-

Posts

338 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Pete Jaquith

-

-

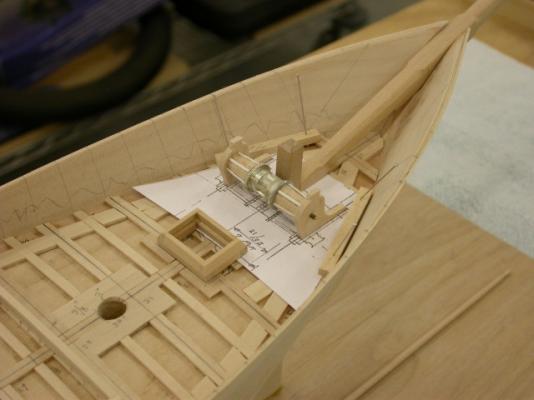

In surveying the machine carved hull; I found that the deck surface was too low, lacked adequate camber, and lacked shear forward.

This problem was corrected by fitting a deck framing system constructed from bass strip wood. After completing/fairing the deck framing system, the location of major deck structures were laid out. The mast holes were drilled at this time with the aid of a pedistal drill press.

In preparation for deck planking the following were fabricated:

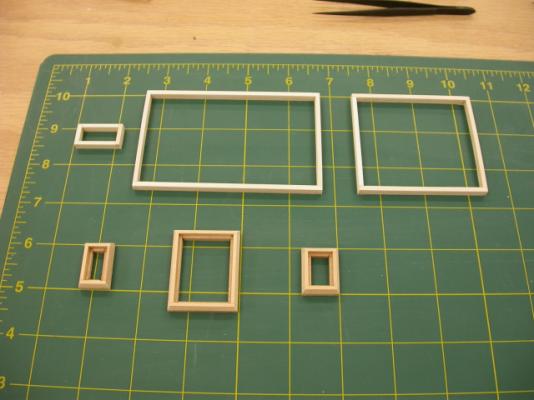

>>> Hatch/house coaming were fabricated with half lapped corners

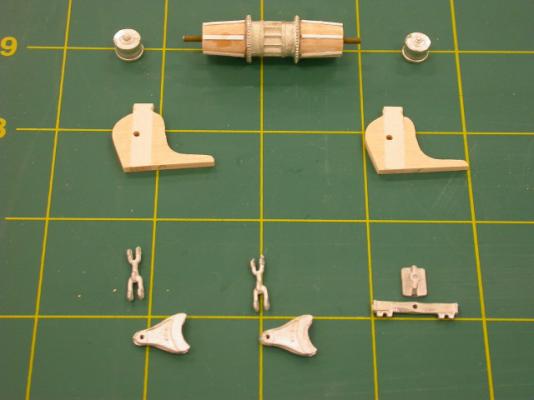

>>> Bowsprit, jibboom, dolphin striker, and Samson post

>>> Anchor windlass (used portions of a Bluejacket windlass kit)

With the heavy construction complete, future construction will turn to the finer points of deck planking, deck furniture, etc.

Pete Jaquith

Shipbuilder

- Mahuna, Rudolf, MarisStella.hr and 10 others

-

13

13

-

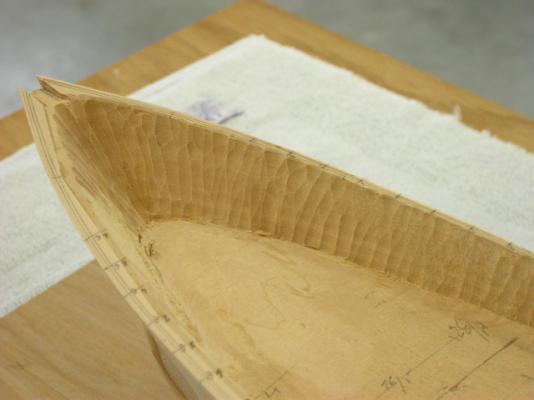

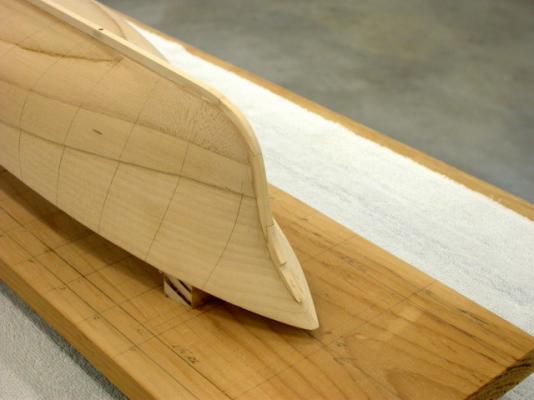

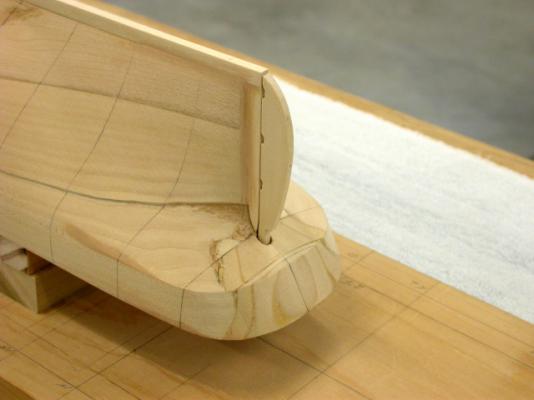

With the exterior hull planking complete, the next challenge was carving the bulwark interior surfaces. Carving was done with sharp gouges, sanding sticks, and an electronic thickness guage.

Note that in installing the exterior counter planking, two coats of wood glue was used to ensure the glue had an opportunity to soak into the the end grain of the counter. This created a strong ply type structure that could withstand the strain of carving out the bulwarks' interior.

Pete Jaquith

Shipbuilder

-

Thanks for your interest in "Newsboy" 1854

I have attached a thumbnail of a print of Brigantine "Newsboy" 1854 by George F. Campbell. This is the picture illustrated on the cover of a "Ship Modeler's Jackstay" by George F. Cambell (good reference for your library available from Model Shipways).

While I have no family connection to "Newsboy", my fore farthers did sail on similar merchant craft in the mid 1800's. Other ship of this period which I have a connection is "Volante" 1853 by William H. Webb (also on my build list). I am a graduate of Webb Institute of Naval Architecture founded by the shipbuilder William H. Webb.

With respect to the Topsail Schooner "Eagle" 1848, I have posted pictures in MSW's Completed Scratch Build Gallery. I will consider posting a build log after we complete "Newsboy".

Pete Jaquith

Shipbuilder

- avsjerome2003 and clipper

-

2

2

-

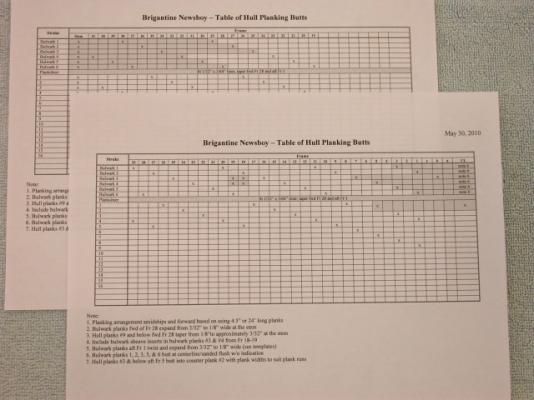

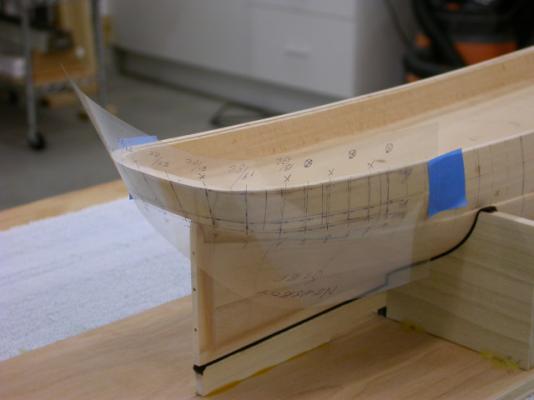

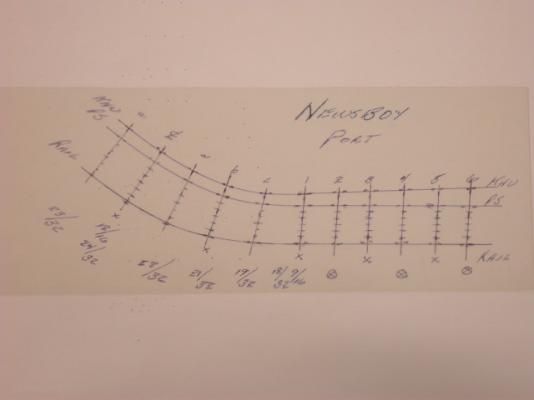

Next steps include laying out and fitting exterior hull planking. Planking butts were laid in the normal pattern using the table illustrated below. Due to their shape, the bulwark counter planks were templated with a sheet of clear mylar. Planking material included: (a) 3/64" x 1/8" hull planking; (

3/64 double bead plankshear; and, © 1/32" x 3/32" bulwark planking. Planks tapered at the bow and stern, but with the exception of the counter plank shapes were not extreme. The plankshear was fitted at this time but will be glued in place after painting in order to establish a clear color break.

3/64 double bead plankshear; and, © 1/32" x 3/32" bulwark planking. Planks tapered at the bow and stern, but with the exception of the counter plank shapes were not extreme. The plankshear was fitted at this time but will be glued in place after painting in order to establish a clear color break.As the hull will be coppered, hull planking started approximately 1/8" below the waterline.

Pete Jaquith

Shipbuilder

-

Thanks for your interest in "Newsboy".

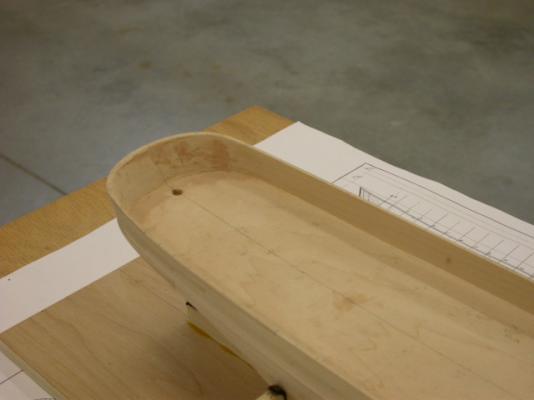

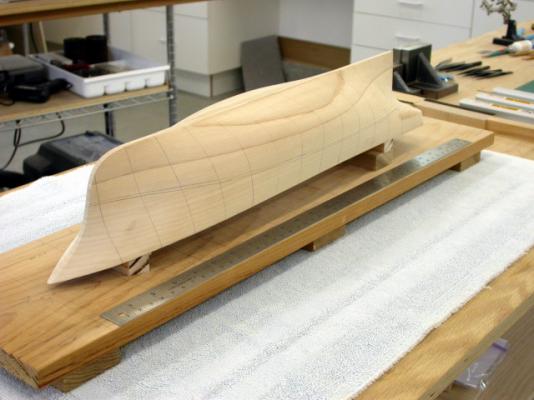

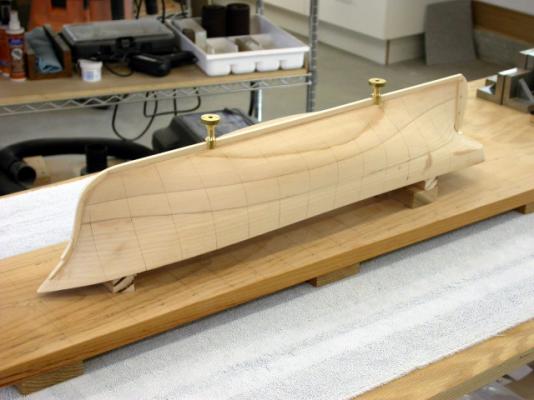

The principal component used from the original kit was the carved hull. After surveying, the hull was carved in the inverted position using a building board and art board templates. The hull block was positioned with the waterline level, parallel to the building board, and with stations vertical. Shaping was accomplished using sharp gouges, chissels, and firm sanding sticks for fairing. As the hull will be overplanked, the hull was finished using 180 grit sandpaper.

After the hull was carved to the outer hull lines, the upper hull from 1/8" below the waterline to the cap rail was recessed 3/64" for hull and bulwark planking. Following completion of hull shaping; the stem, keel, and stern post were fitted. Additionally, the rudder was fitted (to be installed later) and the pedestal holes drilled at this time.

Pete Jaquith

Shipbuilder

- jct, MarisStella.hr, mtaylor and 11 others

-

14

14

-

The brigantine Newsboy was designed by Dennison J. Lawlor of Chelsea, MA (designer of the very successful pilot schooners Dancing Feather, Hesper, and Phantom) for owners Dabney & Cunningham of Boston. Newsboy was built at the Joshua C. Adams and Elisha Brown shipyard in Owl’s Head, ME where she was launched in June, 1854. She had a length of 111 feet, beam of 27 feet, depth of 12 feet, and tonnage of 290 tons. While described as a brigantine, the rig is more accurately described as a hermaphrodite brig because there were no square sails on the main mast.

The Newsboy was engaged in the triangular trade: carrying lumber and manufactured goods from New England to the Mediterranean; transporting wine, oil, and fruits to the West Indies; and returning to New England with rum, molasses, and sugar. The Monthly Nautical Magazine said “having a reputation for speed, by wringing reluctant laurels from her competitors who have chanced to fall in company with her at sea….she does her designers no discredit…her log will speak for itself”.

The model is built to a scale of 3/16” to the foot (1:64) based on an old Model Shipways solid hull kit and plans by George F. Campbell. The model is plank on solid construction, with built up bulwarks, planked decks and topsides, coppered bottom, and scratch built deck furniture/fittings. Limited commercial fittings will be utilized where appropriate, and the rigging will be proportional linen line with Warner Woods’ blocks. The Brigantine Newsboy is my 4th wooden ship model and the 2nd in my series of mid 1800’s American merchant sailing ship models.

As time permits, I will attempt to post the high points of my previous MSW Build Log.

Peter Jaquith

Shipbuilder

Newsboy 1854 by Pete Jaquith - Model Shipways - Brigantine

in - Kit build logs for subjects built from 1851 - 1900

Posted

Thank you for your interest in "Newsboy"

With the deck framing complete, next steps include deck planking, waterways, covering boards, deck scuppers, hause & chain pipes. I enjoy this work as it requires some design work to optain the desired effect and with finishing it will start to give the model some color. Key points include:

>>> Deck planking fitted around hatch/house coamings, anchor windlass support planks, etc,

>>> Deck planking and margin planks fitted to waterway planks

>>> Deck planking nibbed into margin planks

>>> 1/16" x 3/32" deck planking

>>> Caucking simulated with black non-blead fabric markers (quick pass on one edge only)

>>> Waterways rise forward as covering board/plankshear have greater shear than deck planking

>>> Coamings, waterways, covering boards, and anchor windlass support planks left loose (final installation after painting and deck finishing)

It should be noted that this arrangement is typical of vessels build with machine cut planks. Prior to the advent of machine sawed planks, ~1800, deck planking often curved and was nibbed inboard into adjacent planks.

Pete Jaquith

Shipbuilder