-

Posts

589 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CAd My Fingers

-

Model Machines 4" Table Saw

CAd My Fingers replied to dewalt57's topic in Modeling tools and Workshop Equipment

Congrats on your Jim saw, they are awesome--know you'll totally enjoy yours! However, they are dangerous as all get out...not from a getting hurt standpoint but instead to your wallet--you'll likely want to buy other Jim tools after driving his saw for a bit! I have a few other Jim tools and they all are top notch, and I totally love using them. Have fun! Jay -

Inter-library loans are one of the best kept library secrets around (i.e., many folks aren't aware of this wonderful resource); however, most libraries participate. I've borrowed a number of rare tomes over the years that otherwise would have been impossible to obtain. If you're looking for a particular book, give WorldCat a search: http://www.worldcat.org Not only does WorldCat give you information on a book you're seeking, it also lists what libraries around the world that have the book--this is a very useful research tool. Cheers, Jay

-

After you clean the primer and etc. off and give it all a sanding, first put on a coat or two of sealer. From there, give the 1st post in this thread a read--Alistair gives some excellent advice on hand painting, the rest of the thread has good info. also: http://modelshipworld.com/index.php?/topic/6168-how-to-hand-paint-larger-areas-of-a-model/?hl=painting Hope that info. is what you were looking for. Cheers, Jay

-

Thanks, Max--looking forward to this replacement vice, esp. after reading all these great reviews--definitely need this "third hand" in my arsenal of tools! Cheers, Jay

-

Tim, thanks for your answer--very much appreciated! I am definitely sold and will purchase one--that lack of rotation in my current vice is exceptionally frustrating (to the Goodwill it goes). Thanks again, Jay

-

Tim, in reference to your 2nd picture above: When the ball is in that position, can it freely rotate? In other words, in that picture could you rotate the ball so that your ship and vice jaws are vertical? My current vice's ball "locks in" at that position, and thus I can't rotate the vice to other angles, which is often not helpful! Thanks for the great review and your input! Cheers, Jay

-

You'll want the 120v (for the US) model; many other countries are above 220v; therefore, the saw requires a different motor voltage that will run under those respective voltages (it's common for power tools and etc. that are sold world wide to come in 110-120v & 220-240v versions). Cheers, Jay

-

Yep, save up for a Byrnes saw--for a bit more, it's definitely worth it! Cheers, Jay

-

Very nice work, Luca--your Cutty looks great! About your missing photos: Yep, you'll have to re-load them due to an issue with the MSW server a few days back--a lot of pictures were lost due to that glitch. Again, great work! Cheers, Jay

- 121 replies

-

- cutty sark

- artesania latina

-

(and 1 more)

Tagged with:

-

Absolutely gorgeous work, Michael--your craftsmanship never ceases to amaze me! Would love to spend time in your shop learning the underlying techniques and skills you bring to your work!! Cheers, Jay

- 2,196 replies

-

Need sharp scissors

CAd My Fingers replied to USS MAURY's topic in Modeling tools and Workshop Equipment

Gingher scissors are excellent, come in a variety of sizes, but also are rather expensive--love the ones I have! Cheers, Jay -

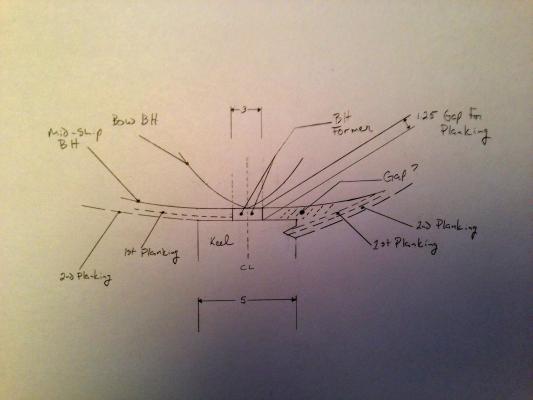

I think I'm tracking now, Mike on what you're looking at doing. Where it'll matter are the bulkheads (BH). Check them on your warped BH former to see if the BHs are flush with the bottom of the former. If they're flush, then your garboard should be able to flow sweetly into a keel-cut rabbet (am guessing you'll use a slightly broader plank for your garboard). My initial thoughts are that if your BHs aren't sitting flush with the former, then I'd really consider not cutting a rabbet into your keel. However, I would test the magnitude of how this will effect the planking if a rabbet were cut. You can test how things will work/look by tack gluing a couple of midship and bow BHs (before the stem sweep) with PVA (alcohol will dissolve the bond) to the former along with scrap pieces of 5mm breadth keel. Cut one simulated keel side w/a rabbet and then dry fit a 1st and 2nd layer of planks on both sides to see how they lay if you use a rabbet and how they lay if you don't. In the attached drawing, I quadrupled the scale of your parts (am assuming 1mm for 1st planking and .25mm for 2nd planking thicknesses). Hopefully it'll give you a visual of what I was mentioning above about how non-flush BHs may be an issue. The left side shows how the kit likely was designed to accommodate for planking; the right side illustrates potential issues in this case if a rabbet is cut into your keel. The forward BH is has much sharper profile than probably your kit forward BHs, but it should give you an idea of potential issues as your near your stem sweep. Cheers, Jay

-

Mike, both approaches sound reasonable. I'm guessing the kit is dbl. planked, so if I understand correctly you'll be increasing the width on each side by just over 1mm for the rabbet? In addition to being slightly out of scale (~ 2mm @ 1:75 is just over 1/2" real world, so not huge), if you increase the width of the stem and stern posts, you may want to see if those changes will impact the kit's steps for the head construction, bulwarks and rudder fits, and so forth. Cheers, Jay

-

Mike, Russ is right on about twists. I did a build that had a bent and also twisted plywood keel. Did the soak-and-glass bit that I mentioned above; while that got rid of much of the problem, it didn't get rid of all it. Long story short, the slight bend and twist that still were there caused a number of issues as I went further into the build (plus, overall it just was a crappy kit). In the end, the build came out well but I fought with a lot issues due to the warped keel. Since you have a scroll saw, I'm still recommending cutting a new keel--if you have the spare wood, you can give it a few goes 'til you get the keel you want. On the one hand, all may work out OK after you fix the keel you have; on the other hand it also may set you up for a lot of hassles further into your build or when it's done (will the twist continue to warp out?)...why chance it? An alternative to using Swiss Pear for your keel is Baltic Birch plywood--I think it's been mentioned in a few forum posts, and you'll definitely find stuff about it using Google. Cheers, Jay

-

Mike, I've had mixed results with soaking plywood keels and then putting them between heavy sheets of glass (used glass vs boards because the glass is straight--picked this up from Don Dressel's planking book). Also, there are a couple of posts/threads on the forum that discuss scoring the keel to get it straight that looked like a viable solution. Personally, I think cutting your own new keel is the way to go, esp. if you're planning on upgrading/scratching a lot of your kit anyway--then you know the foundation of your build is both true and solid. Cheers, Jay

-

Has anyone used this product?

CAd My Fingers replied to Ulises Victoria's topic in Modeling tools and Workshop Equipment

Yep, agree with Keith and Brian--I use Titebond PVA and have been happy with it and use regular PVA when I want more time to adjust parts or where I care how a visible seam looks (like Keith said, Titebond dries yellow). Only rarely do I use CA glues. Cheers, Jay -

Great innovations, and very nice work Tony, and your lathe work on the cannon looks great! Cheers, Jay

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Burton Pendants, Tackle and Falls

CAd My Fingers replied to BANYAN's topic in Masting, rigging and sails

Hi Pat, glad that was of help! There was just enough there to go along with Parkins and Marquardt--it's always nice to find those helpful contemporary tidbits. I like your idea of a shroud cleat for the fall--I'm partial to these less seen details! Cheers, Jay

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.