Paul Le Wol

NRG Member-

Posts

1,060 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Paul Le Wol

-

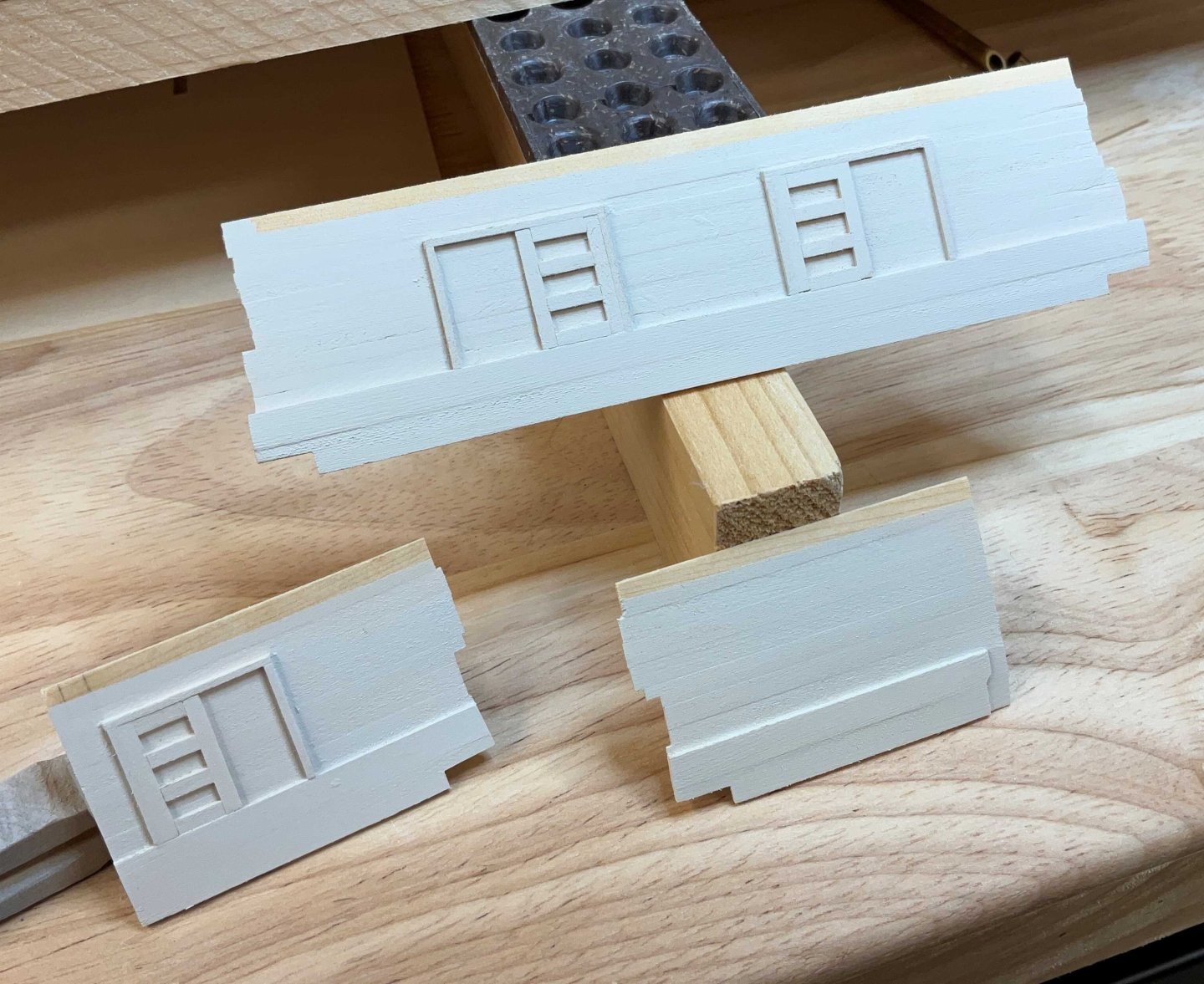

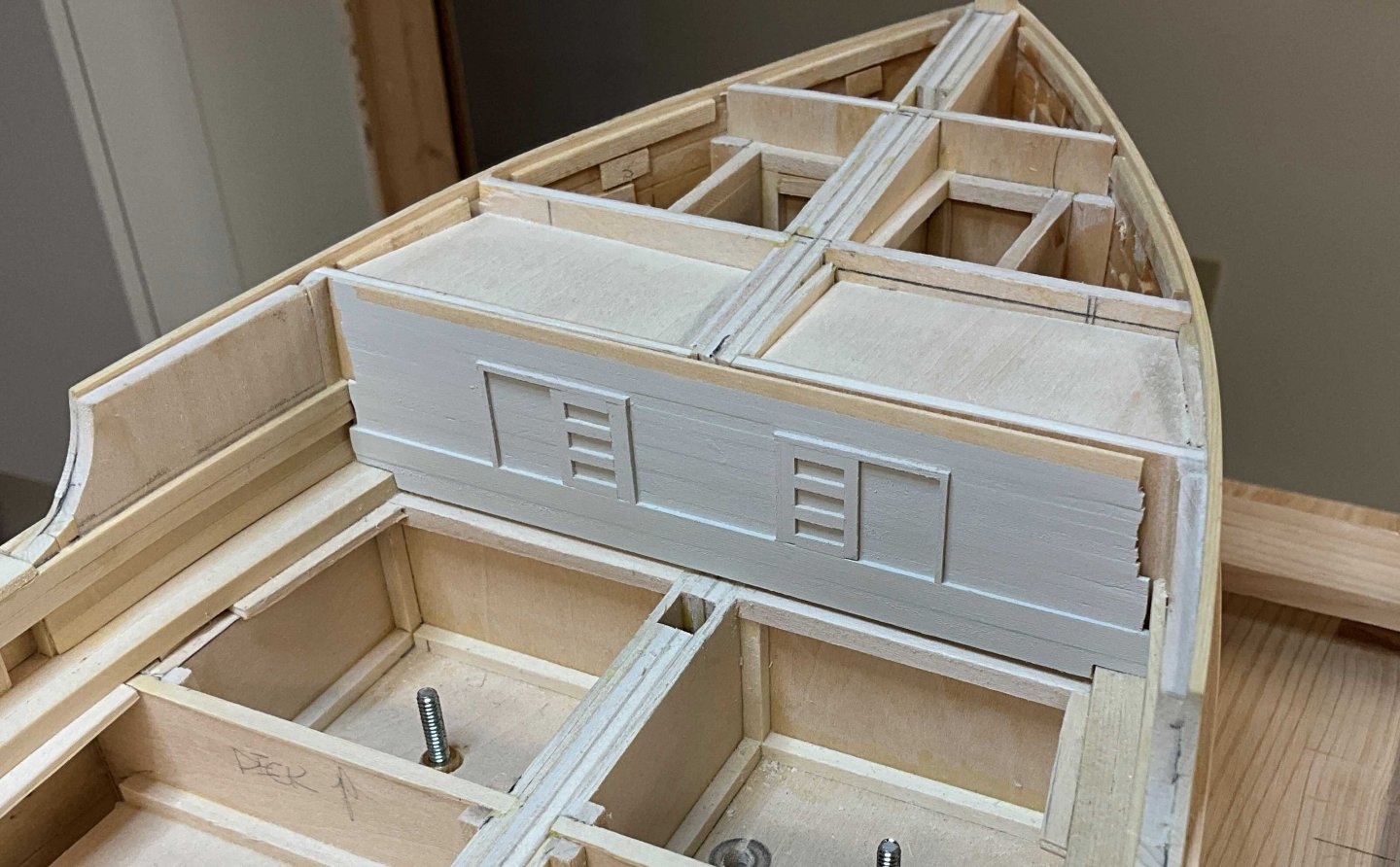

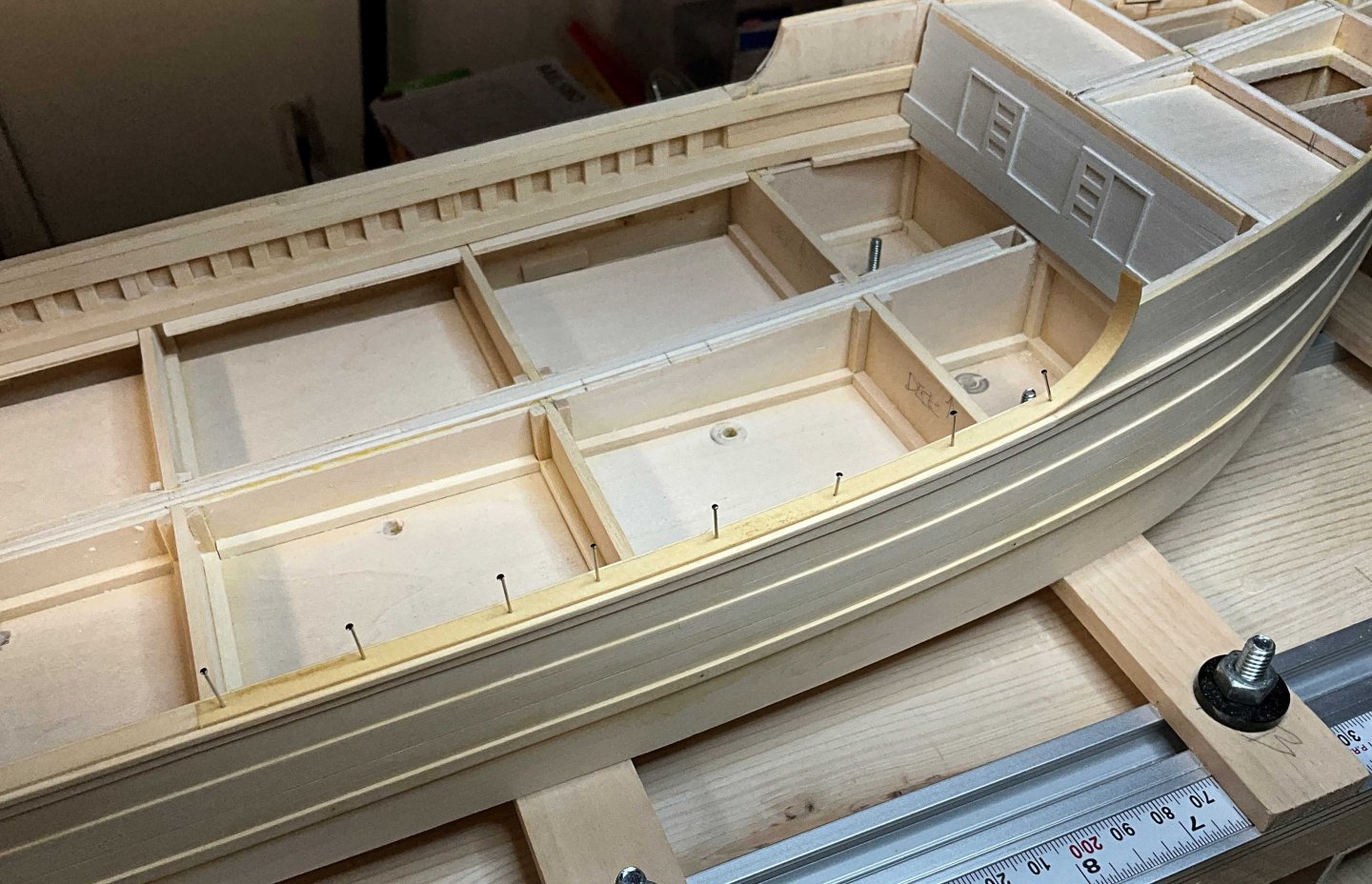

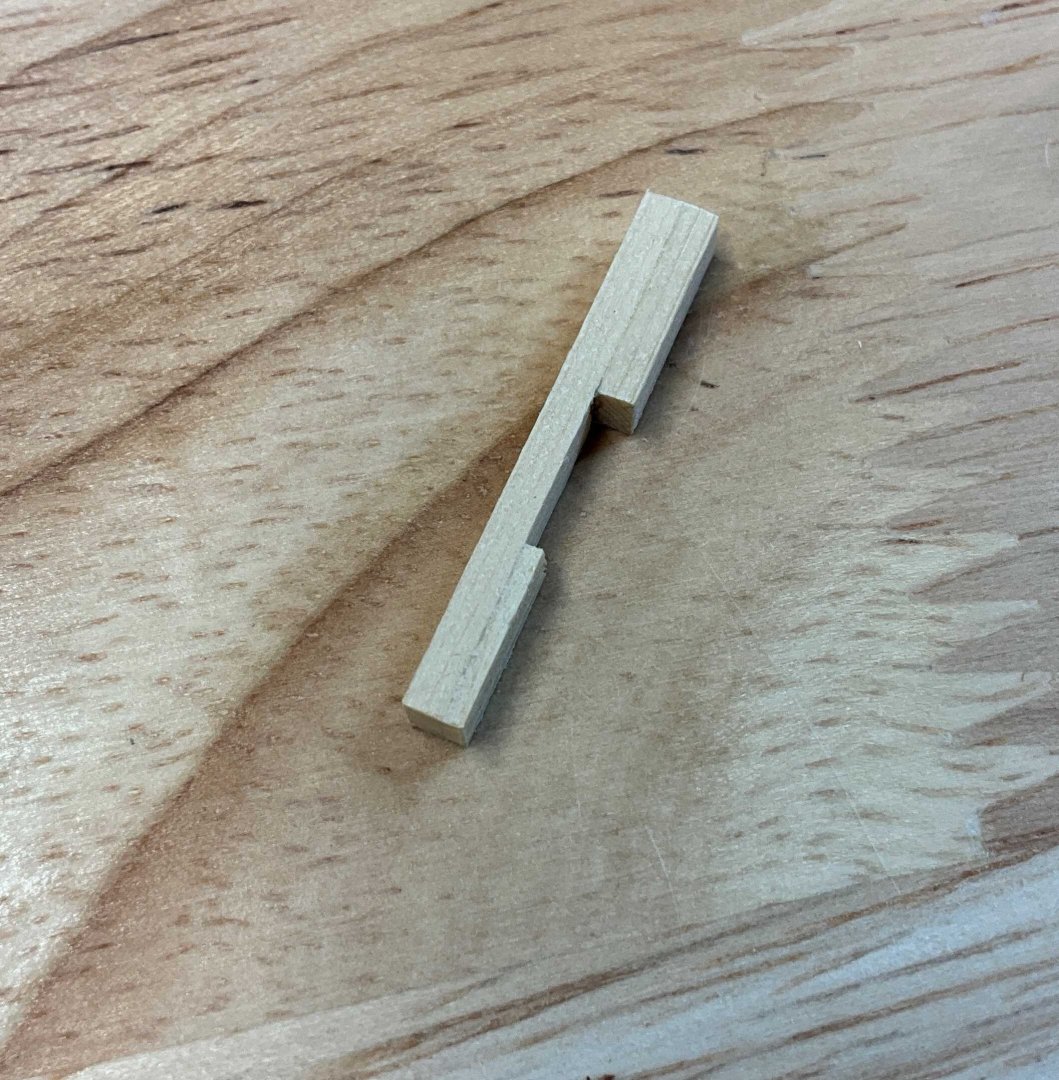

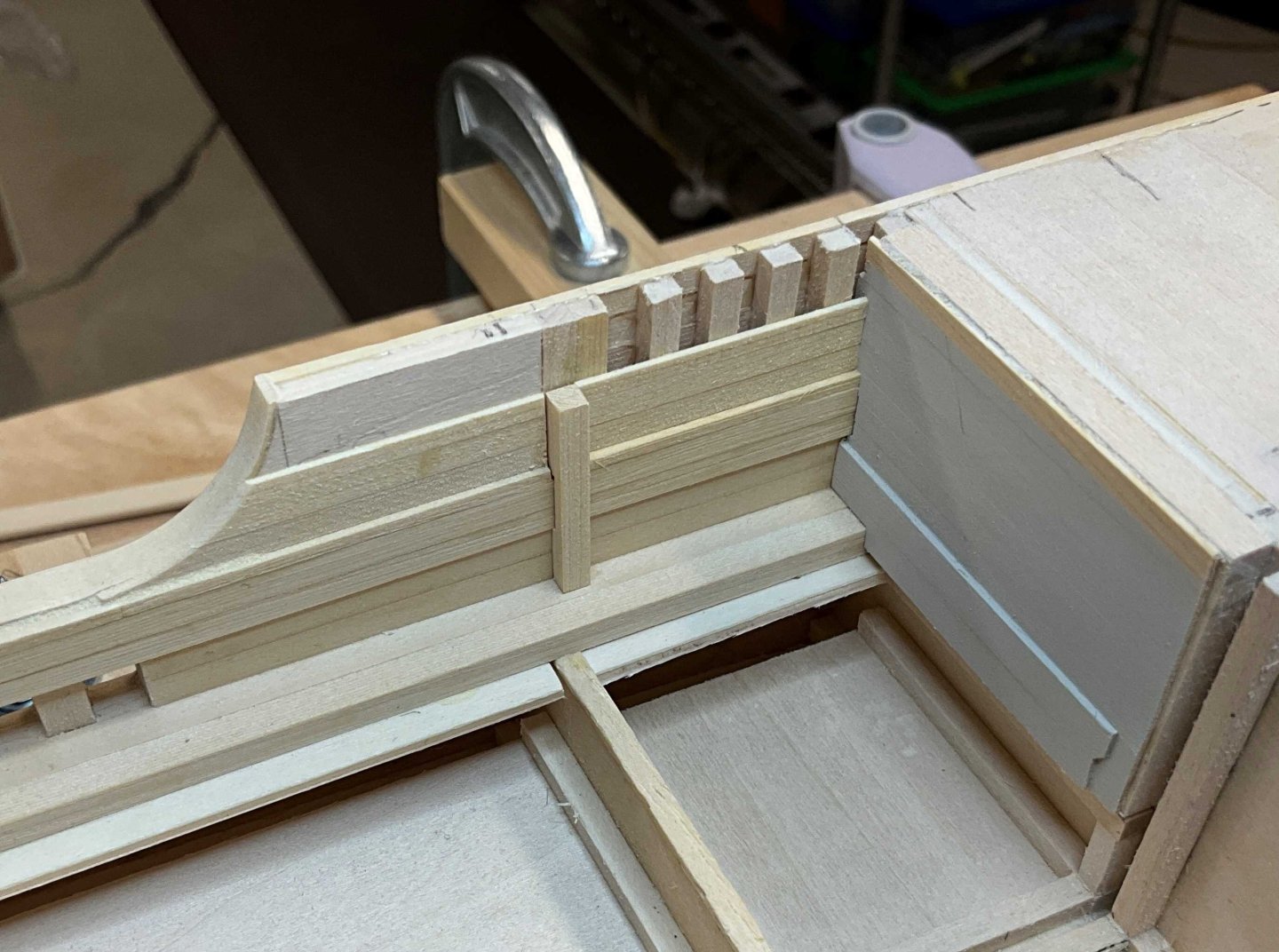

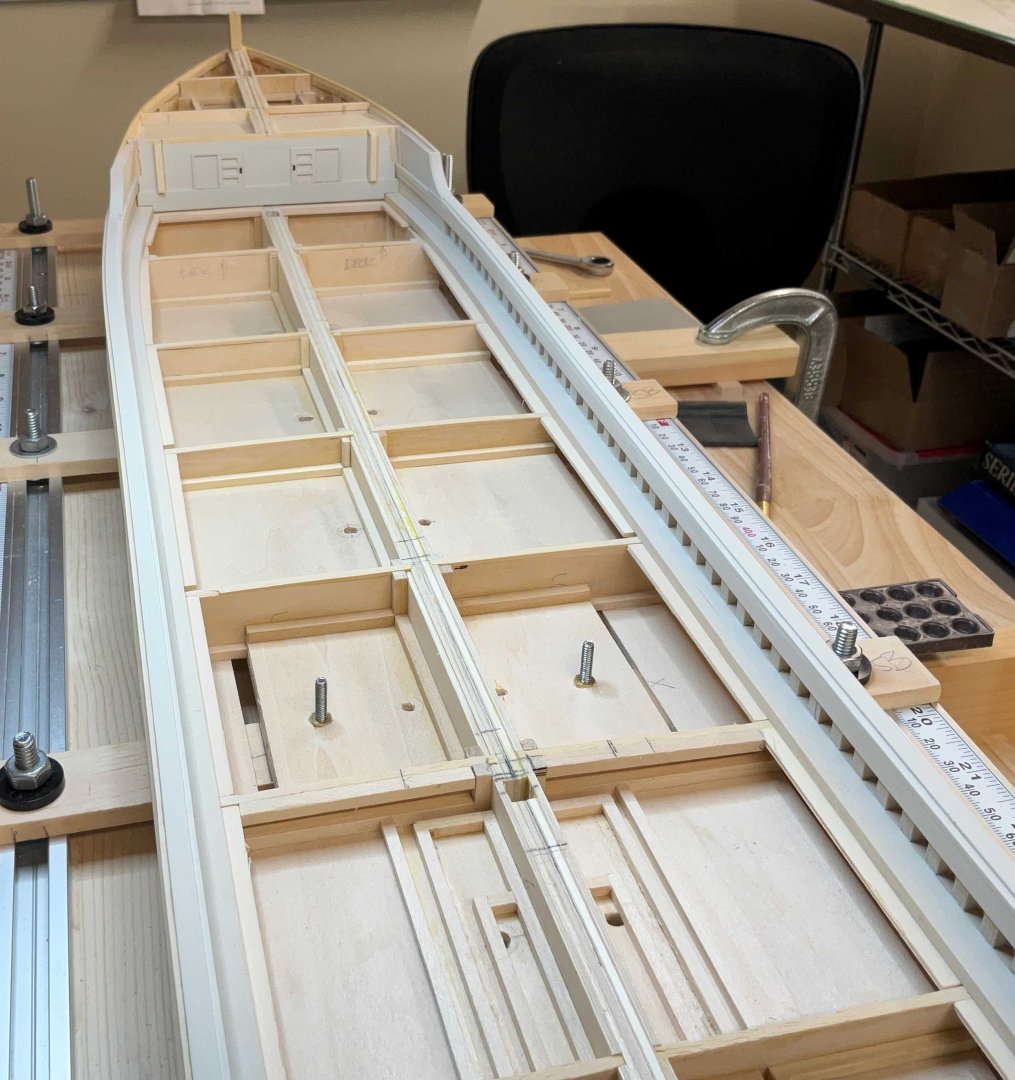

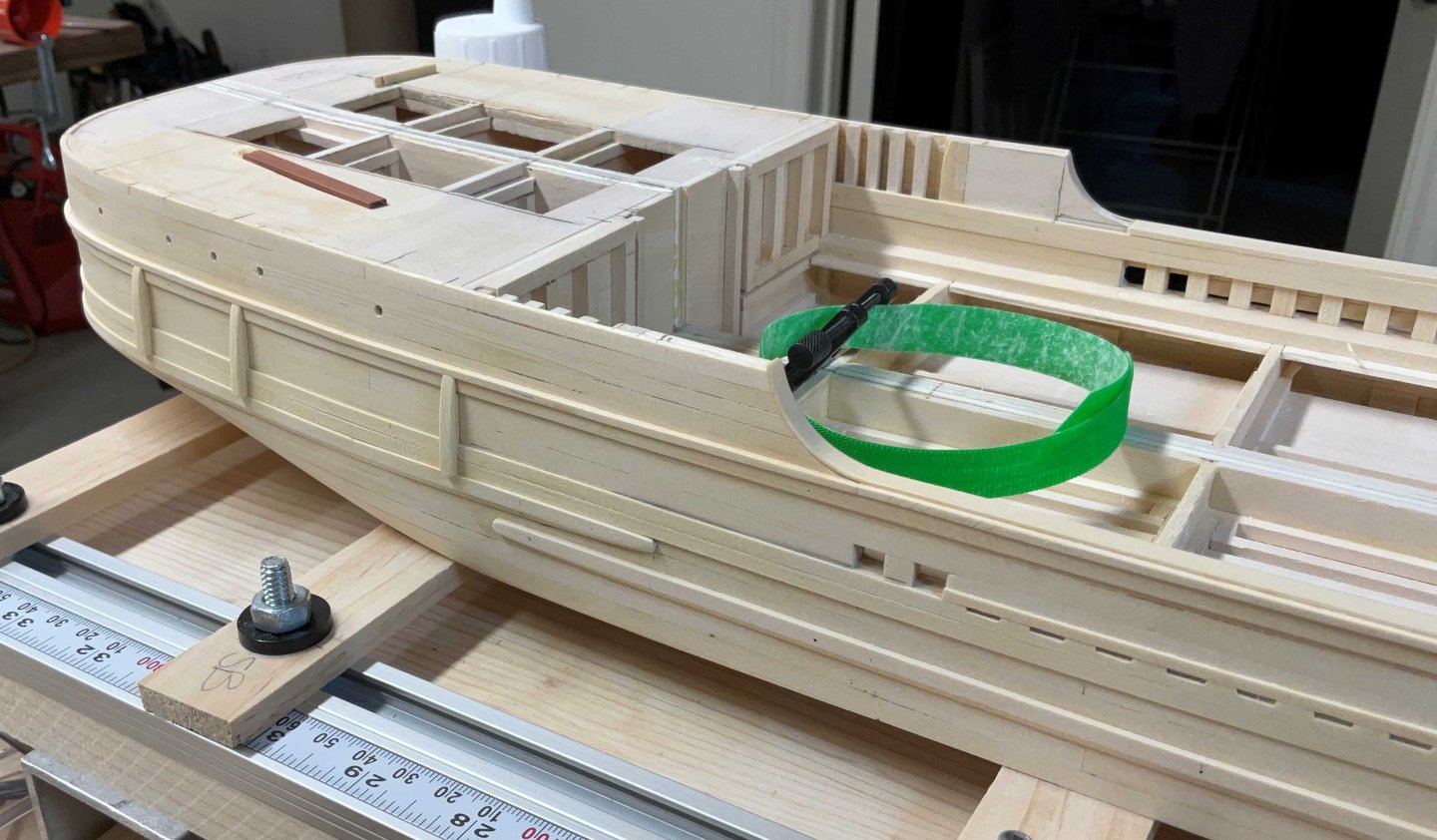

Hi Everyone, I hope you are all well. Thank you very much for the Comments and Likes. The bulkheads at the fore and aft ends of the main deck have been sided with 1/32" horizontal edge glued strips of 5/64" AYC. The sliding doors were glued to the siding and then everything was painted with Vallejo Model Air White Grey (71.119). The chafing planks were finished to the forward end. The bulwark planking was done next. There is a stanchion in there so there was a lot of measuring and cutting These areas had to be completed before the Main Deck House could be installed. The bulwarks were airbrushed and except for a few attachment points she is ready for the deck house and the sub deck. Hope to see you soon!

-

She looks beautiful Gary! Good luck in the Photographic Competition.

- 121 replies

-

- Lucia A Simpson

- AJ Fisher

-

(and 1 more)

Tagged with:

-

Bob, congratulations on completing your Golden Hind! She is exceptional.

- 46 replies

-

- Golden Hind

- airfix

-

(and 2 more)

Tagged with:

-

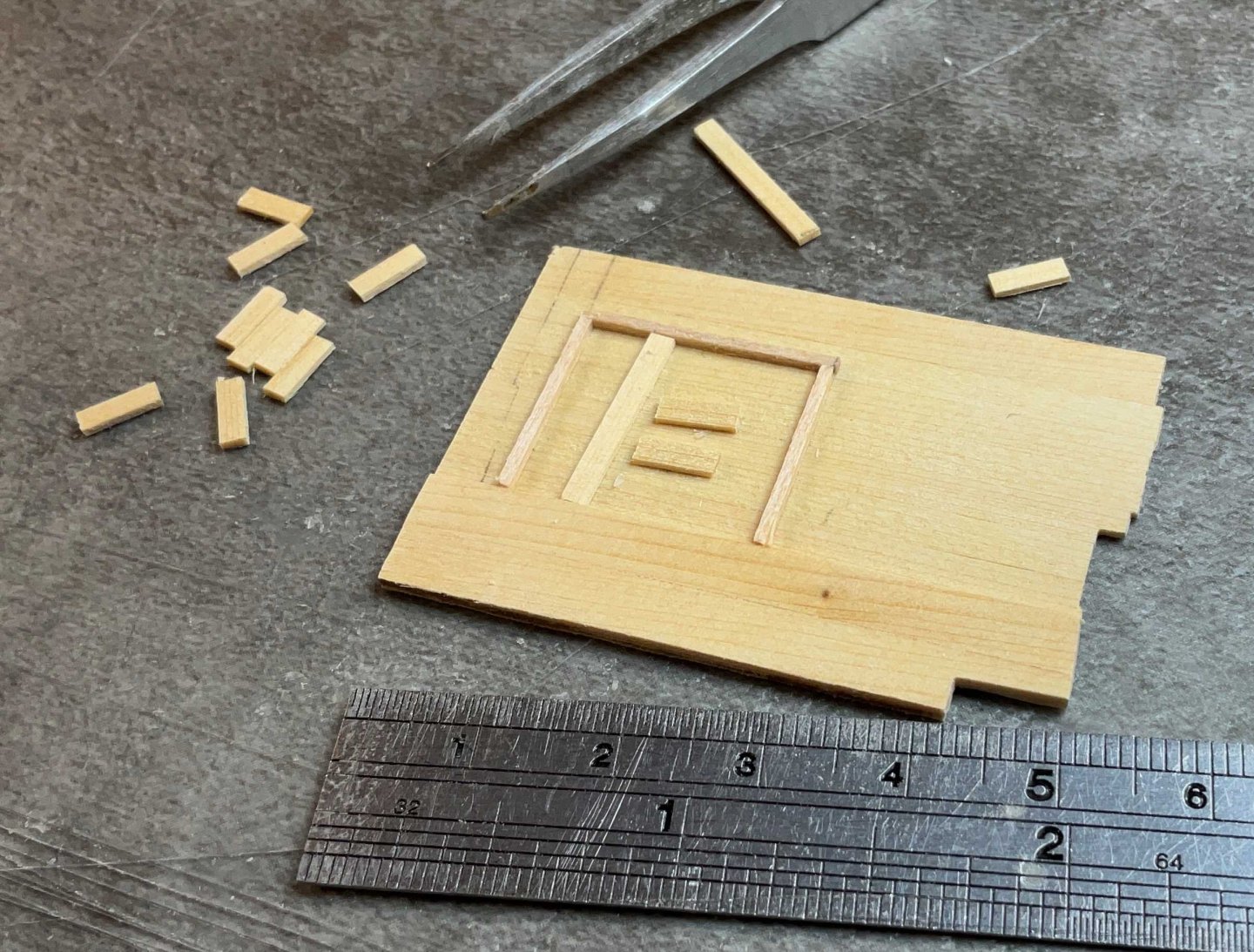

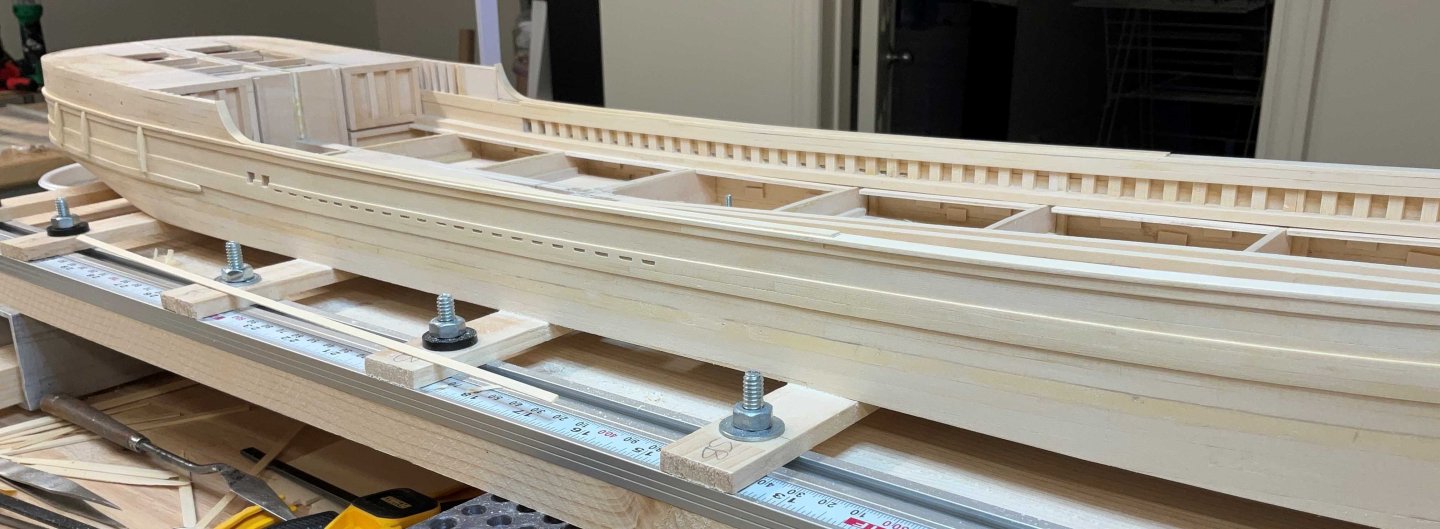

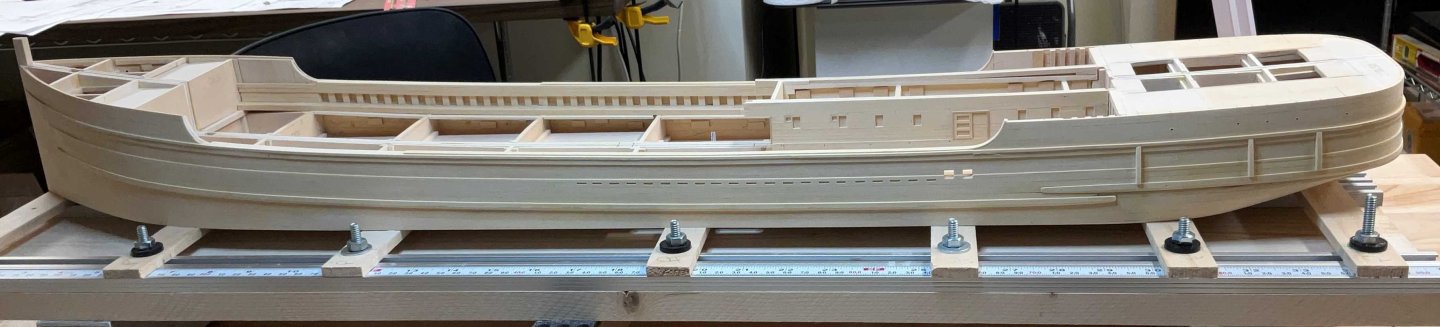

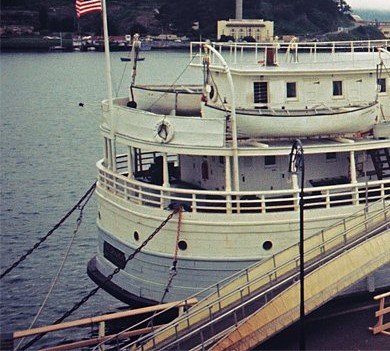

Hi Everyone, hope you are all well. Thank you for the Comments and Likes. I had a bit of a setback last week. This is part of a photo that Phil @Dr PR posted in his SS Wapama 1915 Steam Schooner thread. I had not noticed in other photos or drawings how prominent the planks just above the guard at the stern were. The drawings show that the bulwark planks are 3 3/4" thick and the hull planking is 4 1/2" thick. Adding this detail would mean that these planks would have to extend down to the guards all the way to the bow. The guards would hide the fact that 1/32" planks were added. Well that's the hope anyway. Starting at the stern, three strakes were added. Two @ !/32"x1/8" and one @ 1/32"x5/64". The scuppers had to be filed into the new veneer planks. I decided to remove the guards port and starboard because they drifted down a bit at the bow. Gluing the new guards back on under the new planking went a lot easier. The new planks were feathered into the hull planks at the bow before they get to the metal anchor protection plates While this was going on the chafing planks were attached to the main rails. I just happened to have a rigid cardboard shipping tube that was the right size to hold it at the curved part. The main deckhouse was glued together and placed on a jig in order to complete the doors and siding. This is what she looks like today. Next will be the hawse pipes and portlights. Hope to see you then.

-

Hi Keith, in the 2nd video that you posted in Post 17, it shows a chain driven boat. It doesn't look as heavy duty as the one you are modeling. Maybe the drive depends on the towing capacity.

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

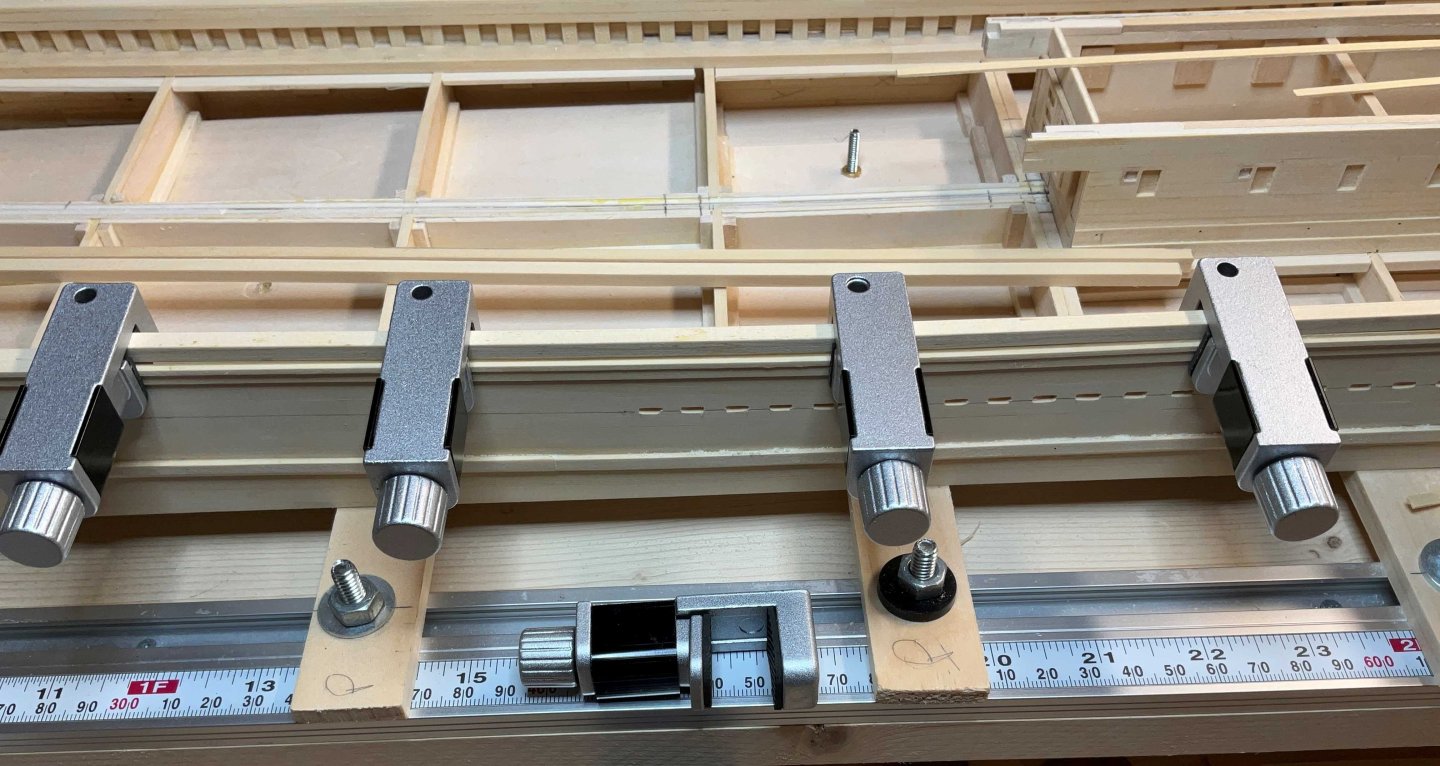

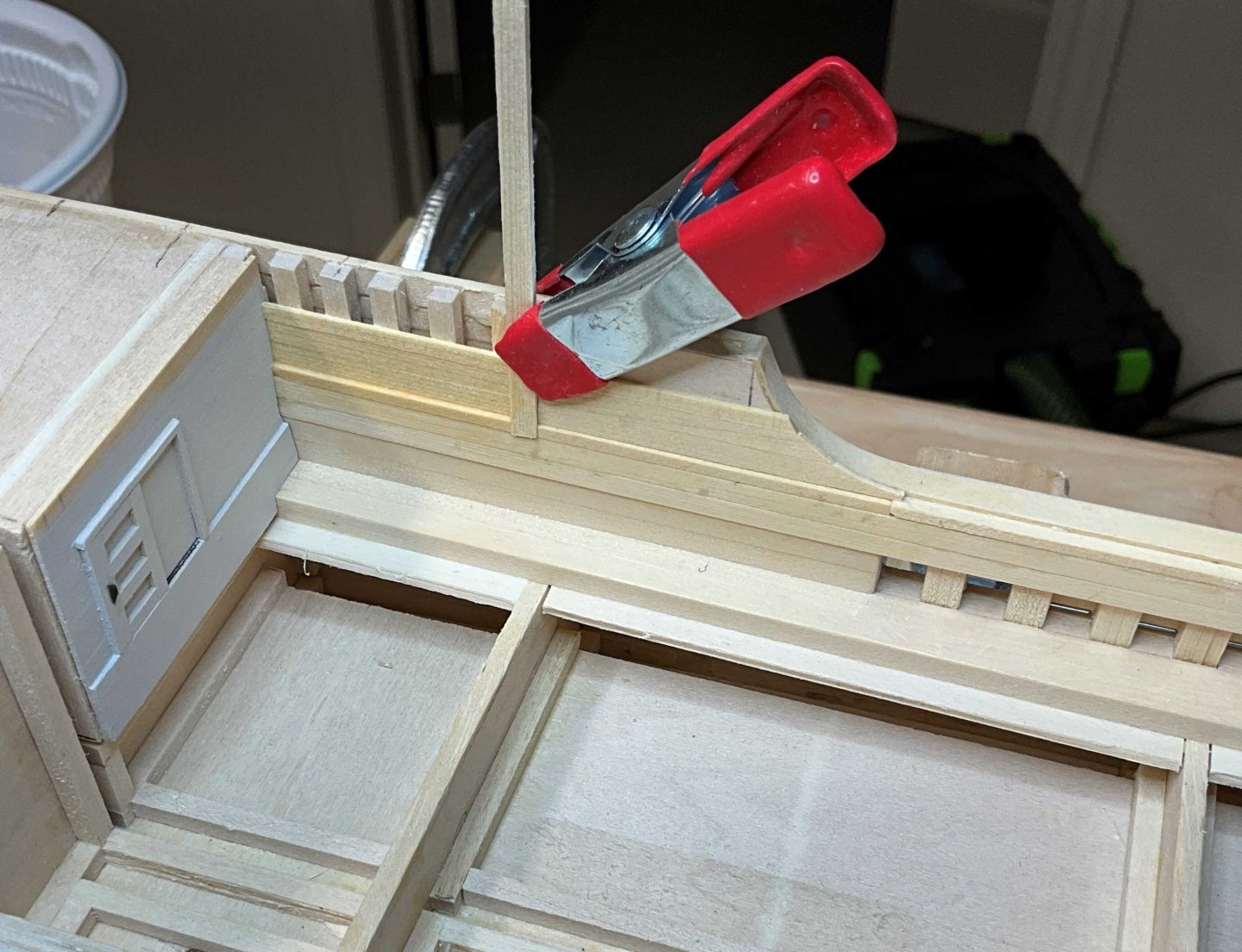

Bought these clamps from ama zon last week. They were 33CAD for 8 of them. The jaws have soft pads and they open to about 15mm. I like them for jobs where you need uniform pressure applied as opposed to spring clamps that may skew the parts.

-

A mighty fine looking completion Glen. Congratulations!

- 106 replies

-

- Kentoshi-Sen

- bottle

-

(and 1 more)

Tagged with:

-

Chris, congratulations on completing your Alert. Wonderful job and looking forward to your Cheerful build.

- 38 replies

-

- Alert

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Gentlemen, thank you very much for your comments! The hull planking and the siding are AYC. I’ve found that a coat of clear shellac followed by painting turns out pretty nicely on the cedar. The biggest issue I think would be having glue blotches after applying a coat of WOP. And I have already bought the paint for it😀

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.bbf010536da0d0ca81b53451e1cfe0a3.jpeg)