-

Posts

698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NavyShooter

-

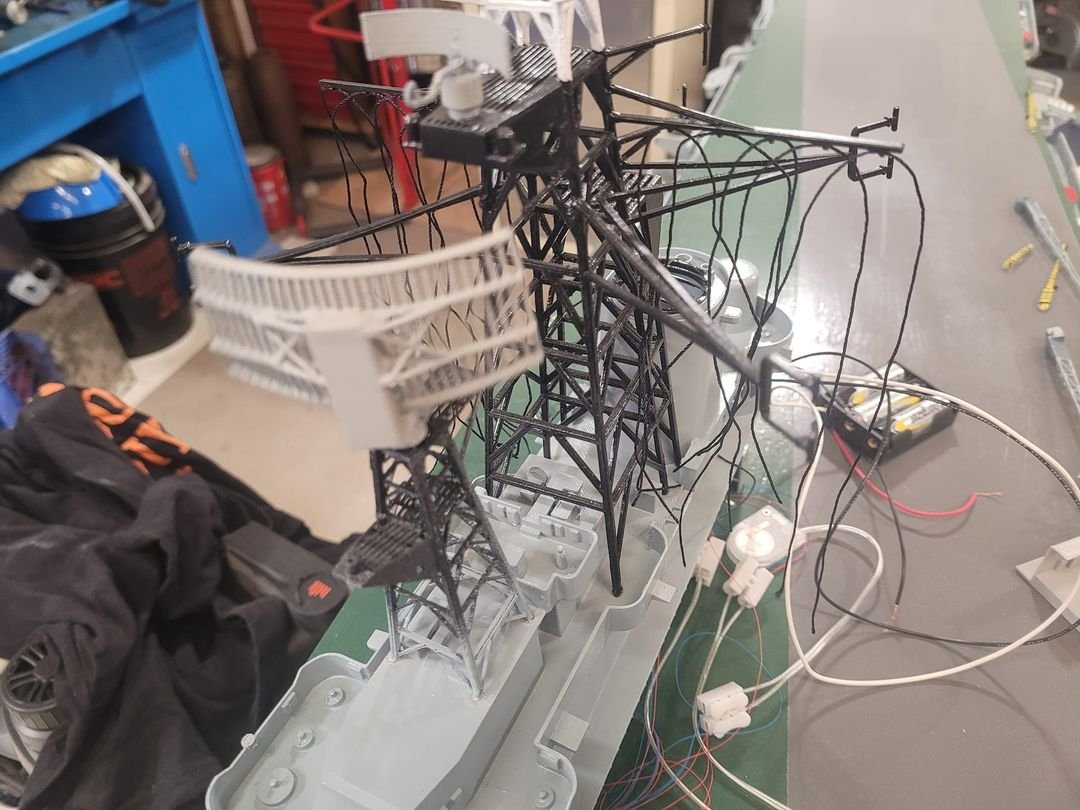

I've got a good start on the plank that I'll be using as the base - a layer of polyurethane applied to both sides of it this evening. I need some more lumber to finish it up - some oak for the supports, and some rails for the bottom edges to add some stiffness and strength. So, while I was waiting for the paint to dry, I decided to have a peek at the mast, and maybe run some of the signal halyards. Ended up running all 10 of them. I didn't tie them yet, I haven't thought that far ahead, but the lines are run, so that details is about 1/2 done. I'm not sure how much more rigging I'm going to add - in looking, there's definitely a flag to be hoisted from the mainmast, but I'll have to see where that is to run. This is the first time I've ever actually done rigging on a ship model, so I'm pleased that my initial design actually worked on this!

-

Very nicely done! I like how you harkened back to the original WW1 photo, and the scene is well laid out and presented. Having seen a Whippet in person up in Borden, I was a bit surprised at the size of them, I've seen FT-17's before as well and the Whippet is much larger than I'd thought it would be. Great work! NS

-

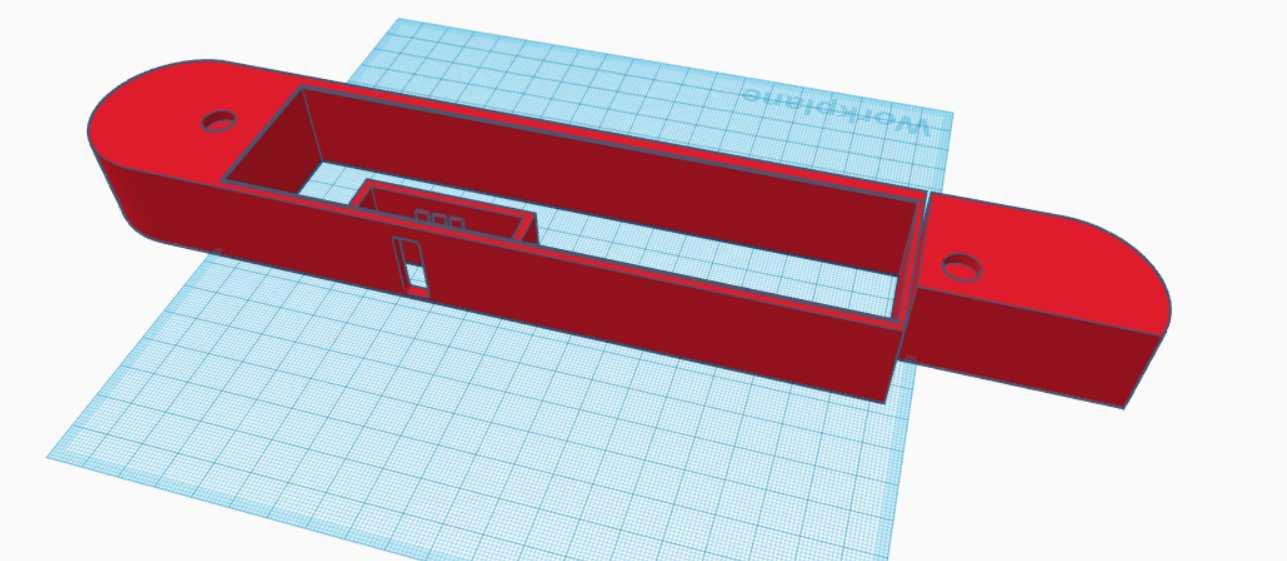

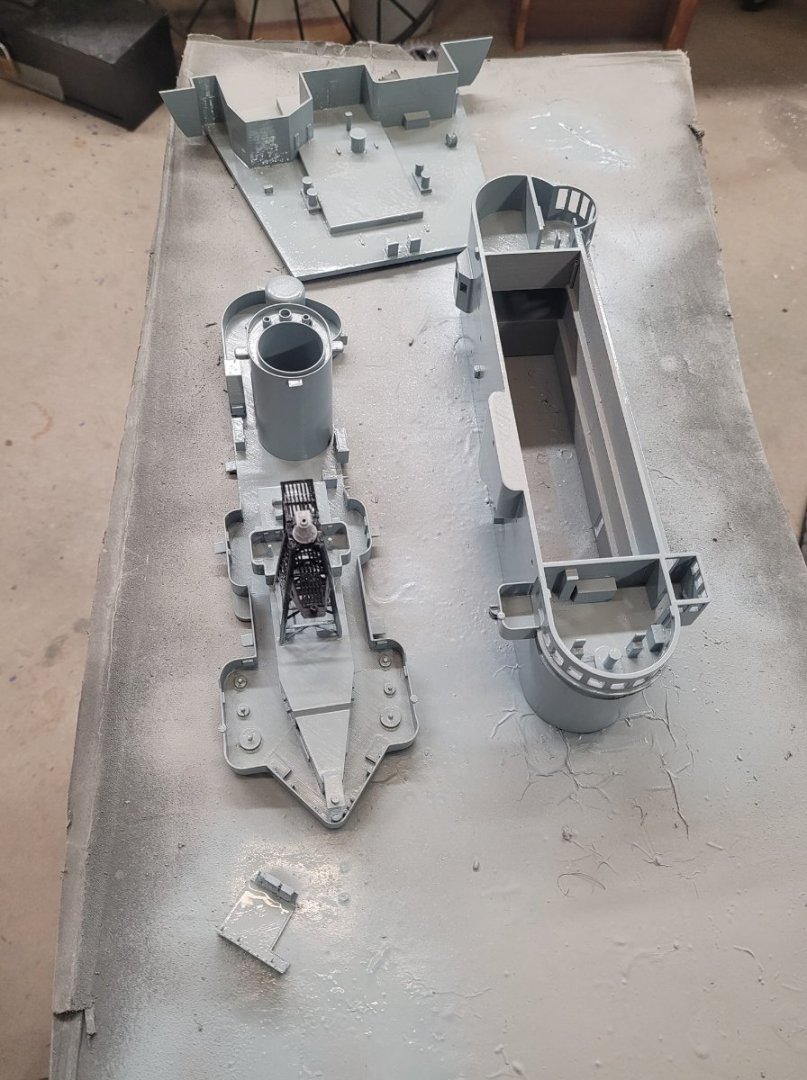

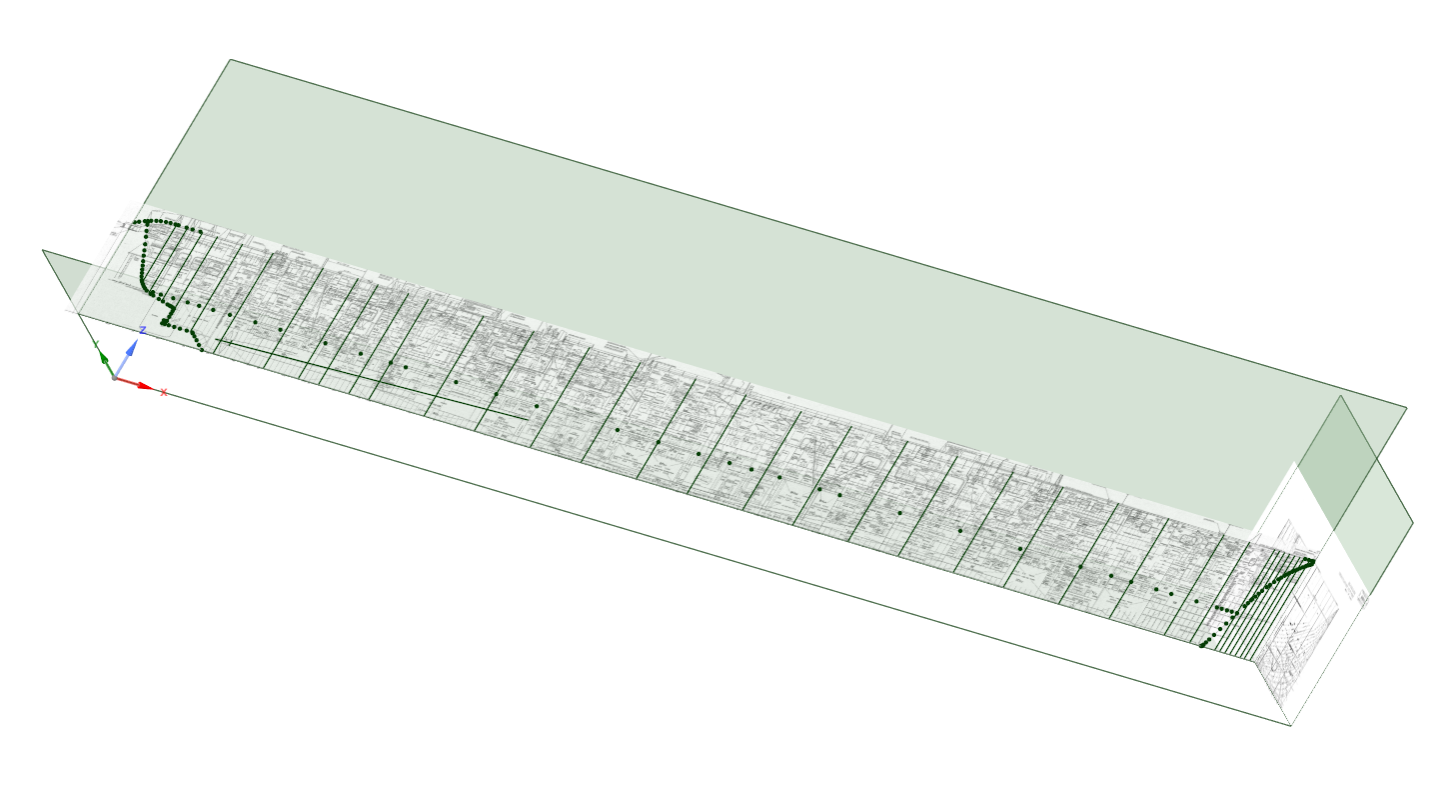

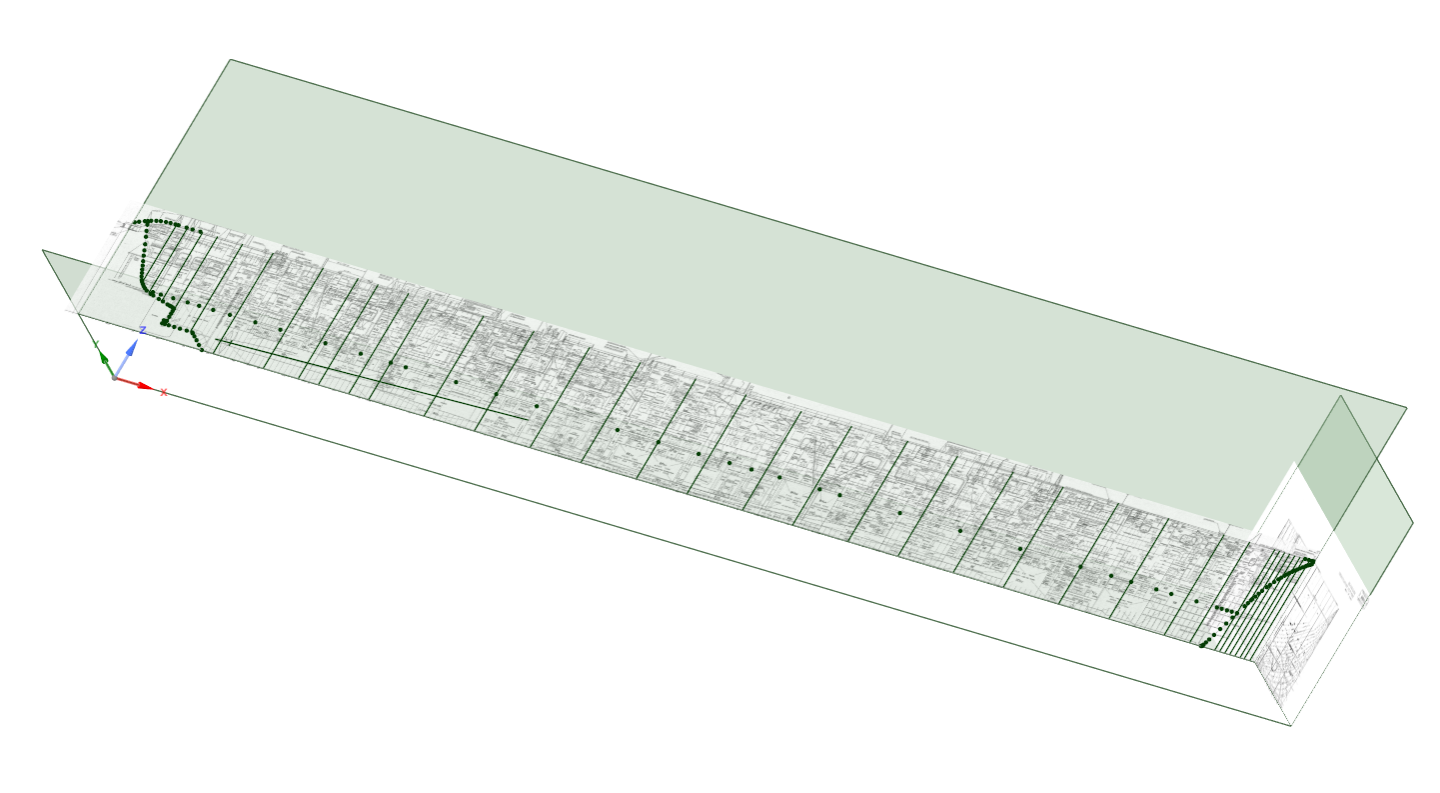

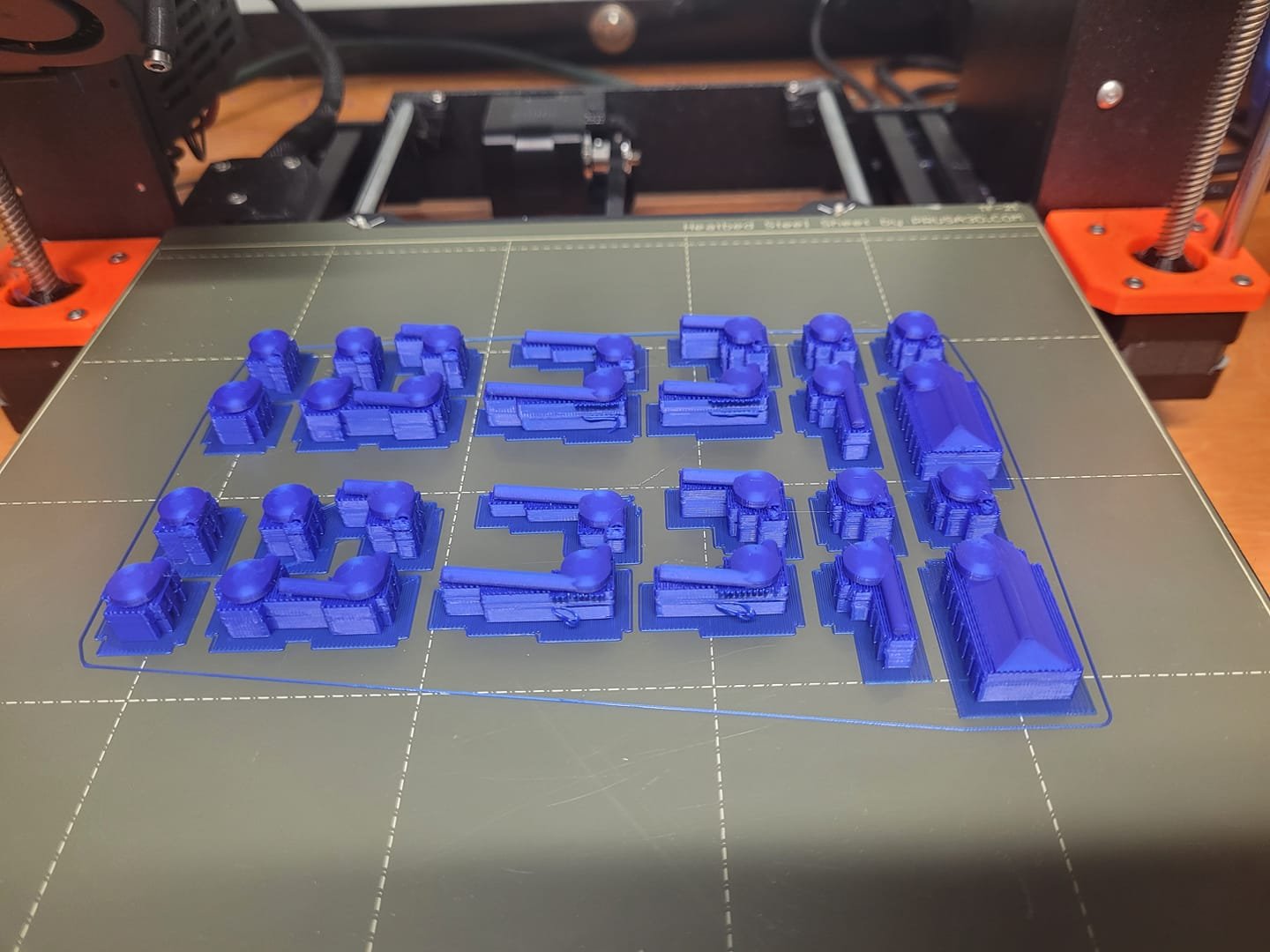

I've been pondering how to attach the 3D printed island to the deck, and have come across a solution. I took the 3D design, and superimposed it on a simple block - and made it a negative space/shape. So, now I'm left with a pair of blocks the size and shape of the inside of the base of the island. I will simply be able to attach these blocks to the deck, and drop the island onto them, and it should stay on. Note, the 'room' is actually visible space through a door in the island, so I built a space to be 'seen' in the shadows. I'll probably stick an LED light in it too just for the effect. This will take about 6 hours to print, so I'll let it run while I'm at work tomorrow and we'll see how it fits! Considering I'm planning to bring the ship to a show in a week and a half, I've made myself a list of priority items to complete in the time I have. Priority 1 - Build a keel block/carrying support Priority 2 - Assemble and test the elevator system Priority 3 - Mount the Island and get some LED lights working and the Radar dish spinning Priority 4 - Detail painting in the Hangar deck I suspect I'll be lucky to get the first 3 done. We'll see what the week brings!

-

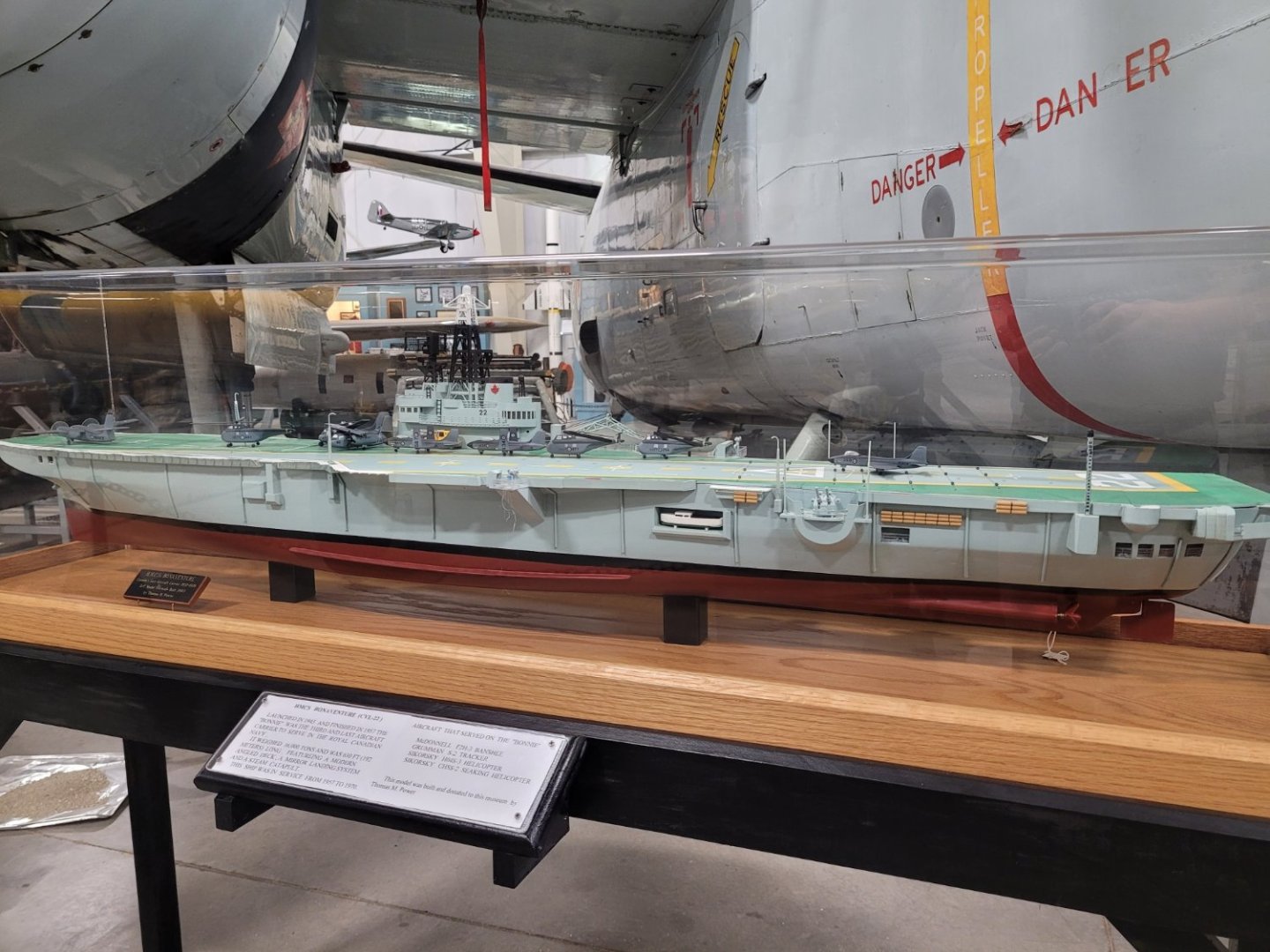

So...the most inspiring build, and the one that I'm really judging my own build against is that of Dan Linton. His model is on display at the National Aviation Museum in Ottawa, and I recall seeing it there when I visited with the family about 2 years ago, but did not get a picture....that said, there's an old website called "Carrier Builders" where Dan did a 7 page build log showing much of the scratch-built detail that he put into his construction, and I have looked to his pictures and build log for insight. Here's the 7 pages, and one of his photos: Building a 1:144 R/C HMCS Bonaventure: Part 1 (carrierbuilders.net) Building a 1:144 R/C HMCS Bonaventure: Part 2 (carrierbuilders.net) Building a 1:144 Scale R/C HMCS Bonaventure: Part 3 (carrierbuilders.net) Building a 1:144 Scale R/C HMCS Bonaventure: Part 4 (carrierbuilders.net) 1:144 r/c HMCS Bonaventure: Part 5: The Details (carrierbuilders.net) HMCS Bonaventure: 1:144 scale r/c: Part 6: Air Wing (carrierbuilders.net) HMCS Bonaventure: Part 7: Display (carrierbuilders.net) I am personally in awe of this man's skill, and have attempted to reach out to him a couple of times through a club in Ottawa, but haven't had much success.

-

I am lucky to live in the city where HMCS Bonaventure was homeported back in the day. There is an institutional memory associated to her, and there are 4 other models of her in the area which I am aware of. I have, over the past year, visited 3 of the 4, and a friend of mine who has the clearances and approvals visited and photographed the Bonnie that is in the Maritime Forces Atlantic Headquarters building for me. I have been pondering the question of 'how much detail is enough'? And 'what does right look like'? as a part of this build process. I had the chance to meet the builder of two of them - the one at the Maritime Museum and the one at the Atlantic Canada Aviation museum were both built by the same person. He's a great person, and works as a model builder at the Maritime Museum, and has for several decades. So....what does right look like? I can see some examples of what wrong looks like - in particular, the model at the MARLANT HQ has the flight deck colours reversed. The angled deck section should be gray, the rest of the deck green. There is an early photo I've found that might show the whole deck as green - but...that's a mix-up. There's also some in accuracy in the aircraft - the blue on the HSO4 is quite obviously wrong. But, to be sure, the models are certainly representative, and there is no one who would ever question that it is "THE BONNIE" that they are portraying. Then there's the question of detail - how much is enough? If I look at the large scale (appears to be 1/48) at the Shearwater museum, they have had some damage done to the model years ago (apparently a kid was standing on it?) and so some of the original details were lost, and have been replaced with paper printed details that have been glued in place to give the image of 'stuff' being in the catwalks on the sides of the flight deck. The other models all have varying levels of detail, there are some with fire fighter boxes, some have spools, there are some ladders, deck cranes, etc. The one 'standard' seems to be that there must be aircraft on deck. And that must be a 'mix' of aircraft - always include Trackers, and some helos. So, in looking at the other 4 Bonnies in the area - from 1/200, to 1/144, to about 1/48, I can honestly say that with the amount of variation between them, and the amount of detail that I have on mine already, I think I've exceeded 'museum quality' for the local museums at least. Which, I think, means that I have 'enough' detail, even though I'm still making more. All this to say, I'm pretty pleased with how my Bonnie is coming along....but read along to the next post to see the 'WOW' standard that I'm sort of judging myself against. NS

-

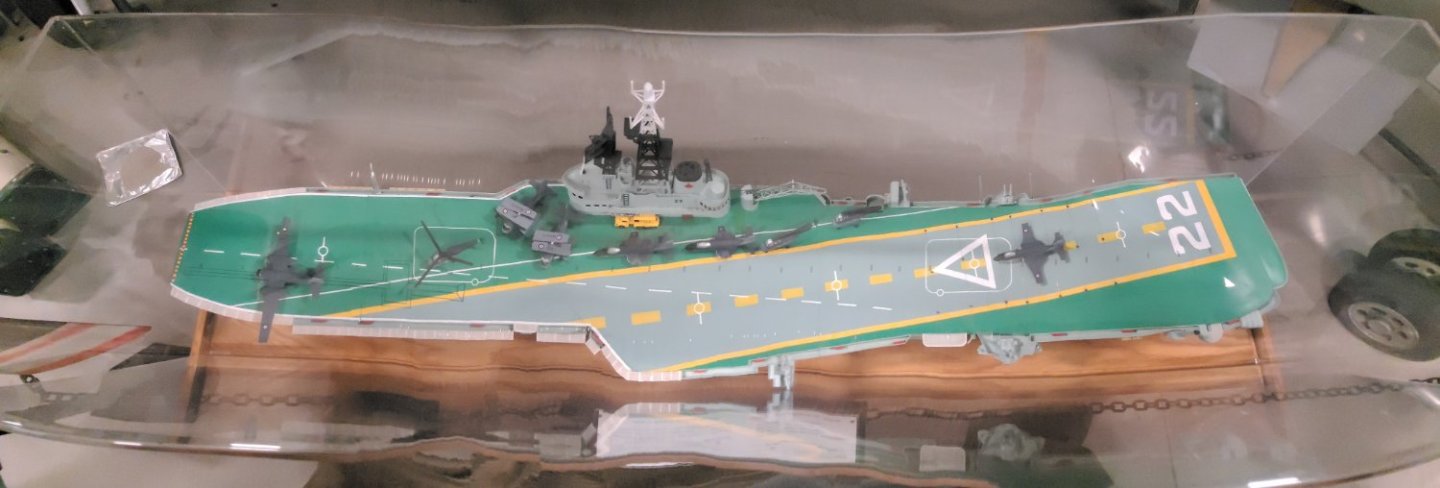

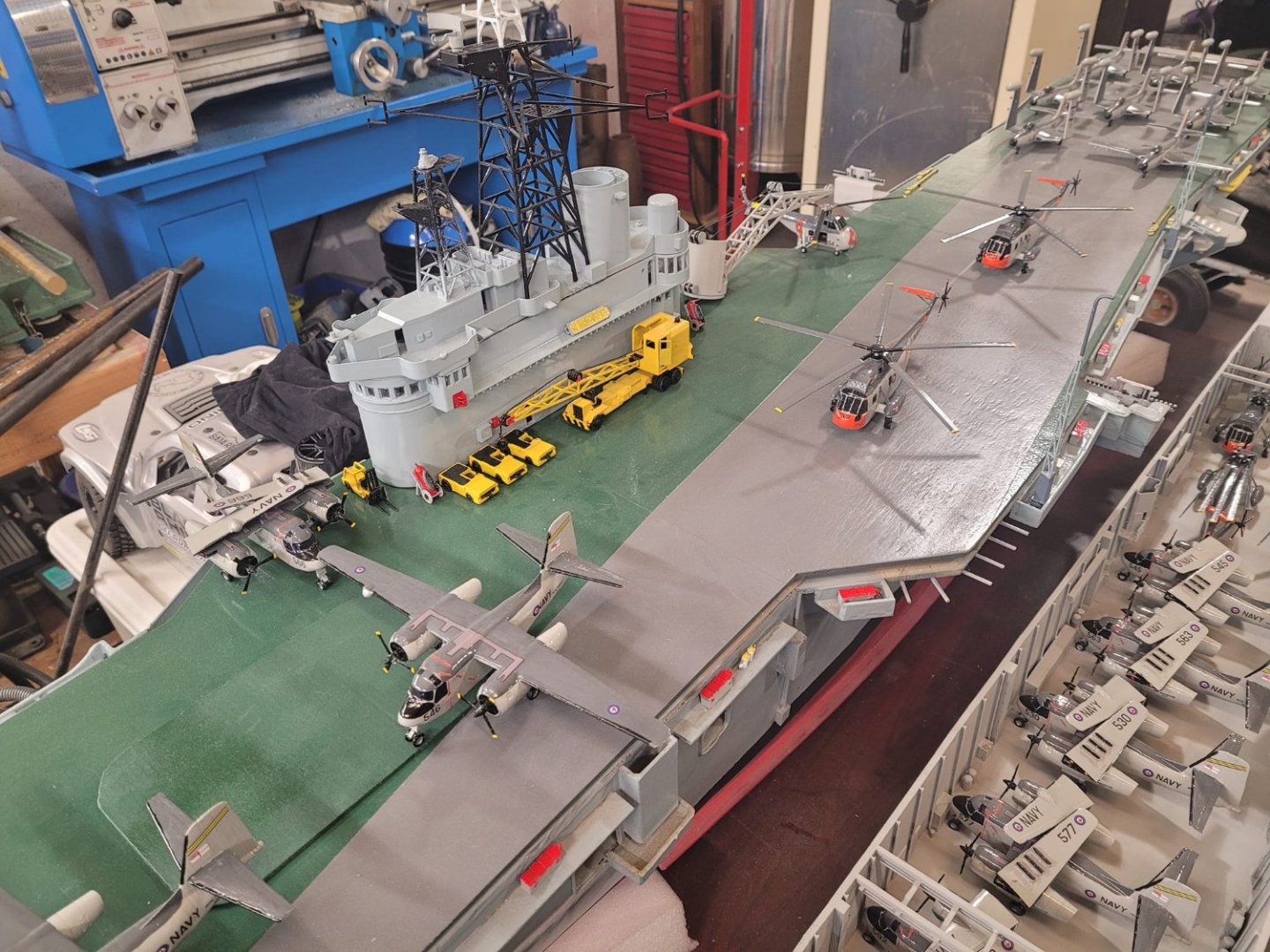

Alrighty....a little update on the Bonnie. I'm bringing her in 'as is' condition to a display at the Halifax International Boat Show in 2 weeks, so I decided to dress her up and see what 'as is' condition looks like. I have printed and assembled the new hangar deck, which has the necessary wells for the elevator lift mechanisms. The hangar deck is going to be a lift-in/lift-out module that will fit below the flight deck when I'm all finished, and the flight deck is going to get sliced up with 'hatches' to allow access to remove the entire module, as well as provide access to the anchor deck area, and the rudder area below the aft cable deck. I didn't glue any of the accessories in place, in fact, none of them are really in the right spots, I just wanted to get some imagery to share with a couple of folks so they could get an idea of what I'll be bringing along to the show. I'm quite pleased with the progress - there's still a long way to go, but getting the elevators figured out has let me move the bar along considerably. NS

-

Your work is inspiring! Having watched the build over the past several months, seeing it develop and the detail that you've laid your hands to come to completion...well done. You are a master of the art of model ship building! NS

-

F4U-1A Corsair by DocRob - FINISHED - Tamiya - 1/32

NavyShooter replied to DocRob's topic in Non-ship/categorised builds

Your problems have been overcome - patience is a good thing! -

Hi everyone from Brisbane Australia

NavyShooter replied to Ray Durant's topic in New member Introductions

Welcome aboard! -

It was pointed out to me by a Sea King pilot that I had the blades rotating the wrong way...so I had to rectify that. New blades have been printed, and are now on the way to paint. Including for the static aircraft. In other news, I saw an update from Bob Griffin (who's in the UK and is building a model of the HMS Victorious) showing his new aircraft lift. I reached out to him to find the source of the scissor lift, and have now ordered a pair of similar ones for myself. My project has been slightly stalled on this aspect, as I have to figure out the elevators before doing a bunch of other stuff. -I can't re-print the hangar deck until I figure out the elevators -I can't fit the electronics and other hardware until I figure out the hangar deck -I can't cut the access holes in the flight deck until I fit the hangar deck There are a bunch of 'to do' items that have been pending this step, and these mini scissor lifts are exactly what I've been looking for I think.

-

Today I got a bit more 3D design work done. Problem #1 that I had to solve was the rotor blades on the Sea King actually spin the opposite direction to that shown in the pictures I've posted...so I've redone the file, and will print some new blades when I get home tonight. With that fixed, I have to ponder whether or not I'm going to fix the 3D file for the folded version of the rotor blades...I might just leave them. After that, I still had a bit of time to play with, so I finished the design on the arresting wire spools. Bonnie has 7 wires - and only a few of them are 'the same'. So, some calipers and some sketch time later, here's what we have. I'm going to print 2 of each of them I think. One that will be 'no wire' for display only. The other set I'll do with elastic 'wire' between them. They are on 6mm pins, so they'll be able to be switched out if I'm going to have the aft elevator in use or anything like that.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.