-

Posts

45 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by a49kid

-

-

I'm building one at the moment too, will post it up soon ............

-

Hi Grant, gee you had a few issues there, but you guys worked thru them and it is working good now, and also looks good.

And it looks like all your problems were caused by a bend prop shaft and the universal you were using.

But in the fault finding process you re manufactured the thrust block and made a new flywheel.

Anyway, the build should continue smoothly now.

Yea the old and grungy weathered look....................

-

Hi Grant, your AQ is coming along very nicely, and yes all that planking looks good.

I just used a fine paint pen on the supplied ply wood, I’m happy with it.

And sometimes I think, how much extra work and time should I put into a model.

Your hardwood mounting looks very professional, but I would have used 4 of the inserts to hold down the plants base plate.

And yes with the plant lower, it aligns up nicely with the prop shaft, and a nice small uni.

I just hope my twin universals all works OK.

And your Flywheel looks good too, mine is a little different concept / design.

Did you use the engines 5mm output shaft or made a longer one.

And I’m sure you will sort out the issue with the burner / boiler.

And I'm still to get mine running.

It is a pity you can’t see my build thread on the other forum. -

Hi guys, and yes I also have a Build Thread on ‘Ships of Scale’.

That is a very active Forum, and they send me notification emails every day.

They are taking up a lot of my time, almost too much, can’t get any building done.

And every time I come here, it takes me 10 minutes to find my Thread, maybe at 74 I’m just getting forgetful on the procedure here.

Anyway I can’t spend time Posting on two forums, so I may have to end this Build Thread of the African Queen here.

But will stay as a member and check on other builds here. -

On 7/28/2022 at 5:00 PM, gjdale said:

Thanks for the kind comments and the likes folks.

I made a simple display base from some scrap walnut I had laying around in the “big” workshop. I had considered doing something more elaborate but, in the end, decided that less is more. I have ordered a small brass name plaque that will be placed on the front bevelled edge, but otherwise I’m calling this done.

Final photos (pending receipt of name plaque).

Hi Grant, yes everyone Loves a 'Ship in a Bottle' ...............

- Keith Black, gjdale, Mr Whippy and 2 others

-

5

5

-

On 7/3/2023 at 3:30 PM, gjdale said:

Thanks for all the input guys, and also for all of the 'likes'.

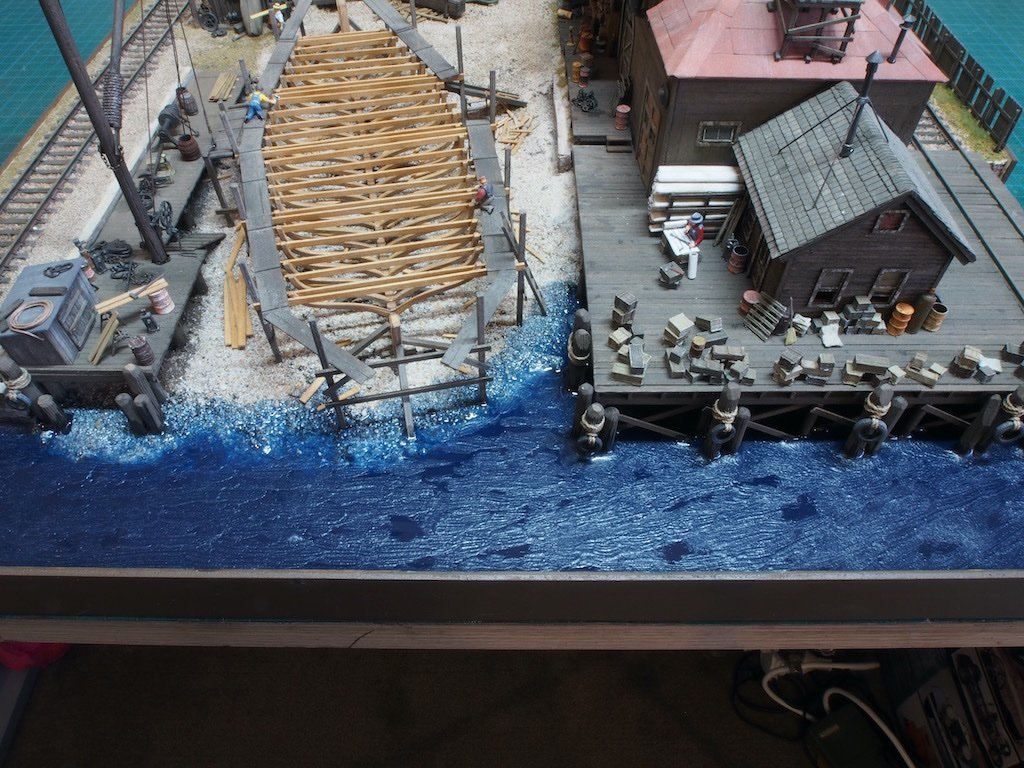

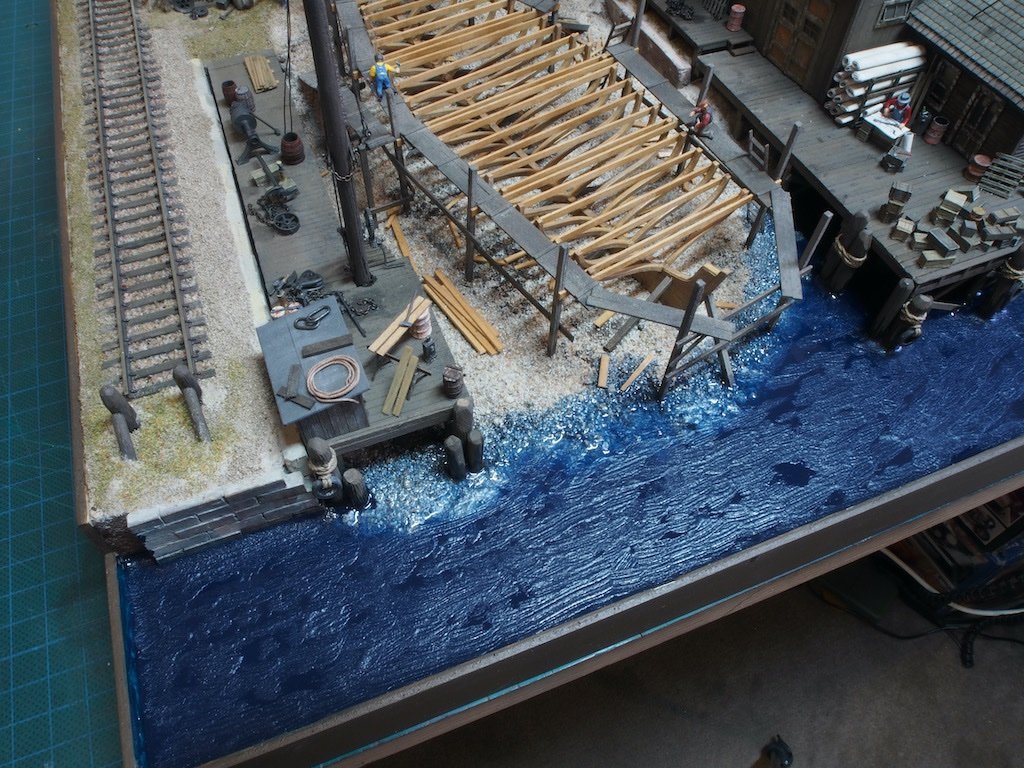

Finishing the Diorama – the Water (cont’d)

So I acquired some AK Water Gel Effects (AK8007) and applied this with an old fairly stiff brush. The effect I was looking for was that of a gentle breeze across the water surface, with occasional clear patches of no breeze.

As this is my first attempt at this process, I would appreciate some further feedback and/or guidance/tips to improve the appearance. Are the "wave lines" too distinct? Would I be better off using a more "stippling" method to remove/reduce the line effect? The good thing about this product is that I can add more to change the effects.

Here is the first attempt.

Thanks in advance for any and all input/advice.

Hi Grant, I just Love your Diorama here, you are a true Artist and Craftsman.

What scale is this, and all the little 'accessories' everywhere, did you buy them on the Net.

Ha Ha, just noticed, yea the heading Text, 1:87 or HO ..............:) -

Yes continuing on with this build of the Billings African Queen, on a Very Cluttered bench.........

As I have discussed above, this was a steel hull boat, but I have decided to timber plank over the plastic vacuum formed hull.

I guess most smaller boats of that time were timber hulls anyway.

I’m using 0.5 x 10 mm strips, and this is the first time I have done ship planking. so a big learning curve ……..lol

But I’m probably not doing it in the correct or normal way.

But at least all my planks go the full length of the hull. No ‘fill in’ bits here, whatever you guys call those bits.

And yes I tapered the planks fore and aft. And as the planks also need to curve / bend up and down, I came up with my own solution for that.

I cut thru the 10mm planks about 7mm, on the opposite edge to that that needs to curve up.

But we still had the one full length plank.

And yes this leaves gaps that need to be filled, the wider ones with wood filler, and the very close ones just fill with the Sand & Seal.

Yes this method would be unsightly if the hull was going to be stained, But as this is going to be painted, all these expansion cuts will not be seen.

It has been filled and 2 coats of sealer on it here.

Will then Grey Primer it, and I suspect more imperfections will new show up, so a little more filler and primer.- Tossedman, Ian_Grant, king derelict and 3 others

-

6

6

-

Hi Guys, and Grant, it may seem like I haven’t been doing much boat building lately, but actually I have been.

But I have taken a short rest from the filling, sanding, sealing, primer and top coat on the Queens hull.

Yes I’ve been making the Drink / Gin crates, 4 of them. And all the ‘planking’ on them.

It is quite a time consuming exercise.

Currently waiting on some more bottles for them, will post photos when all complete.

And I must say I love my cut off tool I bought a couple of weeks ago.

A wooden kit you assemble, but I changed the kit blade to a UK Stanley one, it is much sharper.

And for the crates, you set the stop and then cut the strip wood to all exactly the same length that you want.

And the precise cutting is very very fast.

-

Finished the hull planking, and that was quite a job for a first time planker.

I’m using 0.5 x 10mm strip over the plastic hull.

I figured boats of that size and at that time would be timber boats.

I’m now in the process of filling and sanding, and then sealer, primer and top coat, I hope you will still be able to tell it is timber planked.

And I don’t care if mine is not true to the original, I would rather have a timber hull than a plastic one.

I’m using this Wood Sealer, and I’m liking it. Made in the UK.

But I don’t think this would be suitable for stained timber hulls.

Some information on the African Queen.

It was a 30-foot boat built of sheet steel in the United Kingdom, for the British East Africa Railway for service in Africa, on the Victoria Nile and Lake Albert and used from 1912 to 1968.

It was originally named the L.S. Livingston, and had a diesel engine.

In the movie the steam engine was just a prop. -

1 hour ago, Ian_Grant said:1 hour ago, Ian_Grant said:

This same builder also found 1/12 scale (standard doll house scale apparently) figures; the Hepburn was a perfect appearance and pose. Can you tell us where you found your Bogart and Hepburn?

This is a build I would consider for the future - interesting and out of the mainstream.

Two places that sell 1:12 figures, ETSY, Melody Jane Doll House and Minimum World, Search Dolls House Figures.

I wanted 2 seated figures.

Very nicely painted resin molded figures, but then I modified them with my Dremell, and re painted them.

So they don't look like the figures here now. I will cut and rotate Charlies arm / hand to have it on the tiller.

And I have to make a big hat for Rose.

Sorry no pics yet, still working on them -

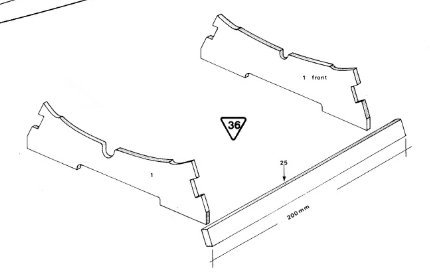

Another thing that has now annoyed me about the building instructions.

They could be clearer, and more detailed drawings re the build.

Yes this is only a small thing, but I would have liked to have made the stand as Billings had intended.

With the joining timber going a little beyond the hull support pieces.

And others have made the same mistake as me.

-

-

-

-

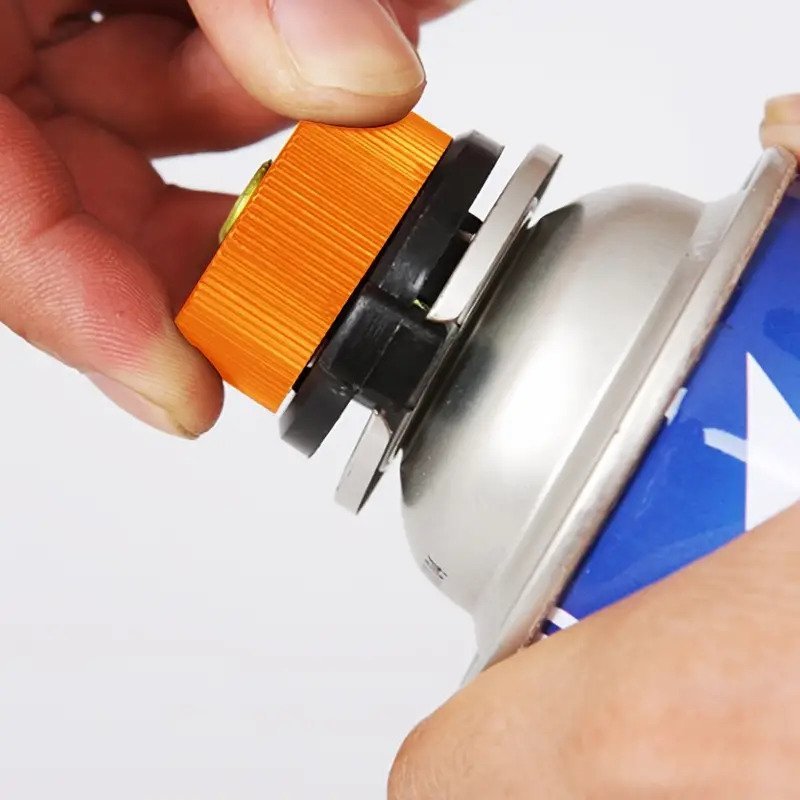

Hi Grant, a bit of info re the Steam Plant, or do the kids call it ‘Heads Up’

Now to fire up the steam boiler, it uses Butane Gas.

But you cannot fill it’s gas tank with a normal Refill gas can, a copper pipe is in the way.

In the engine box the guy has supplied a 100mm brass extension tube with a screw fitting.

Now you screw that pipe onto this orange adapter fitting.

Then this adapter twists onto the filler can.

But you need a special can, and it took me some time searching to find one.

Come from Sydney, can’t buy OS as it’s “Dangerous Goods”.

The Universal cans don’t work, and the red plastic nozzle is too long. -

- bobandlucy, mtaylor, Canute and 1 other

-

4

4

-

A few days ago I added a bit to the rear of the boat, (is that the stern), actually for the rudder.

Put a reinforcing board on for the rudder tubing, but I slightly mucked up.

I should have added the hull planking before I glued on the board. But much too hard to redo it all now re the tube locating at the bottom and at the top, where I have added a half round piece.

So I have just added a bit more timber either side of the tubing, it will all look good after a little filler and it is painted

And another builder was thinking like me and has done the same thing.

And he is very much into realism with his weathering…………… -

1 hour ago, Tossedman said:

Just found this thread and am now following along. You're making good progress Wayne. I like what you're doing. Which MCM steam plant are you using? I looked on their website and they have a plethora of them. I've always been intrigued by steam and this looks like it could be a way to get into it.

Hi Todd, go the the start of this Thread, and read down, and a Lot of your questions will be answered.

Including for the Steam Plant............#4034

And I have some 1:12 figures here, Dremmel modified and re painted, but I have now discovered that a guy is making some very good Humphrey and Katherine 3D figures -

-

Hi Grant, gjdale, how is your build going, I’m still on the hull planking, not an easy job.

I had to make room for the boilers gas burner, a half round in the floor joist and some of the floor removed.

And yes I drilled holes in the ply plate, to accommodate the screw heads under the Steam Engine base plate.

But I’m finding it a bit disappointing here, very few replies / comments, just Likes like Facebook.

In the old days Forums were very active places.

Maybe they just like Square Riggers here.

- gjdale, BobG, GrandpaPhil and 6 others

-

9

9

-

Continuing on with this build.............

I decided to plank the Queen, well I mean the Billings plastic hull doesn’t look very nautical to me.

I figured boats of that size and at that time would be timber boats.

Anyway, after I have filled and sanded, and then sealer, primer and top coat, I hope you will still be able to tell it is timber planked.

Otherwise I should have saved all my money, time and effort on this job. I mean, will it just look like the plastic hull painted.

Yea I not a big fan of doing any planking, all the calculating, measuring, trimming, sanding and gluing down.

Using 0.5 x 10mm x 1mt strip I got from Float a Boat.

I’m about half way thru this project.

Then I thought I’d do an online search of this boat.

Wow, it Was a Steel Hull ……………

Anyway, it’s my boat, and I don’t care, it’s going to be a timber boat.

Some information here on the African Queen, or more correctly, the Livingstone.

The African Queen was a 30-foot boat built of riveted sheet iron in 1912 in the United Kingdom.

For service in Africa on the Victoria Nile and Lake Albert where the movie was filmed in 1950.

It was built for the British East Africa Railway and used from 1912 to 1968.The African Queen was originally named the L.S. Livingston, which had been a working diesel boat for 40 years.

The steam engine was a prop, and the real diesel engine was hidden under crates and other cargo.

It is now docked next to the Holiday Inn in Key Largo, FL.

- BobG, yvesvidal, GrandpaPhil and 5 others

-

8

8

-

-

-

On 3/12/2024 at 4:56 PM, gjdale said:

I can’t believe that it has been almost five months since I updated this build log. Life has thrown a few unexpected twists and turns my way recently, and it has only been in the last few weeks that I have felt remotely interested in returning to the modelling desk.

I can at last report that the hull planking is complete – at least as far as the initial sanding. I still need to go back and apply some filler into the inevitable gaps, but overall, I’m reasonably happy with the how this has turned out. A couple of overview shots to show progress as well as ‘proof of life’.

I’ll proceed with some filler and a final sanding before I trim back the excess ABS around the top of the hull. Hopefully it will not be another five months before the next update!

WOW, your completed planking looks great, as I have asked, what did you glue it down with.

How did you work with those ridges ?? in the plastic hull, what, just somehow planked over them.

.jpg.3d5b9353cfed27bc7b9ae76a2c79f07e.jpg)

Stephenson's Rocket by a49kid - OcCre - 1:24 Scale - Wayne

in Non ship-related reviews

Posted

I have now finished this OcCre Stephenson’s Rocket model.

Yes I know this is a wooden Boat / Ships Forum, but I believe we can also Post other models here.

And yes this very early locomotive kit is made by OcCre, Spain, who also make some very nice ships kits.

And this Early Rocket Locomotive is like those ship kits in that it has Laser cut plywood, Wood strips,

Brass tube and rod, and brass and cast metal fittings.

The Colour Pic build instructions are good, but sometimes they could also do with some added captions / instructions.

And the parts lists are good. It is 1:24 Scale.

But I will have to say I did go astray a couple of times, and needed to go back and ‘fix things’.

And I don’t think I’m as sharp now as when I was in my 20 – 30’s.

But in the end I’m very pleased with the finished result.

And I added a Driver, some Coal, and made a Track for it to sit on.

And I upgraded the wooden dowel stack to ½” tubing, and it looks better.

I used Tamiya spray paint and their acrylic jars.

And yes the skill level is right up there.