-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by dirkske

-

-

53 minutes ago, Wintergreen said:

Looking good Dirk.

Check out one of the moderators here, Chuck P on youtube: https://www.youtube.com/channel/UCPncZte1NZzmc-n7AMS7z6A

He has a set of instructional videos about plank bending.

Also, be careful with too much soaking since the planks change size quite a bit. Depending on species of course, but anyway.

Keep it up!

Apparently there should be no need to moisten the thinner strips. I may need to upgrade to a hotter iron. But this one is very practical being so small in size. Maybe I'll just stick with it and live with having to apply heat longer.

- Keith Black and Wintergreen

-

2

2

-

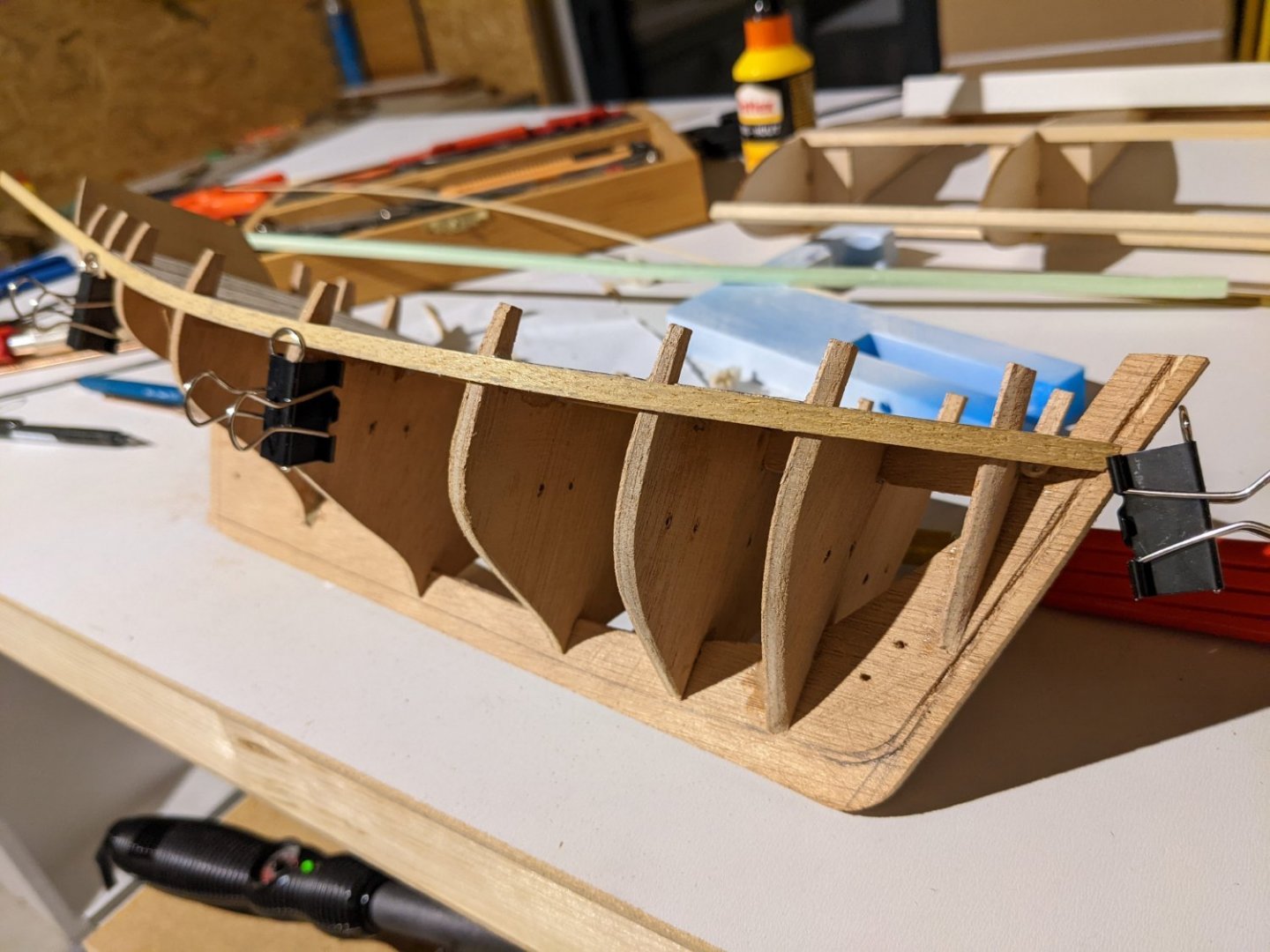

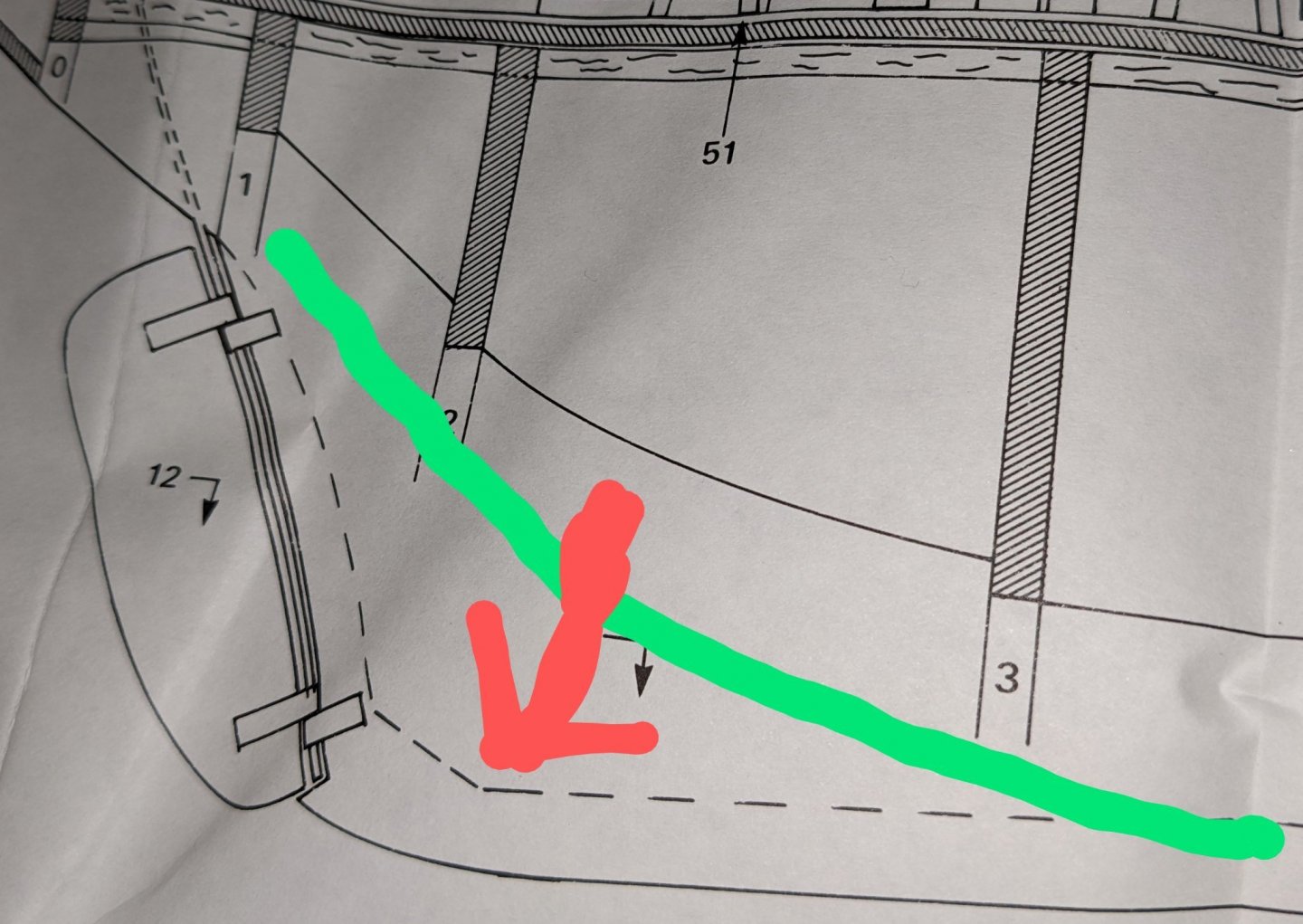

I recessed the ?bearding? line along the bow. Also sanded the frames.

I gave a shot at bending the first plank. And look and behold, what is likely commen practice and utterly boring to most of you is giving me such joy.

The plank sits in place, curved, without any persuation 😁

I uses my plane covering iron again, but need to give it a good clean. The covering glue residue rubs off on the planks.

Does anyone use a heated bed from an old 3D printer as baseboard for these bending operations? It might help heating the planks more equally from both sides. Or are the planks typically soaked tranferring the heat more easily in depth?

It does seem to work when heating from a single side. But it would not hurt being able to shorten the heating duration.

Did I mention this build will be a slow one? 😋

- ct mike, BobG, petervisser and 4 others

-

7

7

-

17 hours ago, BubbleHead said:

I do not beleve it's a good idea to have laser cut partes cut some where else, you neve know where the plans may end up.

Agreed, if the cutter was selected by the builder. But if Chuck was to select a reputed single one per economic region... I can't imagine that such a company would be less thrustworthy as the builders buying the plan. Given the amount of builds, those type of companies may not have an interest though.

Regardless, the lasered parts are no longer an issue, since the 2D parts are detailed on the plans (I initially thought they where not).

I have the tools to CNC route the 2D parts myself (although handcut may be quicker). So for me personally, those are not an issue.

For the 3D friezes etc I will have to sponser the gready government 😔

-

On 12/29/2021 at 8:59 AM, G.L. said:

Hello Dirk, welcome to the MSW forum. Where in Belgium are you from?

Aarschot small little town along the Demer river. I live out of center in the old dunes that have turned to 'iron stone' over the centuries.

- G.L., Keith Black, mtaylor and 1 other

-

4

4

-

-

Thank you Wintergreen 👍

Unfortunatly I allready started framing, thus chiselling this out will be difficult. Ah well, difficult is not impossible.... 🙈

-

2 hours ago, Edwardkenway said:

If you can cut your own bulkheads and keel former, there is a vendor in Estonia (Hobbymill EU) who does a timber package for Winchelsea, then just purchase the laser cut chapters as and when you require them.

If the cost is not too much the customs and vat are pretty low on smaller less weighty parcels.

I must have misunderstood, I thought the plans are partial, to, understandably, prevent piracy.

-

2 hours ago, Chuck said:

....

in addition….for the cost…you will never be able to buy another project like this…

Thrust me, I'm not trying to debate quality nor value. Just saying that in EU, depending on country, cost is roughly double to that in USA (due to taxes, customs and handling charges) and that is a pity.

So maybe, just maybe, you could consider to select a fabrication partner in EU which pays you a royalty?

I am lacking experience to tackle this project, but having a EU source would make it a no brainer to purchase the base package, plus some specifics for a future build.

-

6 hours ago, No Idea said:

I emailed permagrit and asked them to make me some blocks with fine grit on both sides - They did and it was not a problem and I was really happy with what they sent me. Great service!

That is great. I however prefer to retain the course side. As said, it comes in handy for other uses. And I don't see me wearing out the fine side quickly. It is a solid product.

-

On 10/7/2018 at 12:24 AM, Chuck said:

I ship almost anywhere in the world. Except for China, LOL

Sadly, added 21% vat (at receiving end on top any usa vat), shipping cost and customs % calculated over all the previous plus a flat fee customs declaration cost make that very pricey starter kit 😔

-

I for one love their tools. Yes, the course side is seldom used in fine modelling. But heck, its there when you need it. And VERY handy when you do work around the house. I have most of the reviewed products and over the years each has come in handy. Either for hobby, or around the house.

-

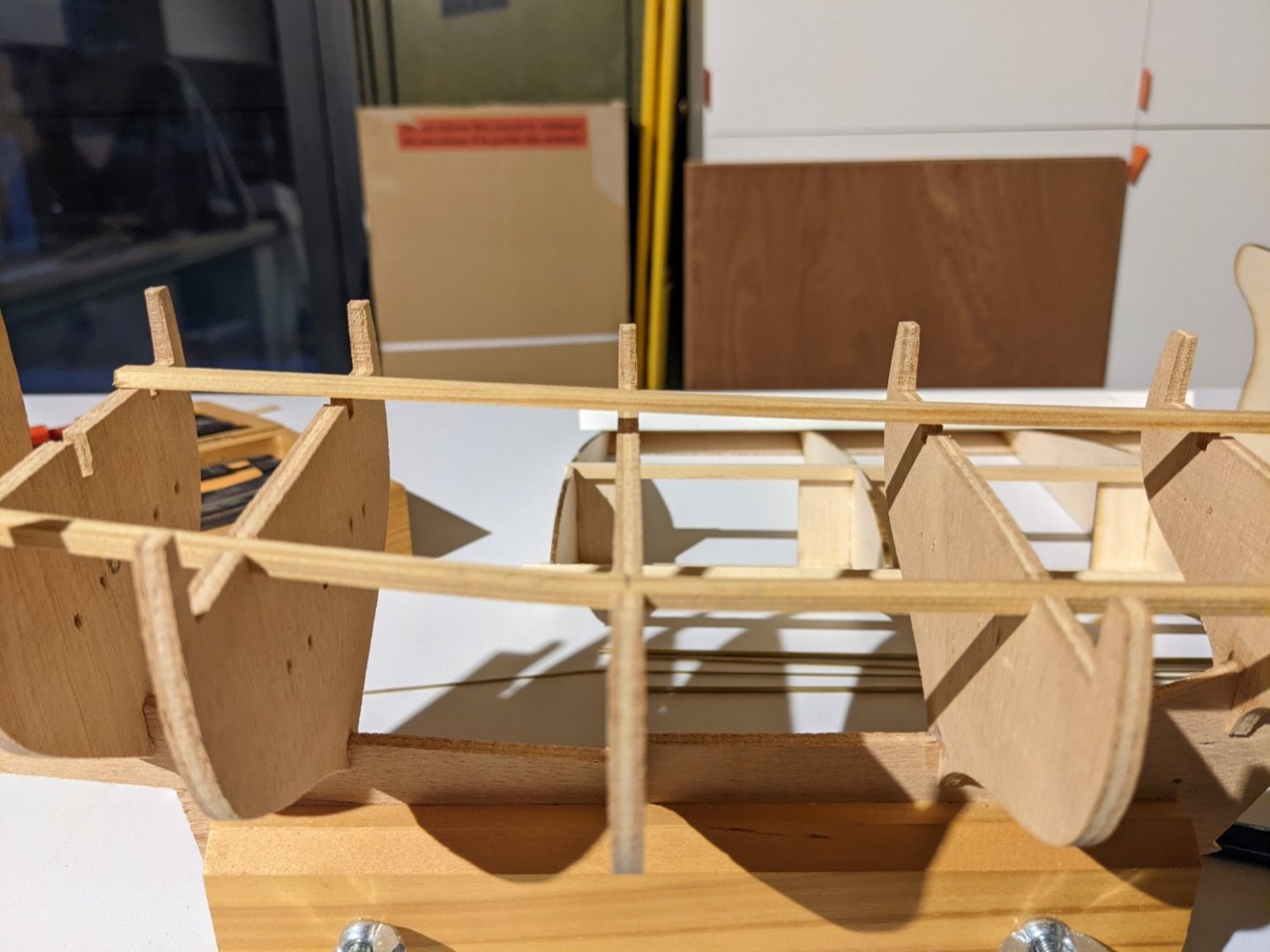

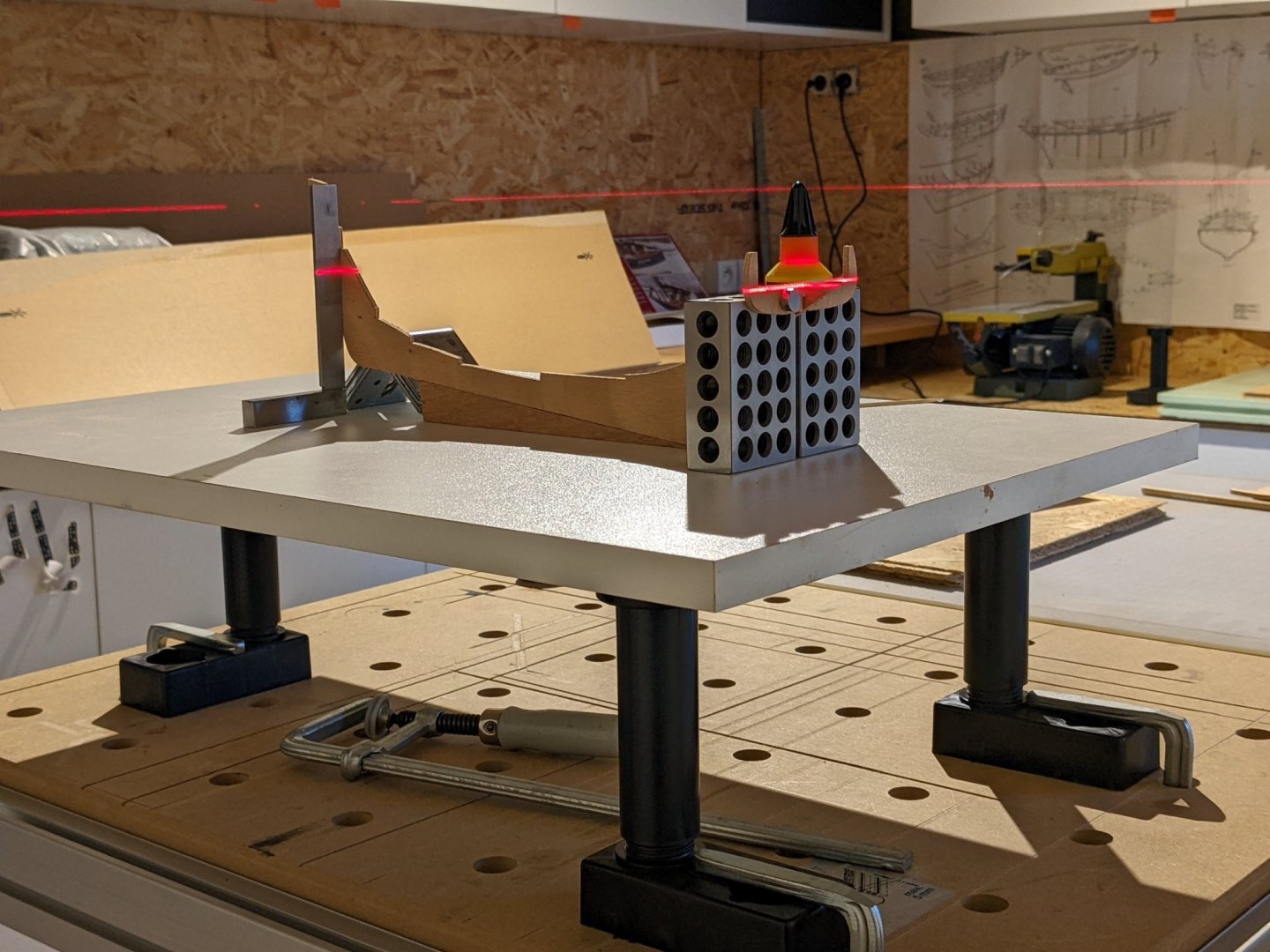

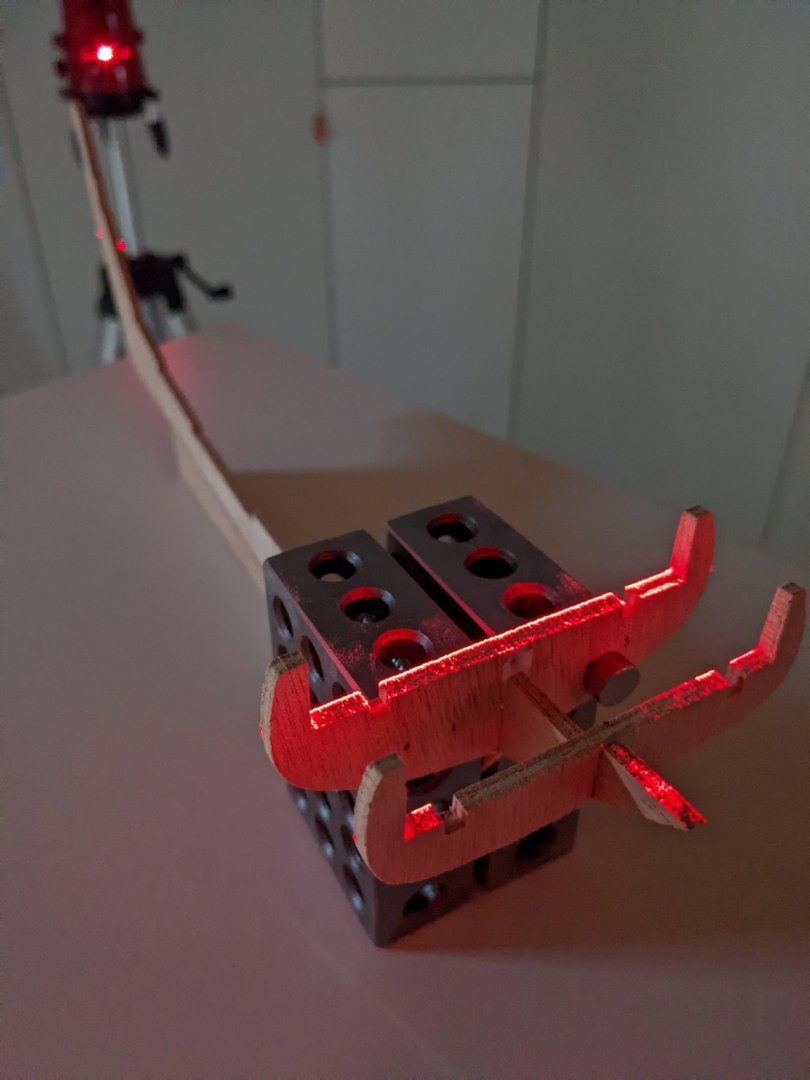

Aligning the first former after sanding the keel to thickness accepting all the formers with a very faint friction fit.

I am still missing a level, or even flat, building bench. This due to a recent (and still ongoing) house rebuild. So, as a stopgap I levelled a leftover board using, again, leftover adustable IKEA cabinet feet. Next I used the same laser to level the first bulkhead.

Turned the lot 180deg around and so it continues.

- ccoyle, king derelict, Keith Black and 4 others

-

7

7

-

-

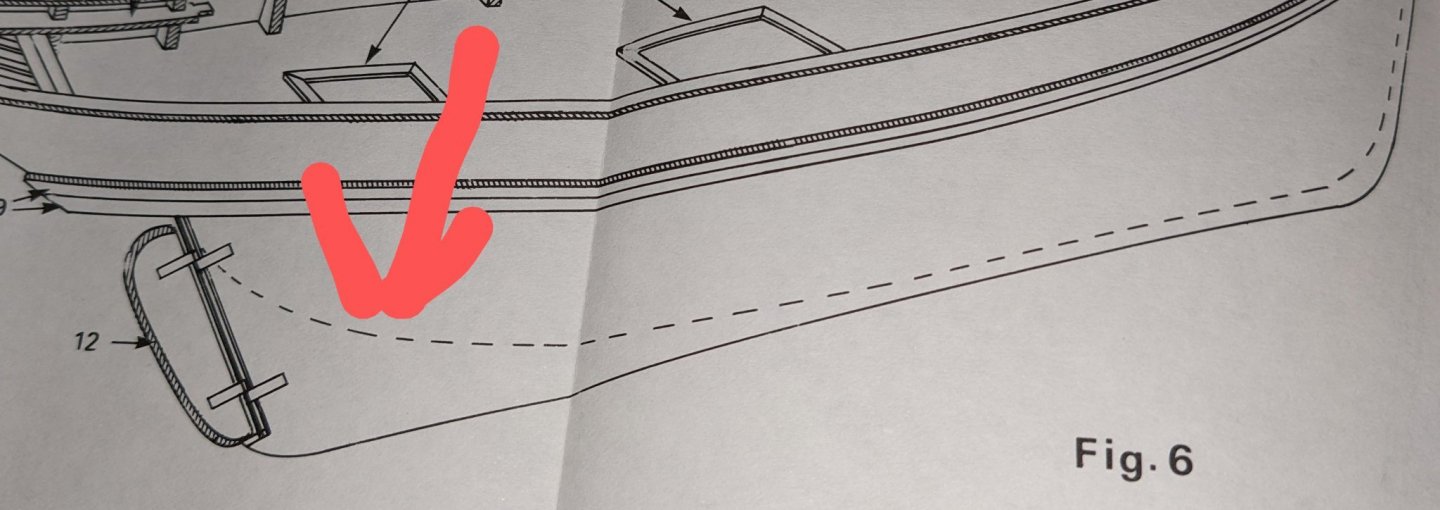

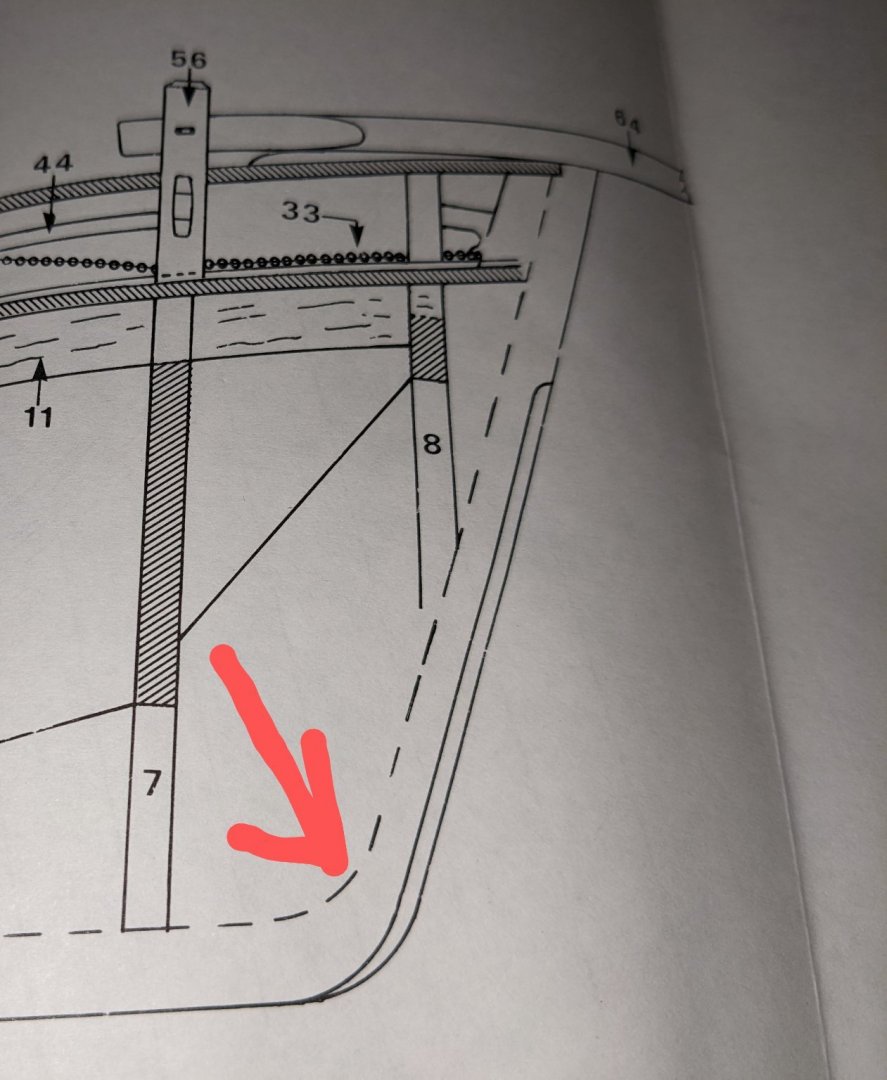

Currently I'm getting my bearings on the kit.

Let me start with a question on fitting the hull planks.

My initial line of thought was that the line indicated with the red arrow was where the hull planks meet with the keel.

While this seem possible at the bow, that does not add up at the stern. Thus, I must be misinterpreting them.

What do those lines indicate? Is it the start where to taper the keel frame to, say, 1/3 thickness?

-

- BobG, Baker, Ryland Craze and 4 others

-

7

7

-

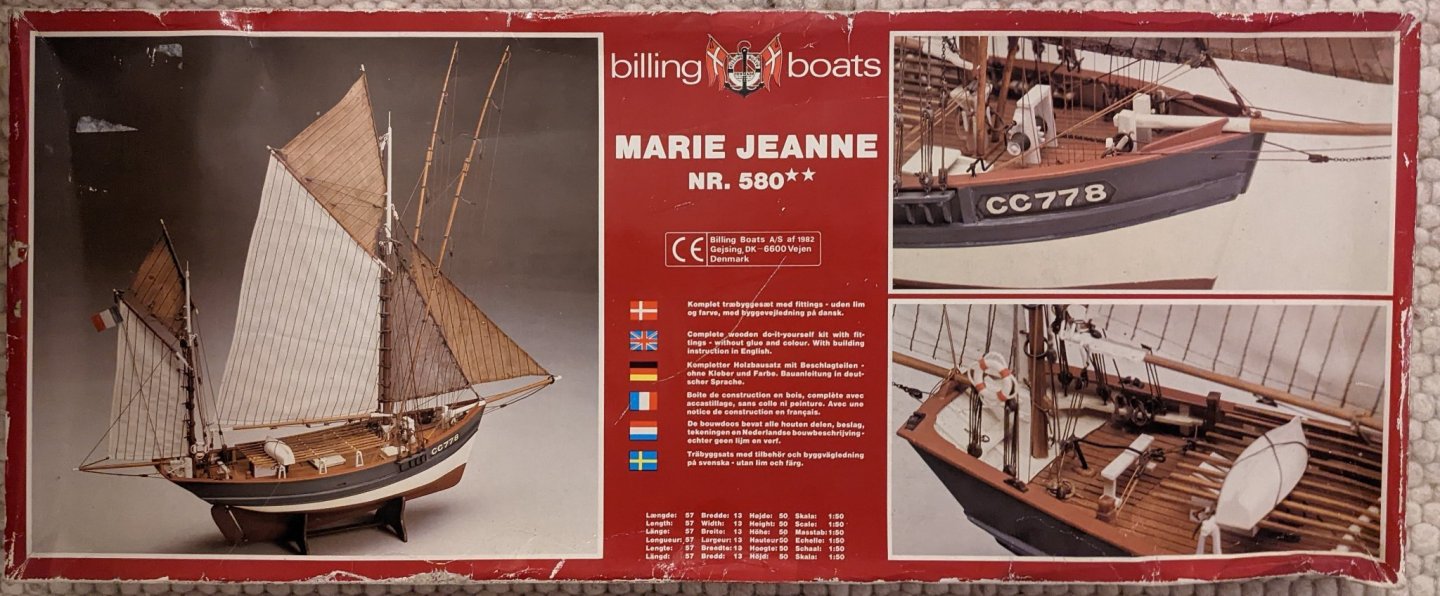

Hi all,

My name is Dirk and recently joined the MSW forum.

I have always loved the looks of the old wooden sailing ships. Be it fishing boats, yachts, first rates or anything in between. They all have their own type of appleal.

I'm quite sure I 'inherited' the modelling bug through my late dad. Although so far I never started a wooden boat kit.

My dad did several times though (although both of us mostly in RC planes). His latest he never got to finish (BB Regina). I'd love to complete it, as the end result, and process, would truely provide a threasured memory. Sadly, I have zero experience, thus need need to climb the learning curve.

I purchased a couple of kits to practice on, prior to completing dad's partial build. Being 2 BB Marie Jeanne kits and 2 additional BB Regina's.

So, looking forward to the interaction with you all.

Sincerely

Dirk (Belgium)

Designing my own hull...

in Building, Framing, Planking and plating a ships hull and deck

Posted

You could try the free version of DelftShip. But it leans toward CAD

https://www.delftship.net/