canopies to protect the cabins from damage. I'm using the preformed canopies, but they still need quite a bit of work in cutting them. The kit actually supplies two sets of canopy braces as they are easily damaged when cutting and fitting them. I didn't need the 2nd ones : I glued the bracing to the canopies with PVA, let it set, and then wicked some Plastic Super Glue along the edges. Everything held very well : I'm displaying the model with opened doors to show as much interior detail as possible : This HUD took me over a day to make : The gunner's canopy fitted : Danny

-

Thanks guys . Popeye - the inner skin is only on those sections where the interior is visible, The other sections only have the 1mm thick framing to glue to. Next we move to the forward landing gear bay : The next section of framing : Now I'm starting with the outer skins. The framing needs very careful fairing, as there is absolutely NO margin for error. Lots of dry fitting after shaping each skin was required : The joins between sections of skin have a separate joining strip which is glued to the inner face of the skin so they line up without a step. The laser-cut frames have a recess in them to allow for this strip. These also need to be carefully faired : Danny

-

Regarding the "Sharpie" you are using for the planking edge colouring - see if you can get one of these. It is an Archival Ink pen available from most art supply stores, Officeworks or on-line which doesn't bleed into the timber like any other pen I've tried and is also waterproof, which won't smear when you apply PVA glue. Get the "Brush" size and use the side of the nib to apply the ink. Also - the end join between planks should also be "caulked". Danny

-

The gunports don't actually line up with the waterline, each deck is slightly different. The height of the ports is actually determined by the sheer line of each deck. Adding port liners is a very good idea as they are actually used in real practise - after all the planking needs to be attached to something around the port . Click on THIS LINK to see how they look. Check out the following posts as well. Danny

-

That would be me . Unfortunately I completed the model just before I found MSW, so there is no build log for it (a few pics are in the Gallery - click the link in my signature), but I could give you some advice on building her. There are about a dozen build logs of the Corel Victory in the Quick-Find Index for Wooden Ship Kits (click this LINK) but none are marked as Finished. Danny

-

Allow me to be the 3rd then - Welcome from a couple of hours North . Danny

-

With the pilot's and gunner's cabins completed (for now) work moves to the rear compartment. I "glazed" the windows with some frosted plastic cut from laminating plastic, which is 0.07mm (70 microns) thick : Both the interior side walls are completed first : The left wall has the door cut out to display the interior : One of the bench seats. I used a jig to hold it for easier construction : Next the rear wall and ceiling needed to be made and attached before I could fit the seats : Finally, I started the upper framing : Danny

-

Looking at the way the planks have already bent around the bow you should be fine when they dry out - there shouldn't be any "spring-back". If you still have a problem and you don't mind a half-hour drive I have a home-made plank bender that you can borrow - it works a lot better than the Amati one. Danny

-

Thank you all . The start of the build is the cabin. The laser-cut parts are perfect, much better than I could cut by hand in 0.5mm and 1.0mm card. Here is the main framing : Two of the instrument panels. These have some very small parts. The gauge panel is laminated in 3 parts - the gauges, a very thin piece of clear acrylic from a cigarette packet, and the fascia which has been punched for the gauges : The axe and fire extinguisher took me half a day to make : The panels fitted to the cabin : Danny

-

Beautiful job Ed. A masterpiece of a model and a great build log. I've enjoyed every update . Danny

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

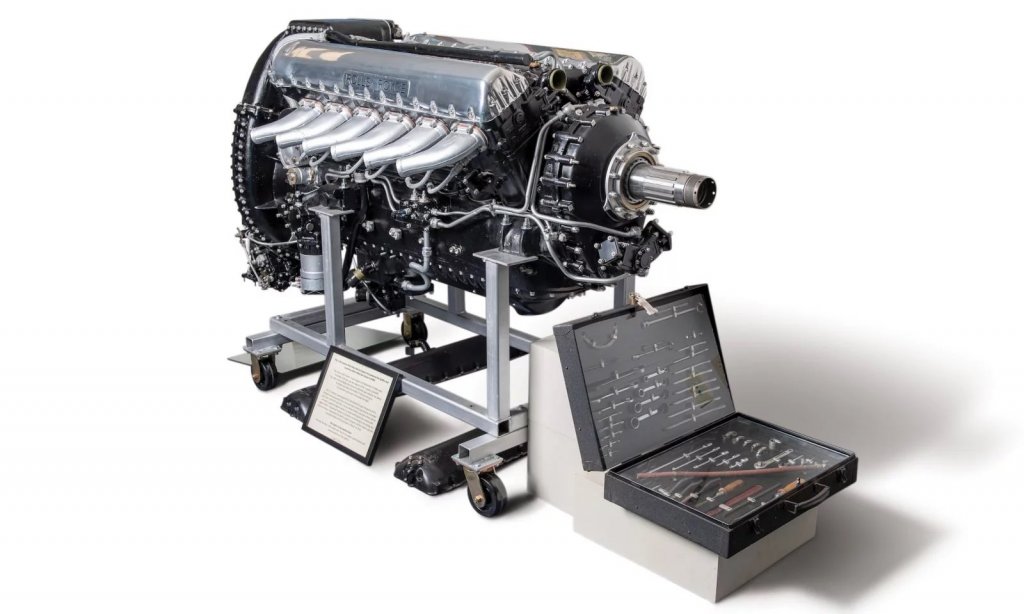

Hi all, My latest Card model - A Halinski kit of a Russian Mi24D Helicopter. Here are the pics of the cover page, 2 of the 3 pages of the laser-cut pieces, resin wheels and a preformed canopy : This is going to be my most difficult card model to date. There are over 4,000 pieces (HMS Hood had about 2,500), some of them half the size of the smallest I've done so far. This should be FUN . Danny

-

Thank you all. This model is now finished, here are the final pics including the lower tank and some skin bracing. Here are the parts for the bracing - lots of careful cutting. I cut one side of each piece first, applied a little CA glue and then cut the other side. This prevented the piece from distorting as some of them were only 0.3mm wide and were very difficult to cut : Here are the finished pics : Danny

-

Ted - are you kidding me ??? Your modelling history is almost EXACTLY the same as mine, just in a slightly different order (the Revell Constitution was my first ship model at the age of 13, which I bought from my pocket money). That was followed by several others including Mayflower and Cutty Sark - I still have the Cutty but it needs restoration which I'm not going to bother with. My first Wooden ship was Charles W. Morgan which I built at age 25. Weird eh . From looking at your previous models and your woodworking experience in my opinion the only thing you may need to learn is Planking. There's plenty of advice on this Forum on doing that, so that's covered. Also plenty of Build Logs to show you the step-by-step way of building a wood ship. So dive in - choose one of your collection, open a Build Log for it to get any advice you may need (and to show us how good you REALLY are at wood ship building ) and get cracking. Mark has a good point about the possibility of the brittleness of your kit timber, so check it out. The planking timber may need to be replaced, but extra timber is available from various sources. Danny

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.