-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HIPEXEC

-

I put a lifeline on the last stair in case it slips out of my tweezer like the last one did. Now that I have a line tied to it, I shall fit and glue it.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

One stair to go! The problem is, when I was trying to be a perfectionist with one final adjustment to that last stair.....it slipped out of my tweezer and into the deep dark hull forever! I had made some extra stairs, so I shall dress those up and attempt the installation of the final stairway. I have to clean up the glue on the stairs in the pic. Thanks for all the great comments.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Three stairs installed and four to go. I've been working on these stairs for over a week now and what amazes me is. when my ship is finished, with full rigging and sails, I doubt anyone will be able to look down those hatches. Oh well! I'll know.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Welcome to the Constructo can't-bend-the-wood club. Making that curve might better be done by cutting it out or bending smaller pieces and fabricating the bend to size. I did that with my Constructo USS Constitution.

-

Love those clamps...your Admiral can hang out laundry in between clamps. I also like your use of thumb tacks to bend planks.

- 1,350 replies

-

- constitution

- model shipways

-

(and 1 more)

Tagged with:

-

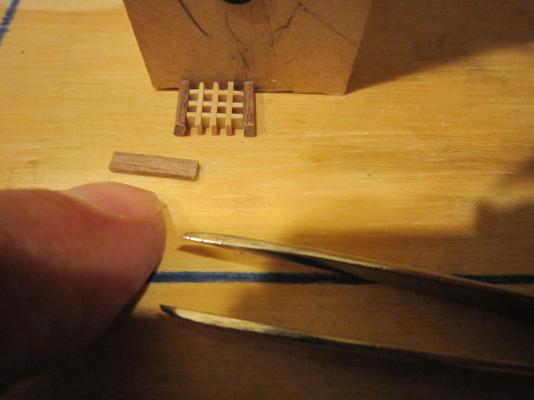

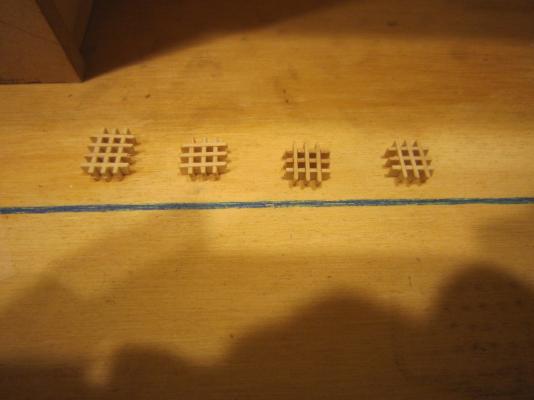

Not every step is perfect, but I made way more than I will need, so I can cherry pick the best sections. These steps look much better than the Constructo steps since they each have wider landing treads than Constructo's.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

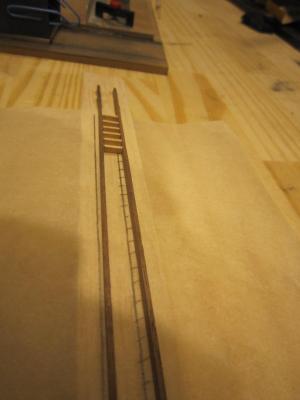

No...it's not Jacob's ladder....it's my mass produced stairs! All I have to do is clean up some extra glue and then cut them to size. So far so good!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

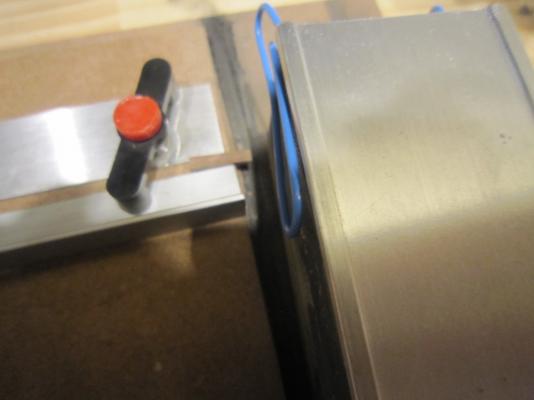

Tim, It's great for mass production jobs. All pieces cut will be the exact same length, but the pieces require some square sanding with your micro-sander to make all cuts precise. Even with a very sharp blade, it cuts slightly off perpendicular

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm experimenting with making my own stairs. I do not like the parts Constructo gave me. I'll play with this for a while and either have success or some more scrap wood.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

My big fat hands knocked off a davit while working on the stairs....pinned and glued! So, I put up some false masts with spare dowels I had to remind me there are glued down things sticking out of the hull and to watch where my big, fat hands go.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Dave, Nice idea. I'll try any and all ideas until I like the results.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

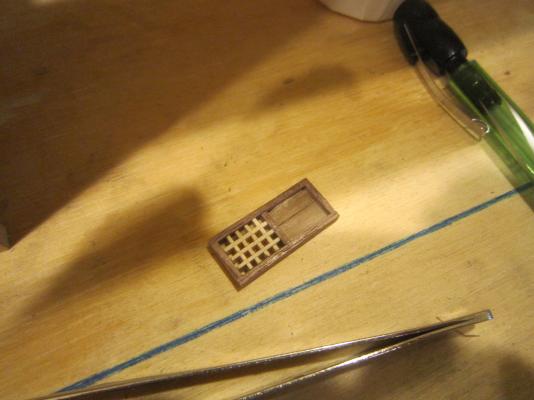

While I'm pondering steps, I dry pinned the bowsprit. I used a 2mm dowel for a pin. I will remove it now for later installation. Now I can glue the last grate.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Yes, Constucto gave me pre-cut step sides, but they are so thick, they leave only a little room for the actual step? I'm still pondering how to attack this problem.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Sam, I like the idea of a wedge or block down below. I dropped a piece in and had to fish it out of the hull....no fun. You're right....I continue to buy new tools. My Admiral marvels at how my work area has grown and grown and grown! Thanks, Rich

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Help! I need tricks and tips to build and install seven sets of stairs from the main deck to the gun deck. Constructo just says, make and install the stairs? No instructions?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I made the chimney from a 6mm dowel and painted it. I drilled out some material in the end to make it look like the chimney opening. I'll pin and glue it tomorrow. I glued all grates except the bowsprit grate. I also glued a shim in the bowsprit hole so the bowsprit slides in perfectly exactly at the correct angle. Next, I'll make the dowel hole through the bowsprit and deck, so when it comes time to mount it, it should just slip into place.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

My version of miniature carpentry continues. You can't see my thumbs...but they both have bandaids on them since I discovered my miter box and micro-sander both had a sharp edge and cut each thumb. I kept wondering where the blood was coming from?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Made the bowsprit grate, but didn't glue it on yet. I'm still playing with what to do with the bowsprit mounting.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I simulated the bowsprit dowel process by using a very small dowel and drilling a like size hole through the bowsprit into the simulated deck and using PVA, glued it. Wow! Pretty strong bond. and even through I did a sloppy job, you can hardly see the dowel.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I thought of drilling the deck, but I get cold feet thinking about drilling in the deck. Pinning might be good. I also thought about doweling it so the dowel would match the bowsprit wood. What do you all think of that?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.