-

Posts

3,084 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jaager

-

No, not Navy, although they are close neighbors now. I was PHS. Two LSD are in, but parked around the corner and a container ship whose engine seems to have not worked for at least 10 years and I guess belongs to the Reserves is hiding the Cyclones and and experimental stealth twin hull vessels. So, you have whatever is being substituted for White Pine these days, or may be Eastern White Pine. With a hardwood with a Janka hardness rating closer to 1000, the sharp edges stay more crisp and do not ding as easily.

-

White Pine is a traditional species for a solid hull. The pine that you are getting is probably from a tree farm, a species or hybrid species chosen for rapid growth and a straight trunk. I would guess wide grain that is high contrast. It could also have gummy sap. Not a particularly good choice for model making. Yellow Poplar is a good choice. It is a bit too soft for POF hull construction for my taste, but it will do the job well. With the proper cutting tools, Yellow Poplar should work well. I used it for a plug to make a 1840 1st launch and it cut and sanded well. It carves easily - you just need a sharp edge and fine touch to keep from removing more than intended. The only real downside is the green color if it is left natural and clear finished. You do not identify your location - if you are in North America, see if there is a hardwood vendor in your area. Hard Maple and Black Cherry are at the low end of cost for a domestic, and are about as good as it gets for our use.

-

Weldbond is a PVA adhesive. It is pH 4.5 instead of pH 3.0 for Titebond II so it is 15 times less acidic. Not a significant factor for wood to wood, but possibly makes a difference in longevity with paper or natural fibers : linen, cotton.

-

gluing pre-stained wood

Jaager replied to a topic in Painting, finishing and weathering products and techniques

A wood dye should have no effect on a PVA bond. A stain is a surface coat - similar to paint - it would depend on the specific product - but there is a chance that a bond may fail because the stain seals the wood pores and blocks penetration of the glue polymers. Your best bet is to do the experiment on scrap wood and determine the effect. The stain manufacturer could have altered the formulation and if someone had an answer from years ago, it may not apply to your situation. -

If the African wood produces more problems than it is worth, you might consider a different tack. Your original complaint is rooted in your choice to use a stain. Stain is essentially a paint - it covers. You could get to your original goal by using a wood dye. Aniline wood dyes come in two flavors - water base ( aqueous ) and alcohol based. The aqueous soaks in more than the alcohol and may be clearer when finished. The cost is that it takes longer to dry and the first application tends to raise the grain of the wood. The fix is to either fine sand after the first application and then do another - which may produce an inconsistent finish - or treat the wood with water or water with 1:10 PVA added to lock down the fibers - sand after and then apply the dye. Dyes come in several primary colors as well as various wood shades. White is the one that will require a paint.

-

Sources for Rigging tables before Steel 1794 wanted

Jaager replied to archnav's topic in Masting, rigging and sails

There is a ready source: SCANTLINGS OF THE ROYAL NAVY 1719-1805 Comparisons of 1719, 1745 Establishments, Ship Builders Repository and Steel’s Elements and Practice by Allan Yedlinsky This specially formatted book (14”x8 ½”) is divided into 2 sections. The first shows all of the scantlings from the 1719, 1745 and 1750 amended figures in an easy to use spread sheet format. Seawatch Books -

Book binders PVA is a choice. It dries clear and if slightly diluted should mostly soak in and not produce a film layer. Titebond works well for wood, but it has a pH that is about as acidic as vinegar ~ 3.0. Another option would be to use black ink to dilute - You could get a larger supply of the tan and dye it with a walnut dye and have something that is closer in color to rope treated with pre-petrol age tar. Is your rope cotton or linen? If it is a synthetic polymer, I have no suggestions. The only synthetic or polymer that I am willing to use at all is the PVA itself.

-

You could make up the keel off the boat. Using a jig - plywood or glued up scrap cut and sanded to match the inside of the keel. - a second piece that is the shape of the outside of the keel. The wet layers of the keel sandwiched and clamped between the inside and outside jigs until dry, The keel should then lay naturally on the hull. When the keel is dry from the wet clamping - you could fit the bottom two layers on the hull and drill holes for pins or bamboo dowels thru the keel layers into the hull spine.then glued up and clamp the layers to set. After the glue up - the pins fit into the holes and used to site the keel. The outside lamina would hide the pins and keel would be more secure than if using glue alone.

-

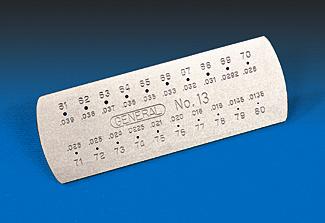

For the trunnels: bamboo skewers are easy to find. There are very long ones and shorter ones in most grocery stores. I have gotten a supply recently that is a softer species, will split straight down end to end more readily, and pulls better. The negative - they do not standup to much push force, so the hole needs to be a gauge larger. I have wire drawplates, and they work a champ for drawing wire - can get any wire gauge that there is a hole for. They are not so good at sizing bamboo. I got my setup before Jim Byrnes became a source so I use a General No. 15 I find that drawplate tongs work pretty well - with or without the addition of a sandpaper gripper layer. for #61 down, a General No. 13 works well. Here, 220 grit sandpaper and my fingers are enough.

-

Not just trunnels, Titebond II - I apply a thin coat to both surfaces. I just read something else that I have incorporated. End grain to end grain does not make for a strong bond. No big deal for deck planking, but can be for frame timbers. The new technique: apply a thin coat of PVA to the end grain surface and let it dry. Then when gluing up the stick, only one surface needs any fresh glue. For decks, a separate supply of glue can be used that has burnt senna, walnut,or similar dry pigment added to simulate caulking.

-

Being old school - Davis/Underhill - it is sort of a belt and suspenders sort of philosophy - using both glue and pegs. The deck would be clamped using brass pins with a small piece of wood between the head of the pin and the plank. The pin bent to apply pressure to the piece of wood. With brass, if the pin is stuck, it can be cut off and filed. I have been calling this "hutchocks". When the glue dries the pin holes are then drilled for bamboo trunnels. Working at 1:60 - a #70 is about 1 3/4" dia. in scale I find that the hole needs to be at least #68 or #67 or #66 to get a push fit without the bamboo getting stuck and breaking. Before driving home the dowel, a smaller steel pin that has been deeply dipped in 9 parts Titebond III -1 part water is run thru the hole a couple of times to provide the knotting. The peg is cut off using a sharp single edge razor blade. Then the planking is sanded and scraped. A problem with this when at 1:72 or smaller is that it starts to get to #80 dowels to keep the trunnels within anything close to scale and #74 - #76 is as fine as pins get. And things are sort of fragile.

-

Anyone own a Woodcraft spindle sander?

Jaager replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Bob, With a free 1/2" shaft you are potentially golden for options for the machine. 1. You loose the table, but for free hand - if you wish to save on the cost of the sanding medium: There are sleeveless drums - they use sheet sandpaper: 06P14.jpg Woodcraft has 3" x 3" , 2.5" x 3" , 2" x 3" drums with a 1/2" set screw socket mount. They have a 1/2" rod for a chuck to grip. Peachtree Woodworking Supply has 3" x 3" , 2"x 3" they also have 4.5" x 3" and 6" x 3" for a large surface. Both also have 1" x 3" and 3/4" x 3" but the socket mount is 1/4" - they have a 1/4" rod As far as 1/4" tools: There are shaft arbors that mount on a 1/2" shaft: 3ZN03_AW01 s.jpg They are available from multiple sources, but low quality will likely not run true. Granger has arbors that are 1/2" x 20 (fine) threaded at the business end as both RH and LH. They can mount buffing and grinding media - with a 1/2" hole. I am guessing that your machine turns CCW - I confuse myself with LH vs RH, but Grainger has a 1/4" chuck - it is only 1/4" though - that threads on the 1/2" x 20 shaft and tightens down with CCW rotation. 1F612_AS01 s.jpg With this chuck, the 3" x 1" and 3" x 3/4" drums can be used. In addition 1/4" carbine burrs can be mounted. 259700_F.jpg Wood Carvers Supply has a wide variety of choices available. For our uses, the fine carbide seems coarse enough. There is a Jacobs chuck that will mount on the 1/2" x 20 rod at Harbor Freight image_18878 s.jpg Again, CCW holds it down. With this chuck you can use the Microplane tools 1" x 2.5" and 2" x 2.5" 828821 s.jpg These cutters are designed to use CCW rotation and have a 5/16" rod for a chuck to grip. If you find a tool with a 1/2" rod and want to mount it, Grainger has a 1/2" shaft coupling: 6L013_AS01.jpg I have just made my own version of this machine, but with inspiration from Jim Byrnes - his machines are 1/3 HP - 2 pole - but are ~ 3400 RPM - twice what a sander wants - I bought a 1/3 HP self cooling 2 pole 1700 RPM motor and wired it with a drum switch so it will rotate CW as well as CCW. I am right handed and prefer working on the right side of the drum. But when sanding the rail end of a frame on the left arm - the drum tries to throw the work. Flipping a switch to reverse the rotation solves the problem. But with CW rotation, the chuck wants to walk up the threaded rod. Set screw mounted tools work either rotation. I will have to think about how and if I want to add the belt sanding option. I had not thought of that possibility until your post. These tools work fine for free hand use. For cutting the bevels on frames, the change is continuous so a table is not much use - free hand seems about it. I am thinking that the 4.5x3 and 6x3 drums will give me plenty of room to work. I also want to use the Microplane and 3" drums as an edger, to sand and true up boards that are too wide to fit my sanding planer. The arbors and chucks are not turning as precisely true as I wish. So, as much as I hate have to tear down my lathe to clean up the steel cuttings, I will probably bore my own shaft couplings from 3/4" steel rod, bore a 1/4" hole in one end and 1/2" in the other and drill and tap for set screws in one and 5/16" by 1/2" in another. -

Anyone own a Woodcraft spindle sander?

Jaager replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Mike, Unless you intend to model at 1:36 or something like that, the additional surface area with the belt over a 3" drum may not offer that much more function, but that or the drum allows you to sand with the grain, while a disc or vertical belt sands across the grain. For sanding end grain for precise match up , I trust the disc over any sort of belt because a belt will have give in/out. -

Anyone own a Woodcraft spindle sander?

Jaager replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

Bob, How are the drums mounted to the motor shaft? More to the point: what is the bare shaft like? Is it a 1/2" steel rod or a proprietary setup? If it is proprietary, how is that attached to the actual motor shaft? -

False Hull Fillers

Jaager replied to achuck49's topic in Building, Framing, Planking and plating a ships hull and deck

What power tools are available to you? -

John, Holly is a difficult wood to season. The piece you have has probably been infected with Blue Mold. It is grey or blue and it discolors the wood. The good aspect is that it only discolors, it does not rot. You can use it with no worry. I was working Holly logs into billets and as the band saw blade approached the end it was pushing water ahead of it, so communication inside the wood is easy. Most who want Holly are after the snow white effect. To preserve that, Holly must be harvested in Winter and rushed to a kiln to stay ahead of the Blue Mold. For most of our uses, it does not matter. In your case, it makes for a more realistic decking color. Holly takes well to wood dyes and makes for an easier to use Ebony when dyed black and the mold does not matter It bends like a champ,so is good for hull planking, it just looks better dyed or painted. The scale effect of the grain is about as good as it gets. BCD, Open pore species- such as Oak, Ash, Hickory, Black Walnut - do not scale well, so are maybe not among the better choices. Basswood in pre-scribed sheets is what kits used to provide for decks. The wood scales well and will work as individual planks. It is just too soft and ready to fuzz for my taste. Yellow Poplar is light weight and easy to work and stays crisp. You have to be picky about the planks unless you want a greenish deck. Soft Maple might get you some grey effect in areas of a board, but mostly it is close to white. It is soft, and can fuzz or be brittle. As a horticultural specimen Soft (Water) Maple is a weed. Hard Maple will make for a good deck if you want something that looks like Rupp Arena. Sycamore ( American ) is brittle and has a pattern that is too busy ( an alternate name is Lacewood ). What the English call Sycamore is a species of Maple that is close but not quite as hard as Hard Maple.

-

Anyone own a Woodcraft spindle sander?

Jaager replied to Landlubber Mike's topic in Modeling tools and Workshop Equipment

The unit on sale looks to me to be the same Asian generic that Harbor Freight sells. -

I think I missed the problem that started this. This looks like a POB build. It also looks like Burroak is trying to get by with a single layer of planking. My thoughts: in POB the molds are generally spaced too far apart to provide an unambiguous surface for the planking to lay against. Wood is organic - it has inherent variability in response to stress. The distance between molds gives the planking an opportunity to display that variability. I doubt that even the most precise thickness sander can produce stock without some +/- variability along and between planks. The original shipwrights had to adz or plane the surface of the planking to get a smooth surface, we should expect to do sanding, or scrape, or plane. It is probably wise to leave the planks a tad thick to provide something to remove without being able to read print through a too thin final thickness plank. The planking is going to react to changes in heat and humidity over time. Without a near solid support and having been forcefully clamped while the glue sets up, the planks are going to flex and swell at different rates.

-

Model Shipways Willie L. Bennett Questions

Jaager replied to FlounderFillet5's topic in Wood ship model kits

To get it on the record and this may come with the kit: There is a full size guide that is 56 pages long. WILLIE L BENNETT, CHESAPEAKE BAY SKIPJACK 1899 LANKFORD,BEN MODEL SHIPWAYS BOGOTA, NJ 1981 I believe "Old Ben" was the kit developer. Other relevant publications: NOTES ON CHESAPEAKE BAY SKIPJACKS 1944 CHAPELLE,H I CHESAPEAKE BAY MARITIME MUSEUM ST MICHAELS, MD 1981 SKIPJACK SAIL PLANS RUBIN,NORMAN N NAUTICAL RESEARCH JOURNAL 1978 24 72-73 19TH 20TH SAIL MASTING RIGGING FISHING A THE WILLIE L BENNETT AND NOTES ON OTHER CHESAPEAKE BAY SKIPJACK LANKFORD,BEN NAUTICAL RESEARCH JOURNAL 1983 29 61-83 19TH 20TH NA CONSTRUCTION MASTING RIGGING DECK HULL A SKIPJACK NOTES HECKLINGER,FRED NAUTICAL RESEARCH JOURNAL 1984 30 29 19TH 20TH SAIL FISHING RIGGING A CHESAPEAKE BAY SKIPJACK - A MIDWEST PRODUCTS KIT EVANS,ROBERT L SEAWAY'S SHIPS IN SCALE 1993 4-3 58-61 KIT 20TH SAIL FISHING B -

For a full size assembly I just used an epoxy to bond steel to wood. I have tried the syringe applicator in the past and I had a tendency to push one end more than the other so I had to express more than I needed to equalize the two components. But that waste was of no consequence because I use it so infrequently that most of it tried in the applicator before I used it all. This time I used J-B Weld original - it comes as two 1 oz tubes and is < $5.00 US. It has about a 5 hr set time so you have a while to play with it. It takes 24 hrs to cure. Then it can be filled, sanded, tapped, drilled. It is ugly (dark grey) and messy and goes where you don't want it if you are not careful. Wear gloves and mask any surface where it is not wanted. It is cheap enough that mixing too much is not an issue.

-

Sometime between 1815 and 1861 the USN "suits" directed that the inner and outer surfaces of the hammock rails be wooden panels. They looked better because they could be painted. etc. It seems that the crews of ships did not favor this. This was a source of dangerous splinters when struck with a projectile. When the situation tended to the possibility of sure combat (an actual war), it seems that some captains replaced the wood with webbing and canvas. I am betting that "It is better to do and ask for forgiveness later, that ask for permission." is a Navy tradition that goes back far farther than we know.

-

Where to find 28 gauge black wire?

Jaager replied to David Spindle's topic in Masting, rigging and sails

If you have a draw plate with one wire gauge at the large end, you can draw the wire to any gauge that the plate has a hole for. It would be regular copper or brass wire since no coating will survive the process. -

Hull plank length

Jaager replied to Mau's topic in Planking Techniques's Click Here for Topics dedicated to planking!!!!

This is American from 1826 - HASN - General Instructions for building a Sloop of War No length specified, but " No plank to be more than 12" wide at midships." I would think this would hold generally as a width max for any ship. Deck plank Heart Pine "no more than 10" in width" "Average length to be 40'." We had a lot more trees than France - and most were 1st growth. The pine was probably from the southeast US and the trees were 80-120 feet tall - mostly straight - and free of branches until near the top. The White Oak could also be 80' tall - so long plank "could" be had - the wood is much heavier the effort in manipulating the logs probably constrained how long they cut the logs. Unlike deck planks, hull planks have curves and sometimes recurves. The spilling required with an especially long hull plank would probably involve more wasted wood than most builders would tolerate. -

The only reason I can think of to seal the first layer of planking in the two layer system would be if it was being used as a mold and the intention is to pop the 2nd layer off after it is formed. otherwise raw wood is optimal for the bond of the second layer. Better results may be had using yellow PVA - like Titebond II ( or Titebond III if you are compulsive). I read directions about a process to use yellow PVA as a contact adhesive by precoating and letting it dry - I forget what the step for bonding is and I can't find the reference. With planking - it being a fit-adjust - fit-adjust process, I see no advantage in instant bonding anyway. I am compulsive about coating both surfaces - but for planking excess glue squeeze out is not a helpful thing so just completely wetting both surfaces lightly is the goal. For end grain to end grain - the bond will never be strong - but the way to get as strong a bond as possible would be to pre-wet both ends with the PVA - let it dry - and add more when gluing up. I made a miniature sponge stick glue applicator by gluing a round tooth pick to a small piece of foam packing. You can cut it just as wide as the plank and it will leave a just wet surface behind it.

- 10 replies

-

- El Pilar power boat

- 1:27

-

(and 1 more)

Tagged with:

-

Look higher up in the forum: Member's Build Logs Build Logs for SHIP MODEL KITS Pinned 18th century English Longboat - by Chuck - c.1760 Your very kit - as done by the developer of the kit -

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.