-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Chestcutter

-

-

- etubino, flyer, KARAVOKIRIS and 4 others

-

7

7

-

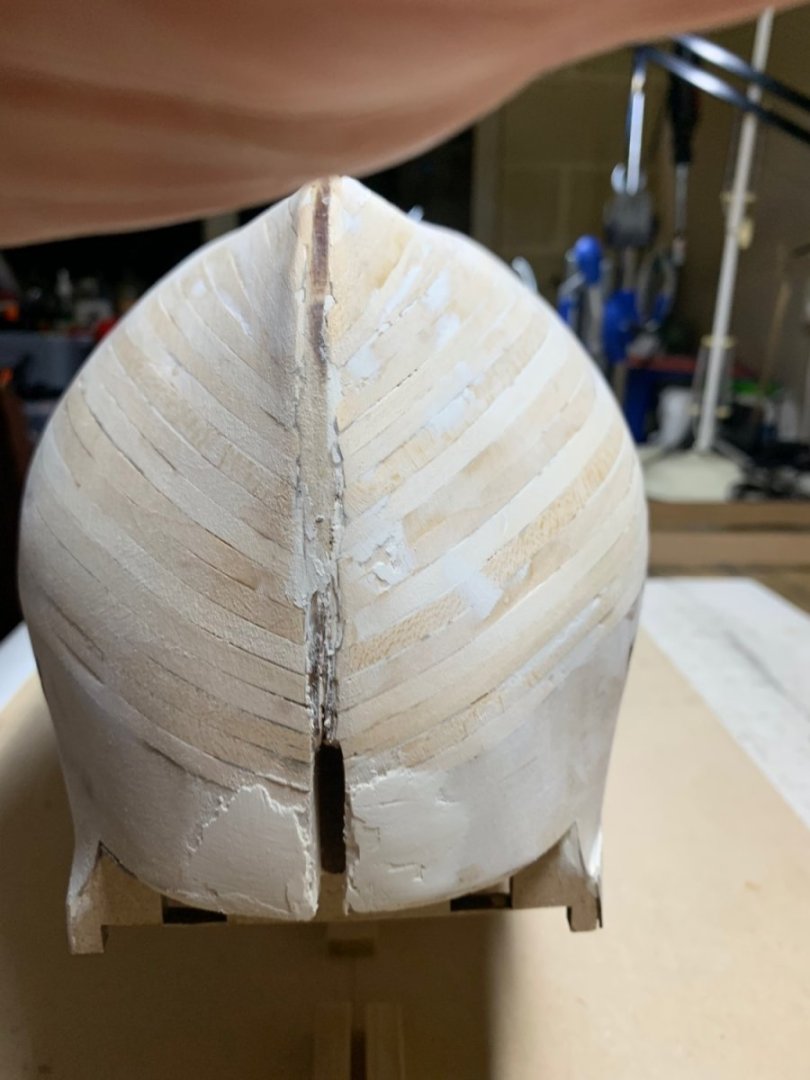

On 3/8/2023 at 7:29 AM, allanyed said:

You first planking layer was done really well and is similar to how the actual ships were planked. All the strakes look to end at the rabbet as they should. A little tapering of the planks from the dead flat to the stem would have helped a bit but overall looks great.

Is there a reason you did not do this for the second layer? Picture below to see what I mean.

Thanks.

Allan

Hi Allan thanks for looking at my build log. The reason the second planking layer didn’t have all planks extend to the bow was related to the different plank widths 7mm for first layer and 5mm for second layer, which made the tapering more difficult. Also given that in the first layer the upper portion of the hull was not planked but had the ply parts made it easier to do. I agree that the appearance of the method I used is not historically accurate or as pleasing to the eye, but I knew that the copper sheathing would cover it so accepted the lesser outcome.

-

- Prowler901, ccoyle, KARAVOKIRIS and 2 others

-

5

5

-

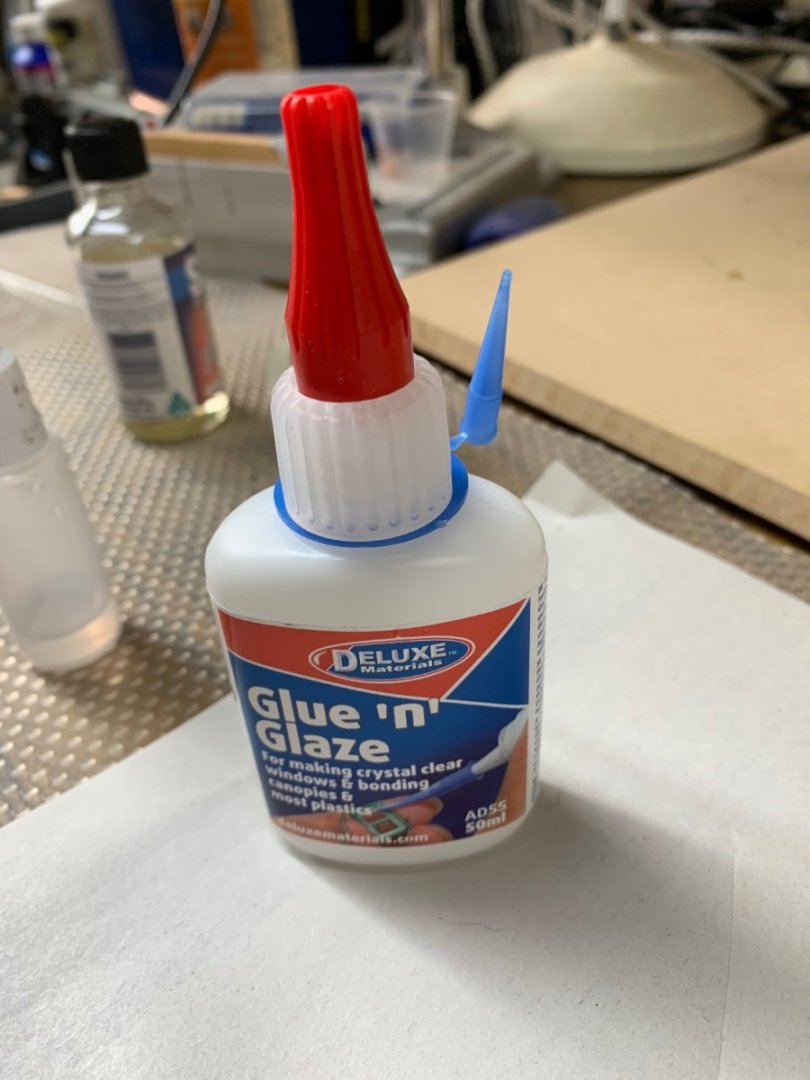

8 hours ago, AON said:

Where did you buy the glue 'n' glaze?

It looks very good indeed.

Hi Alan,

I bought it online from Australian hobby supplier, they are an excellent source for many great tools and supplies, highly recommend their service.

https://www.hobbytools.com.au/deluxe-materials-ad55-glue-n-glaze

Using the product was easy, there are some good YouTube videos to assist. It suggests that openings greater than 6mm can be done easily, but larger openings can be built up too. I am happy with the result, looks better than sticking acetate on from the back.

Thanks for looking at my log.

-

- Prowler901, AON, mort stoll and 1 other

-

4

4

-

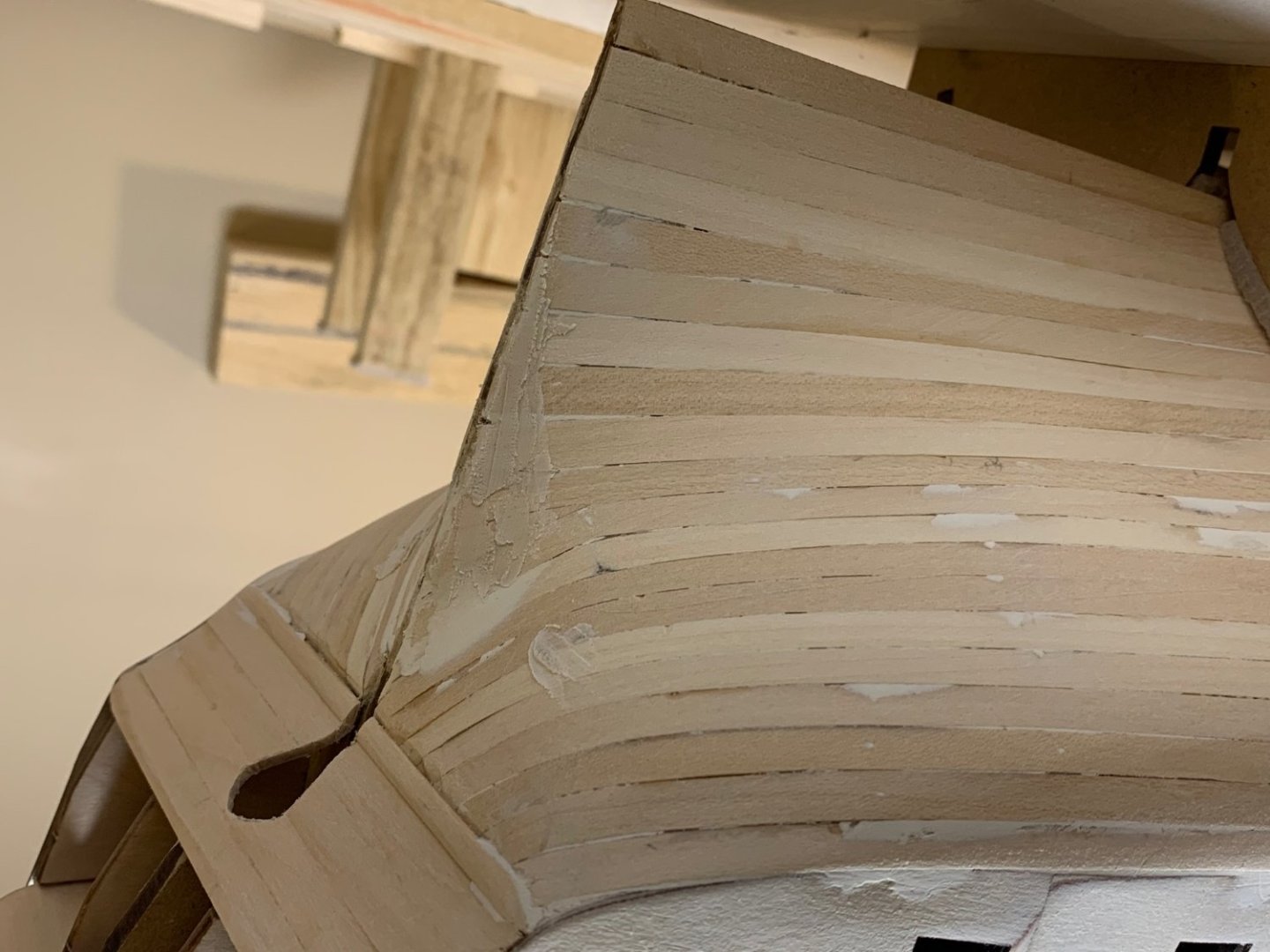

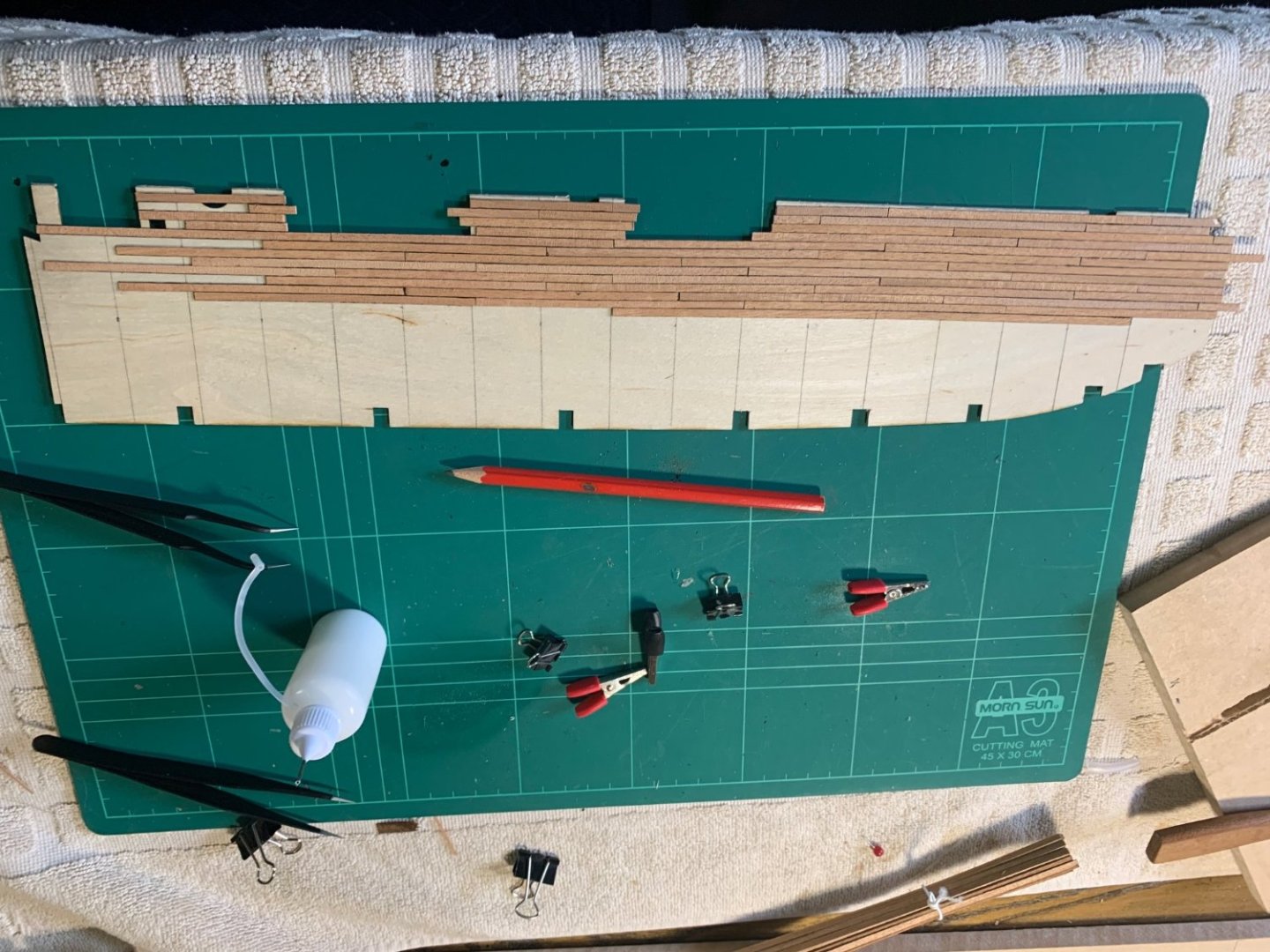

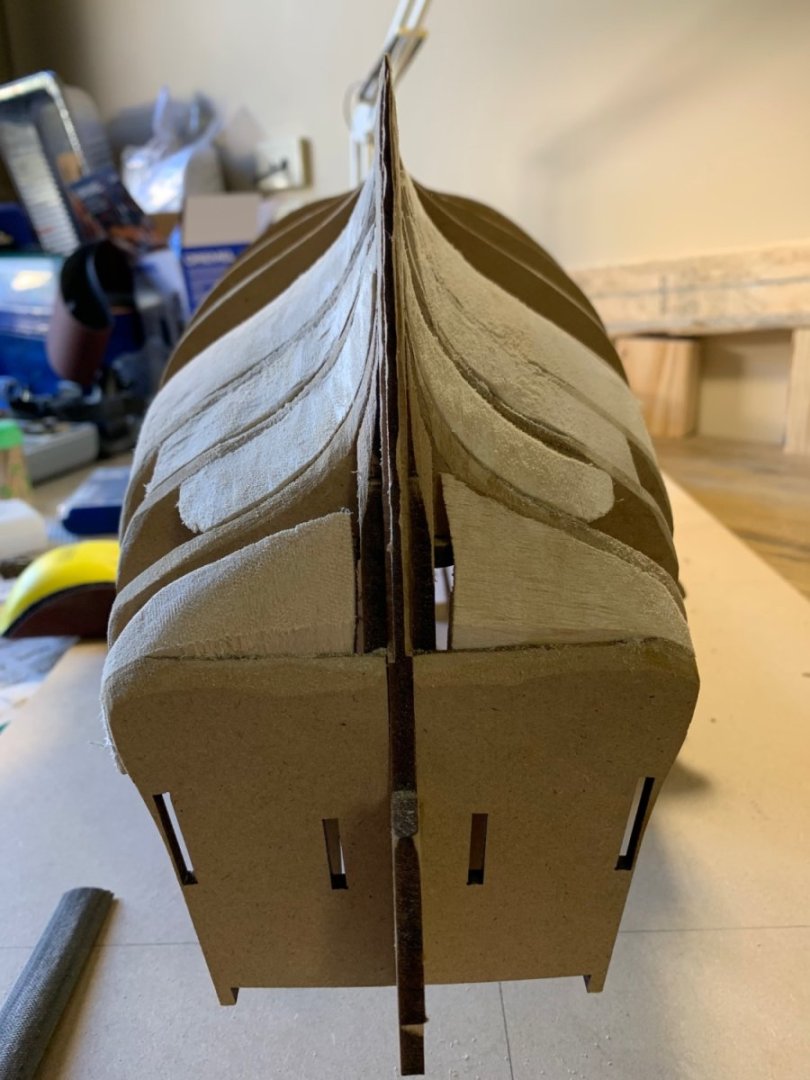

First planking done. The stern area is challenging. The lower counter fell apart after soaking and bending, so I replaced it with lime wood strips.

Sanding and filling at present. Trying to get a smooth hull that seems good enough is elusive. I need to use all my senses and look in light fro different angles to pick the high and low spots.

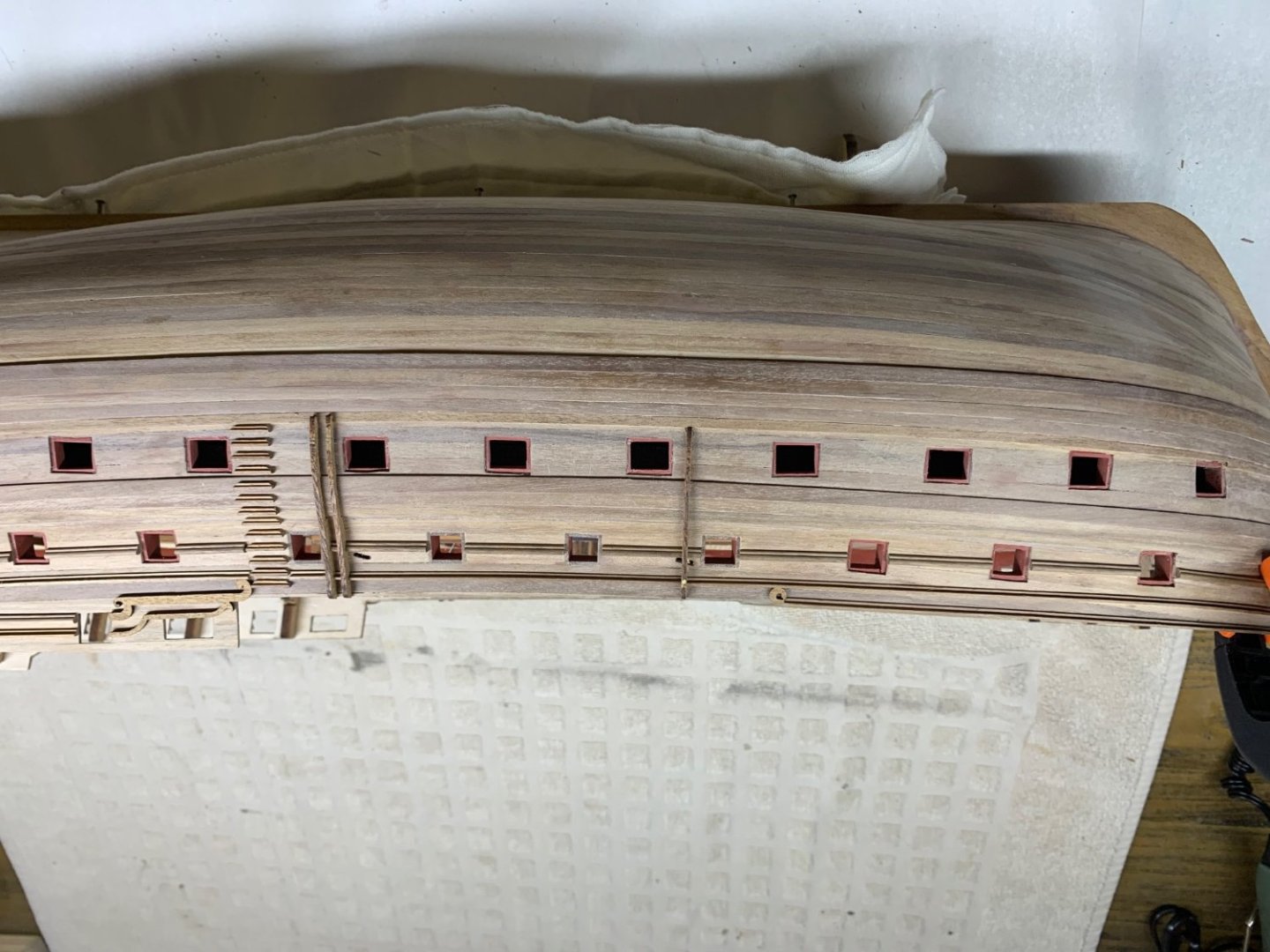

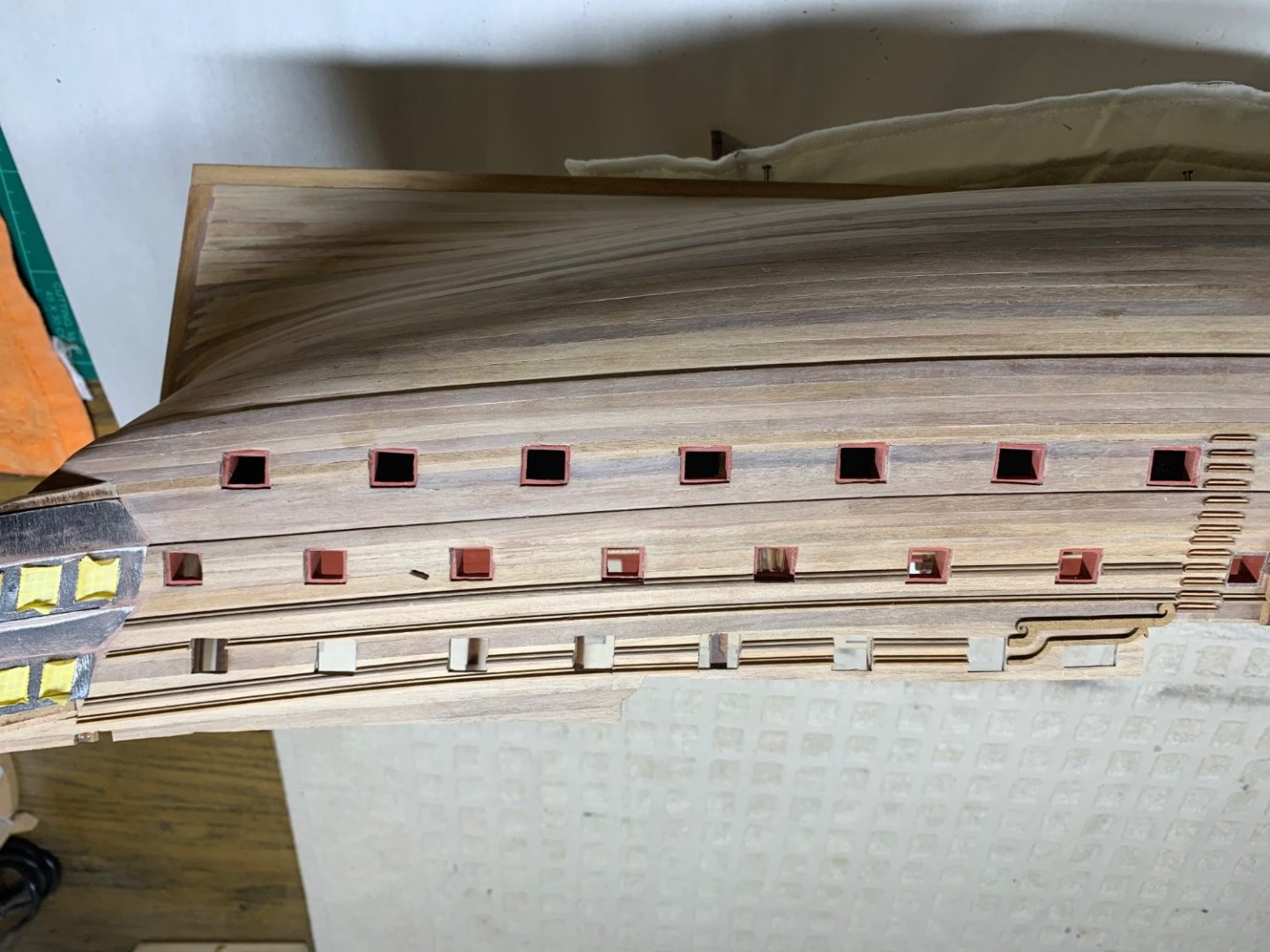

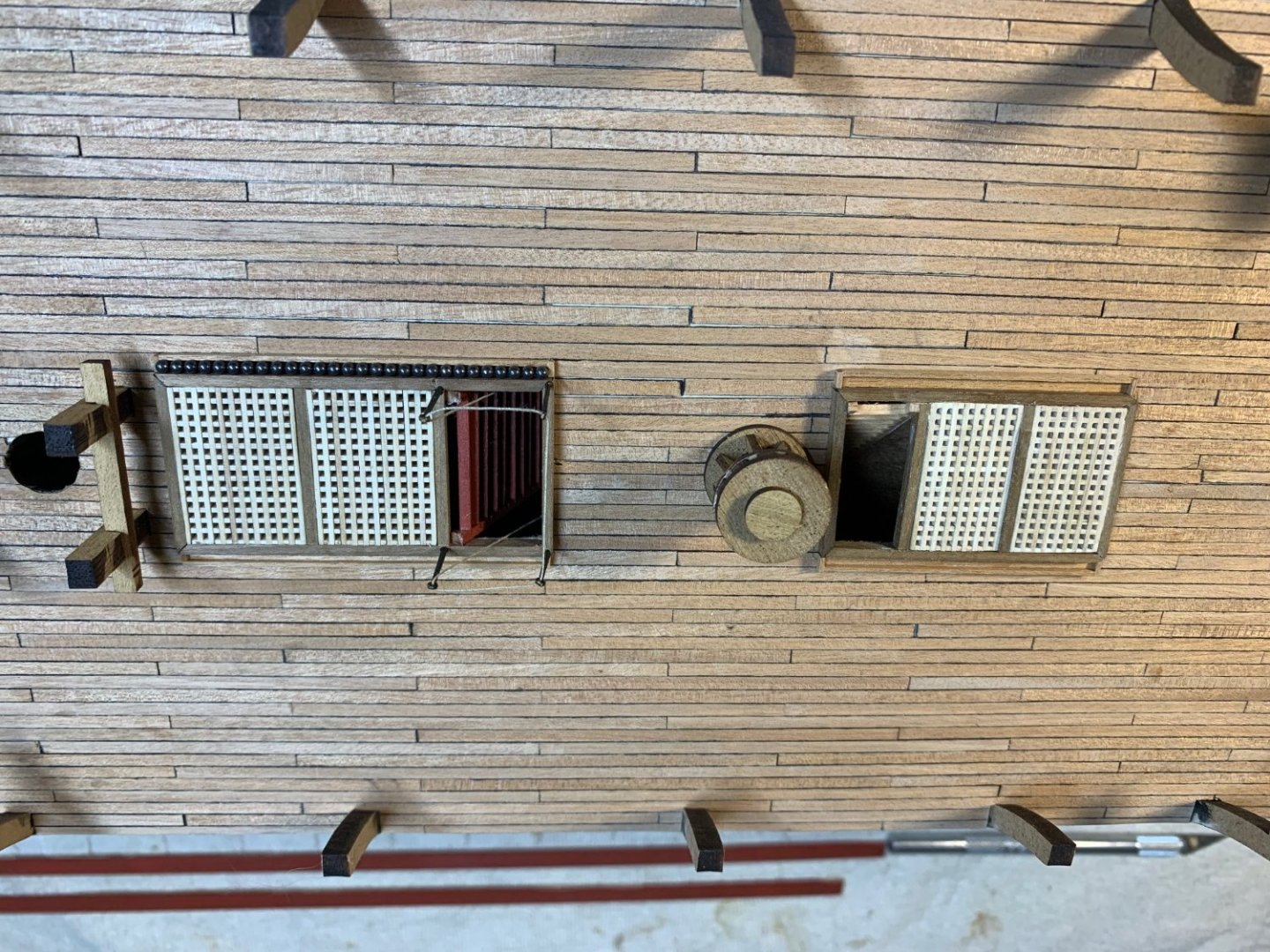

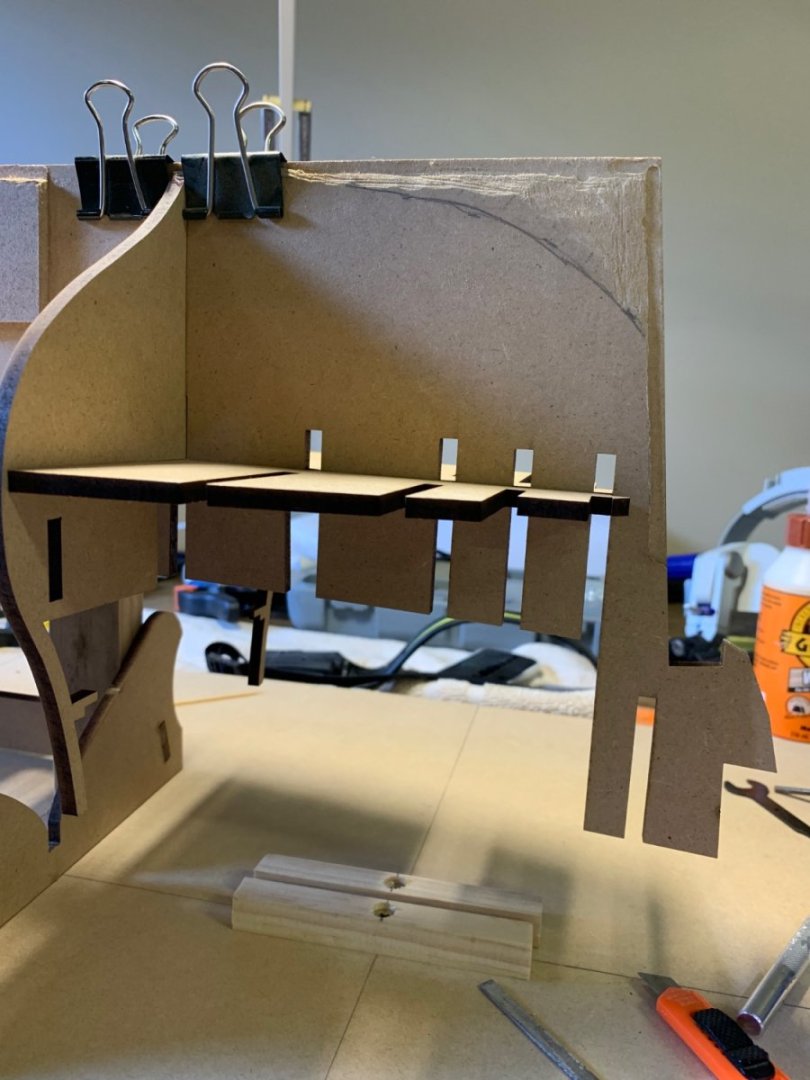

Planking the gun ports with lids to get them recessed before 2nd layer planking. Tried making tubes but wasn’t happy with the squaring and cutting caused breakages. Did them with vertical sills the horizontals which were press fitted with finger pressure to get a good seal. Planning to paint them all before second planking.

Sorry if some of the pics are upside down. I don’t have a computer to fix them.

- flyer, Esap, mort stoll and 5 others

-

8

8

-

Thanks for the feedback Peter.

I have enjoyed your Bellerophon build log, and use it to help guide my journey amongst some other great Vanguard logs.

I will try to manage my photos with the computer in future, as I see the use of mobile devices has this inversion bug thing.

Thanks for the tip on painting etched brass parts. I have very little experience with painting and am appreciative of any tips and suggestions. I am currently waiting on an order for etch primer https://www.metrohobbies.com.au/products/sms-plp04-etch-primer-50ml?currency=AUD&variant=31872588742741&utm_medium=cpc&utm_source=google&utm_campaign=Google Shopping&gclid=Cj0KCQjw7KqZBhCBARIsAI-fTKLfhUY3jMVNTXO-xwZTxMSMU7jCaYdMu31iRDxcF4ZPhvu0bLWpHY0aAi3-EALw_wcB&gclsrc=aw.ds

from an online hobby source. I am planning to use an airbrush where suitable.

-

- mort stoll, ccoyle and Mr Whippy

-

3

3

-

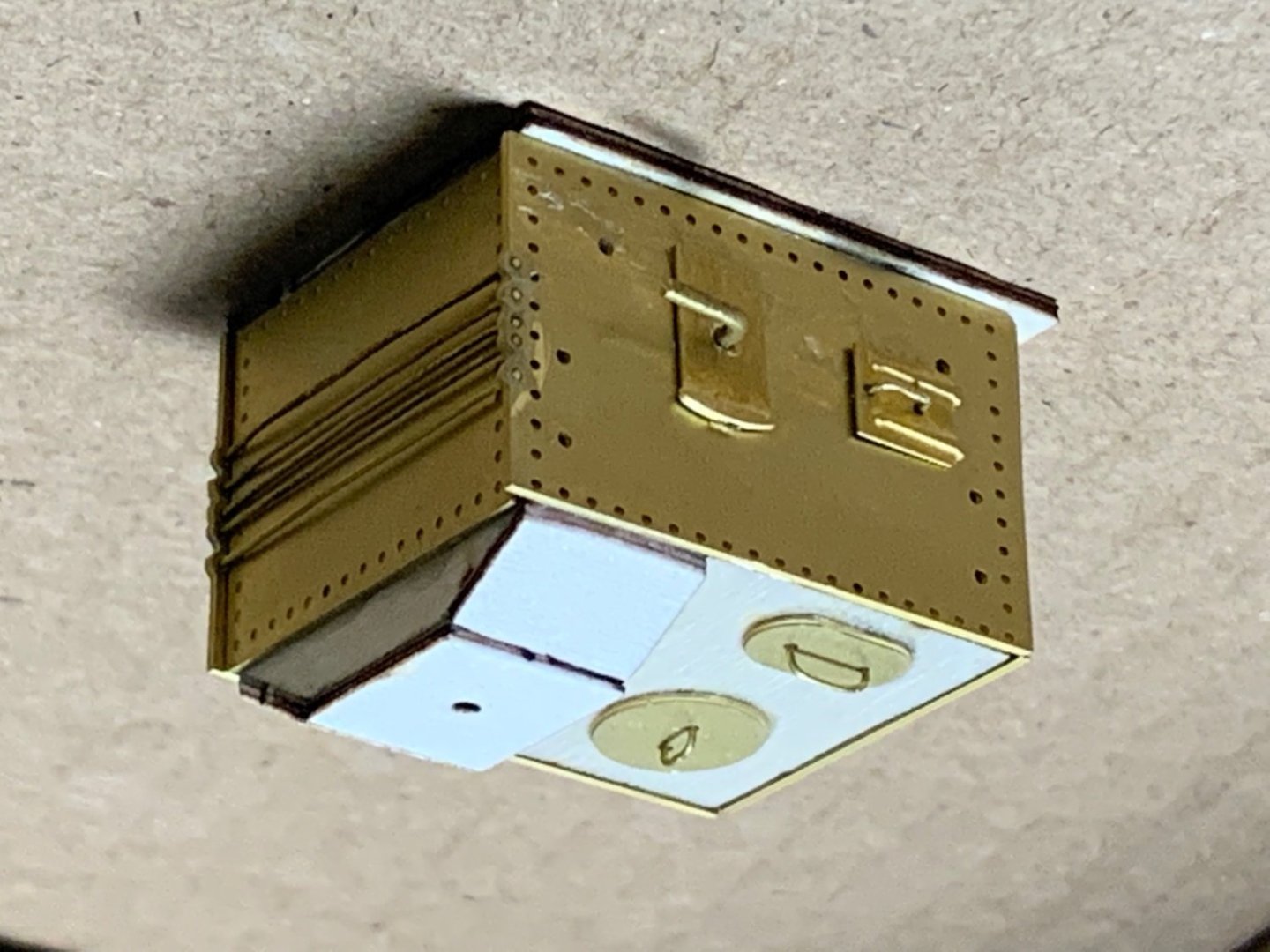

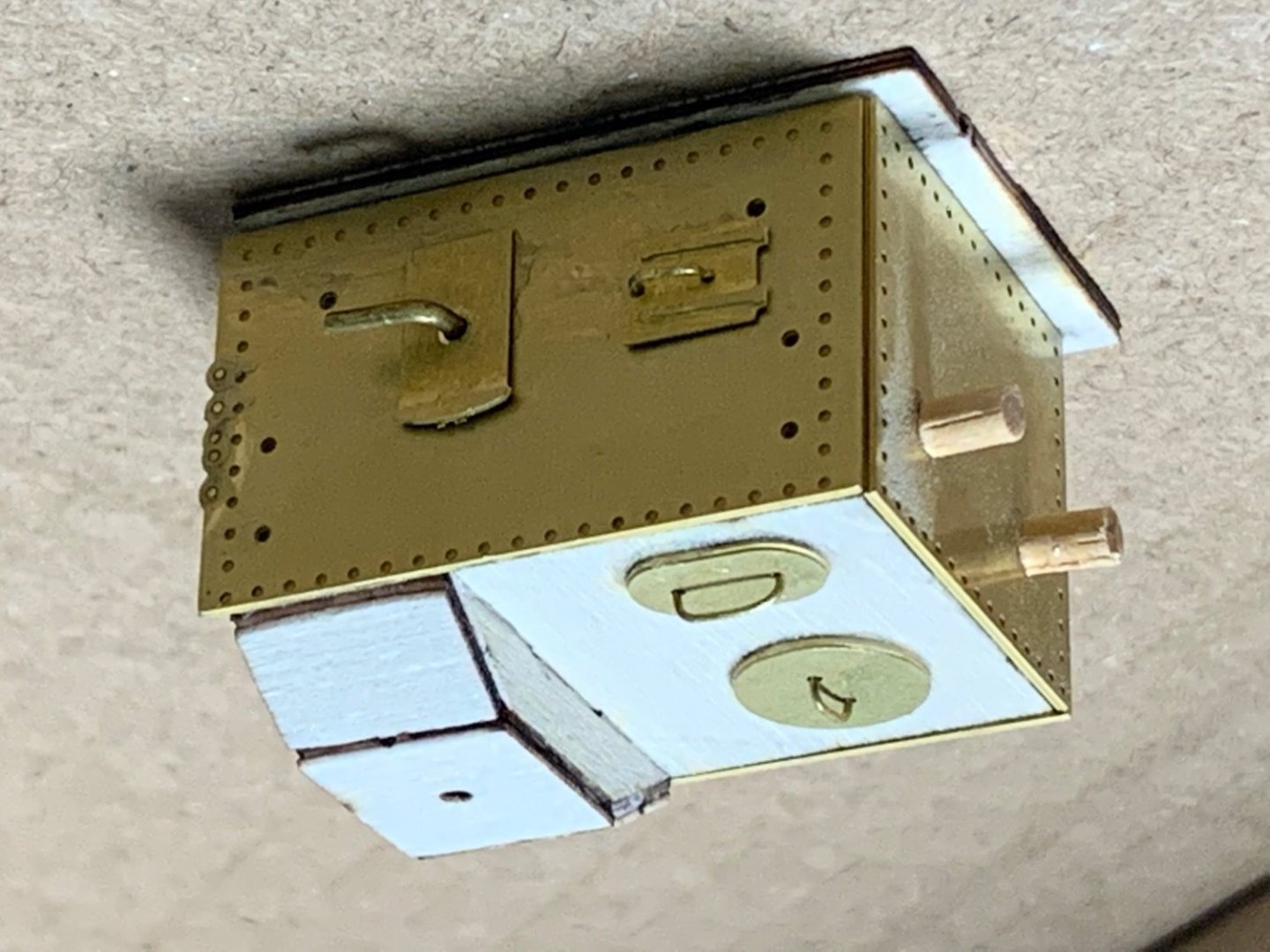

I am looking for some advice from any members on the MSW forums.

Have started to build the ship stove for the Vanguard. It has both plywood parts and covered with etched brass parts. The finished stove needs to be black in colour and the details on the brass are quite fine.

My question is what is the best way to assemble and colour the parts?

Paint first?

Paint with brush or airbrush?

What is best way to paint the etched brass parts? Do they need a primer? Any recommendations to primers?

or Use Blackening acid like the Birchwood Casey Brass Black?

Paint after assembly?

Thanks for your advice in advance.

-

Thanks Mort. I will probably do this too.

-

Started planking the upper gun deck. I have noticed the first error in the plans/instructions. The larger imaged building instructions indicate planking with 0.6 x 3mm Tanganika, whereas the smaller written instructions say 0.5x3mm. I couldn’t find any 0.6mm, so assume it’s just a typo.

others have reported in their build logs that the length of the strips are suggested to be 120mm by the instructions, but I am unable to find any reference to the size of the planks to be used or the jog pattern.

I chose 100mm which is easily divisible by 4 to map out the jog pattern on the deck.

The instructions recommend sealing the deck with varnish once completed and sanded.

Can I ask some advice from others regarding how to glue further fittings to varnished or painted surfaces, I understood that glue doesn’t bond well to treated surfaces. So I am inclined to varnish after deck fittings in place, or should I just tape out the areas where further fittings and glueing will be required?

- ccoyle, mort stoll, GrandpaPhil and 1 other

-

4

4

-

Have added the last bulwark, No 17. Also painted the dummy barrel strips, planked the mid portion of the lower gun deck where it might be visible, and remembered to drill holes for the handrail from the stairway down to this deck before it becomes inaccessible.

Have started to get the gun deck ready. Have decided to cut it in half as the instructions suggest is one way of approaching it.

A question for some of the more experienced modelers here : I read that most planks were 6, 9 or 12 feet long. So my calculations for a 12 foot plank at 1:72 scale is 50.8 mm. This seems to be shorter than what most others have used in their builds as best I can tell from photos. Also planning a three butt pattern.

What length should I cut the planks? What is the trenall pattern at the ends and in the middle of the planks?

Thanks for checking in on my build.

- mort stoll, GrandpaPhil, etubino and 1 other

-

4

4

-

Now sanding the filler blocks and fairing the frames.

Also got the dummy gun barrel struts into frames. This was a bit tricky as described in other logs of this kit.

I sanded down the outer edge of the slot in frame 2, and the corresponding edge on the strut. I then made some compressions on the inner aspect of the leading 3 cm and by levering the member at the fourth frame away from the midline (keel) and pushing from behind got the members into the slot.

Everything glued and once dry will paint the dummy barrel wood and the chamber black.

- etubino, Kusawa2000, bruce d and 3 others

-

6

6

-

-

Have started the build. Have been reading carefully the instruction manuals and diagrams. Also trying to read other build logs.

Current plans are:

1: build a cradle stand to support the hull upright and inverted, with padding to avoid unwanted marks to the hull

2: Assemble tools and make a clear workspace. Trying to get my Dremel router working.

3: Mobilise the parts for initial assembly and clean the mounting tabs off.

4: Glue two halves of keel and bolster the join with Mdf off cuts, and glue false deck halves

5: Dry fit the bulwarks after numbering and checking sequence

6: Mark out the bearding lines at stem and stern

7: Debulk the deadwood area with router and graduated sanding to depth of 1.5 mm to rabbet the first planking to maintain equiplanar to stern post

8: Apply Mdf re-enforcement to keel to take a screw, 6G-40 mm to allow fixing to display pedestals

9: Glue bulwarks, starting with #6 and #12 to sit in cradle.

10: use bulwarks 1,2,3,4,15,16 and 17 to create a form to shape balsa filler blocks to sit between bulwarks and support first planking

11: Fair the bulwarks with emphasis on fore and aft frames.

Question for the more experienced craftsmen. How does one ensure symmetry of the fairing of frames from port to starboard sides?

-

12 hours ago, Dave_E said:

Welcome Aboard Mate! Welcome back to the hobby. Is there a short version of that handle or a name we may call you? 😀

Michael also works.

Thanks for the welcome from everyone.

- Dave_E, Keith Black, Ryland Craze and 1 other

-

4

4

-

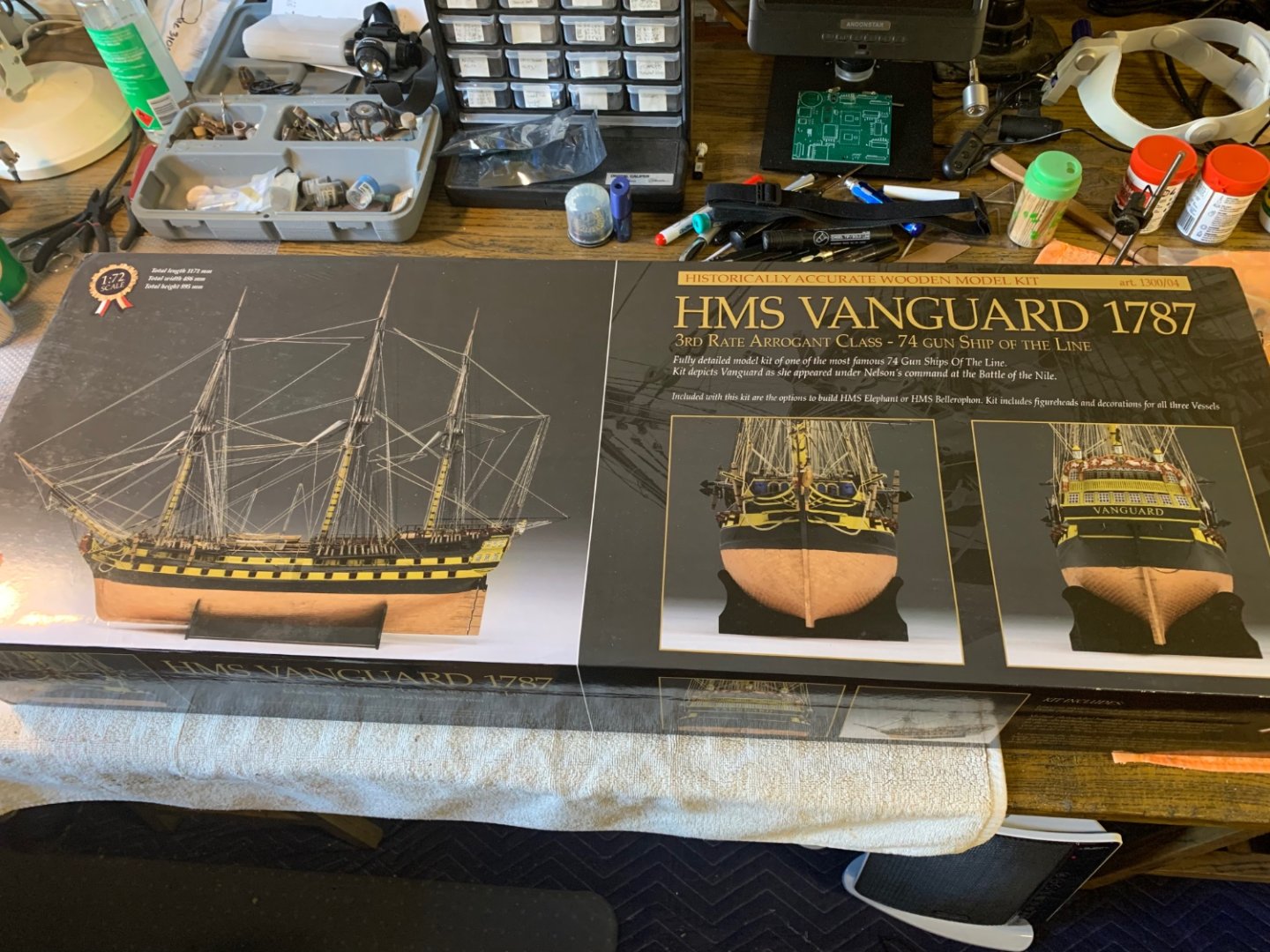

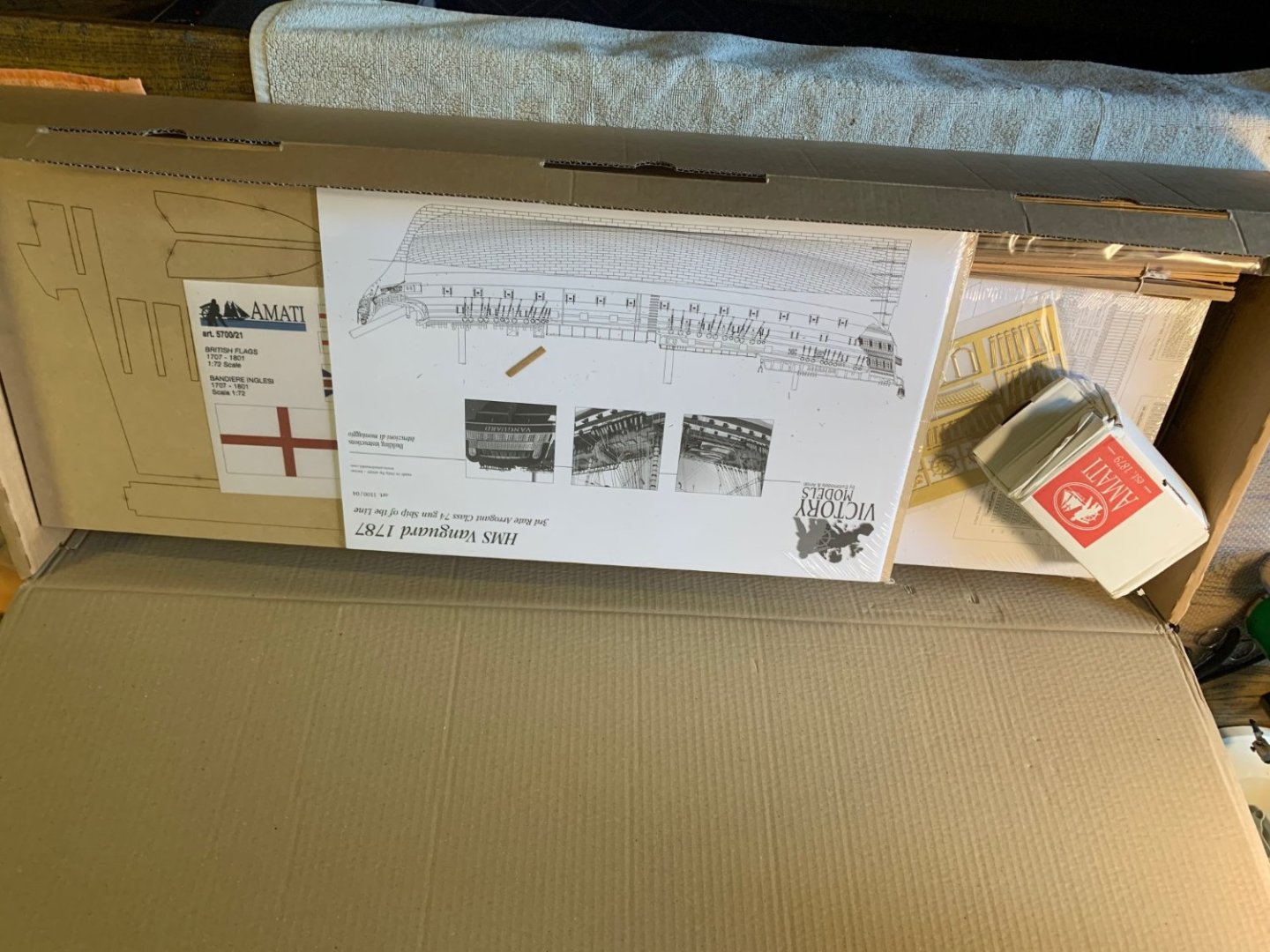

Starting my build log.

I have always wanted to build one of Nelson’s ships, and this model has had good reviews and ticks all my boxes.I am under no illusion that it will be a challenge and hope that my build log will attract much welcome advice and commentary.

I am strapped in and ready for the long and rewarding journey.

- GrandpaPhil, chris watton, bruce d and 7 others

-

10

10

-

I would be humbled to introduce myself and my shipbuilding trials and tribulations. I am living in beautiful Geelong in Australia and have recently become a grandfather, and my son has moved away from home, hence I have more spare time.

Previously, I did some model building including AL Independence, AL HMV Bounty cutaway kit, Panart Armed Pinnance and Panart Caroline.

My modeling skills had a prolonged period of rest, 21 years, but now I have jumped back in and acquired the Victory Models HMS Vanguard.

I have seen some of the inspirational build logs by some of the MSW members and hope to be able to learn much for my build.

I plan to post a build log for the Vanguard, and to be a worthy member of this esteemed group.

Thank you for reading my post.

Chestcutter

HMS Vanguard 1787 by Chestcutter - Victory Models - 1:72

in - Kit build logs for subjects built from 1751 - 1800

Posted

Painting finished with yellow bands following the curve of the wales not the gunports, as she was pre 1798.

Refreshed the gunports sills and sealed with polyurethane Matt varnish (PMV). The PMV did a nice job protecting the paint and taking out the shiny black finish of the Dull Black paint I used.

Sorry that all the photos are upside down, probably because I’m downunder in Australia. I can’t seem to get them upright. Please don’t strain your necks looking.