-

Posts

629 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by kruginmi

-

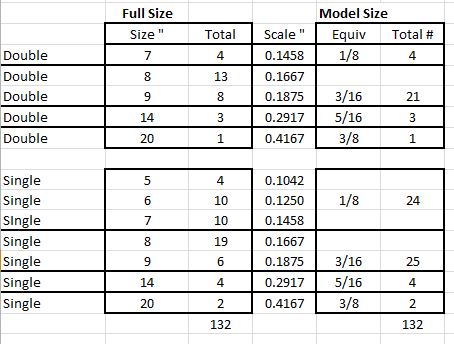

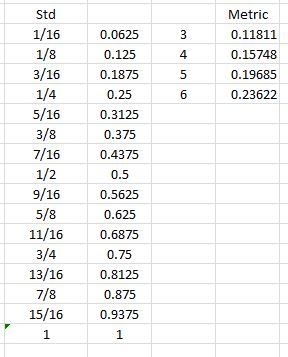

So after finally settling down on understanding the number and type of lines, I can move into the job of estimating what type of work I have in front of me with regards to blocks. Currently I am showing 132 blocks are needed for this cross section (wow). For the basic type (single and double) there are: So you can see the actual ship had 12 varieties of these from 5" to 20". For the model on a first pass I am looking at cutting this down to 8 types from 1/8" to 3/8". So, for example, the 5, 6 and 7 inch single blocks are combined to the 1/8" scale block. The question now is whether or not I should combine more, to like three of each type. Feedback welcome. For the rest of the blocks, the numbers are much smaller (besides the dead eyes): There are one offs that I can think about actually making without going a little crazy. Still need to go over the blocks again and am sure to add more - the biggest mistake I keep making is to double shown quantities to account for port and starboard. Really enjoying the process, hope to start building again soon! Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

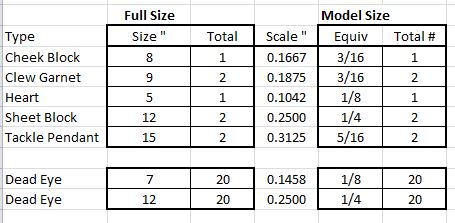

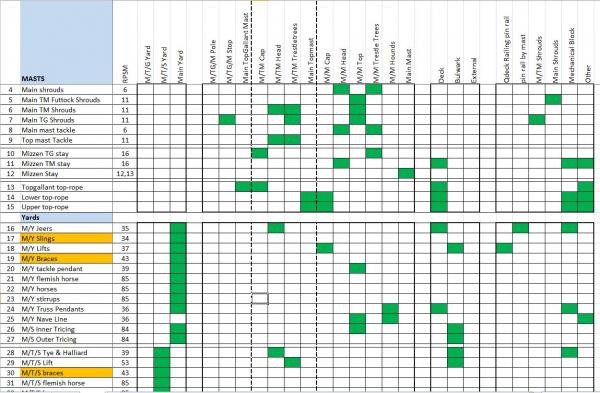

This is an updated partial look at my DRUID rigging details spreadsheet, centered on main mast connections. I am liking this more and more. This will be pretty standard for detailed rigging systems in the future for me: If you read across any row you can identify all rigging lines that are accounted for and the run of the lines themselves. So, for example, the Main Yard Jeers (7" line) has a one 20" double block attached to the yard, two 20" single blocks lashed to the Main Mast Head, a double block attached on the deck by the mast then a second double block for mechanical gain, then on to a sheave in the rail prior to affixing to the pin rail. If you read down any column, you can see what connections any one part should have. So the Main Top Gallant yard is exactly identified (all the sail work lines are farther down out of view). I am still working through the sheet from several different angles to insure its completeness. Next steps are to identify the lay of each line and also whether any serving is required. Lots of in depth learning which is making me very comfortable with the subject matter. mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

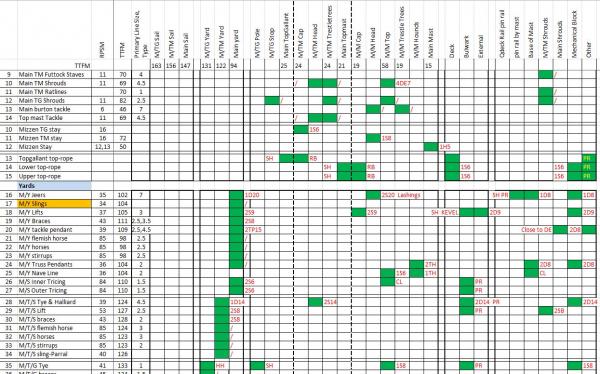

Rigging, rigging, rigging. I am relatively new to the details of this subject and prior to going much farther on the masting work wanted to have a firm plan on what should be done when, specifically regarding blocks / thimbles / and collars. Before I get into the details I am working three questions with respect to this cross section: 1. Should I include rigging features that are used for the sails on the main mast, but have no termination. A good example are the braces. The pendants can be quite long and will be left dangling since the forward connection points are not present. 2. A related question are rigging features that are used for the mizzen or foremast. A good example are the mizzen stays. There are several collars on the main mast that would lead these stays to the deck below. 3. Last are the temporary used features, like the topropes for raising the topmast into place. My initial thoughts are: 1. Include them, but shorten up the pendants so they don't stick out so much. They will be empty blocks at the end of the pendants. 2. Include them. Again, empty blocks. 3. I would like to include these for education opportunities (both for me and people looking at the model). I need to insure with all the other rigging place these can be in place. For my education I am using TFFM - Antscherl, Rigging Period Ship Models (square rigged) - Petersson, Anatomy of the Ship (Endeavor) - Marquardt, Masting and Rigging of English Ships of War - Lee and Plans for the HMS Brilliant from the Smithsonian (prior to renaming Druid). This is an American cargo ship converted to a British Sloop of war so there are lots of questions and deviations from any one source. The first task was to understand what rigging lines I need to handle and what they touch. This is captured in a spreadsheet still undergoing review (partially shown): Green means there is a touch point between the line and the component listed at the top. For my sanity I split the masts into component pieces. Once complete I can look down through any column and insure every one of those touch points are handled (hopefully prior to putting on the model). After tracing everything a couple more times and verifying them the next step will be to identify line diameters and block types and sizes (TFFM at its best). Then I will feel confident enough to proceed. My biggest issue was getting this global view. For running rigging, the diagrams 'usually' don't include the details from the standing. Something was always missing for simplicity. This spreadsheet overcomes that issue. Lots of learning. I feel like I should re-read those Aubrey-Maturin books now, I would have a MUCH better understanding of the at sea events. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

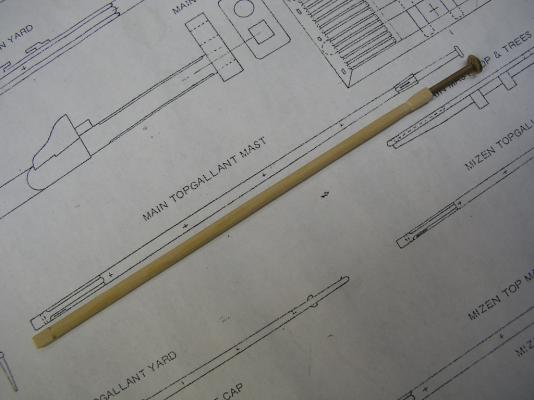

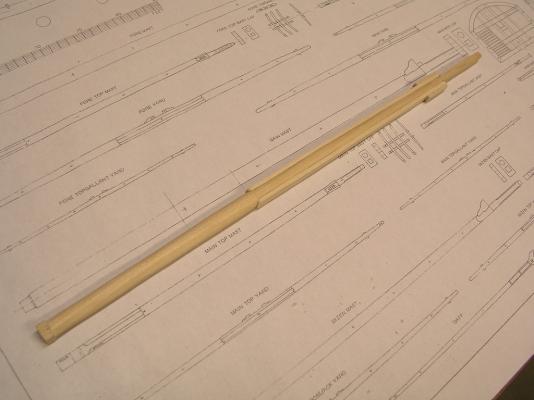

Thanks everyone for stopping by! With a bit of time I decided to tackle the top gallant mast out of a piece of boxwood. It was coming into shape pretty quick and I was liking the result when, bang, the top pole snapped off. Too much pressure / not enough support. From history I learned to take a breath (okay, I uttered some stuff first but then....) and calm down. My first instinct was to go at it with another try, but it was a shame with the first one shaping up so well. I leaned back and laid out my options. I actually decided this was a good thing. Better snapping now then when you are pulling on the backstay and the whole assembly comes off. The wood here gets pretty thin so I decided to try something to provide some added strength. I grabbed some thin walnut dowel I had nearby and drilled in a hole for it to sit - what could I lose. With some glue and a good snug fit it didn't take too long to put in a much stronger replacement. With some more walnut I added the cap and sanded to shape. Lemonade out of lemons. I am sorely tempted to not paint this piece and leave it as a nice capper to the mast assembly. What started out as a negative has definitely turned into a huge positive. I love this hobby. Still some more sanding to do on the mast section itself. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

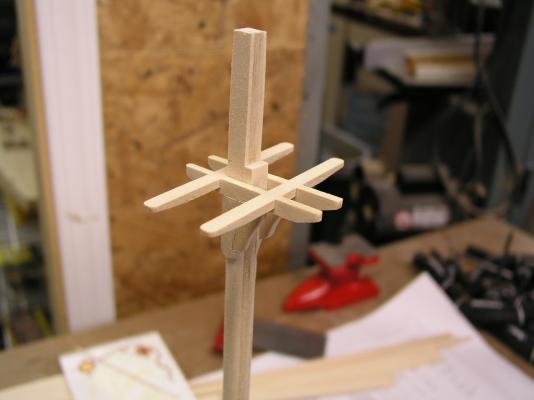

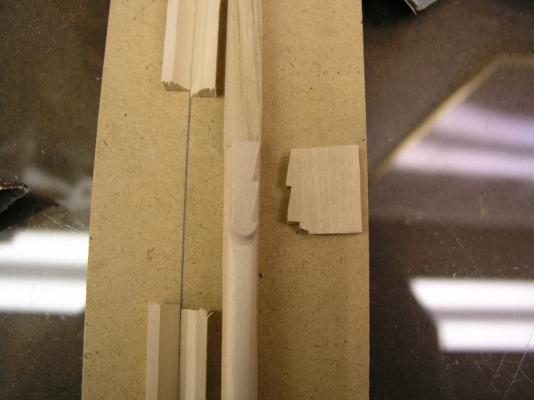

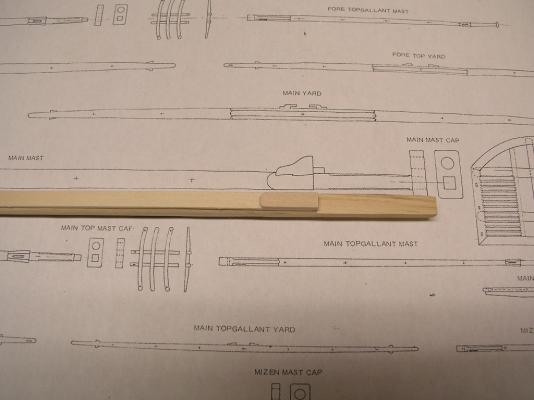

I have spent most of my time studying rigging, but decided to produce some results. Next up was the top mast: With the jigs and the process talked about in TFFM this wasn't too bad, and done in an evening. Truth be told it did take two tries. It is hard to see the octagonal section above the bottom square section but it is there. It should pop with some paint. It fits just snug into the main top trestle trees. The top rope sheaves or fid hole have not been cut yet. The same process will be used for the top gallant mast, but with thinner stock. I cut the rough square stock out of basswood but think it is just a little too thin. I will use boxwood for this - as well as the topmast trestle trees. I couldn't help putting the top gallant plug in place: The topgallant mast and associated trestle trees is the goal for this week. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

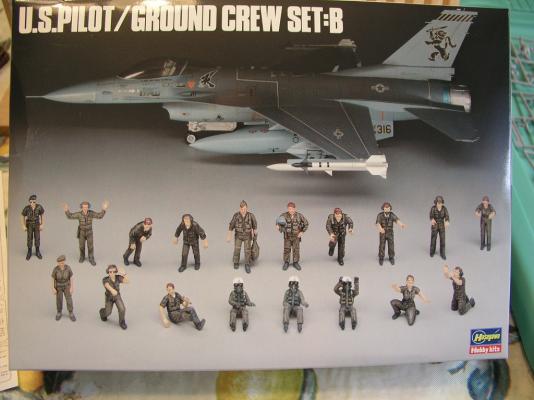

The berth deck height is correct, Mark. My issue now is to decide whether to shorten the figures I have to bring them more into a 5' 6" or less arena. I can't just take a little from the torso, since their knuckles will drag on the floor - need to shorten the arms also. This 'short cut' of getting base figures isn't getting so short anymore! Maybe I will just put bandages around their heads to show where they keep bashing them against the beams! Or to be safe, add scale yellow tape warning of the low overhead..... Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

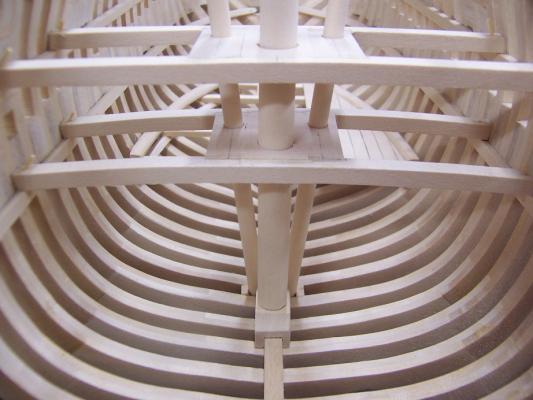

With the hull structure totally accessible adding the berth and gun deck beams was straight forward: This caused one of those, ummmm moments. You can see my 1/48 scale figure posed on the orlop deck - all 6 ft of him. Looking at it from a different angle: You can see the guy would have to almost crawl to get around down there. My guess is 6 ft wasn't the optimum height for sailors. Do I need to modify the figures for height?? Luckily the only thing that will be going on in the orlop will be 2 people in their hammocks grabbing some shut eye so I can skirt the issue. But I need to think about even those on the main deck (and above). Would 6 foot tall crewman appear correct with the rest of the scene? On a side note I am working on having the beams/decks as assembled being removable as a unit until I choose to affix them permanently. Much easier to work the details and paint this way. For painting I visited a local wood specialty shop and was steered towards General Finishes water based sanding sealer for my first coat (usable over even wood that won't be painted). Then I had been thinking about using Model Color acrylics for the actual paint. I created a test paint area and laid down the sealer and paints. Where their was no sealer the paint was absorbed very quickly and faded out as expected. The sealed areas still seemed moist 5 minutes later, but much more vibrant color. I still will need a couple of coats (more if white / lighter colors) but that is to be expected with acrylics. Finally I turned my eyes (and brain) skyward and have started the compressed instruction set of understanding all rigging. With a subset of rigging (one mast) I need to start to understand what is and what is not present. Secondly, what blocks are required and why. Not an easy task. The only thing to state is to keep at it and keep reviewing and things will start to fill in and make sense. Stay Building my Friends, Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

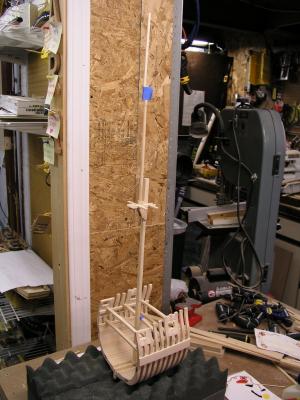

I thought about it, then thought about some more, then gave myself more time to think about it. I could think of no overriding reason that the base was still needed with it's current state and all the lines transferred that I could think of. So...... Big day in the Krug household, the Druid-X is free. I added the main mast to provide some sense of proportion. This thing is going to be tall, that is for sure. Next task is going to be the deck beams and then the mast step. I am hopeful the completed decks will slide (easily) in and out. That will help with fitting, gluing and access. The vision is starting to take shape. Keep Building my Friends, Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

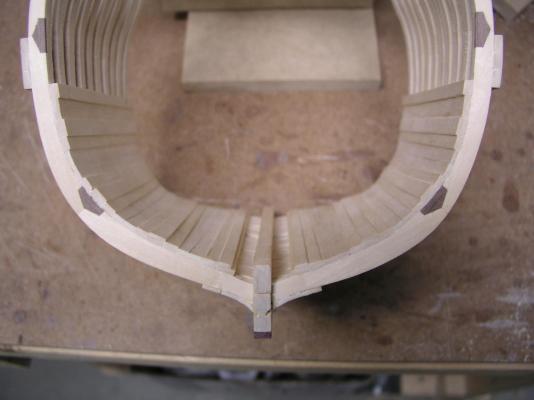

More progress, The cobwebs are being cleaned out! Next was the linings for the gunports. With everything planked and painted I was not going for actual methods here (plus it follows the same method I used on the full hull model). First issue was to reinforce the ribs where the cuts are to occur so I added spacers. I wanted the resultant cut to result in a firm ledge for the base sill so I insured the correct angle with a piece of wood that went all the way through the hull. Then the spacer material was slid in, marked then cut. After gluing in top and bottom sill I again used the long piece of wood to verify it was laying flat. You can see the port templates I made to continually check the resultant hole was consistent with the other ones and correct with regards to the plans. The side sills were then measured and cut out in a similar manner. Then once again a whole lot of gentle sanding to get the hull back into the correct profile. The top of the second gun port is the railing so the rest of the rib (jig) was removed since it was no longer required. These sills need to get painted red prior to planking the outside - which will be yellow. Next up are the gun and forecastle deck clamps. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Getting back into it means re-igniting a lot of brain cells and old memories. Returning to the hull I spent a few hours sanding (and more sanding) (and more sanding) to get the whole hull trued up inside and out - primarily on the upper untouched surfaces. I think I am now pretty close. Using the power of the Hahn method, transferring the plan key points to the hull was done quickly and very accurately. This included the top railing location (cut off point from the jig), gun and forecastle deck beams, and the four gun ports included in this cross section: The biggest lines to add are the main chains, which I need to use another sheet of the plans to locate. My next jobs are to cut and insert the gun port linings and also add the other deck clamps. This will allow me to add the actual deck beams and get the mast footing in and all lined up. As a side project I am starting to think through the crew. This will not be a sterile cross section. I got for last Christmas the following 1/48 figures: My initial list shows the following requirements: Cannon Crew: 3 figures Officer: 2 figures Deck Scrubber: 1 figure Rigger on Spar: 2 figures Ratline climbers: 2 figures Person in hold: 1 figure People in hammocks: 2 figures Am I missing anyone? That would be 13 figures. I am going to sort through the 36 figures (2 of each pictured) and start defining who will be used for what. There will be amputations, putty and maybe even some molded parts. A nice side project when things are drying. Another consideration I have to figure out sooner than later is what type of paint to use (and also primer). This will be a painted ship. The hull will be yellow and black (blue accents), gun deck red (except the floor), everything below deck white. Mast will be white with Black tops. I will need to start doing some experimentation on some extra basswood. I need to get the wales black before adding additional planking next to it - much easier. Still undecided on coppering the bottom or just painting white. That is enough for now, Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Thanks for asking Patrick. Finished my third (and last) ~Olympic Triathlon of the season two weeks ago. Hung up my bike at least for this year. Pretty happy with my results, now to get flabby (and modeling) again. I need to be in some sort of shape to deal with the two teenagers in the house - so much drama. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

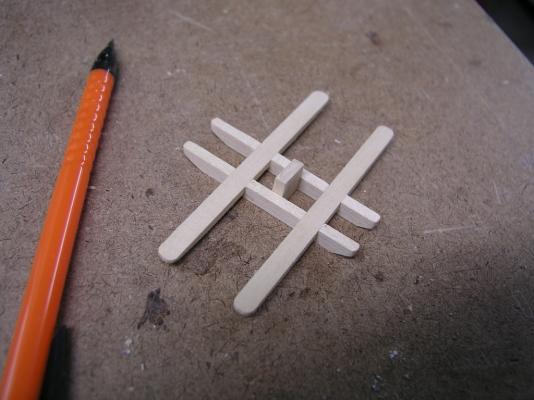

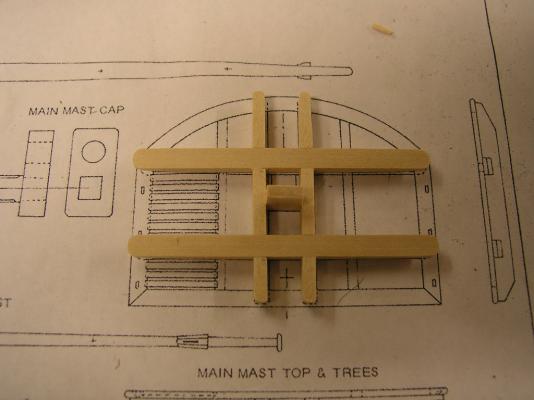

Excuse me while I get my sea legs again.....but with the start of fall my workshop has come alive again. I wanted to start with something smaller, so opted for the mast top supports. Nothing too huge or taxing but it did involve careful measuring and a couple of slots.... The whole mast will be primed and painted - the mast head black. Doesn't look too shabby for something that will be almost totally hidden before everything is done! It is still totally removable for work on the platform. Stay Building my Friends, Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

On to the bibs. One lesson learned I have taken to heart is when working with a complex mating surface (ie non straight) I do not cut the whole part to shape and hope for the best. I always have to file a little here, scrape a little there with the result being the constructed piece is just a little 'off' on one face or another. This is especially true for me for stems. So, I focus on one edge at a time, starting with the mating edge required. The target shape was cut out of the mast join and then (supposedly) transferred to the oversized piece and cut out: Once the join was satisfactory I marked and cut out the top edge, insuring it totally aligned with the bib top on the mast. Now the curving part is easy (compared to the rest). The curves where drawn out, cut and sanded. Before gluing I produced the other bib piece (marking the finished one with which side it belongs to FIRST). Replicating the curve was much easier piece to piece off ship. After all that work (maybe two hours in the workshop) I glued the bib pieces on. Looking at the plans for the two thousandth time afterwards I did realize the bibs were not only supposed to support the top beam but also slightly go into the topmast space. Initially you wonder how the heck that happened. I finally opted to laminate a 1/32" piece of basswood on the inside face for this issue. The top will be painted (black) and it will be basically invisible (unless pointed out, which I try not to do). So, reprieve and lesson learned for the next mast down the road. Stay Building My Friends, Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

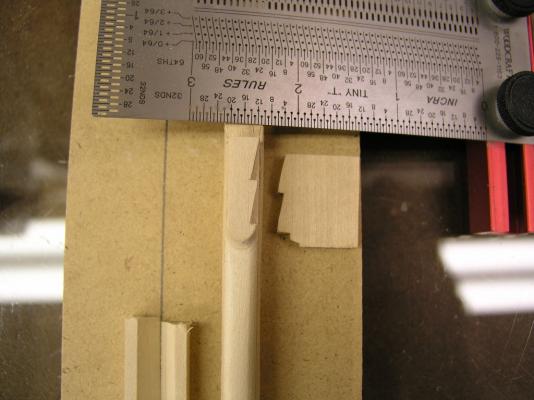

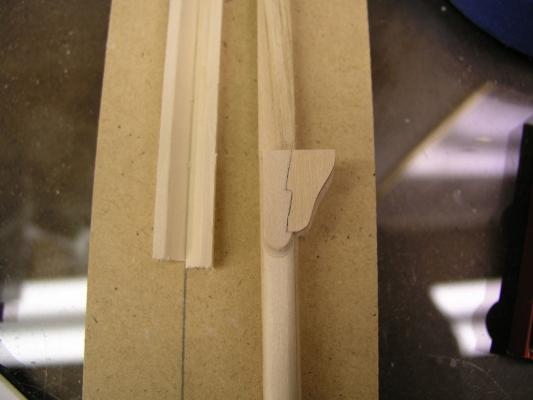

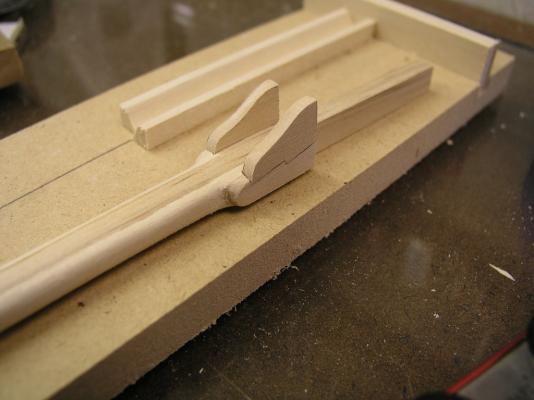

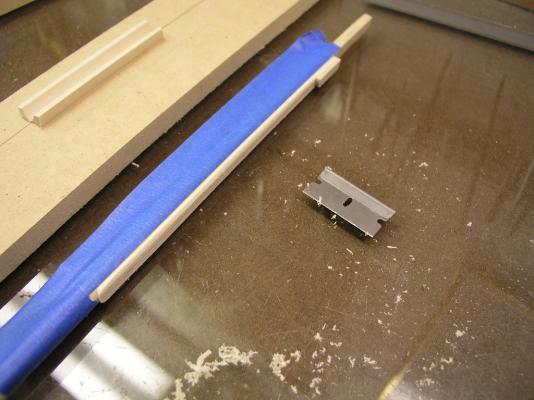

With a little time I jumped into the bibs and cheeks. First up was to glue in the blanks for both: So far so good. There are a few small gaps but a little sanding and some glue will get rid of those. Also, the mast will be painted so no worries. Now for shaping the blanks. I wanted to protect the mast itself so I used some painters tape to provide a cover for the mast itself. Most of the shaping was accomplished with a razor blade. A relatively short time later I had both sides done: For anyone new to making masts (such as I am) I would suggest practicing on basswood, even if that is not your final wood for your model. Shapes, methods and results can be done to understand the process prior to your final try. Thanks for stopping by, Mark P.S. Finished the second Tri making all my target times. Working towards the final one of the season on September 12.

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

That hesitation you have after having successfully created a proportional sized mast and then knowing the next step was to cut into the mast to make mating surfaces for the cheeks..... After having cut the main mast into an octagonal shape I found scrapers much better for making the final shape round than sandpaper. It was especially satisfying laying the constructed mast over the plans and seeing very close conformance to the specified dimensions. So on to the cheeks. I picked out the wood to use as the cheeks and then subtracted that width from the mast head base. Then the bottom of the cheeks was picked out based on period photos (not annotated on plans) and a straight line drawn connecting the two. Then a combination of the jig saw and a lot of sanding gave me a straight join area. I will use two layers of wood to accomplish the bibs. I just think that would be a lot better looking than taking a thicker piece of wood and shaving off most for the cheeks. Slow but sure progress. Another Sprint Tri in four days..... Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

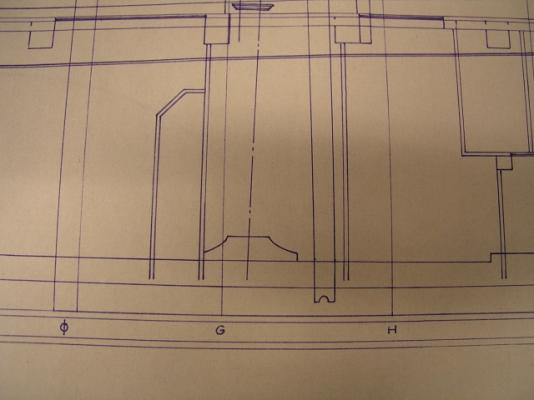

This 'step' is coming up soon (pun intended) and I ask for some recommendations. The ship plans only show the mast step from the side: This shows a step on the keelson that appears to be parallel the keelson. Note that the forward well wall pushes against the forward part of the step (no space for wedges). For my full ship model oh so many years ago I made my best guess at how to do this: From other builds (and the TFFM) the steps tend to lie perpendicular to the keelson with wedges forward and aft on the keelson to affix at a particular spot. I am leaning towards using this perpendicular step and not what I did on the original build. Thoughts? Again, this was originally an American built cargo vessel from 1774. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

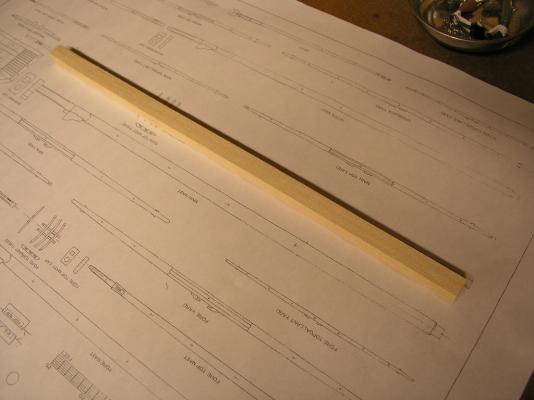

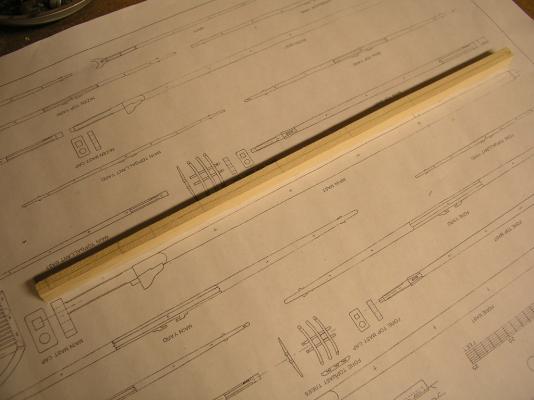

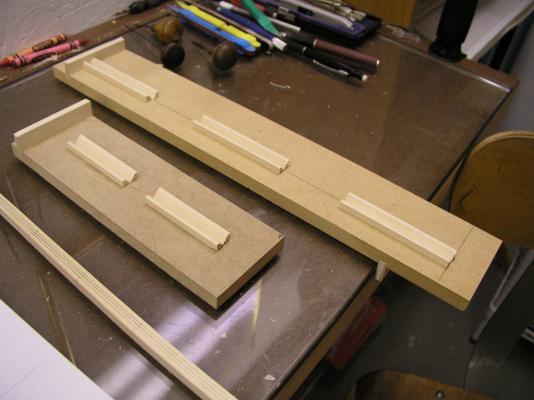

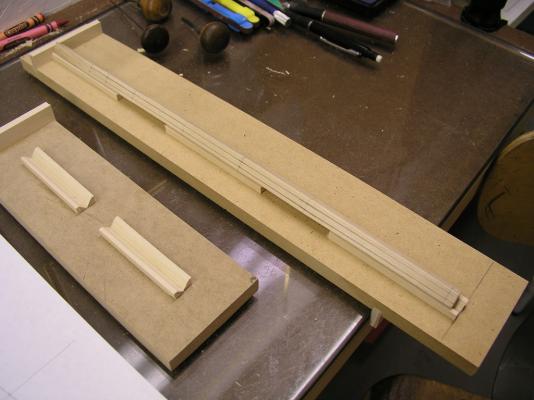

Now where was I? It seems a common question this time of year. First off, a pic of my primary hobby the last couple of months, finishing a local sprint triathlon (my sixth). Not even close to a podium finish but I enjoy them. So on to the main mast. The Druid plans I have show a max width approaching 1/2" so a wood blank was first cut to this dimension: I then transferred the dimensions at the identified portions of the mast and planed, chiseled, and sanded to the correct profile: next up was to make the appropriate portions of the mast octagonal and for this a jig was required. I ended up making a small and large one at the same time for future spar work. I put a stop block on the bottom for solid footing against the edge of the bench. I dialed in the correct proportions on each face to render an equal octagonal face and hope it works out. It didn't take too long to construct so if the first one has issues I will easily use it as a learning exercise and construct another better one. No worries. So tonight the mast sits in the jig ready for taking off some wood. I intend to leave the tenon and the cap area square to allow laying flat if required. I added an extra area near the 45 degree slot for this flat work. However, my next race is a week from Saturday so tomorrow AM I need to do some running..... Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Nils, I am doing my modeling lately by watching this build. Love the progress. mark

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Moving forward as time allows. Buttoned up the lower hold inner planking: Big item for me is a self imposed milestone, with the addition of the keel, false keel (purpleheart of course) and garboard strake I have now surpassed the initial build in completeness. It wasn't a quick redo by any stretch but one I have no regrets for. I now need to add the 3/32" planks next to the wales and think about painting them black while it is still easy. I also want to get some deck beams in and maybe start getting a main mast prototyped out. Oh, a stand. Alright, a long list of things. Always a next step.... Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Something I had meant to say with the last photo (an admission): Some may notice the limber strake looks differently spaced with regards to the keelson than previously. This is what happens when you just plow ahead and forget the basics. When ready to apply I went to the previous prototype and liked the look so glued in at the same distance. I had conveniently put aside in my brain that the limberstrake should still straddle the futtock join. Of course this join had moved in the new build. The next day this suddenly struck me and I wondered if I should do anything about it. The join was on the aft side of each frame so once this was totally built and mounted 99.9% of people would have no idea of the issue. But I would. Luckily this was the perfect time for access so a quick deconstruction later I was able to re-glue in the correct position. I probably spent more time sweating over the decision to re-do it than the time to actually make the change. Soon as I started planking the outside this wouldn't have been the case. So, lesson learned, never take for granted the next step of construction. Always think it through, especially the why it is there. mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Innovative approach to building the deck, I like the result. I am putting that idea into my idea toolchest! Small scales intimidate me but you are making it look easy. Thanks for sharing, Mark

-

Completing a first planked hull is a MAJOR milestone that most people that start (especially without the help of this website) never get to. I look at my first hull with all its issues but I was never so proud of the accomplishment. You are doing great, keep it up. Everyday your technique is getting better. mark

-

Patrick, thanks for stopping by! I was pretty surprised with this cross section. Having completed the full model in the Admiralty Style I had originally thought this was just going to be just a small scale repetition of that build. I never knew what I didn't know. The inter-relationship between all the components has really been brought home. You can read as much as you want, but until you build...... Everything is there for a purpose, usually specifically tied to other parts of the build (like the thickstuff). This build has been an excellent learning experience for me prior to undertaking a fully planked one (internally and externally). I am looking forward to raising the mast one day in the future. I like your simplicity comment. Once you put in all the work and you do achieve that simplicity in look that is a key indicator that it was done right. Hopefully this will continue in the future (without any more REDOs!). Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

As they say, a picture is worth a thousand words... Finished the 'stuff next to the thickstuff' and added the proposed filler pieces on one half of the ship (between the limber strake and keelson). These pieces are not glued. The one piece missing is where the pump is located. Next up is the regular planks in the tween spaces and ponder the filling pieces in the meanwhile. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

-

Question: Filler Pieces. Another thread on this forum has talked about filler pieces - wood between the frames from the keel up to a certain level to stop water being caught between the frames and causing rot. This would then form a smooth run under the limber boards for water to pass. I 'assume' that the frame location where the pumps are do not have them to create the trough through which the pumps actually work. This cross section does have the pumps included and I intend to keep a couple of limber boards off to show underneath. Now is the time to add them, the question is do I have the right intent and should I? Suggestions welcomed. Mark

- 172 replies

-

- druid

- sloop of war

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.