Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

-

Posts

213 -

Joined

-

Last visited

Reputation Activity

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

Goedenavond vrienden,

Tonight was a special night because I got to light a burner, melt metal, and do my best to pour it into my model! At the point I was at in carving the hull and installing the rest of the pieces permanently, I figured I better pour the metal into the ballast slot in the bottom of the hull in case it went haywire and wrecked it.

Micromark Type 280 model casting metal. tin/bismuth alloy with no lead or cadmium (I know a deviation from the lead used by the boy in the book). Melting temp 280degF. I bought two 1 7/8" pucks to melt down but only needed one.

I melted the metal down in a tiny pan, which unfortunately had no spout for pouring. It worked well for melting the metal. I have a heavy pot and ladle for melting lead but did not want to contaminate this "toy" with lead. A simple camp stove was used to melt this low temp model casting metal; it melted quicker than you'd fry bacon. The "camp stove" is not the cleanest in the world as this is the stove I use to melt and make beeswax candles, not for cooking, so there is too much wax residue in the basin of the stove which I need to clean up. Back to model making....I will need to remember this handy alloy for future projects.

But now, to back up a bit, before melting the metal, I levelled the hull in a vise in both directions.

Then, with the metal melted, I walked as quickly as I could, the 20 feet from stove to overturned hull. In that time the hot metal formed a semi-solid skin on it's surface which I had to overcome when pouring, and which caused an overflow over the cavity intended for the pouring of the metal. This is visible in the photo. After this initial spilling of the milk, the pour went perfectly and I will be able to remove the metal from the overflow spill. All told, it would be better to use a deeper melting pot with a spout for this task.

Now I will wait for this to cool and I will file and sand off the metal and all will be well. I had a fire extinguisher at my side during this step.

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

Thanks so much for the responses and for sharing your connections to the Paddle to the Sea story!!

Tonight I continued some carving.

I laid out and then carved the recess for the ballast.

I have alot of lead left from past projects wherein I would melt lead and use it in projects. Considering the known health/brain damage risks we now know from lead exposure, I will make a variation from the originally described Paddle to the Sea. I will use low temp model casting metal from Micromark, type 208. I will melt this metal and fill this cavity.

These Flexcut carving chisels are awesome!!!

I am also using my Helle knife:

Hull after rough carving:

Another amazing tool for wordworking, is the SHINTO RASP" pictured below. Amazing, efficient, tool with two different aggressiveness faces.

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

The pictures of the model clearly show a shallow recess in the interior of the canoe. Here I am carving that recess.

And here is the current rough carved status:

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

Hi Everyone,

The book states the model was made from a piece of pine, so here is my raw material, scrap 2x4 from the shop:

The 2x4 is not quite thick enough, so I sawed and planed two blocks which I will glue together to make the hull blank.

Here is the hull blank glued together , and cut and planed to finished length, width , height. I made some paper templates of the plan view and profile shapes of the hull. Tracing the profile here.

Profile cut using the bandsaw:

Tracing on the plan view shape:

Here is the blank cut out on the bandsaw.....all carving from here on out:

-

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

FreekS reacted to Jason Builder in Paddle to the Sea by Jason Builder - FINISHED - Solid Wood - from 1941 children's book of same name

Greetings!

And now I return to the dreams of adventure of my youth! "Paddle to the Sea" is a childrens' book, written and illustrated by Holling Clancy Holling, and published in 1941. It tells the tale of the voyage of a small carved wooden canoe and it's paddler as they follow the currents of the Great Lakes, from Nipigon country out to the Atlantic Ocean. A Native American boy carves the canoe and it's stoic captain, paints it, and places it in the snow, high in the hills over Lake Nipigon. When the snow melts, it takes "Paddle to the Sea" with it, and the book tells the story of all the people, machines, technology, animals and natural wonders that the little canoe model sees on it's epic journey through the Great Lakes to the Atlantic. I loved the book as a boy, and I still have the book. I live in Wisconsin, not far from Lake Michigan, and the book has always been special to me. As a boy I thought how cool it would be to make this canoe and paddler model......now I have decided to do it! Below is documented my best attempt at building as close to accurate a model as possible of the actual "Paddle to the Sea" canoe model from the book.

Making the drawings: There are illustrations throughout the book of Paddle to the Sea, and there are also good clues as to materials, dimensions, and finish. The book tells of the young Native American boy in Nipigon Country (North shore of Lake Superior, around Lake Nipigon), who take "many days" whittling a "piece of pine" into a "canoe one foot long". It also advises of a rudder made of tin and lead ballast. The book also advises "oil paints" were used to paint it, along the with words carved into the bottom of the hull , "Please put me back in water, I am Paddle to the Sea". Starting with the known length of 12", I scaled other dimensions from the many pictures in the book and calculated the various dimensions. Then I took those dimensions and created a life-size, to-scale, color drawing of the model, which I will use to take dimensions from as I build the model.

-

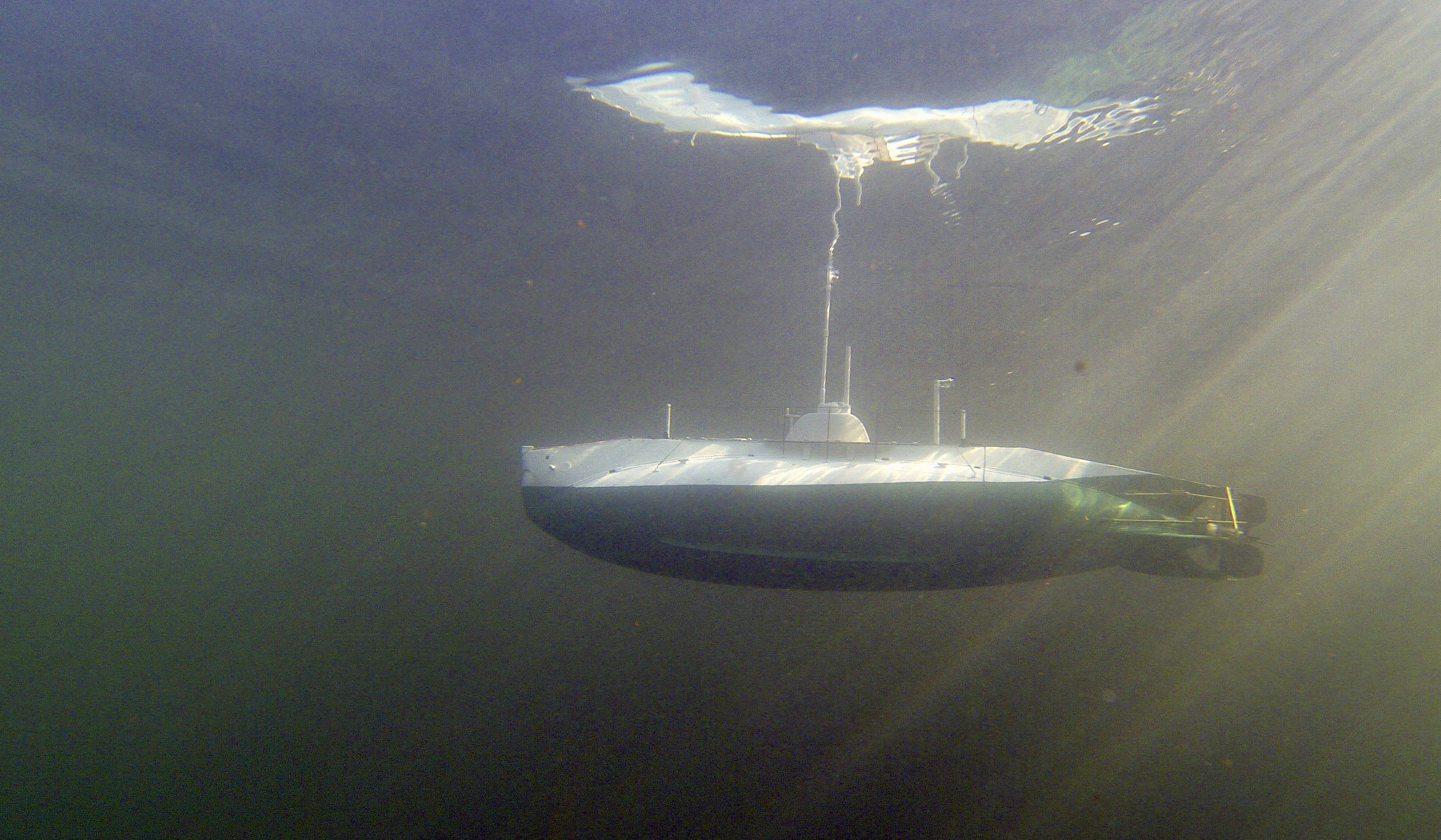

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

No! A chemist!

-

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

No! A chemist!

-

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from KeithAug in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Canute in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from yvesvidal in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from GrandpaPhil in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from Charter33 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Charter33 in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from DonSangria in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from DonSangria in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from mcb in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mcb in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS got a reaction from Rik Thistle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Rik Thistle in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

I’ve gone down a bit of a rabbit hole! Having developed the idea of the functioning front diveplanes described above - the ideas for improvement kept coming! I’ve now got a prototype ready to be built into the hull, where the two movements of the front diveplanes, the folding and unfolding of the planes flush against the hull, and the up/down movement of the diveplanes when sailing under water, are achieved with just one servo.

the up/down movement is achieved with a white gear and a white linear gear.

IMG_0430.mov

prior to folding, the planes are rotated vertical by these white 3D printed cogs. On further movement of the servo the linear cog runs out of teeth, and the white gear contain a magnet leaving the planes in the vertical parking position. Then a brass rod pushed in parallel with the white linear gear folds the planes via the brass gears previously described. A spring made from 0,5mm brass unfolds the gears as the servo retracts both rods until the linear gear re-engages.

crazy complex, but it runs with little friction, uses less than 0,1 amps on a mini servo and uses no current when not moving. Very happy - will need to program an arduino to tie the servo movement to the “dive” and “surface” commands and the diveplanes signals from the transmitter.

now hopefully back to some woodwork, apologies for the distraction!

-

FreekS reacted to Wreck1919 in SMS Karlsruhe by Wreck1919 - 1/100

FreekS reacted to Wreck1919 in SMS Karlsruhe by Wreck1919 - 1/100

Another update: rigging is almost done. All that can be attached to the masts off model is finished. Remains „only“ to do the lower attachment points on deck. How to attach the signal lines on the foremast to the bridge without tearing everything apart is still a mystery to me though…🤪. Looks a bit wild now but once straigthened out it should be ok,..i hope.

cheers sascha

-

FreekS reacted to Valeriy V in SS Blagoev ex-Songa 1921 by Valeriy V - FINISHED - scale 1:100 - Soviet Union

FreekS reacted to Valeriy V in SS Blagoev ex-Songa 1921 by Valeriy V - FINISHED - scale 1:100 - Soviet Union

Details of the bow superstructure.

-

FreekS got a reaction from Ainars in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ainars in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Started work on the water-tight compartment inside the wooden hull. The hull will flood when dived, and the WTC will contain the motors, batteries, receiver, two-way pump and a 500ml divetank to dive the boat.

The insides of the WTC can be accessed by a bayonet between the aft 50mm diameter PVC tube and the mid 75mm PVC tube.

this is the WTC seen from the stern. The white stern endcap will have two shafts driven by a motor inside the 50mm PVC tube. The holes are where the prop shaft and the rudder and diveplanes seals will come. Between the two white parts of the endcap will come a gearbox to counter rotate the two shafts.

Further forward is the bajonet, seen below when opened.

two M4 bolts on the start section fit into the keyholes (strengthened with brass) in the front section and thus the two boat halves can be twisted shut. The bajonet contains O-rings to seal the 50 and 75mm PVC tubes.

this picture shows the bajonet shut and the bolts holding the two halves together.

And finally with the two deck sections attached.

now that I know exactly where the WTC and its connections will come, I can start to work on the prop shafts and their outholders, the rudder and diveplanes and the holes in the wooden hull to flood the boat and enable air to escape.

-

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from mtaylor in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Started work on the water-tight compartment inside the wooden hull. The hull will flood when dived, and the WTC will contain the motors, batteries, receiver, two-way pump and a 500ml divetank to dive the boat.

The insides of the WTC can be accessed by a bayonet between the aft 50mm diameter PVC tube and the mid 75mm PVC tube.

this is the WTC seen from the stern. The white stern endcap will have two shafts driven by a motor inside the 50mm PVC tube. The holes are where the prop shaft and the rudder and diveplanes seals will come. Between the two white parts of the endcap will come a gearbox to counter rotate the two shafts.

Further forward is the bajonet, seen below when opened.

two M4 bolts on the start section fit into the keyholes (strengthened with brass) in the front section and thus the two boat halves can be twisted shut. The bajonet contains O-rings to seal the 50 and 75mm PVC tubes.

this picture shows the bajonet shut and the bolts holding the two halves together.

And finally with the two deck sections attached.

now that I know exactly where the WTC and its connections will come, I can start to work on the prop shafts and their outholders, the rudder and diveplanes and the holes in the wooden hull to flood the boat and enable air to escape.

-

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

FreekS got a reaction from Mirabell61 in Davit & Lifeboat c. 1950 by FreekS - ~1:10 - RADIO

Boat has been ballasted with about 1 kg lead plates - glued with epoxy. Motor mount and rudder are functional.

I made the boat 3cm smaller than it’s static predecessor - to allow some room for the rudder.

after planking the foredeck and aft deck I could test where to put the mounts to hang it in the Davit. The not has 5mm rim in either side but swings out nicely.

In place of the hooks in the decks will come two electromagnets that can each lift 2.5kg and consume 250mV at 6V (visible in foreground).

-

FreekS got a reaction from Ryland Craze in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ryland Craze in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Started work on the water-tight compartment inside the wooden hull. The hull will flood when dived, and the WTC will contain the motors, batteries, receiver, two-way pump and a 500ml divetank to dive the boat.

The insides of the WTC can be accessed by a bayonet between the aft 50mm diameter PVC tube and the mid 75mm PVC tube.

this is the WTC seen from the stern. The white stern endcap will have two shafts driven by a motor inside the 50mm PVC tube. The holes are where the prop shaft and the rudder and diveplanes seals will come. Between the two white parts of the endcap will come a gearbox to counter rotate the two shafts.

Further forward is the bajonet, seen below when opened.

two M4 bolts on the start section fit into the keyholes (strengthened with brass) in the front section and thus the two boat halves can be twisted shut. The bajonet contains O-rings to seal the 50 and 75mm PVC tubes.

this picture shows the bajonet shut and the bolts holding the two halves together.

And finally with the two deck sections attached.

now that I know exactly where the WTC and its connections will come, I can start to work on the prop shafts and their outholders, the rudder and diveplanes and the holes in the wooden hull to flood the boat and enable air to escape.

-

FreekS got a reaction from _SalD_ in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from _SalD_ in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Started work on the water-tight compartment inside the wooden hull. The hull will flood when dived, and the WTC will contain the motors, batteries, receiver, two-way pump and a 500ml divetank to dive the boat.

The insides of the WTC can be accessed by a bayonet between the aft 50mm diameter PVC tube and the mid 75mm PVC tube.

this is the WTC seen from the stern. The white stern endcap will have two shafts driven by a motor inside the 50mm PVC tube. The holes are where the prop shaft and the rudder and diveplanes seals will come. Between the two white parts of the endcap will come a gearbox to counter rotate the two shafts.

Further forward is the bajonet, seen below when opened.

two M4 bolts on the start section fit into the keyholes (strengthened with brass) in the front section and thus the two boat halves can be twisted shut. The bajonet contains O-rings to seal the 50 and 75mm PVC tubes.

this picture shows the bajonet shut and the bolts holding the two halves together.

And finally with the two deck sections attached.

now that I know exactly where the WTC and its connections will come, I can start to work on the prop shafts and their outholders, the rudder and diveplanes and the holes in the wooden hull to flood the boat and enable air to escape.

-

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

FreekS got a reaction from Ian_Grant in HrMs O-13 by FreekS - 1:50 - RADIO - 1931-1940 - Last Dutch Sub “on eternal patrol”

Started work on the water-tight compartment inside the wooden hull. The hull will flood when dived, and the WTC will contain the motors, batteries, receiver, two-way pump and a 500ml divetank to dive the boat.

The insides of the WTC can be accessed by a bayonet between the aft 50mm diameter PVC tube and the mid 75mm PVC tube.

this is the WTC seen from the stern. The white stern endcap will have two shafts driven by a motor inside the 50mm PVC tube. The holes are where the prop shaft and the rudder and diveplanes seals will come. Between the two white parts of the endcap will come a gearbox to counter rotate the two shafts.

Further forward is the bajonet, seen below when opened.

two M4 bolts on the start section fit into the keyholes (strengthened with brass) in the front section and thus the two boat halves can be twisted shut. The bajonet contains O-rings to seal the 50 and 75mm PVC tubes.

this picture shows the bajonet shut and the bolts holding the two halves together.

And finally with the two deck sections attached.

now that I know exactly where the WTC and its connections will come, I can start to work on the prop shafts and their outholders, the rudder and diveplanes and the holes in the wooden hull to flood the boat and enable air to escape.