-

Posts

8,114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by allanyed

-

-

Ben, John, Elia,

Thank you. As soon as winter sets in and snow covers the golf courses, Effie should move along a bit more quickly. Going slow though does have the advantage of being more of a relaxing project for a change, easier to pay attention to the details and less rework.

Allan

-

The hull planking is on and first sanding complete. Hand sanding to a fine finish will be next. I left a section of planking off to expose the framing, but I have decided against installing most of the below deck items inside the hull. I left a little DNA on the keelson after a little slip of a chisel, so there is no denying who built this thing.

I put in a few inside planks for strength and the two mast steps are in place. The deck frames are started. There are a few carlings where there are deck structures and to set up the masts' partners. Once the deck is framed the stanchions and bulwarks will follow.

Allan

- EdT, canoe21, The Sailor and 9 others

-

12

12

-

Greg

Finally tuned in to your current build. Every bit as precise and beautiful as Pegasus. Will she be fully rigged?

Allan

-

Dan,

Fully rigged, oh my. I look forward to many months (years) of following your build. Maybe it will give me the spark I need to go back to rigging something more complex than a schooner.

Keep up the great work.

Allan

-

Richard,

Yes they should lie flat on the table unless the futtocks are stepped or tapered in width as they rise. Even so they would probably be

"flat" on one side.

Allan

-

Druxey hit the nail on the head. Scratch or kit. If kits, far fewer tools are needed. They are all desirable but less of a necessity.

If scratch, have you considered your library as well as your tool cabinet? Steel, Lavery, Lees and recent publications from Sea Watch books by members of this site that will help you in your endeavors.

Allan

-

Loblolly

Couple points to consider:

English walnut has been around for centuries as have ship models. I don't recall ever seeing or reading about walnut being used on the old models. Same for models in France or other parts of the old world. Walnut being rather large trees when mature certainly makes it easier to cut down to modeling size lumber than boxwood for example, yet boxwood is commonly found on contemporary ship models. I suspect it may partially be because walnut is not the greatest wood for ship modeling. My own experience with English walnut is not good but better using American (Black) walnut. It does not fray or splinter like English walnut and seems to be harder than English walnut in that it does hold a nice sharp edge. Walnut sawdust stinks and is a respiratory irritant as well as a skin toxin. I no longer use walnut for these reasons (but I do like to eat nuts from the English walnut better than from black walnut trees.)

For me, it is better to use box, castello, some fruit woods such as apple and pear, or a host of other hardwoods.

Allan

-

Sad, of course it is. But think about it. In 100 years people will look at these phones and shake their heads in amazement at how people had to use a hard device to communicate rather than telepathy or whatever they will be using by then. It will be as interesting to them as ship models are to us. That said, ship models are by far more beautiful and the intricate details that we see were made lovingly by hand, not robotic arms.

Allan

-

Richard,

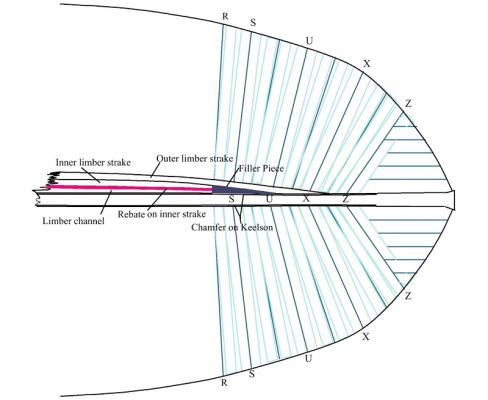

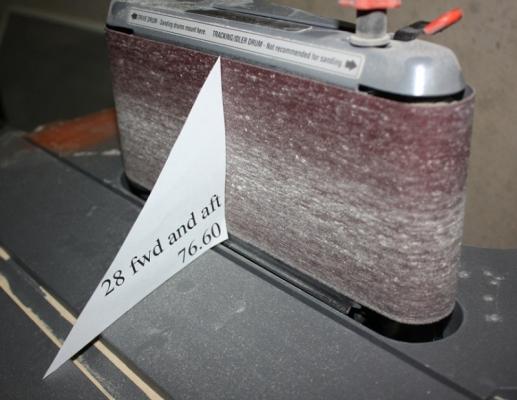

Russ has given good advice. The cant frames indeed lie at an angle, and each cant frame lies at a different angle. They are beveled inboard and outboard to allow the planking to fay completely against the frames as it bends around. These are the most challenging frames to make and to set in place.

I usually make a set of card stock templates, one for each angle, then use these to set the table of my sander before sanding the part of the frame that is secured to the deadwood. This assures that the angle on the frame is correct. To chisel or sand the angle by hand is not easy to be as accurate. In the photo it is marked 28 forward and aft which are the two frames at station 28 which was at the aft deadwood.

Allan

-

-

Bluto,

You have asked for a whole lot of information that by rights takes pages to explain. There are thorough explanations in Ed Tosti's book on Naiad as well as Volume II of Euryalus (36) 1803. These are available from Seawatch Books. You can also get some insight from Ed's really fine build log on the Naiad here at MSWorld.

Allan

-

If you are painting, oak is probably OK. If it is to be left natural, it is quite grainy and does not look quite right. I am not a fan of walnut for anything except that I have used it for wales on occasion and that was American black walnut. My preference is boxwood, European or Castello, the latter being less expensive and easier to find. Box is strong, holds an edge, and with imperceptible grain in most cases.

Allan

-

THANKS GUYS.

I am looking forward to how detailed I can get at this scale (1/4") compared to Michael's Bristol pilot cutter. That has sort of set the bar for me, particularly the iron work.

Allan

-

Thanks Druxey,

The plans from the Library of Congress are pretty good so it has not been terribly difficult, but alas, there are errors that I have found in the drawings and these take time to solve. Without much in the way of other sources on the hull construction I am having to use common sense and techniques I have seen in books on older ships. I hope to be visiting Effie (now Ernestina) in late August/early September to hopefully find some answers to some of the questions that have arisen.

Allan

-

A bit of progress has taken place. Frames are made and partially faired. Couple strakes have gone on which has beefed up the rigidity of the framing a lot. I did not do much fairing inboard down low as the lower hold is filled with cement for a good portion of the hull. Still debating about putting in the lower deck and cabin details. If I decide to cut out sections of the framing to expose areas inboard, at least the area where the frames are removed will get some finishing work. With Effie having gone through several transitions, her inboard layout also change a lot. I am probably staying with how she orginally came off the ways, so her layout inboard was simpler and certainly more austere than in later modifications. Keel, stem, deadwood, keelson are Castello box, the frames are poplar. Poplar is normally a bit soft for my own taste, but as all the frames are doubled, and the grain is running opposite on each pair, I had no breakage and the fairing has shown them to be pretty nice to work with, so far.

Allan

- mtaylor, Wishmaster, harvey1847 and 7 others

-

10

10

-

Certainly much cheaper than blank label paper which I have been using exclusively for a few years now. Will give the freezer paper a try.

Thanks for the tip.

Allan

-

-

I have been following your build for a LONG time Gary (maybe back to Green Dolphin Street if I remember the name of that site correctly) and never tire of your postings. She is looking fantastic!\

Allan

-

-

Jack,

Looking for an answer to the mystery object, but in the meantime, the "bridges" afore the fore and main masts are iron horses. There also fairleads between the iron horses and belaying points.

The aft most "bridge" which is aft of the steering box is not an iron horse but is know as a boom buffer. There were rubber pieces that acted as shock absorbers as part of the boom buffer. There are great drawings and descriptions in Chapelle's American Schooners.

Allan

-

Egen,

She looks beautiful. I find that the fairing done anywhere inboard is difficult. It appears that you have mastered it quite well.

Allan

-

I realized that the body plan did not account for the step and deck elevation difference from frame 24 and aft so I modified the body plan and frame drawings. I also found that the clamp for the weather deck beams on the cross section plans at stations 5 and 9 give dimensions of 3"X9" but the individual cross section drawings show two different sizes. I do not know if the given dimensions are correct or the drawn dimensions. To further complicate matters, an expanded view in the cross section plans shows a strake labeled as a sheer strake fayed to the inside of the frames and a clamp fayed to this sheer strake. Neither of these is dimensioned individually and the cross sections do not show this lamination. A drawing of the framing in the forward half the hull does appear to show this lamination.

Several more frames have been raised, so she is starting to take shape. I printed the frame drawings on pressure sensitive label paper, then cut each frame out and place it on the wood. It is then a matter of cutting them out and sanding them close to the lines before peeling off the paper. Brand name label material is a bit expensive, but store brand is much less costly and works the same.

Allan

- Elia, aykutansin and druxey

-

3

3

-

Thanks Ed,

The Micro Mark setup is the same etching kit that I (ab)used. I still have orange stains from a few drops of the chemcals that landed on our concrete back porch from 4 years ago. They do not go away, period, end. I did the etching outdoors to avoid fumugating myself in the basement.

I did the drawings with Cad as well, and printed them on the clear materials provided, in short did everything right. Alas, half the parts looked OK or even pretty good, but the rest looked terrible. I did not expect 100 percent success, but better than what I was getting. Maybe it's time to try, try again. The laminating machine leaves something to be desired for any thickness over 0.010" IMHO.

Thanks again for the input.

Allan

-

I finished volume I and am now reading volume 2 of 3. The first volume goes from predreadnoughts to 1919. It is extremely well written and goes into personalities of various naval and political figures, ship types, and sea battles. What I have found to be very interesting is the political maneuvering within each country with a navy as well as between countries. One time enemies became allies and vice versa. As late as the 1920's there was animosity between the British and US over having to do with fear of who had the larger fleet in the event they went to war with each other.

The great strength of the French navy at the end of the 19th century was something of which I had no knowledge. The ineptness in the poor use of their naval assets of the various admiralties in Russia, Japan, England, and Germany surprised me. A few miles difference was all it would have taken to have different consequences on how WWI turned out. Jutland could have had a totally different effect on the war had one decision changed on either the German or British side.

Any history buff will enjoy this three volume set, at least based on the first volume and a half that I have read.

Allan

HMS Naiad 1797 by albert - FINISHED - 1/48

in - Build logs for subjects built 1751 - 1800

Posted

Oh my, another build that I must now follow. Your work has sure started off beautifully!

Allan